Patents

Literature

57results about How to "Guaranteed three-dimensional effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polished crystal tile

The invention discloses a method for preparing a polished crystal tile, comprising the following steps of: accumulating a mixture of low-temperature clinkers and high-temperature clinkers on a printed tile surface baked at high temperature; baking; and polishing. The polished crystal tile prepared with the preparation process has high high-temperature viscosity and stable glass network structure, the baked clinker has certain height and has stereoscopic impression and artistic feeling. The action of the skeleton of the high-temperature clinker is favorable to the discharge of bubbles, and the obtained enamel layer has few bubbles, high transparency and high enamel quality. By regulating the proportion of the low-temperature clinkers and the high-temperature clinkers, the preparation method is suitable for different baking temperatures, is convenient and flexible and is suitable for different products.

Owner:广东道氏陶瓷材料有限公司

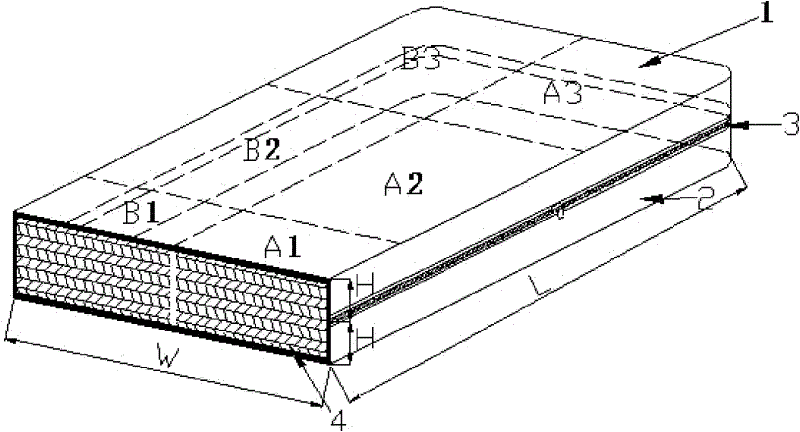

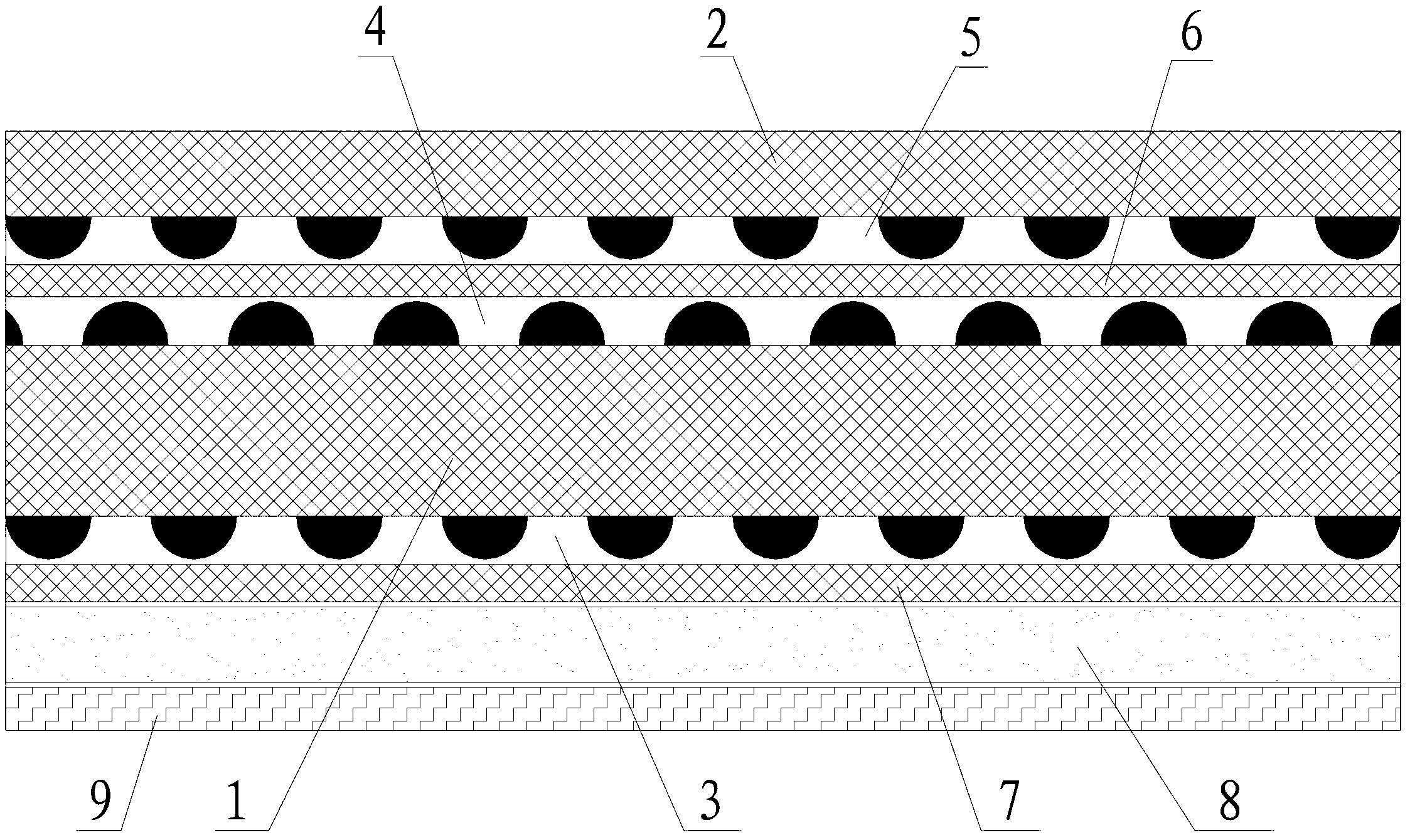

Warp knitted spacer fabric mattress and making method thereof

InactiveCN102613836AEasy to cleanEasy to assemble and disassembleStuffed mattressesSpring mattressesHuman bodySurface layer

The invention relates to the bedding field, and especially relates to a warp knitted spacer fabric mattress and a making method thereof. The mattress comprises an adjustable mattress inner liner and a stereo mattress sleeve, the mattress sleeve is obtained by sewing an upper surface layer, a lower surface layer and a side wall, and at least the upper surface layer and the side wall are warp knitted spacer fabrics; and the mattress inner liner is adjustable and comprises at least two independent inner liner bodies with different supporting strengths arranged in the mattress sleeve, each of the inner liner bodies has a multilayer structure, and at least the top layer is a wrap knitted spacer fabric, so the inner liner bodies and all the layers for forming the inner liner bodies can be reasonably combined and arranged according to ergonomic requirements to adapt to requirements of parameters of the supporting of different positions of a human body, different heights, different body weights and the like. The application of the warp knitted spacer fabric to the mattress sleeve in the invention makes the mattress sleeve have the advantages of elasticity, permeability, ergonomic conforming, bacterial growing inhibition and the like of the warp knitted spacer fabric and simultaneously have the characteristics of dismounting and mounting convenience and cleaning convenience of the mattress sleeve.

