Heat exchanger performance evaluation method under multi-phase condition

A technology of heat exchangers and evaluation methods, applied in indirect heat exchangers, heat exchanger types, heat storage equipment, etc. problems, to overcome the large difference in heat transfer coefficients, a wide range of applications, and the effect of optimal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

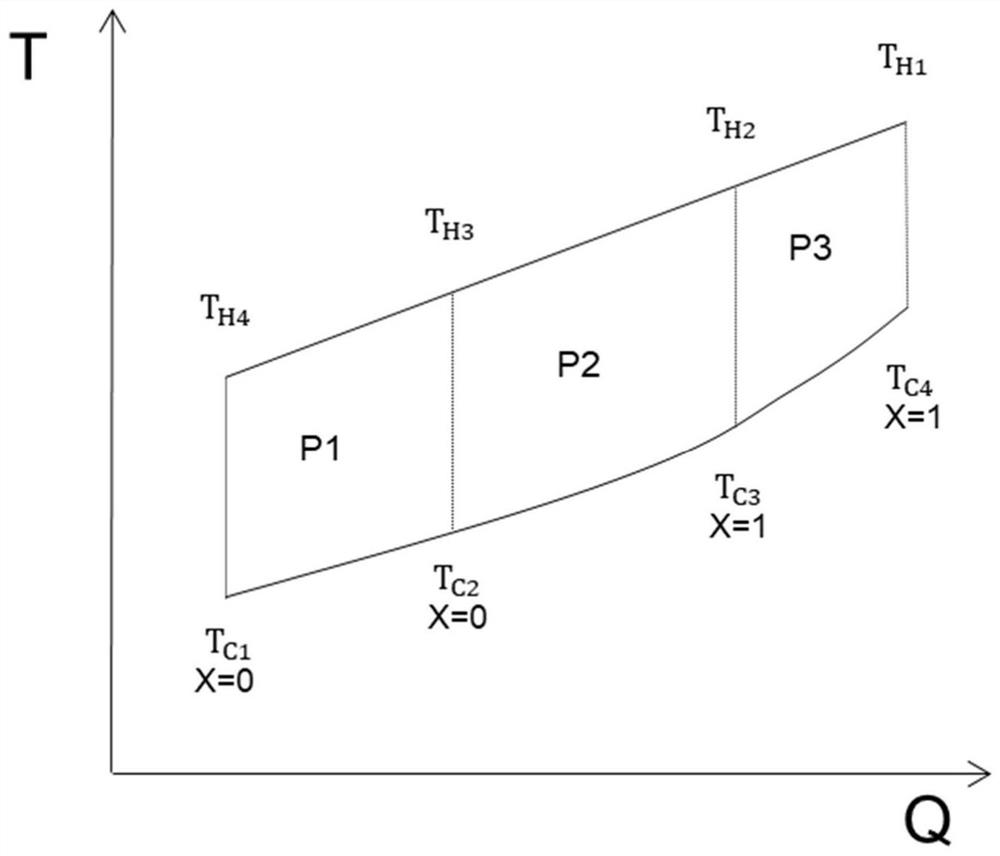

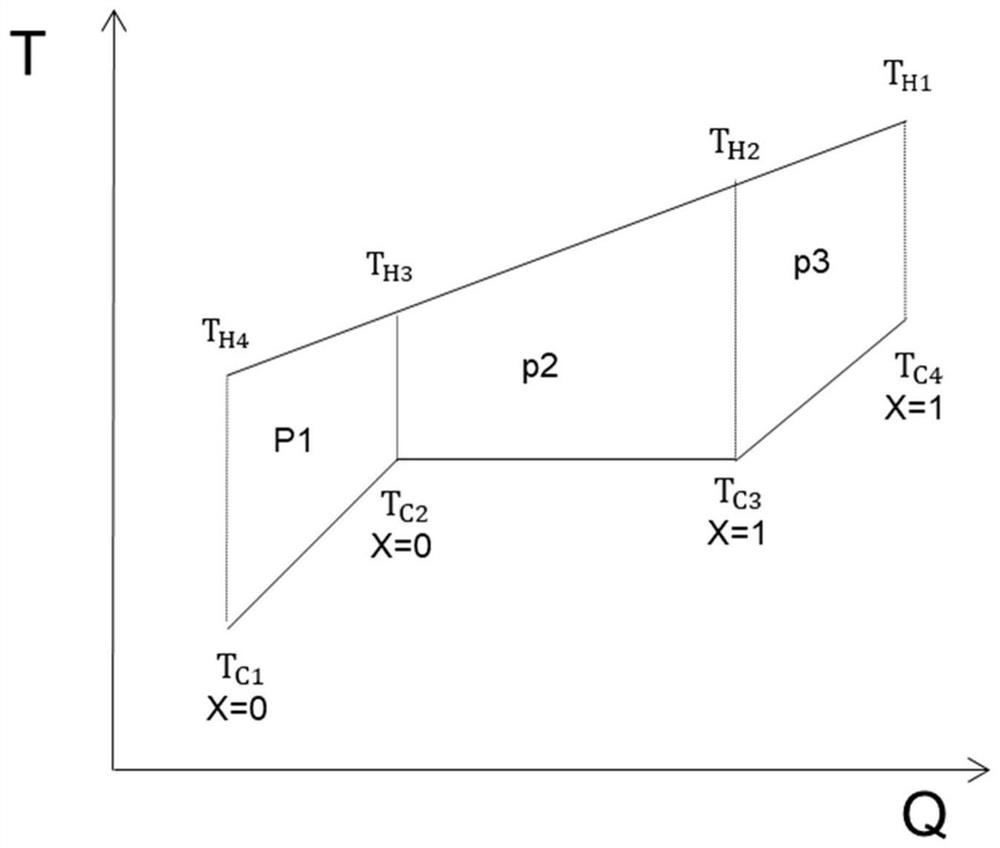

[0044] In a shell-and-tube condensing heat exchanger, a unilateral condensation phase transition occurs during the pure countercurrent heat exchange process. The mixture mainly composed of propane is used as the hot fluid to go through the shell side, and water is used as the cold fluid to go through the tube side. When the hot fluid is imported, it is in the state of full gas. After exchanging heat with the cold fluid, the temperature drops, gradually condenses, and finally becomes liquid. The cold fluid does not undergo a phase change during the entire heat exchange process and is always in a liquid state.

[0045] S1. Segmentation

