Polyurethane coating for shoes and manufacturing method of coating of polyurethane coating

A technology of polyurethane coatings and polyester polyols, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems that the reaction speed bubbles cannot escape the resin body, the problem of coating bubbles, and the separation of leather fabrics. Achieve the effect of improving interlayer peeling strength, high peeling strength of coating, and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-3

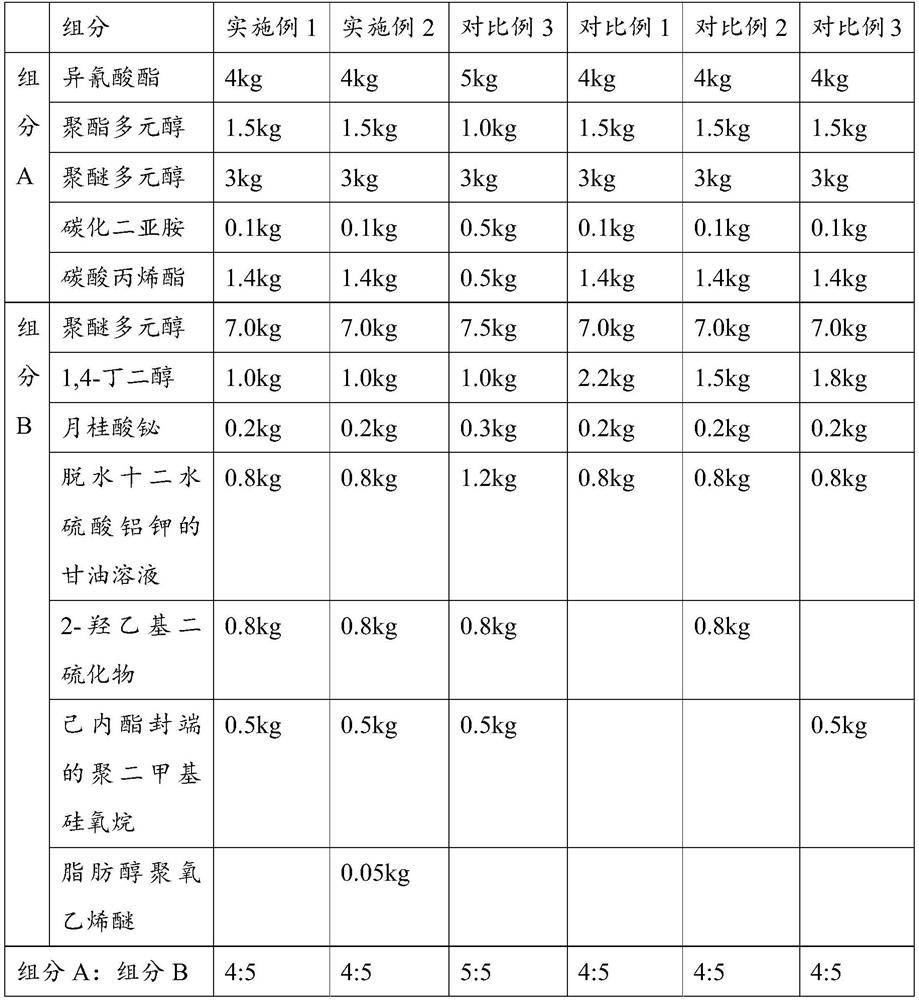

[0052] Examples 1-3 and Comparative Examples 1-3 are polyurethane coatings.

[0053] The raw materials or component contents of the polyurethane coatings of Examples 1-3 of the present invention and Comparative Examples 1-3 are shown in Table 1 below.

[0054] The raw material of table 1 embodiment 1-3 and comparative example 1-3 polyurethane coating or component content

[0055]

[0056] *In the table, the molecular weight of polyester polyol is 2000, the molecular weight of polyether polyol is 2000, and the mass content of dehydrated potassium aluminum sulfate dodecahydrate in the glycerol solution is 10%.