Owner:福建福联精编有限公司

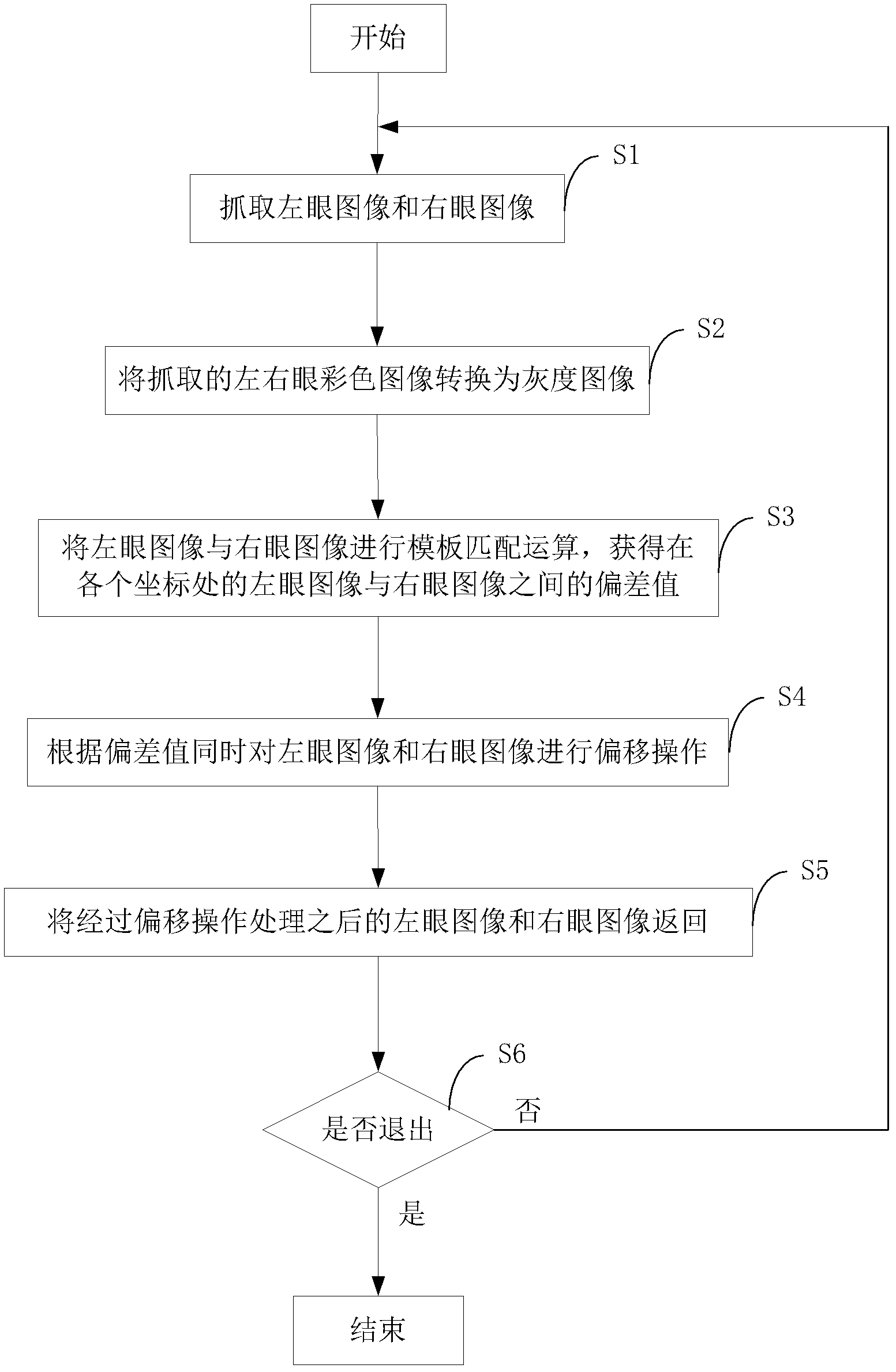

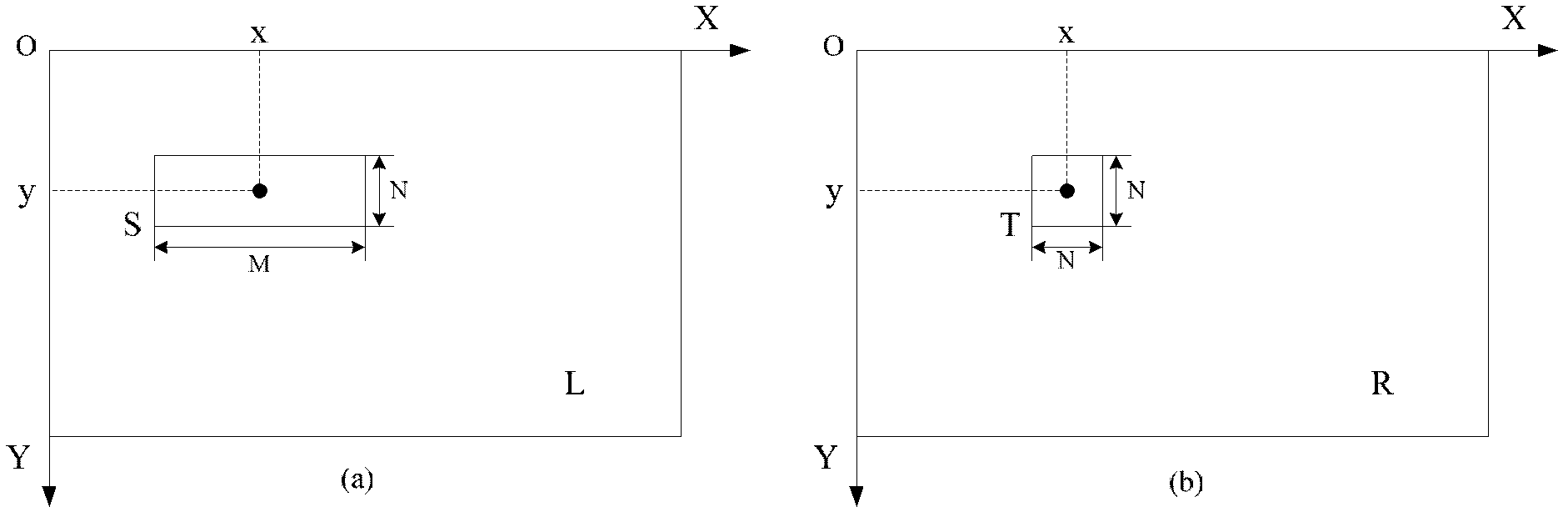

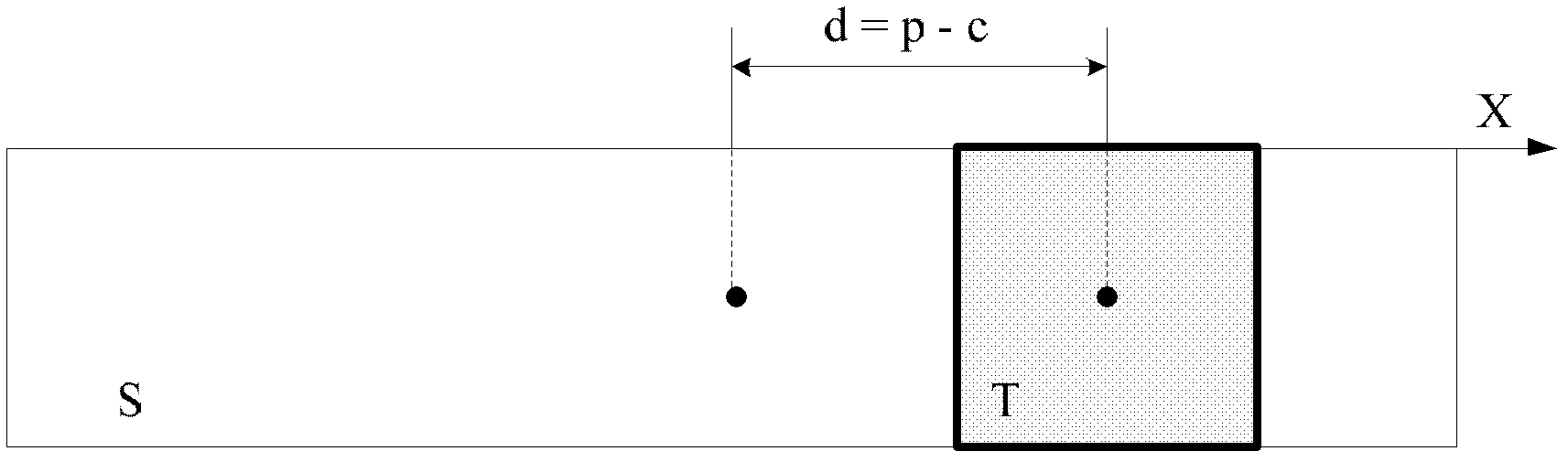

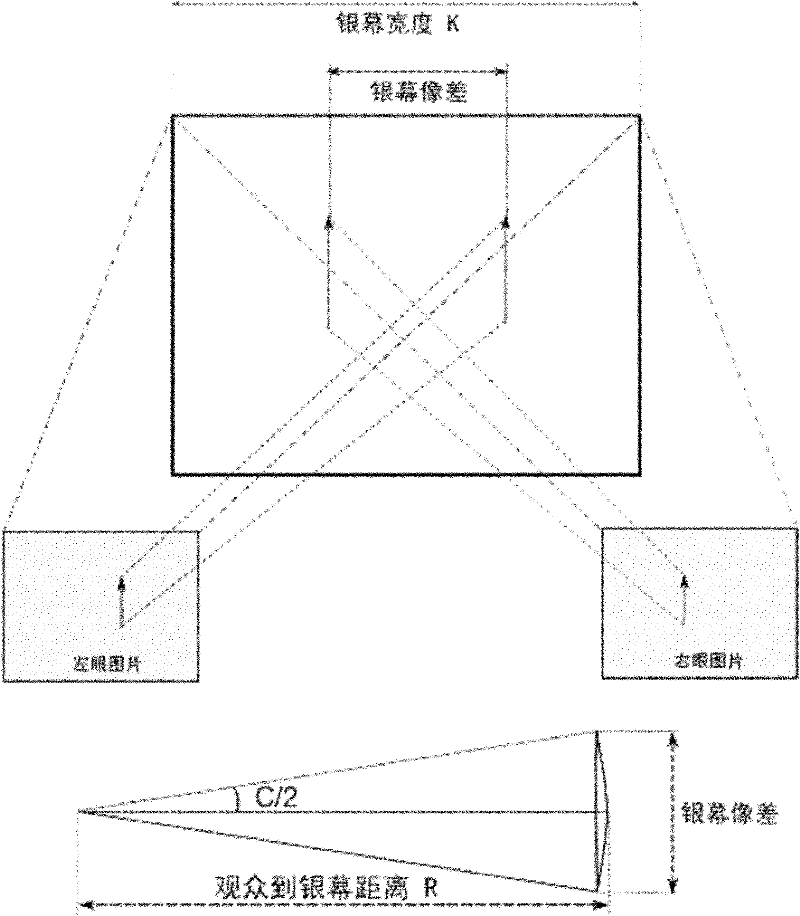

Method for eliminating left and right eye image ghosting, ghosting eliminator and 3D player

ActiveCN102685369AGuaranteed three-dimensional effectLess discomfortTelevision system detailsColor television detailsTemplate matchingParallax

The invention is suitable for the field of digital image processing, and provides a method for eliminating left and right eye image ghosting, a ghosting eliminator and a 3D (three dimensional) player. The method comprises the following steps of: carrying out template matching operation to a left eye image and a right eye image to obtain a deviation value between the left eye image and the right eye image at each coordinate; and according to the deviation value, simultaneously carrying out offset operation to the left eye image and the right eye image. In the embodiment of the invention, the left eye image and the right eye image are subjected to the template matching operation to obtain the deviation value between the left eye image and the right eye image at each coordinate; the left eye image and the right eye image are simultaneously subjected to the offset operation according to the deviation value; the purpose that the ghosting caused by interference in 3D display is relieved is achieved by reducing the parallax between the left eye image and the right eye image; and the third dimension of a 3D-displayed picture is kept, while the ghosting phenomenon caused by interference is relieved, and the discomfort of watchers is reduced.

Owner:TCL CORPORATION

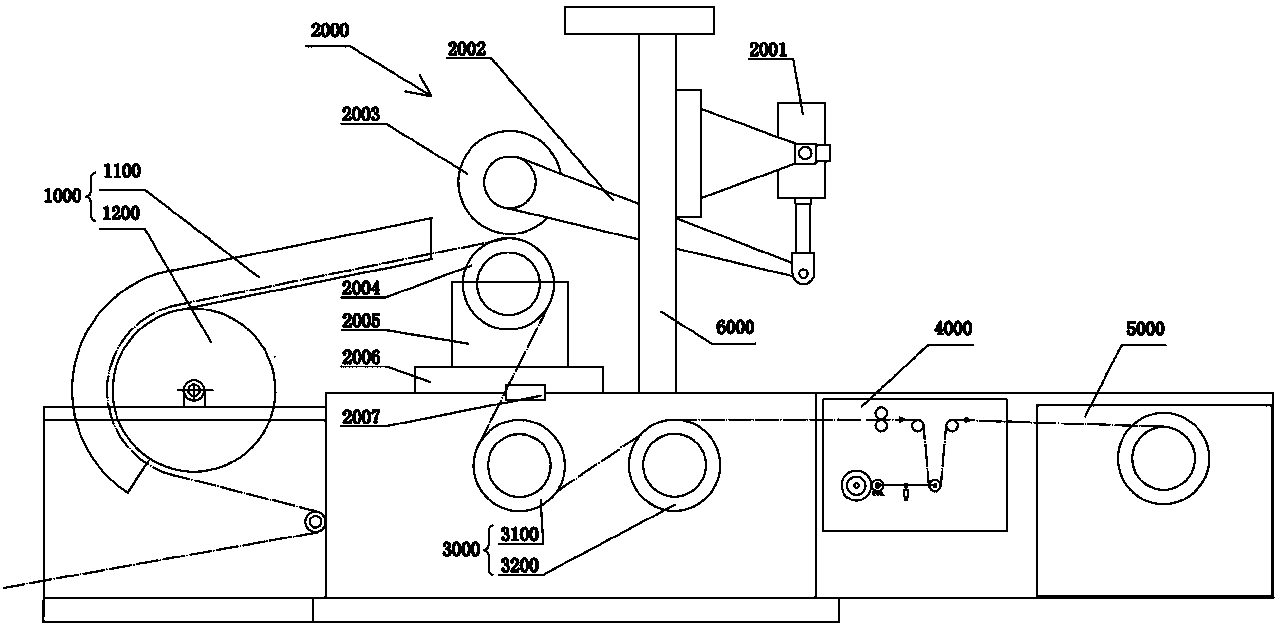

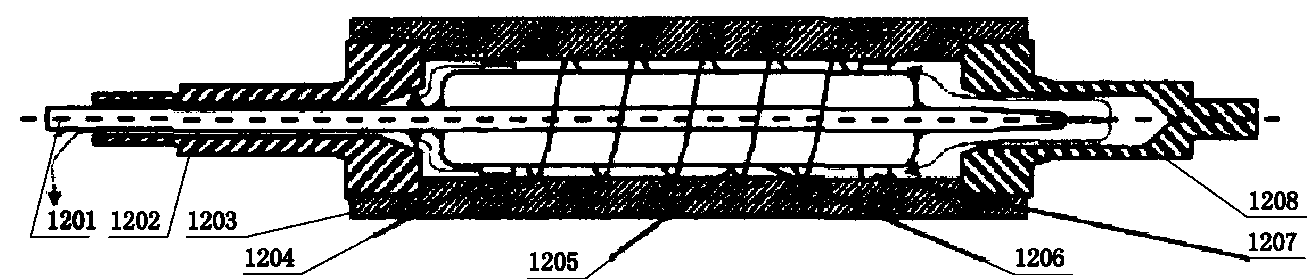

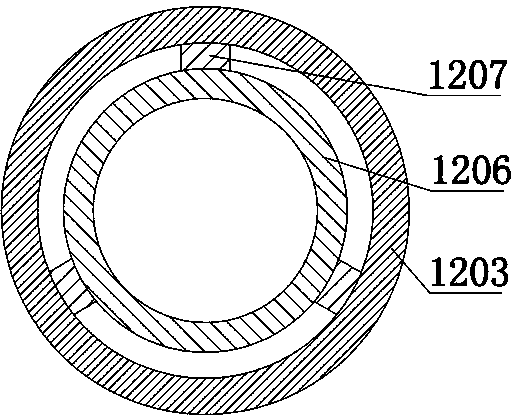

Wallpaper printing system

ActiveCN104002507AReduce in quantityHigh thermal efficiencyMechanical working/deformationWebs handlingEngineeringHeating efficiency

The invention relates to a wallpaper printing system and belongs to the technical field of printing machines. The wallpaper printing system comprises a preheating mechanism, an embossing mechanism, a cooling mechanism, a tension mechanism, a winding mechanism and a machine frame. The preheating mechanism comprises a preheating cover and a heating roller, the preheating cover is arranged on a working surface of the heating roller, the embossing mechanism comprises a press roller and an embossing roller, and the press roller and the embossing roller are parallelly arranged and located on a discharging port of the preheating mechanism. Hot oil single-side inflow and outflow are adopted according to the preheating mechanism for the wallpaper printing system, the number of components in heat exchange with hot oil is reduced, and heat efficiency is improved; according to the preheating mechanism for the wallpaper printing system, an oil guide sleeve is adopted, the area of the hot oil in the heating roller is reduced, the circulation speed of the hot oil is accelerated, and the temperature of a roller can be kept constant to the largest extent.

Owner:陈换换

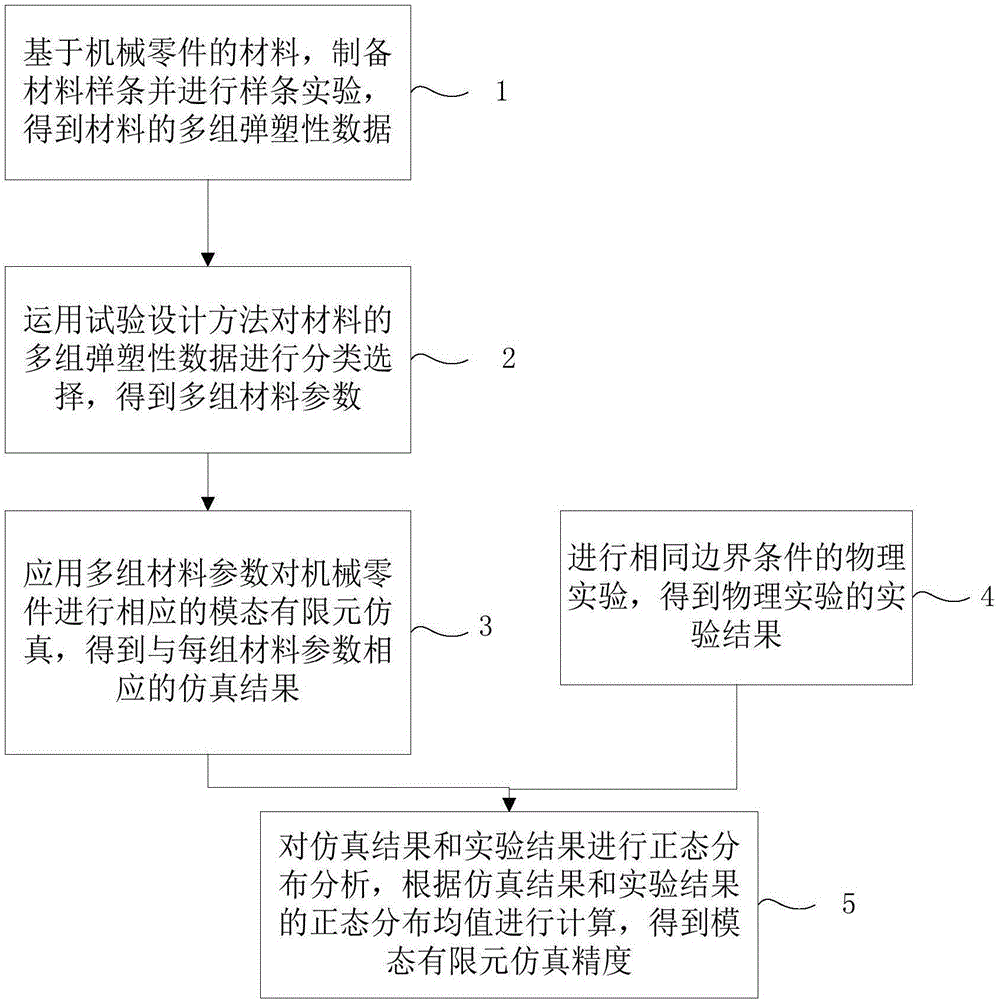

Method for determining modal finite element simulation precision of mechanical part

InactiveCN106777630AThe result is accurateThe simulation accuracy is close to the real situationGeometric CADDesign optimisation/simulationTest designMechanical components

