Continuous casting crystallizer capable of controlling liquid level flow field and wave motion

A continuous casting crystallizer and control liquid technology, applied in the field of metal overcasting technology, can solve the problems of large resource consumption and complicated equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

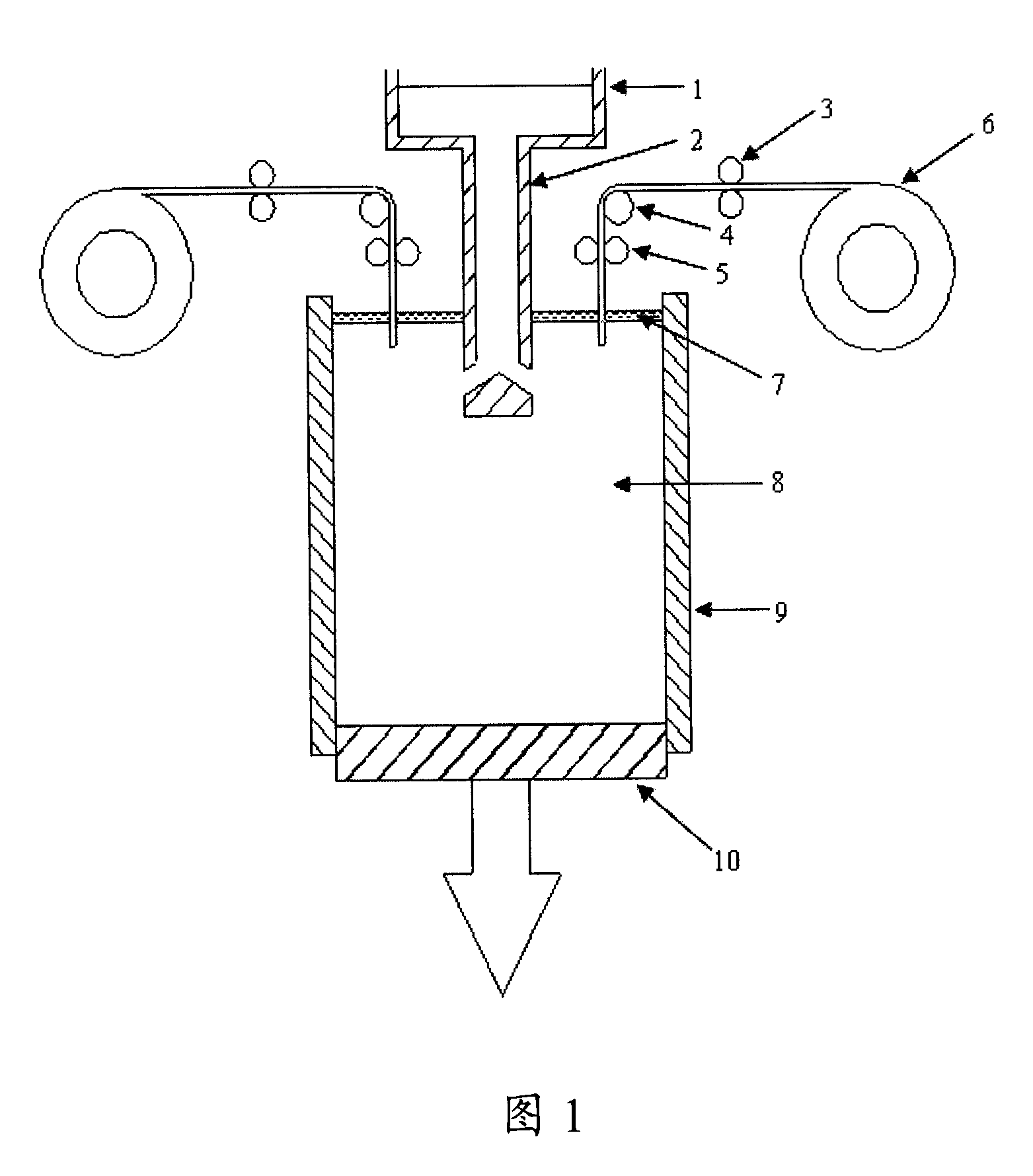

[0010] Embodiment 1: Referring to Fig. 1, the crystallizer device of the present invention includes: molten metal tundish 1, submerged nozzle 2, straightening roller, guide roller 4, conveying roller 5, self-consumable metal plate 6, mold powder 7, Slab 8, water-cooled crystallizer 9 and dummy rod 10.

[0011] The main part of the device is the same as the conventional crystallizer, that is: a metal liquid tundish 1 is arranged in the middle of the top of the metal crystallizer 9 with a cooling water bag, and a submerged nozzle 2 is inserted and immersed in the crystallizer below it. In the molten metal in the device, there is a tapered plunger to adjust the outflow of the molten metal; at the bottom of the crystallizer 9, a stretchable dummy rod 10 is provided, which can pull out the solidified billet downwards.

[0012] Both sides above the crystallizer 9 are also provided with a feeding feed mechanism that feeds the self-consumable metal plate 6 into the molten metal in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com