Curve surface attaching clamp and attaching method

A technology for laminating jigs and fixtures, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of insufficient air bubbles, affecting product quality, poor laminating effect, etc., and achieve good laminating effect , avoid the effect of not being able to fit, and improve product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

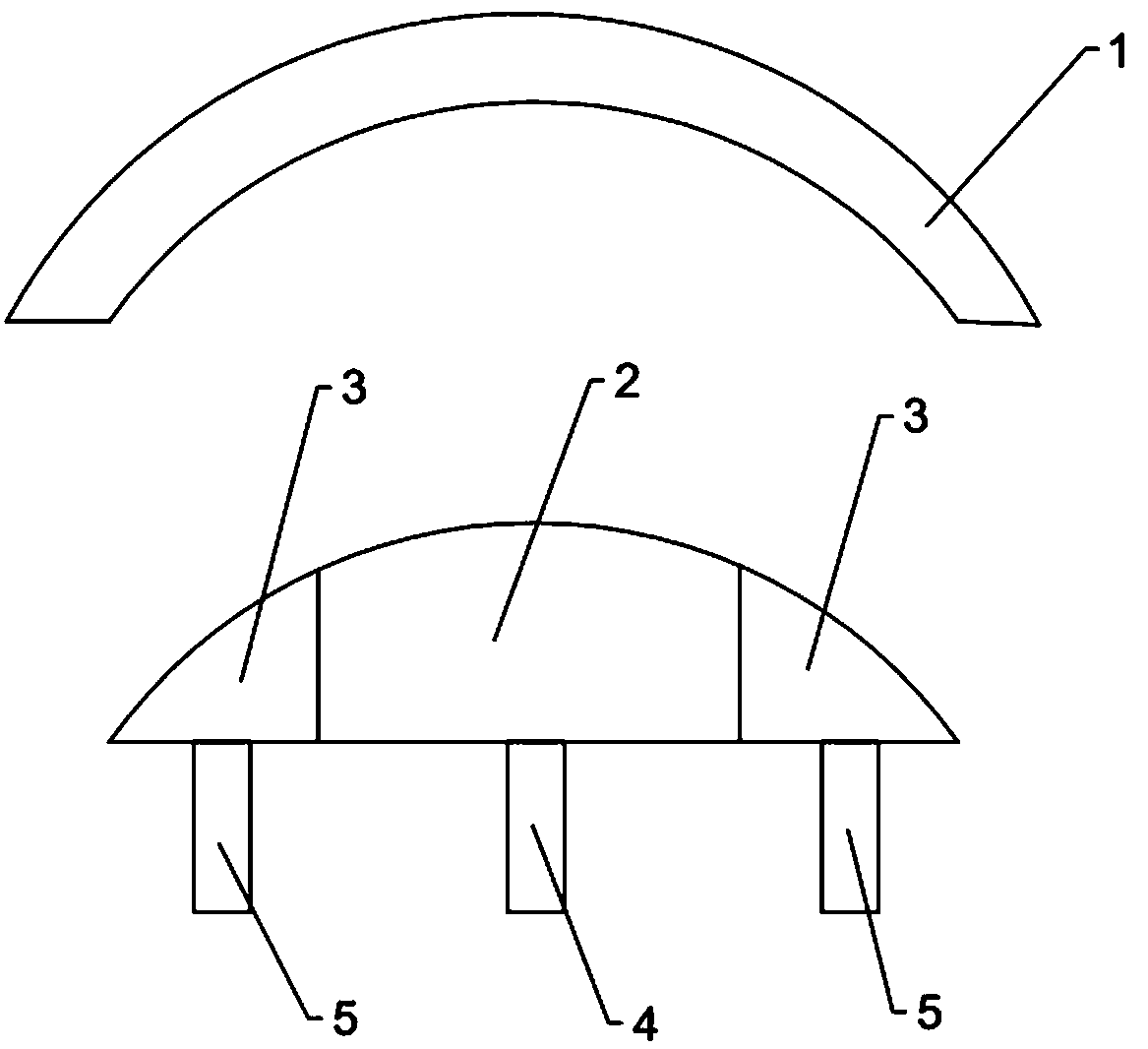

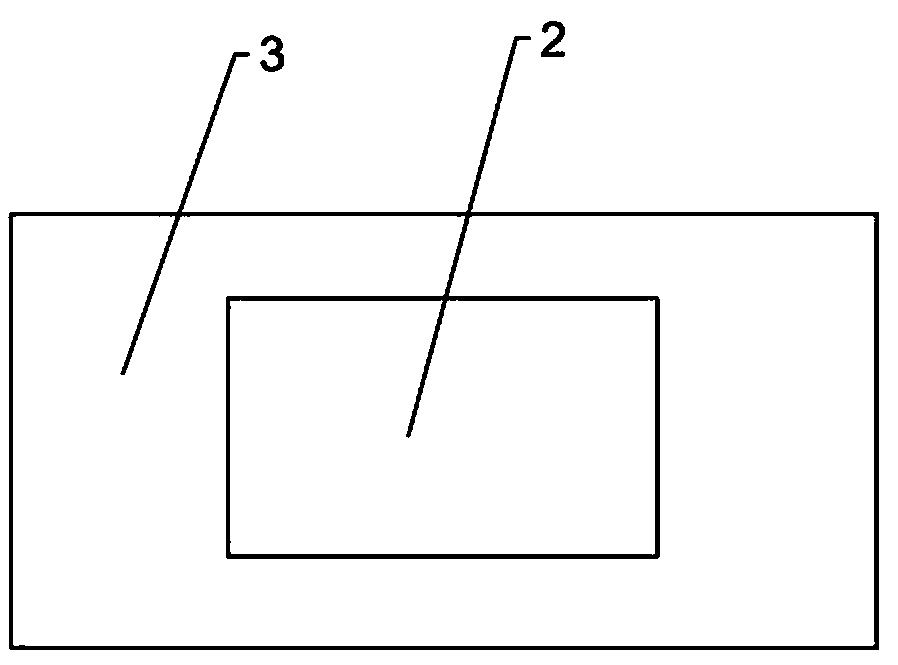

[0026] A curved surface fitting fixture, comprising an upper fixture and a lower fixture located directly below the upper fixture, the upper fixture is used for fixing a curved touch screen, the lower fixture is used for fixing a curved display screen, and the lower fixture includes a first A clamp and a second clamp arranged around the periphery of the first clamp, a first jacking mechanism is provided below the first clamp to drive the first clamp to move up and down; the bottom of the second clamp is provided with The second jacking mechanism is used to drive the second clamp to move up and down. By dividing the lower jig into independent first jig and second jig, respectively controlling the rising height of the first jig and the second jig, the air bubbles can be fully discharged from the middle area of the curved display to the edge during lamination, thereby reducing The generation of air bubbles is eliminated, the degassing process is canceled, and the yield rate of ...

Embodiment 2

[0036] A method for bonding curved surfaces, using the bonding fixture in Example 1 for bonding, comprising the steps of:

[0037] S1. Put the curved touch screen into the upper fixture and fix it; specifically, adsorb the curved touch screen on the upper contact surface through the upper fixture;

[0038] S2. Set an adhesive layer on the curved display screen; put the curved display screen on the lower fixture and fix it so that the adhesive layer faces upward; specifically, adsorb the curved display screen on the first contact surface and the second contact surface through the lower fixture ;

[0039]S3. Lift the first fixture through the first lifting mechanism, so that the middle part of the curved display screen contacts the curved touch screen first, and then lift the second fixture through the second lifting mechanism, so that the curved touch screen and the curved display screen and fully fit between them; wherein, when fully fitted, the height of the first clamp lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com