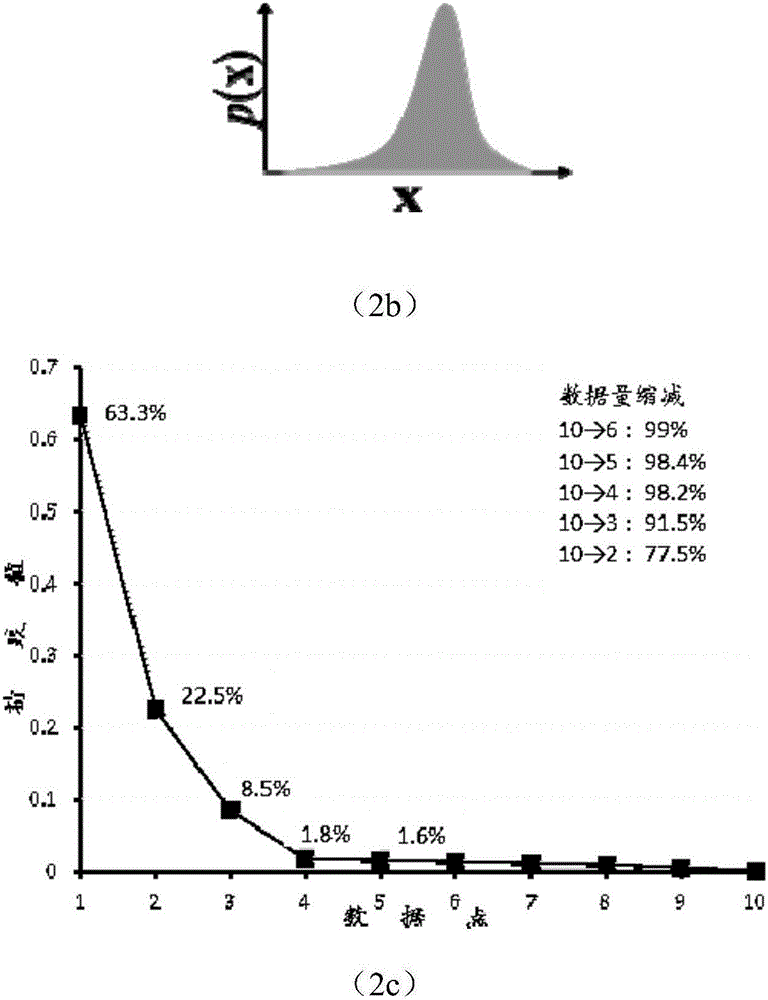

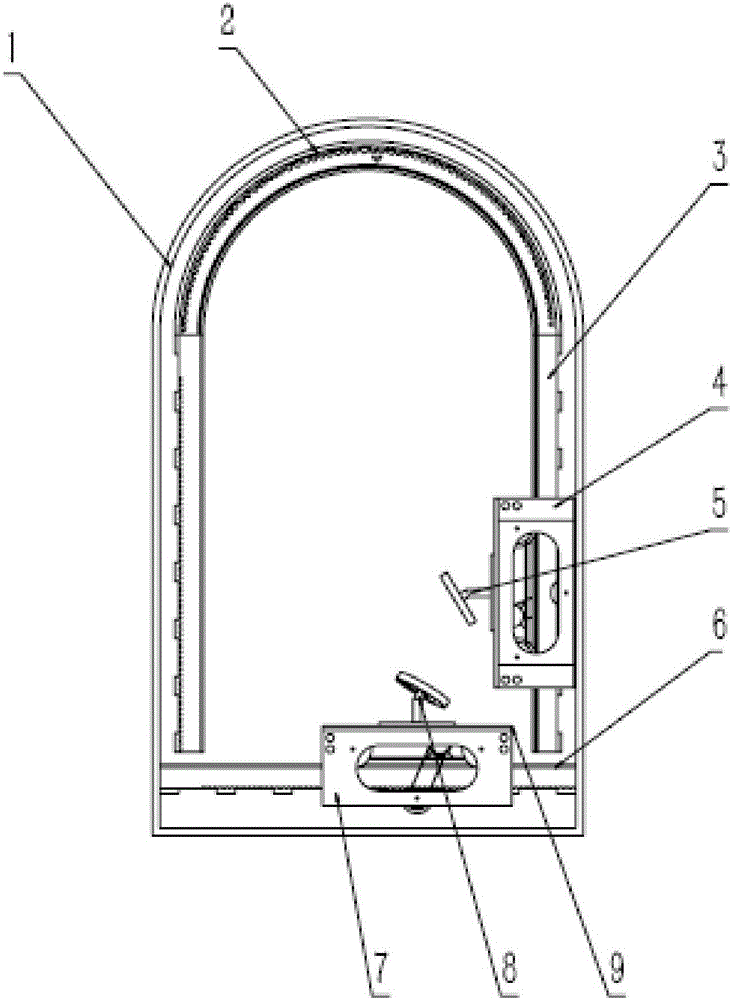

The invention relates to a method for determining modal finite element simulation precision of a mechanical part. The method comprises the following steps that a material sample strip is prepared on the basis of the material of the mechanical part, and a sample strip experiment is performed to obtain multiple groups of elastic-plastic data of the material; a test design method is applied to classify and select the multiple groups of elastic-plastic data of the material so as to obtain multiple groups of material parameters; corresponding modal finite element simulation is conducted on the mechanical part by applying the multiple groups of material parameters to obtain simulation results corresponding to each group of material parameters; according to the finite element model established in the modal finite element simulation, a physical experiment with same boundary conditions is performed to obtain physical experiment results; normal distribution analysis is conducted on the simulation results and the experiment results, and the modal finite element simulation precision is obtained through calculation according to normal distribution mean values of the simulation results and the experiment results. Compared with the prior art, the method has the advantages of being accurate in simulation precision definition, close to the actual situation and the like.

Owner:TONGJI UNIV

High-count high-density jacquard China hemp bedding fabric and product

InactiveCN102121155AWith comfortRetain comfortBiochemical fibre treatmentDry-cleaning apparatus for textilesHigh densityEngineering

The invention discloses a high-count high-density jacquard China hemp bedding fabric. Warps are selected from tightly spun 50S China hemp yarns, and wefts are selected from vortex spun 40S China hemp yarns; the specification of the fabric is 136' tightly spun China hemp 50S * Murata vortex spinning (MVS) China hemp 40S / 173 *110; the number of total warps is 23,520; a second consecutive realistic / abstract single flower of traditional Chinese ink painting skill is applied and spread on the whole ground, wherein the flower breadth is 74 centimeters, and the flower length is 255 centimeters; at least 20 different fabric tissues are applied in the circulation of a pattern; and the heald lifting proportion is controlled at 30 to 35 percent. The fabric has necessary comfort, function and environmental friendliness of high-grade bedding fabrics. Not only main natural properties of bacteria resistance, ultraviolet resistance, moisture absorption, quick dryness and the like of China hemps are kept, but also softness and compactness of the fabric and jacquard weaving luxury reach the requirements of the high-grade fabrics. The prepared bedding also has all excellent properties of the fabric.

Owner:JIANGSU YUEDA HOME TEXTILE

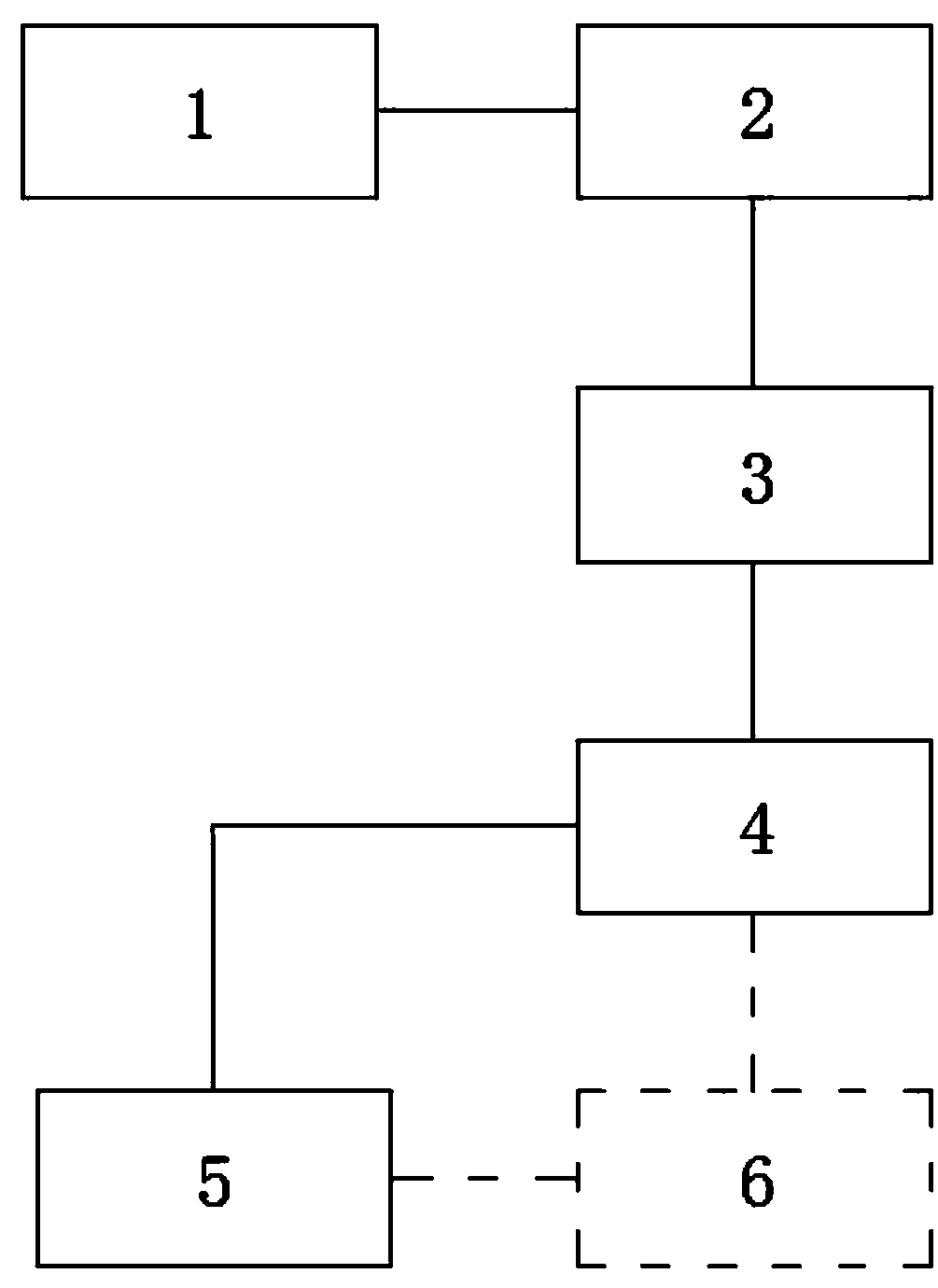

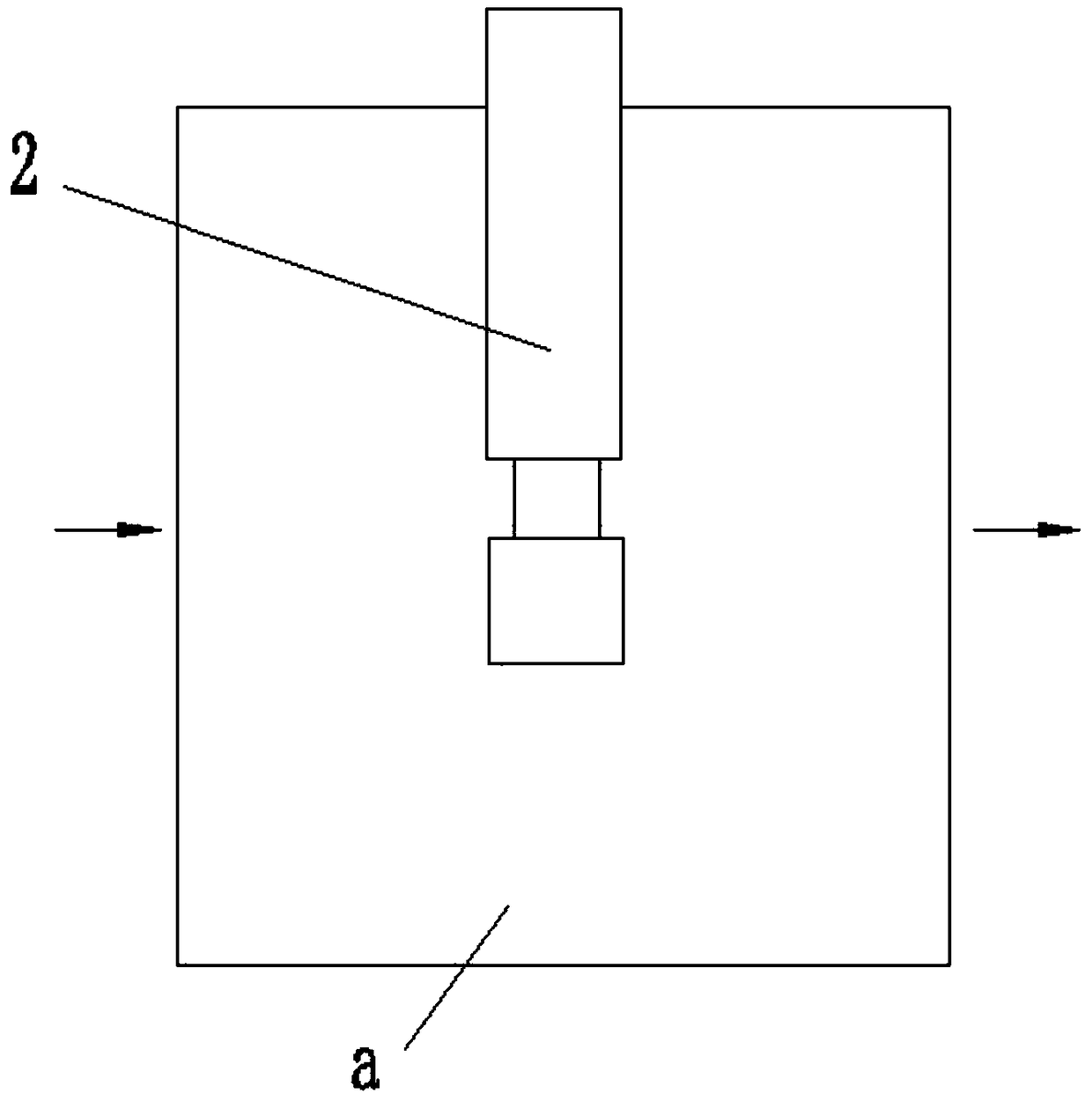

Wind room with detecting function for simulating outdoor flight environment of unmanned aerial vehicle

The invention discloses a wind room with a detecting function for simulating an outdoor flight environment of an unmanned aerial vehicle. The wind room comprises a room body and a working unit, wherein the working unit is composed of a blower fan fixing device, a slide rail and a blower fan. The roof of the room body is a semi-cylindrical closed structural space. The vertical distance between ground of the room body and the circle center of the semi-cylindrical roof is not less than the maximal flight height of the unmanned aerial vehicle in normal operation. The width of the room body is not less than four times of an effective spraying amplitude of the unmanned aerial vehicle in normal operation. The length of the room body is not less than an average operation visual measurement distance of a pilot. The wind room satisfies a requirement for free flight of the unmanned aerial vehicle and can simulate a wind environment of the unmanned aerial in outdoor operation. Factors which comprise wind angle, wind speed and the like and affect operation of the unmanned aerial vehicle are measured. Compared with a traditional wind tunnel test, the wind room has advantages of realizing conversion from a fixed unmanned aerial vehicle mode to a free flight mode, and obtaining a significant scientific meaning in development of an agricultural plant protecting unmanned aerial vehicle in fields of crop pesticide spraying, plant pollination, broadcast spawning, farmland information remote sensing, etc.

Owner:SOUTH CHINA AGRI UNIV

Organic adhesive composite used for silicon solar cell silver paste and preparation method thereof

InactiveCN102304287AGood dispersionEasy to wrapInksNon-conductive material with dispersed conductive materialSilver pasteOrganic solvent

The invention provides an organic adhesive composite used for silicon solar cell silver paste, comprising the following raw materials according to parts by weight: 5-13% of polyamide resin, 8-25% of abietic resin or phenolic aldehyde modified terpene resin, 65-80% of organic solvent and 0-1% of wetting dispersant. The organic adhesive composite exists in silver paste to serve as a carrier or dispersion medium, proper fluid performance is endowed to slurry to fully wet silver powder or inorganic adhesive powder in the wetting silver paste, and the slurry can be dissolved with other accessory ingredients in a mixed mode.

