Low silver-copper alloy board for thin slab continuous casting crystallizer and manufacturing method thereof

A thin slab continuous casting and silver-copper alloy technology, which is applied in the field of non-ferrous metal processing, can solve the problems of easy fatigue deformation, rising surface temperature of crystallizer copper plate, small cross-section, etc., and achieve the effect of improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

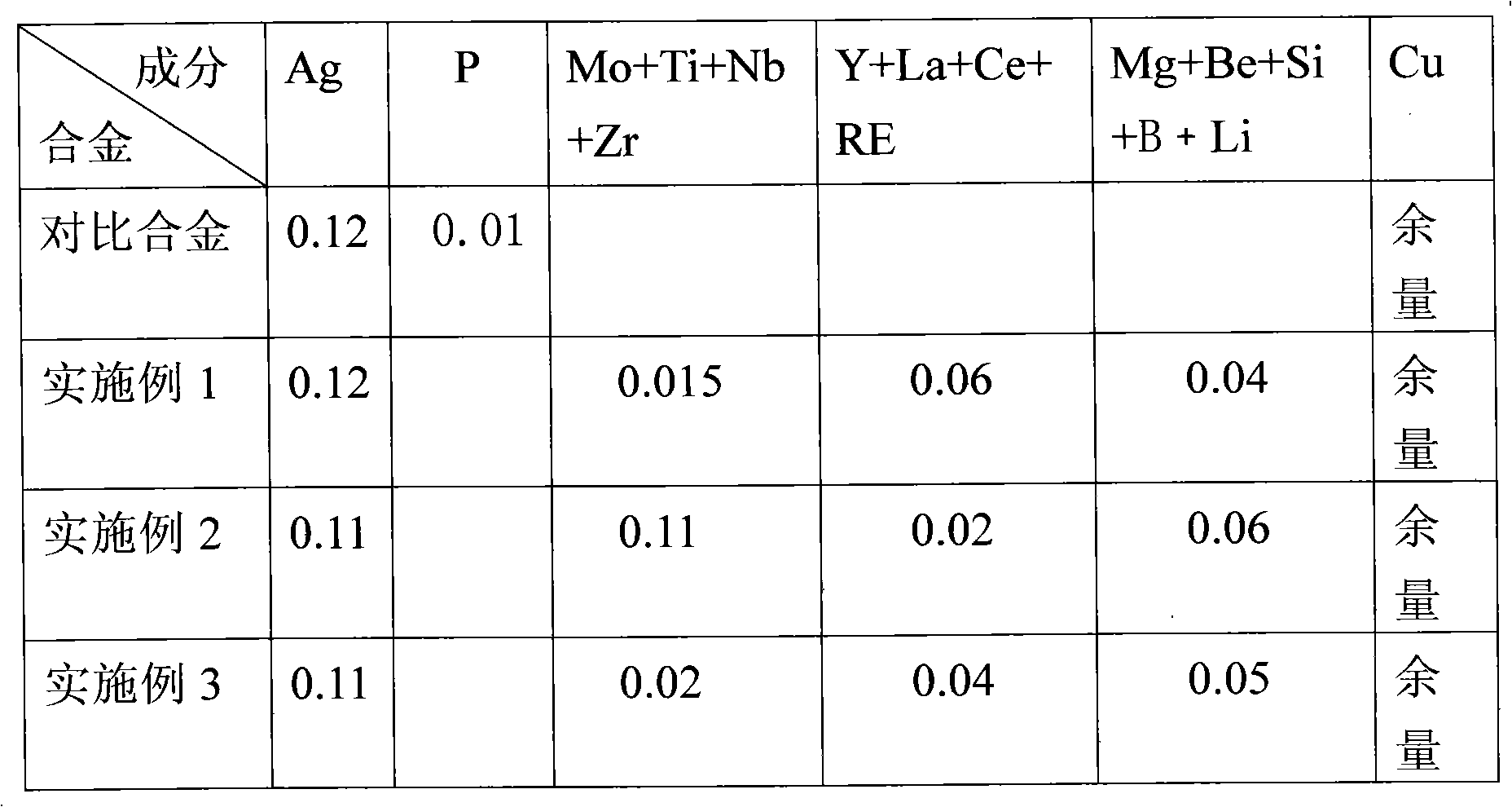

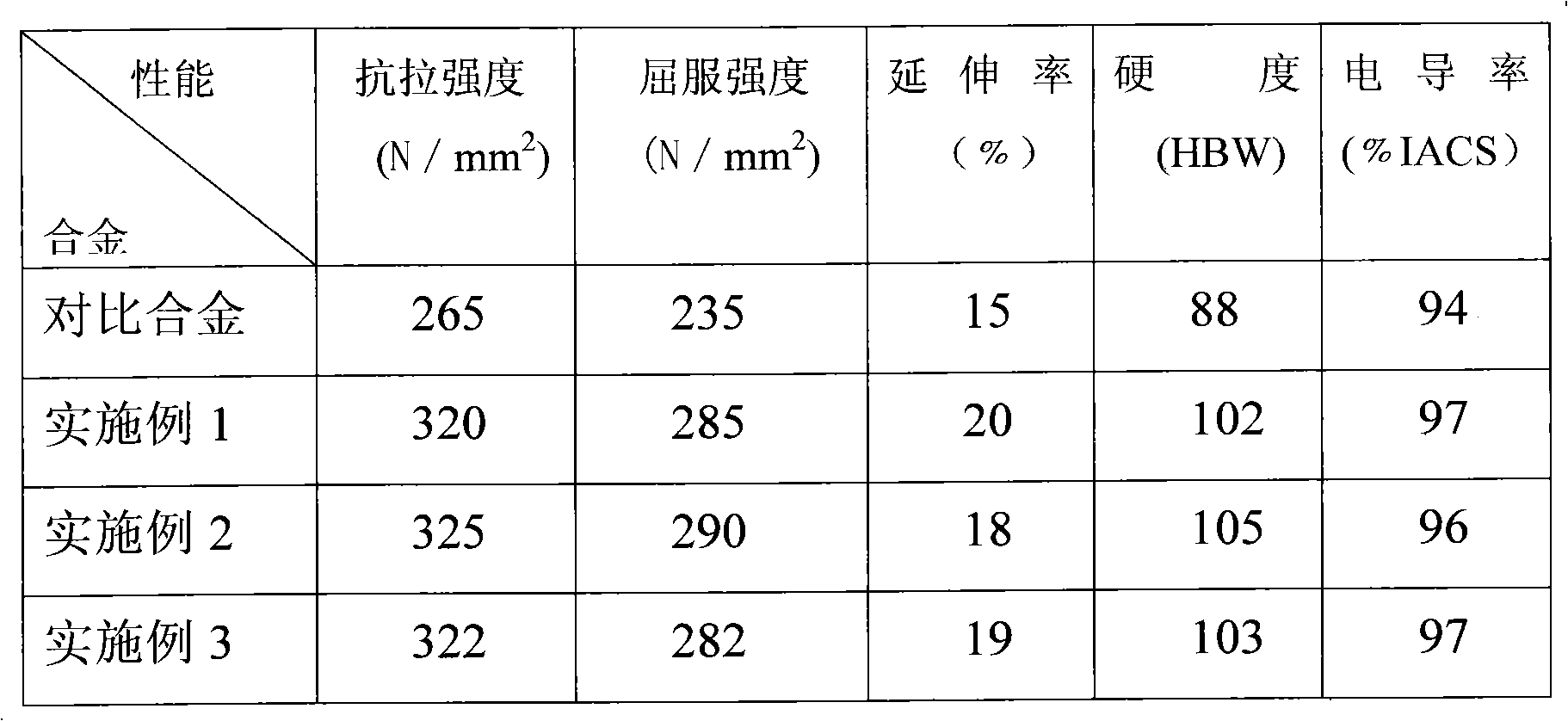

[0019] CuAgMoLaBeSiB alloy is smelted with the following raw materials: high-purity electrolytic copper, No. 1 pure silver, copper-4% molybdenum master alloy, copper-5% lanthanum master alloy, copper-4% beryllium master alloy, copper-5% boron master alloy, crystallization silicon. The alloy composition is shown in Example 1 of Table 1.

[0020] (1).Vacuum melting and casting: use 5 tons of vacuum induction melting furnace for melting. The electrolytic copper is put into the graphite crucible, and the crystalline silicon, pure silver, copper-molybdenum master alloy, copper-beryllium master alloy, copper-lanthanum master alloy and copper-boron master alloy are put into the alloy silo according to the order of feeding. Melt under a vacuum of 20Pa. After melting, the molten copper at 1170°C is refined under a vacuum of 5Pa for 35 minutes. The temperature of copper water reaches 1250°C. Argon is poured into the vacuum furnace to 3000Pa, and crystalline silicon is added under an ar...

Embodiment 2

[0032] CuAgZrNbYBMgBe alloy is smelted with the following raw materials: high-purity electrolytic copper, No. 1 pure silver, zirconium sponge, magnesium metal, copper-4% niobium master alloy, copper-5% yttrium master alloy, copper-5% boron master alloy, copper- 4% beryllium master alloy. The alloy composition is shown in Table 1, Example 2.