[0057] The preparation method of polyurethane coating is as follows:

[0058] (1) Add isocyanate, polyester polyol, polyether polyol, water remover (carbodiimide) and diluent (propylene carbonate) into the reaction kettle, stir evenly, and react at 100°C for 7 hours , remove air bubbles in vacuum (-0.095MPa), cool to room temperature to obtain component A;

[0059]...

Embodiment 4-6 and comparative example 4-10

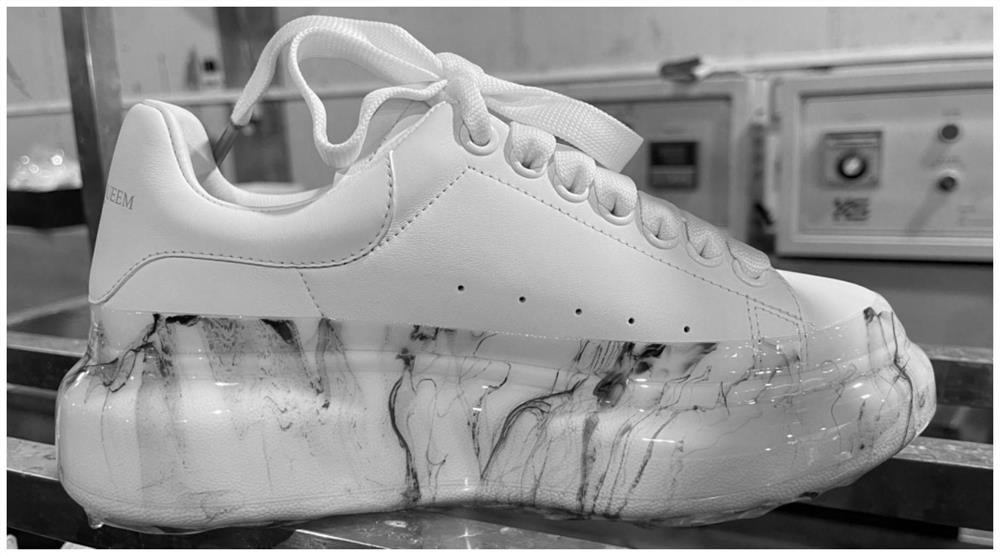

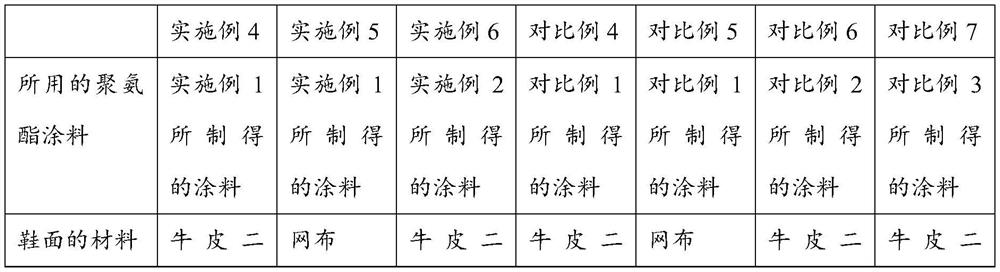

[0062] Examples 4-6 and Comparative Examples 4-10 are finished shoes with polyurethane coatings.

[0063] The polyurethane coatings used in the coatings of the finished shoes of Examples 4-6 of the present invention and Comparative Examples 4-10 and the materials of the uppers are shown in Table 2 below.

[0064] The polyurethane coating of finished shoes is produced as follows:

[0065] (1) Put the upper of the shoe upwards, and set a coating line around the shoe between the sole and the shoe opening;

[0066] (2) make above-mentioned any kind of polyurethane coating flow down from the coating line to the sole along the coating line, the polyurethane coating is coated in the area of the coating line and the bottom edge of the sole to form a coating film, the diameter of the nozzle is 10mm during coating, During the flow coating process, the pigment is mixed with the polyurethane coating to make the coating form a specific pattern;

[0067] (3) Curing and forming at room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com