Owner:IRICO

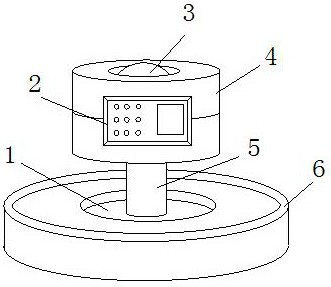

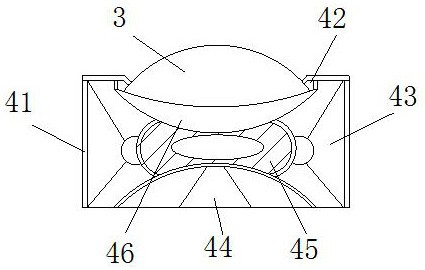

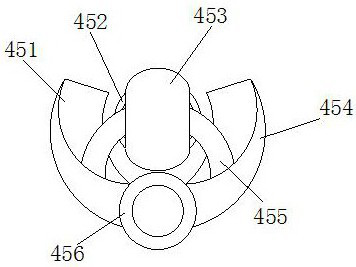

Stereo video shooting device

InactiveCN101794068AGuaranteed three-dimensional effectTelevision system detailsColor television detailsVideo cameraComputer science

Owner:朱仕康 +2

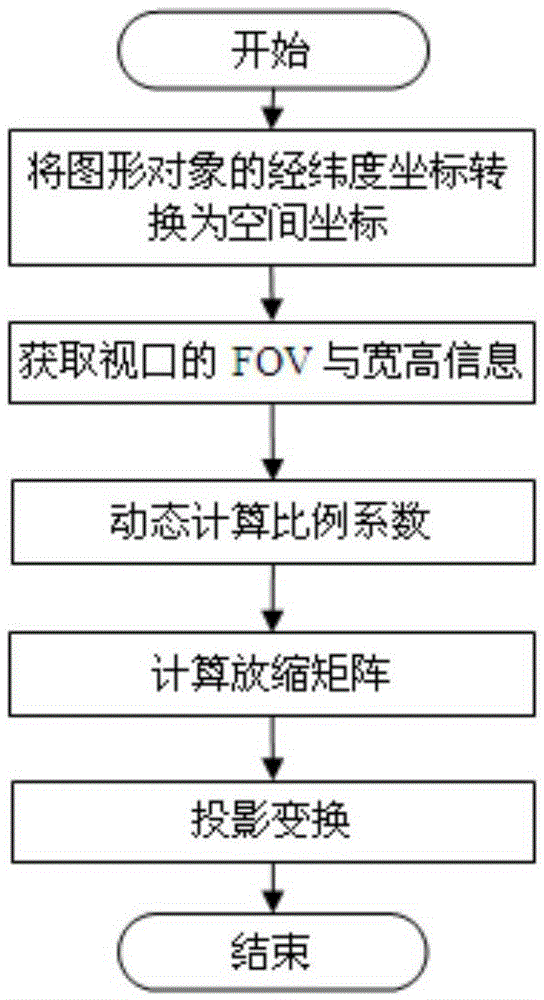

Method for keeping graphic object equal-pixel area display in three-dimensional perspective projection scene

ActiveCN105427371AGuaranteed three-dimensional effectImprove computing efficiencyImage enhancementImage analysisThree dimensional graphicsField of view

The invention discloses a method for keeping graphic object equal-pixel area display in a three-dimensional perspective projection scene, wherein in a three-dimensional graphic frame updating event, an actual proportion parameter of a graphic object is dynamically calculated according to information such as an Fov (Field Of View) of a three-dimensional viewport and a visual section body vertical-horizontal ratio, in combination with a spatial position (depth information) and a basic proportion coefficient of the graphic object, and by virtue of the characteristic that the FOV and width and height of the viewport are statically unchanged, and a pixel area of the graphic object is kept unchanged through projection transformation at different observation positions and from different observation perspectives. The method for keeping the graphic object equal-pixel area display in the three-dimensional perspective projection scene disclosed by the invention ensures a three-dimensional stereoscopic effect of the graphic object through perspective projection, carries out calculation by designing a rational mathematic calculation model, is high in calculation efficiency, keeps a stable graphic display effect in case of scene changes, and will not lead to a phenomenon of pixel area jumping.

Owner:THE 28TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

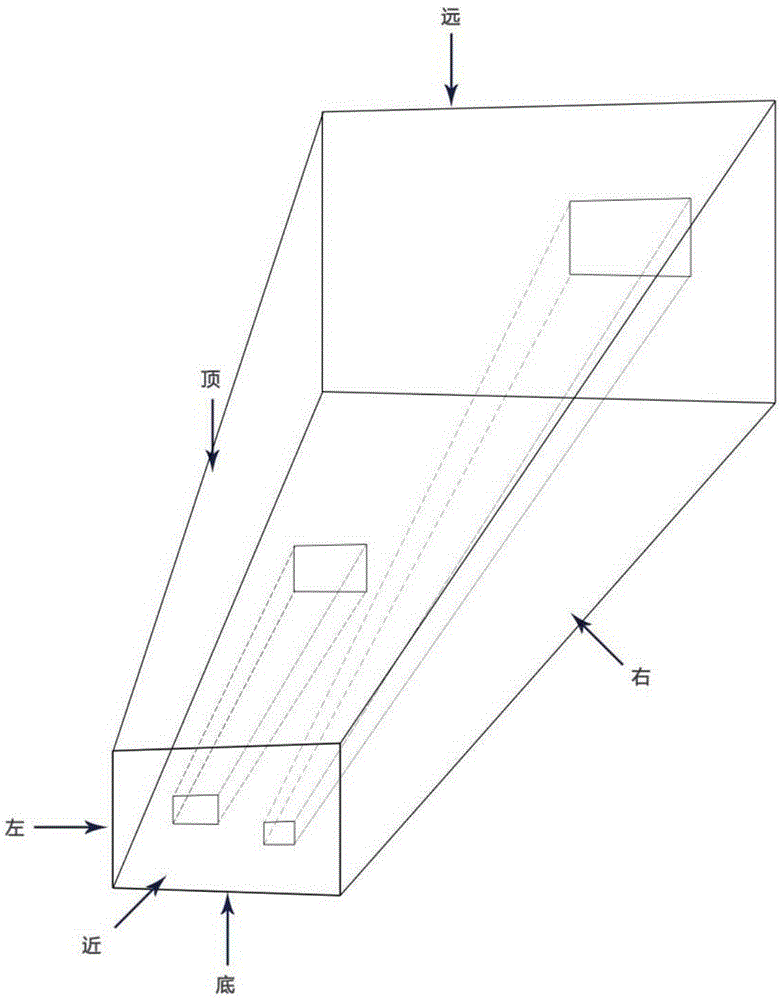

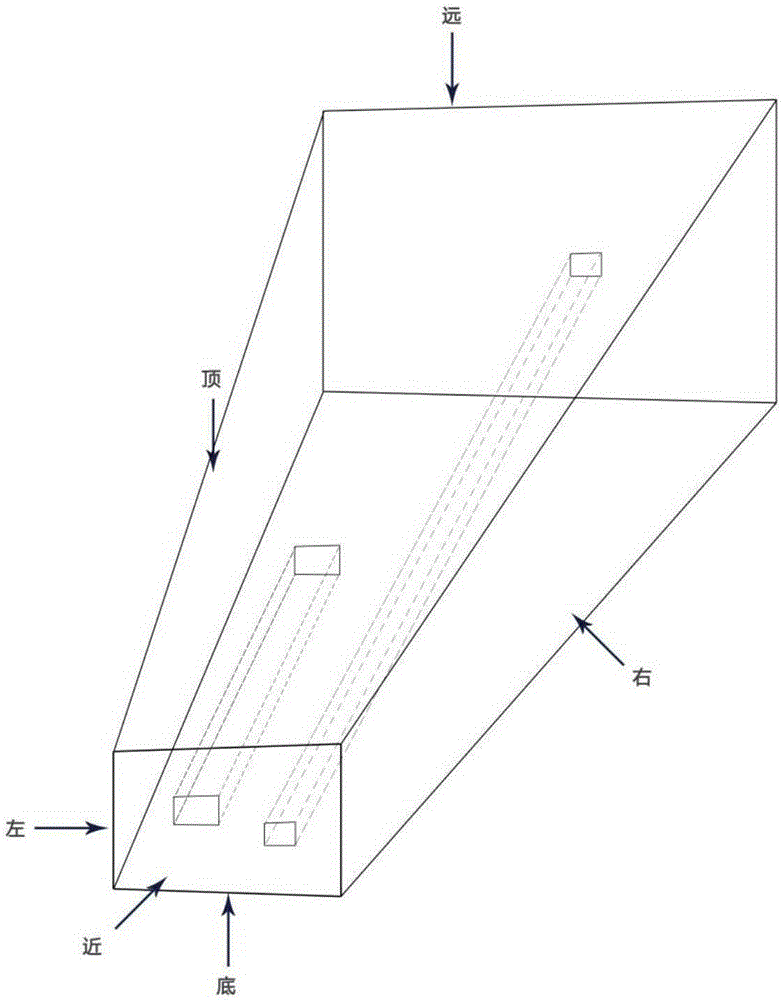

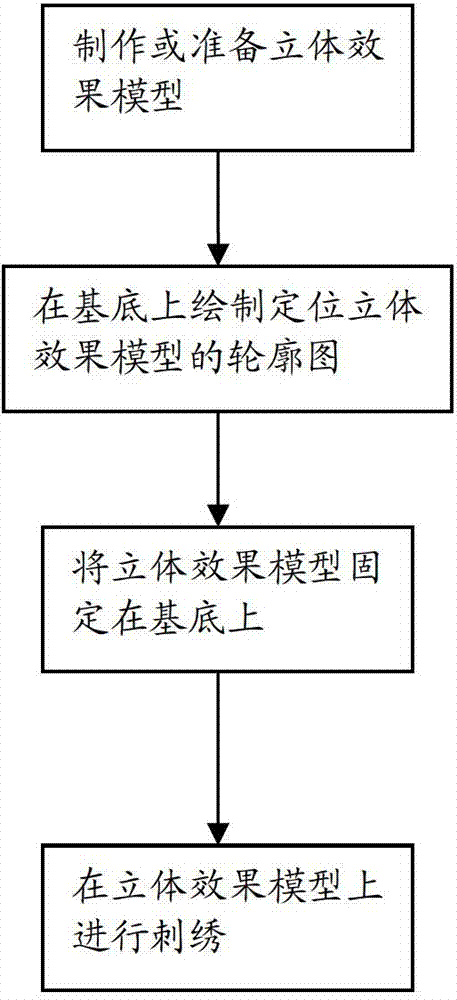

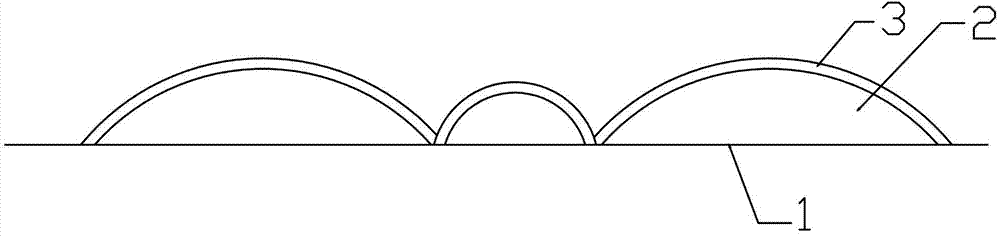

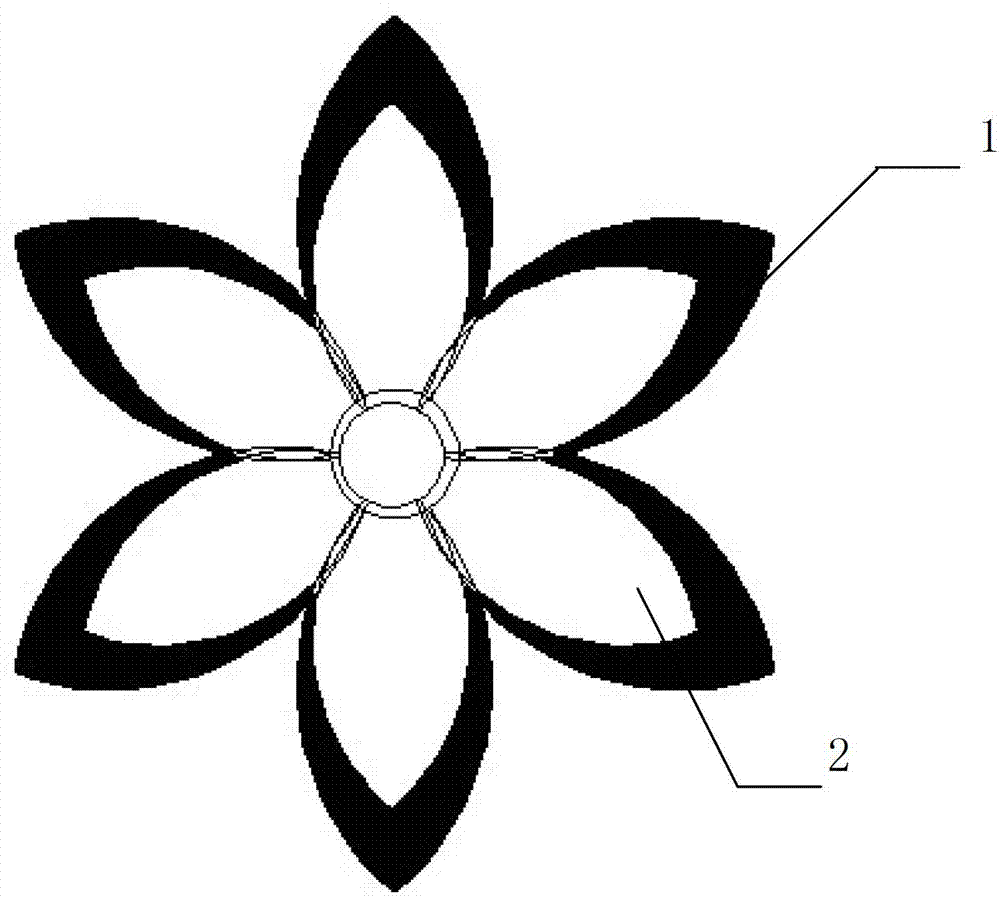

Three-dimensional embroidery and making method thereof

InactiveCN102817191AGuaranteed three-dimensional effectMeet the requirements of different three-dimensional effectsEmbroidering machines apparatusEngineeringProcess engineering

The invention discloses three-dimensional embroidery and a making method thereof. The three-dimensional embroidery is designed to solve the problems in the existing embroidery technology, that the embroidery is poor in three-dimensional effects, large in the embroidery difficulty and variable in quality with each individual. The making method comprises the steps of preparing or making a three-dimensional effect model according to the embroidery patterns and the three-dimensional effect needing to be presented and carrying out embroidery on the three-dimensional effect model. The three-dimensional embroidery comprises the three-dimensional effect model and embroidery layers drawn on the three-dimensional effect model. The making method and the three-dimensional embroidery have the following beneficial effects that the three-dimensional embroidery is strong in three-dimensional effect expression, simple in structure and stable in quality and is simple to make.