[0046] The thermometer measures the inlet temperature T of the thermal fluid H1 is 104°C, the outlet temperature T H4The temperature is 30°C, the inlet pressure is 3.2MPa, and the mass flow rate m of the thermal fluid is 10000kg / h. According to the physical property data of the substance, it is calculated that the thermal fluid starts to appea...

Embodiment 2

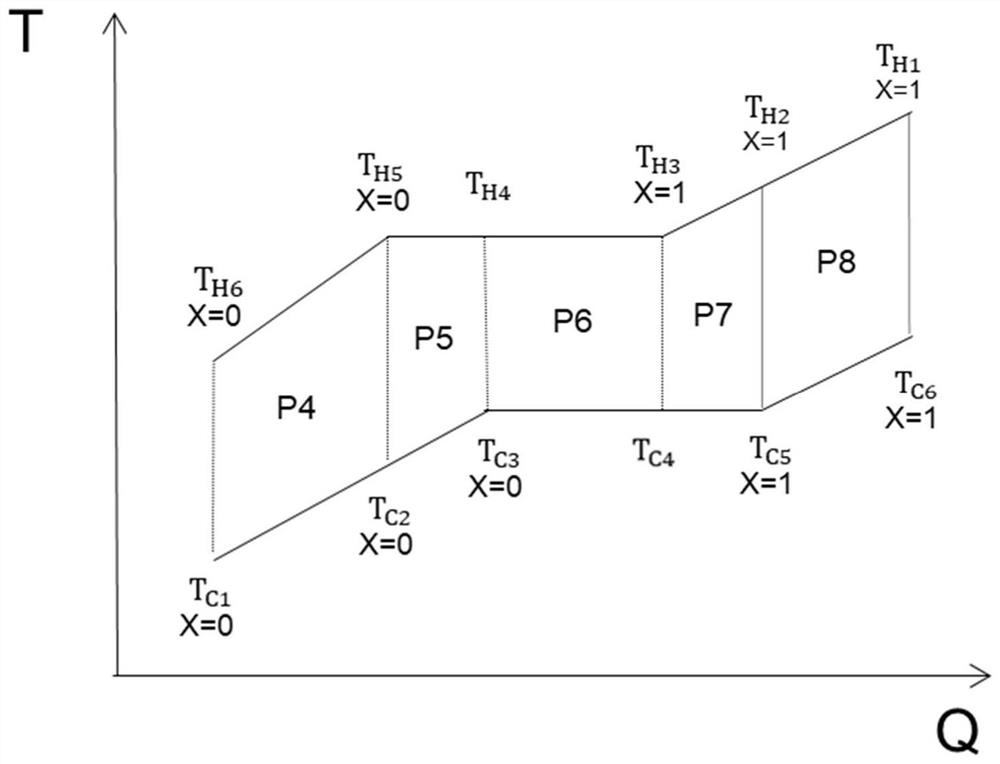

[0080] A vertical double-sided phase change heat exchanger for propylene evaporation and ethylene condensation. Propylene is a cold fluid that evaporates upward through the tube side, and ethylene is a hot fluid that condenses downward through the shell side.

[0081] S1. Segmentation

[0082] The ethylene inlet temperature T measured by the thermometer H1 -10°C, outlet temperature T H6 The temperature is -37.5℃, the inlet pressure is 1.56MPa, and the mass flow rate m of the thermal fluid is 275000kg / h. According to the thermophysical parameters of ethylene, it is determined that its corresponding dew point temperature and bubble point temperature are both -35.7°C at 1.56MPa, ignoring the pressure loss along the way. Propylene inlet temperature T measured by thermometer C1 -45°C, outlet temperature T C6The temperature is -15.2℃, the inlet pressure is 0.05MPa, and the mass flow rate m of the thermal fluid is 230000kg / h. According to the thermophysical parameters of propyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com