[0033] (1) Vacuum melting and casting: Melting is carried out in a 5-ton vacuum induction melting furnace. Put the electrolytic copper into the graphite crucible, and put the metal magnesium, pure silver, copper-4% niobium master alloy, copper-4% beryllium master alloy, sponge zirconium, copper-5% yttrium master alloy, copper-5% boron according to the feeding order The intermediate alloy is loaded into the alloy silo. Melting under a vacuum of 15Pa, after melting, the molten copper reaching 1140°C is refined under a vacuum of 10Pa for 40 minutes, the temperature of copper water reaches 1260°C, and argon is poured into the vacuum furnace...

Embodiment 3

[0045] CuAgTiNbCeMgLi alloy is smelted with the following raw materials: high-purity electrolytic copper, No. 1 pure silver, titanium sponge, magnesium metal, copper-4% niobium master alloy, copper-5% cerium master alloy, copper-6% lithium master alloy. The alloy composition is shown in Table 1, Example 3.

[0046] (1) Vacuum melting and casting: a 5-ton vacuum induction melting furnace is used for melting and casting. First put the electrolytic copper into the graphite crucible, and put the copper-lithium master alloy, pure silver, copper-niobium master alloy, sponge titanium, metal magnesium, and copper-cerium master alloy into the alloy silo according to the order of feeding. Melting under a vacuum of 18Pa, after melting, the molten copper reaching 1160°C is refined under a vacuum of 2Pa for 30 minutes, the temperature of copper water reaches 1270°C, and argon is poured into the vacuum furnace to 2100Pa, and copper is added under an argon atmosphere — Pre-deoxidation melti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com