Owner:JIHUA 3543 KNITTING CLOTHING

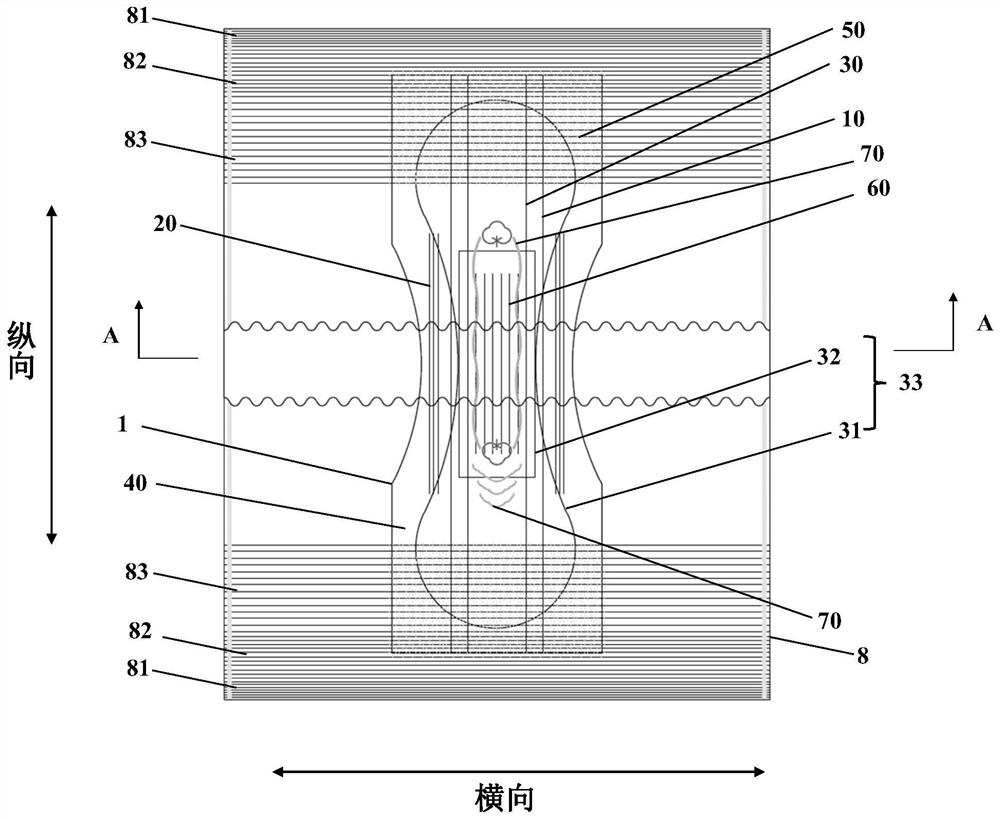

Skirt type absorption article

ActiveCN112957179AFast absorptionReduce reverse osmosisBandagesComposite materialStructural engineering

The invention relates to a skirt type absorption article which comprises an absorption body and an outer layer, the outer layer is of a skirt type structure formed by compounding an inner lining layer and an outer wrapping layer, and the two longitudinal ends of the absorption body are connected with a front waist area and a rear waist area of the outer layer together; the absorption body sequentially comprises a skin attaching layer, an absorption layer and a breathable bottom layer, and side leakage prevention layers higher than the skin attaching layer are arranged on the two sides of the skin attaching layer; and elastic stretching materials are arranged at the crotch position of the absorption body and the front waist area and the rear waist area of the outer layer. The skirt type absorption article has the advantages of being comfortable, attractive, close-fitting and the like, has an excellent using effect in the aspects of attractiveness and comfort, and is a light, thin, comfortable and anti-side-leakage absorption article suitable for being directly worn outside by a user.

Owner:诺宸股份有限公司

Decorative part with 3D visual effect and manufacturing method thereof

ActiveCN103264608AGuaranteed three-dimensional effectEasy to cleanSpecial ornamental structuresAdhesiveEngineering

The invention discloses a decorative part with a 3D visual effect, which belongs to the technical field of accessories of household electrical appliances. The invention further discloses a manufacturing method for the decorative part. The decorative part with the 3D visual effect provided by the invention has a good stereoscopic visual effect and a smooth and clean external surface and is easy to clean. The decorative part comprises a transparent substrate and a transparent cover plate; thus, during manufacturing, a picture and text background layer is printed on a lower side surface of the transparent substrate at first, then refraction bumps and refraction dots exerting stereoscopic refraction effects are respectively printed on an upper side surface of the transparent substrate and a lower side surface of the transparent cover plate, the transparent substrate and the transparent cover plate are bonded to form an integral body through a transparent adhesive located between the upper side surface of the transparent substrate and the lower side surface of the transparent cover plate, and finally, the integral body is subjected to trimming and cutting to obtain the finished decorative part.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

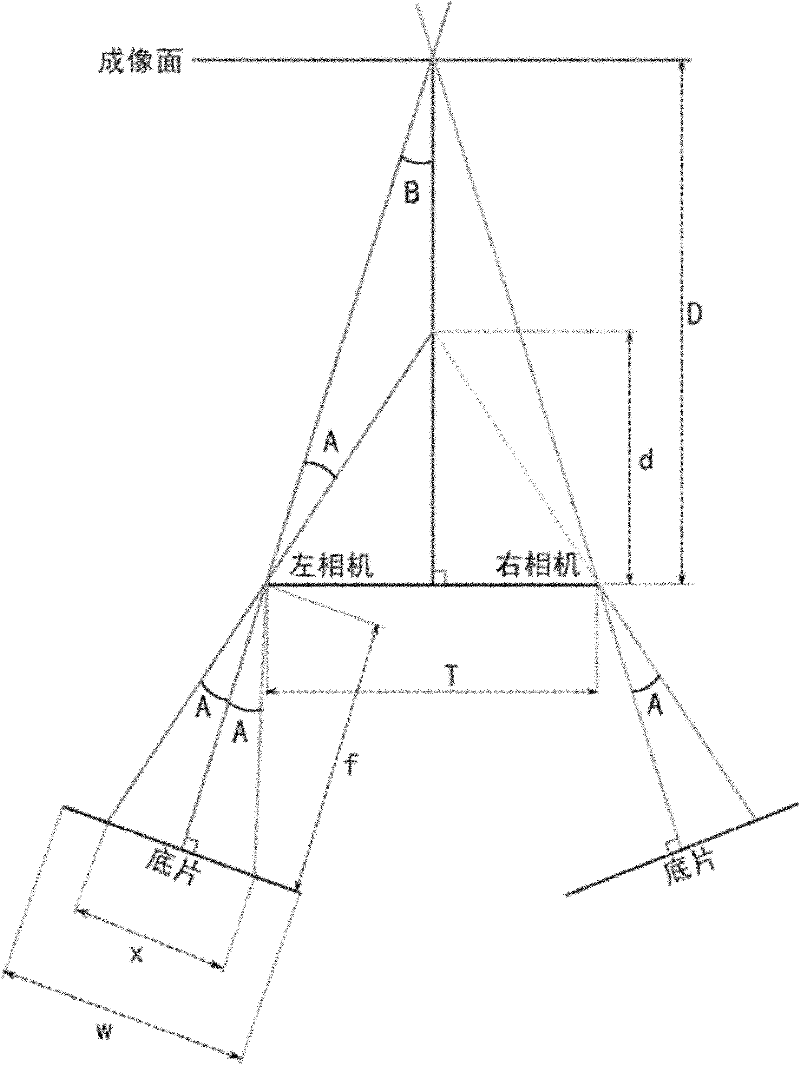

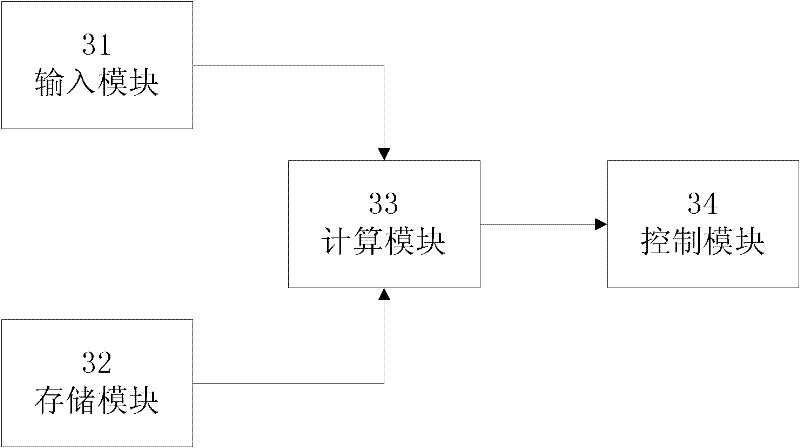

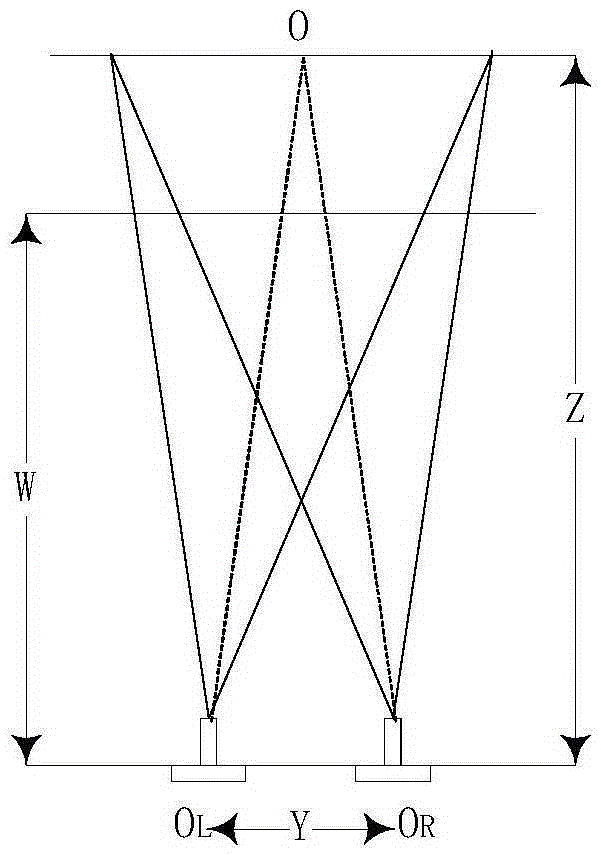

Setting method and system for shooting parameter

ActiveCN102447829AGuaranteed three-dimensional effectTelevision system detailsColor television detailsComputer scienceFocal length

The invention discloses a setting method and system for shooting parameter, in the invention, firstly determining an effect parameter which reflects the three-dimensional effect and / or the watch effect of a 3D-film, then inputting the determined effect parameter and other known shooting parameters through the input module, calculating the adjustable parameter from the formulas stored in the storage module, setting the shooting system according to the adjustable parameter calculated by the setting module to achieve the expected three-dimensional effect and / or watch effect. The invention is capable of roughly predicting the ultimate watch effect in the theater as early as the film is shot, or calculating out the adjustable shooting parameters used in real shooting based on the expectant three-dimensional effect of film, comprising a focal length, an imaging distance, an object distance etc, and ensuring the stereo effect of the final show.

Owner:SHENZHEN HUAQIANG DIGITAL ANIMATION

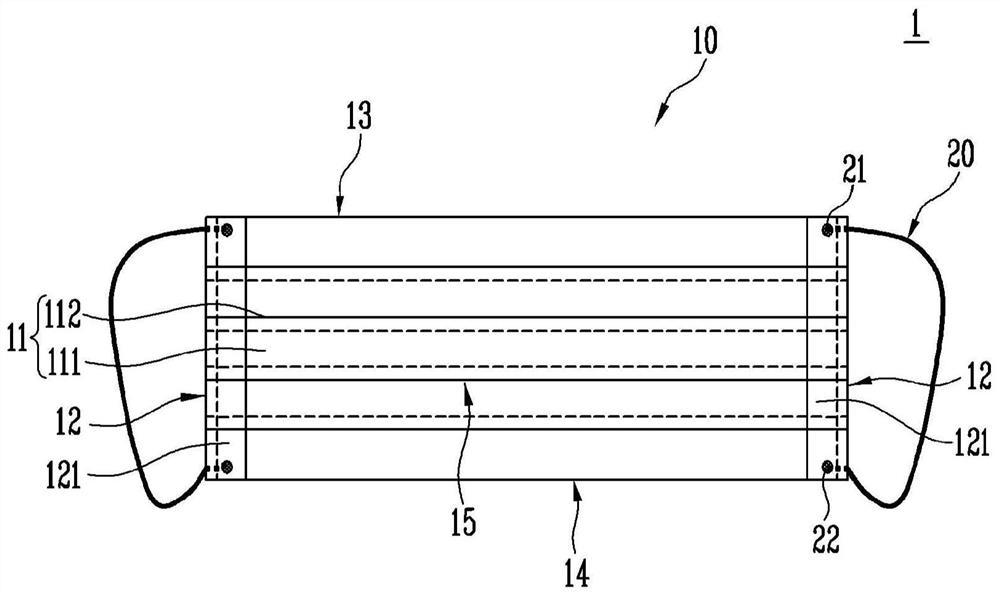

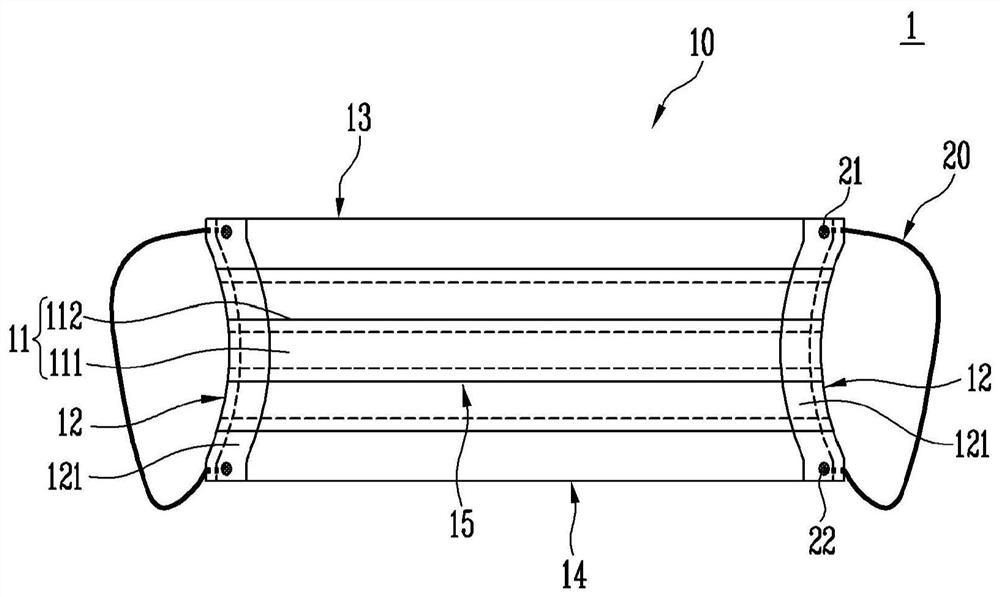

Mask

InactiveCN112437687AImprove convenienceImprove reliabilityBreathing masksProtective garmentChinEngineering

The present invention relates to a mask, and the mask is characterized in that the mask comprises a main body part for covering a respiratory organ of a user; and hooking parts provided on both sidesof the main body part and capable of fixing the main body part to a respiratory organ of a user. The main body part includes a chin cover part that constitutes a lower part and surrounds a chin part of a chin of the user.

Owner:LG HOUSEHOLD & HEALTH CARE LTD

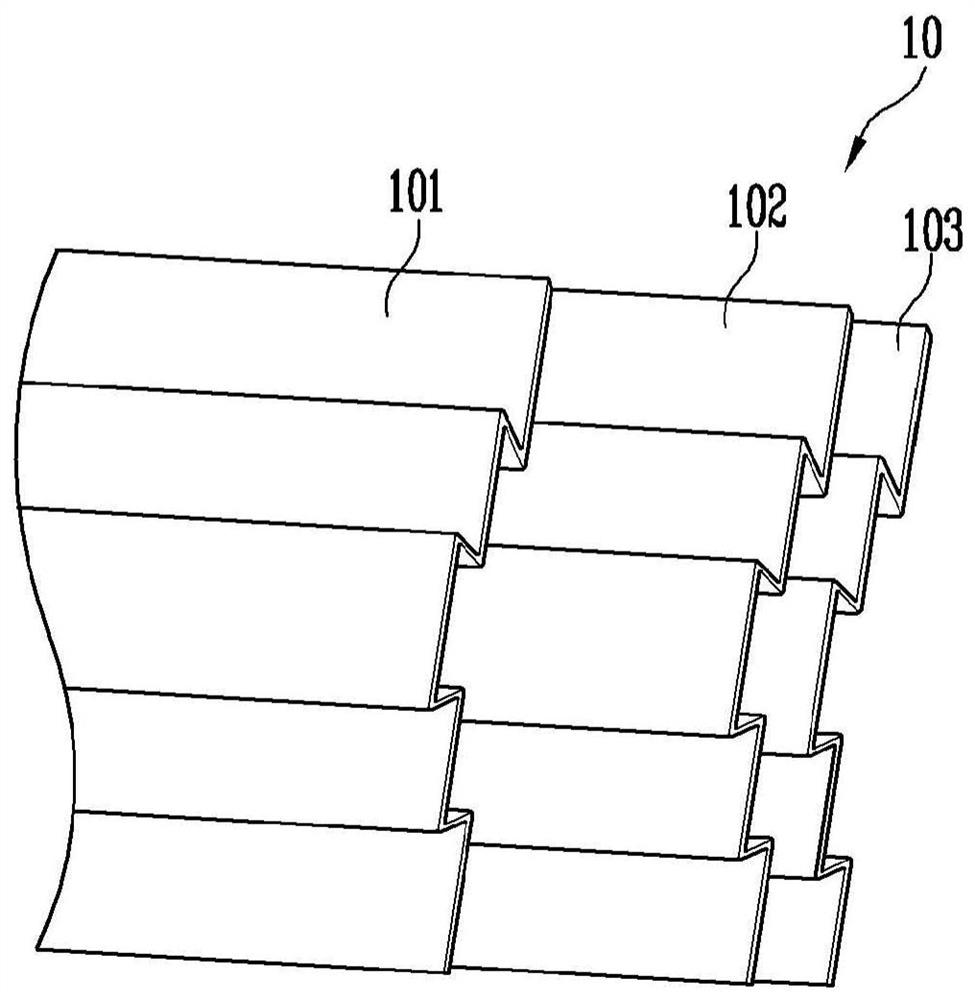

Origami imitation cotton jacquard fabric and processing technology thereof

InactiveCN104695090AGuaranteed three-dimensional effectGuaranteed cutVegetal fibresSwivel-woven fabricsPolyesterPulp and paper industry

The invention provides an origami imitation cotton jacquard fabric and a processing technology thereof. The warp yarn of the fabric adopts CJ9.7tex compact spinning yarn, the weft yarn of the fabric adopts T160D cotton-type polyester filament, the fabric weave origami texture adopts eight pieces of three fly satin drill and eight pieces of three fly sateen, the processing technology adopts specific technology conditions in the weaving, dyeing and finishing processes. The origami imitation cotton jacquard fabric and the processing technology thereof have the benefits that the old paper is used as the carrier in the fabric design element, the paper and the ink flower pattern are tried at the first time, the stereoscopic sensation is strong and the retro nostalgia effect is prominent. For product design, through optimization for the texture configuration, pattern, dressing, weaving, finishing and other technology methods, the fabric is unique in style, comfortable, stiff and smooth, bright in color and high in wrinkle resistance, and the fabric is a high-grade fabric for women.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

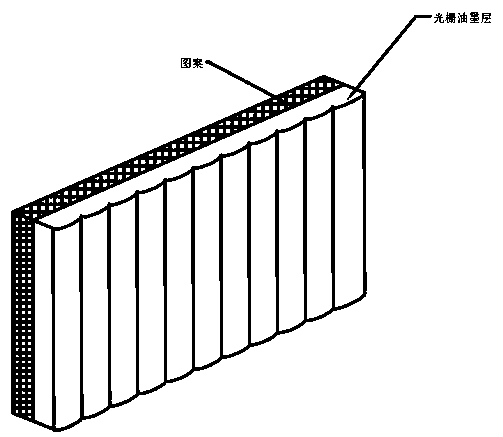

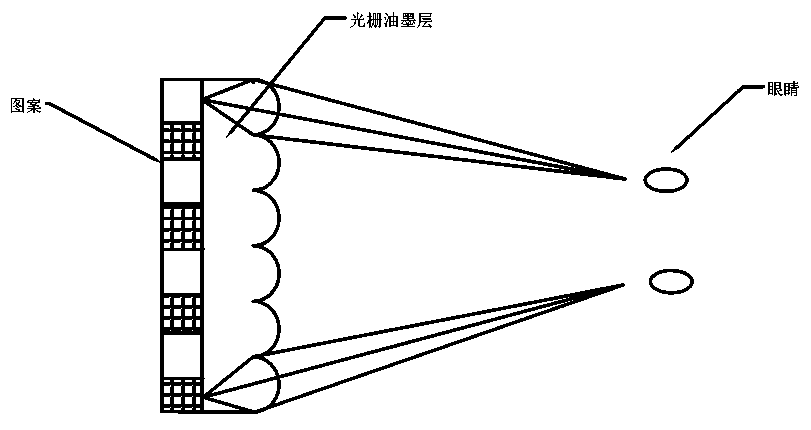

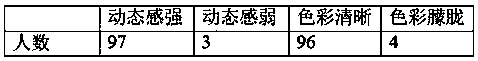

Preparation method for 3D direct-printing grating printing product

The invention provides a preparation method for a 3D direct-printing grating printing product, and belongs to the technical field of printing. The preparation method for the 3D direct-printing gratingprinting product comprises the following steps: (1) carrying out plate making, enabling the output accuracy of a printing plate to be 9500-9700DPI, and enabling the screen ruling to be 700-800LPI; (2) printing a design pattern on raw paper by means of offset printing, and enabling the point shrinkage ratio of pattern printing to be 95%-98%; (3) producing a mold for grating ink, and enabling the resolution ratio of the mold to be 260-280LPI; (4) placing the mold on a grating ink layer, producing a 3D grating, and enabling the thickness of the grating ink layer to be 0.13-0.16cm; and (5) dryingand curing, demolding, and then obtaining the 3D direct-printing grating printing product. The preparation method for the 3D direct-printing grating printing product is capable of ensuring the definition of the observed pattern, and high in resolution ratio, and ensures the glossiness and three-dimensional effect of the pattern of the colored ink layer on the raw paper; and the change of an observation angle presents a dynamic effect, so that the pattern is higher in resolution ratio.

Owner:HUBEI CHINA TOBACCO IND

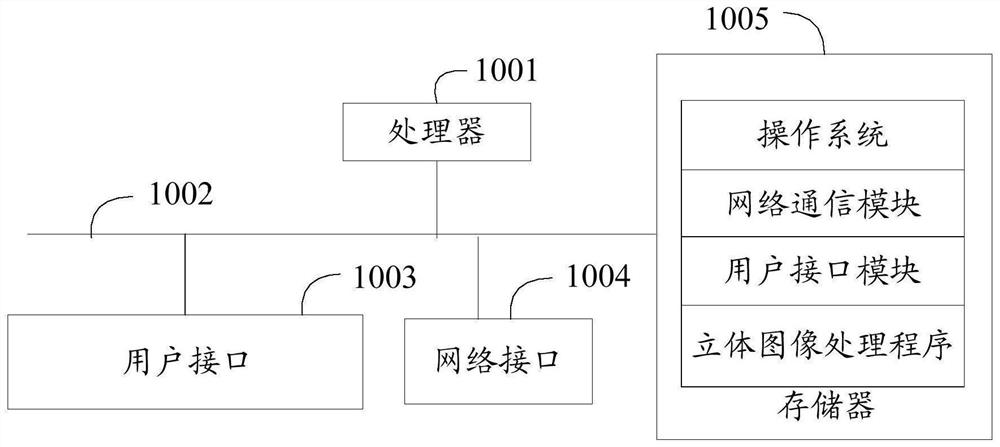

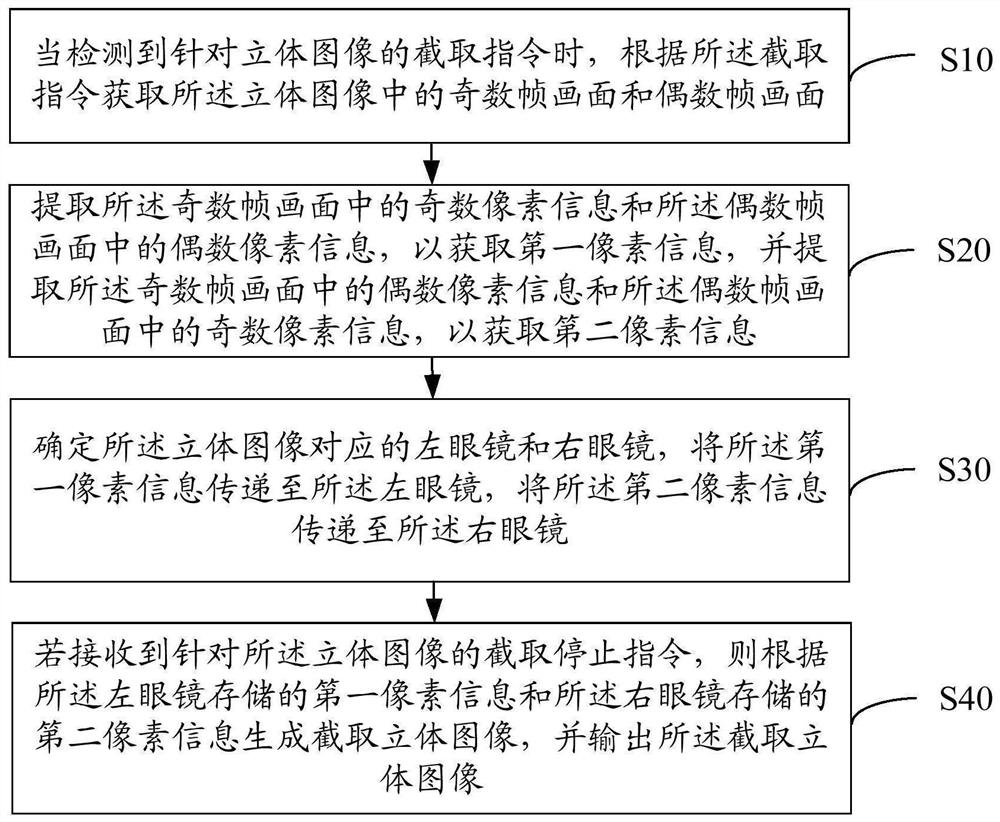

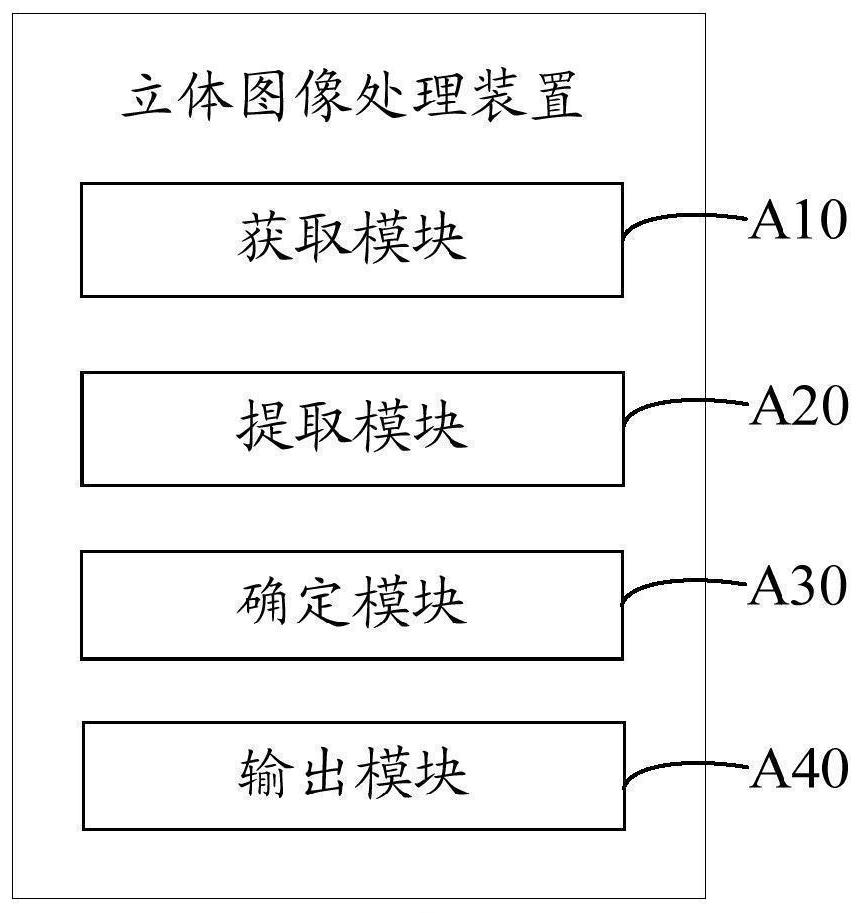

Stereoscopic image processing method, device and equipment, and computer readable storage medium

ActiveCN112333438AGuaranteed three-dimensional effectImprove efficiencySteroscopic systemsInput/output processes for data processingPattern recognitionImaging processing

The invention discloses a three-dimensional image processing method, device and equipment and a computer readable storage medium, and the method comprises the steps: obtaining odd frames and even frames of pictures in a three-dimensional image according to an interception instruction when the interception instruction for the three-dimensional image is detected; extracting odd pixel information from the odd frames of pictures and even pixel information from the even frames of pictures to obtain first pixel information, and extracting even pixel information from the odd frames of pictures and odd pixel information from the even frames of pictures to obtain second pixel information; determining a left glass and a right glass corresponding to the three-dimensional image, transmitting the firstpixel information to the left glass, and transmitting the second pixel information to the right glass; and if an interception stop instruction for the three-dimensional image is received, generatingthe intercepted three-dimensional image according to the first pixel information stored in the left glass and the second pixel information stored in the right glass, and outputting the intercepted three-dimensional image. According to the method, the efficiency and accuracy of capturing the three-dimensional image video are improved.

Owner:SHENZHEN TCL NEW-TECH CO LTD

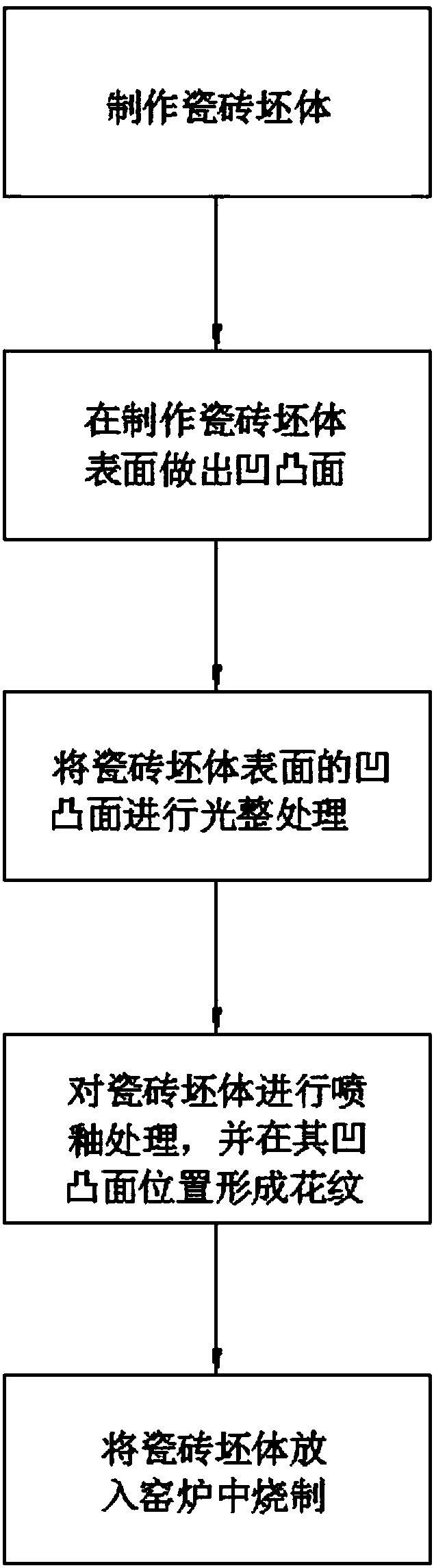

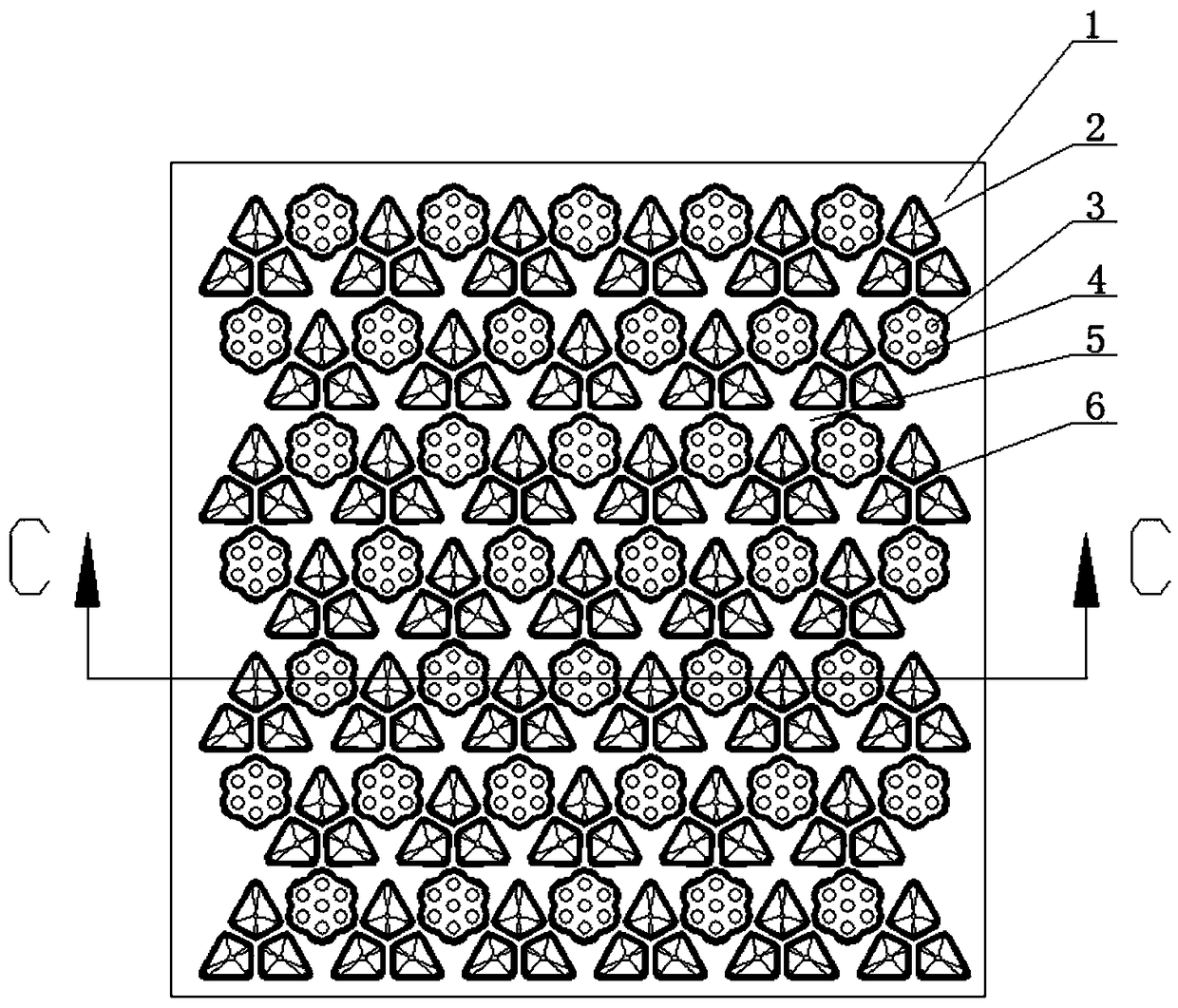

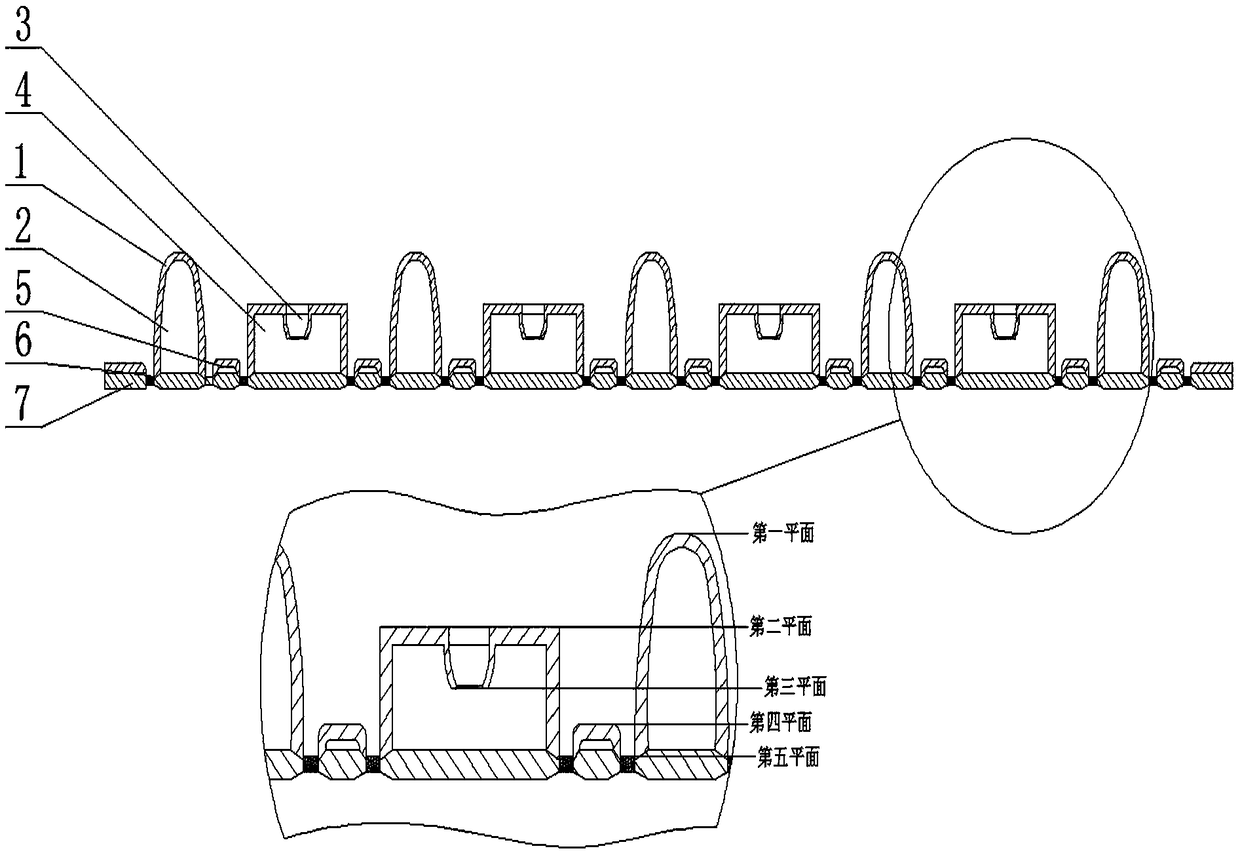

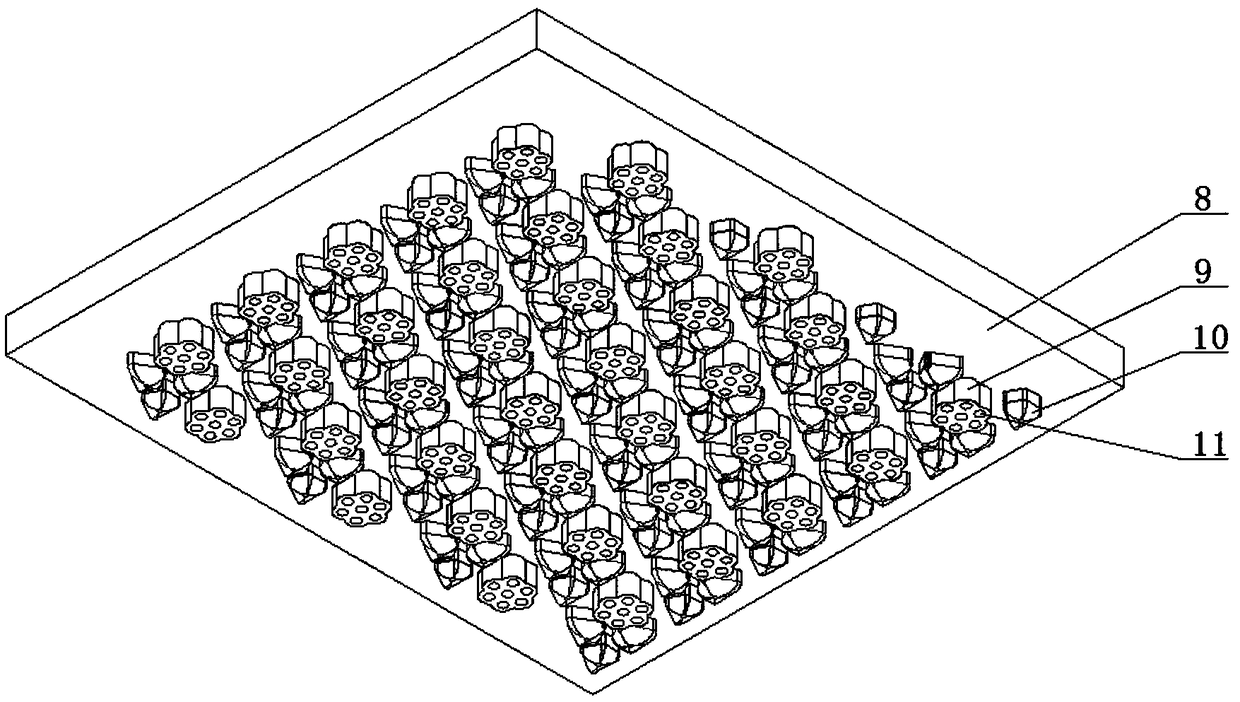

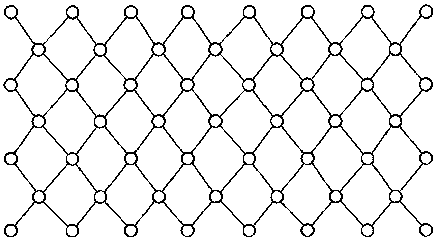

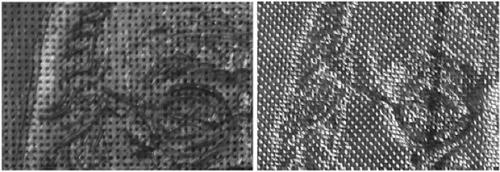

Production process and production system of digital art ceramic tile

PendingCN109203194ASimple production processSolve process problemsCeramic shaping plantsImaging qualityImage quality

The invention relates to a production process of a digital art ceramic tile. The production process comprises the following steps that S1, a ceramic tile blank body is subject to pressing formation; S2, a concave-convex surface is made on the surface of the ceramic tile blank body; S3, finishing treatment is carried out on the concave-convex surface on the surface of the ceramic tile blank body; S4, glaze spraying treatment is carried out on the ceramic tile blank body, and a pattern is performed on the concave-convex surface of the ceramic tile blank; and S5, the ceramic tile blank body is put into a kiln for firing. The production process of the digital art ceramic tile is simple and feasible, the image quality of the digital art ceramic tile can be guaranteed, the image has stereoscopicimpression and can customize the image to be personalized, the image does not fade after being fired, and the problems that a ceramic tile production process flow in the prior art is tedious, the production time consumption is long, the pattern is not clear, color fading is easy and the like are solved. The invention further relates to a production system of the digital art ceramic tile.

Owner:KEDA INDUSTRIAL GROUP CO LTD

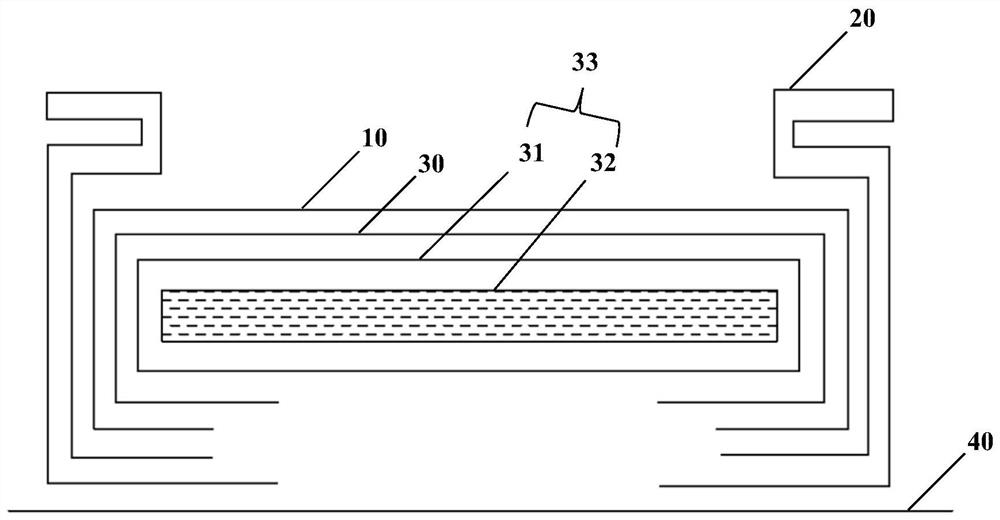

Composite fiber material and preparation method, device and application of material

PendingCN108784934AGuaranteed three-dimensional effectStereo effect conforms toAbsorbent padsBaby linensSurface layerFibrous composites

The invention belongs to the field of fiber products with special performance and composite materials, in particular to a composite fiber material and a preparation method, device and application of the material. The composite fiber material comprises a bottom layer and a surface layer, the bottom layer is glued to the surface layer through a gluing part, protruding points which protrude upwards are distributed on the surface layer and comprise arc protruding points, vertical protruding points and natural half protruding points, and the vertical protruding points are provided with one or moreneedle holes. According to the composite fiber material, the 5D stereoscopic effect is achieved, by improving the layer stereoscopic sense, the contact area is further reduced, the dry and comfortableperformance, air permeability and attractiveness are improved, the composite material is applied to diapers, sanitary napkins or other disposable absorption supplies, and the prepared absorption supplies are good in softness and good in air permeability.

Owner:南京锦琪昶新材料有限公司

Degradable UV gravure embossed sand-feeling ink for gold and silver cardboard

The invention relates to the technical field of ink, and in particular, relates to a degradable UV gravure embossed sand-feeling ink for a gold and silver cardboard material. The ink comprises the following components by the weight percentage: 15%-25% of epoxidized soybean oil acrylate, 10%-15% of acrylate, 15%-25% of 1,6-hexanediol diacrylate, 10%-20% of isobornyl acrylate, 2%-4% of a 184 photoinitiator, 3%-6% of a TPO photoinitiator, 8%-12% of an amine initiator, 3%-5% of sand finish powder, 5%-8% of wax powder, and 1%-3% of an auxiliary agent. The degradable UV gravure embossed sand-feeling ink for a gold and silver cardboard has no solvent and no toxic gas emissions when in use, is environmentally friendly, and has no pollution; the ink after curing has the advantages of strong pattern three-dimensional sense, good adhesion force and good fluidity, can meet the requirements of decorative inks, can be biodegraded after being discarded, meets new concepts of environmental protection, reduces environment pollution, and achieves the purpose of sustainable development.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

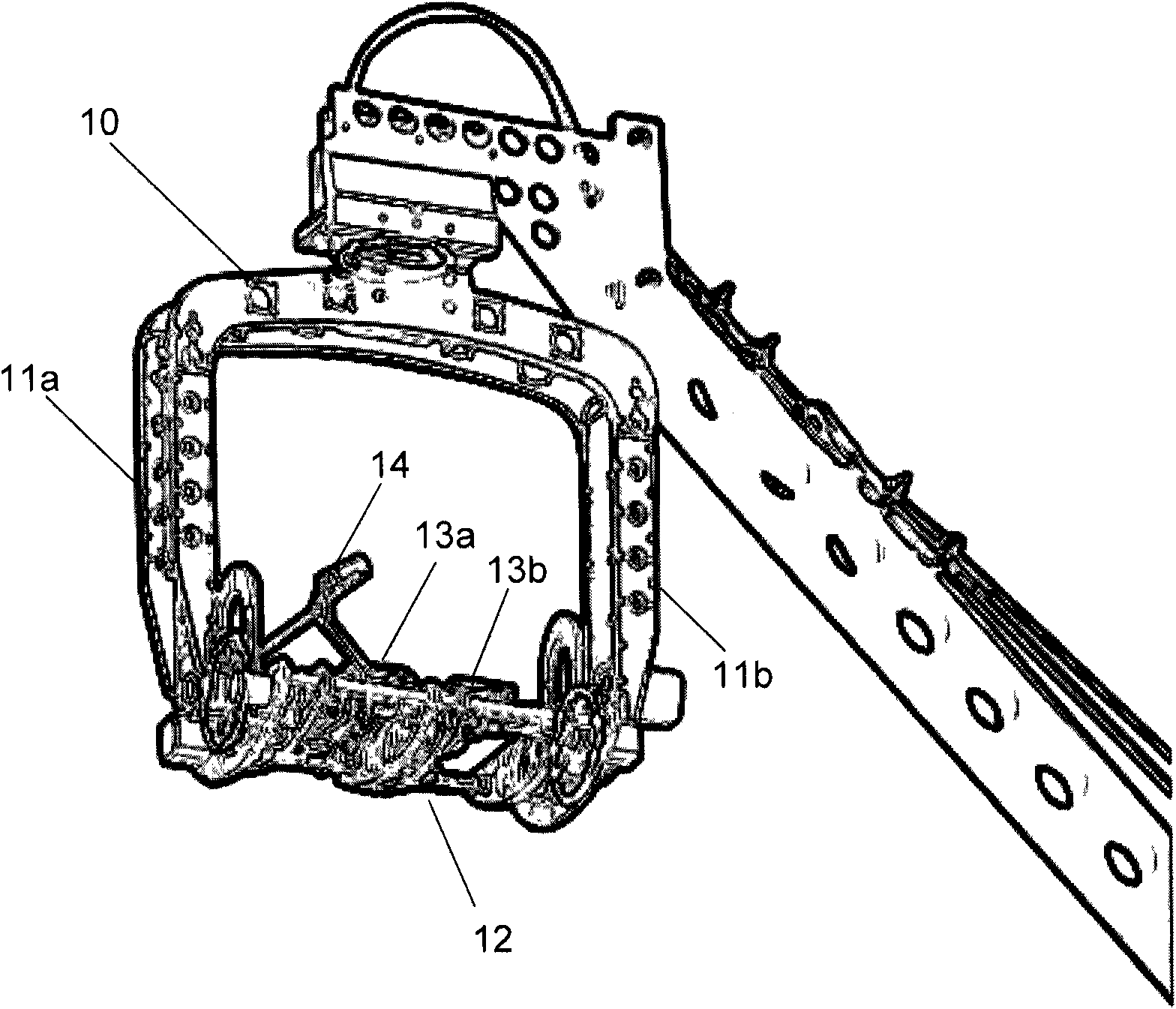

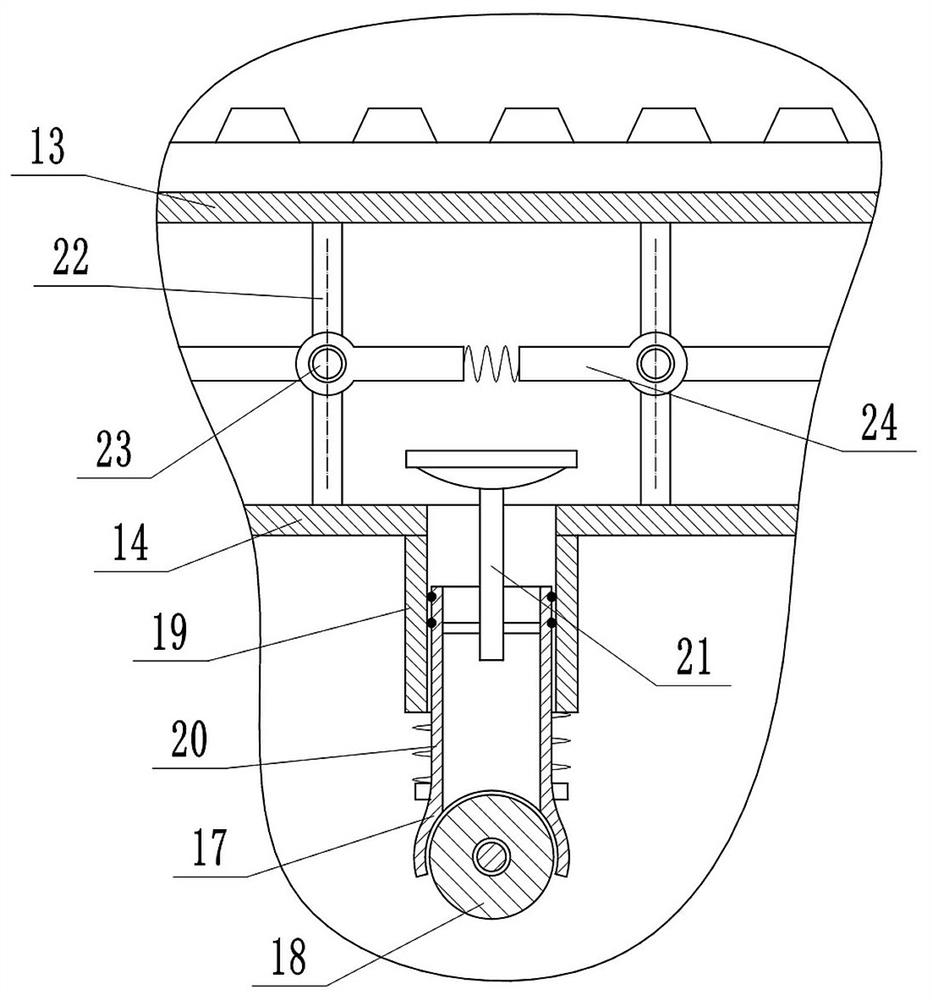

Base for achieving formation of furniture backrest pull buckle and pull buckle formation method

ActiveCN109393807AStrong three-dimensional senseGuaranteed three-dimensional effectSofasCouchesEngineering

Owner:廖晓阳

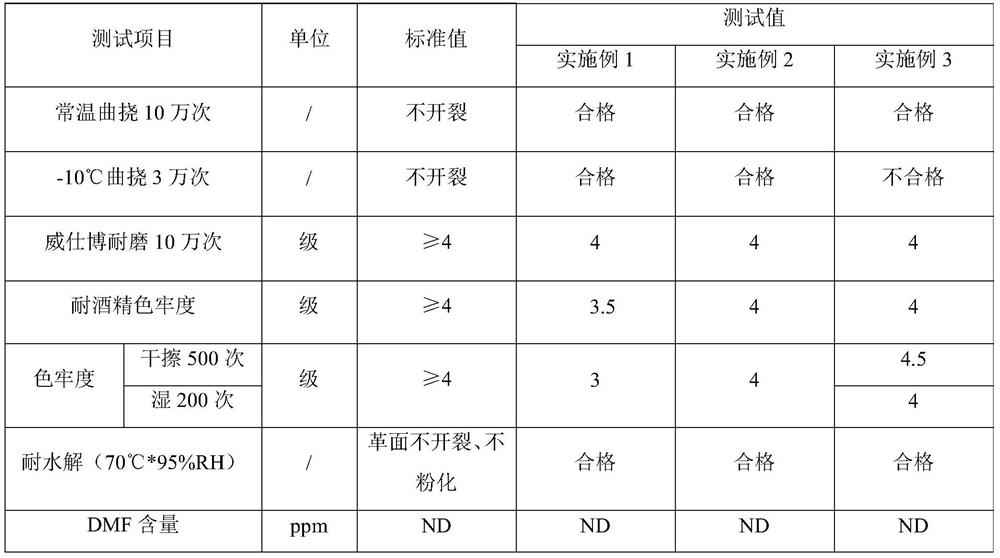

Preparation method of water-based low-temperature printed environment-friendly polyurethane synthetic leather

ActiveCN112593419AReduce pollutionReduce production energy consumptionTextile/flexible product manufactureFurniture partsTextile printerPolymer network

The invention discloses a preparation method of water-based low-temperature printed environment-friendly polyurethane synthetic leather. The preparation method comprises the following steps of coatingrelease paper with polyurethane surface layer slurry to obtain a surface layer composite film; coating the surface layer composite film with bonding layer slurry, and drying until the coating retainscertain adhesion; laminating the obtained coating with synthetic leather base cloth, drying and curing, and stripping the release paper to obtain semi-finished crust leather; and printing a waterborne polyurethane coating on the surface of the semi-finished crust leather, and drying and curing to obtain a finished product. A water-based closed low-temperature deblocking curing agent is adopted, ahigh-solid printing process is combined, and a cross-linked polymer network is formed on the surface of the synthetic leather, so that the durability of the product is improved, the stereoscopic impression of patterns of the product is strong, and the production process is low in energy consumption and low in pollution.

Owner:ANHUI ANLI MATERIAL TECH

Paper forming die, die manufacturing method and paper manufactured by forming die

PendingCN111231493AImprove reducibilityGuaranteed firmnessScreen printersMachine wet endMarking outProcess engineering

The invention discloses a paper forming die. The paper forming die comprises a roller; a plurality of penetrating micropores are arranged in the roller wall of the roller, and one or more pattern characters in common watermarks, white watermarks, safety line windowing zebra grids and paper marking marks are engraved on the roller wall of the roller. According to the paper forming die disclosed bythe invention, an original watermark design draft is highly reducible, and the consistency, the definition, the three-dimensional sense, the fineness and the richness of details of the watermark in the paper are improved, so that the anti-counterfeiting function of the watermark paper is enhanced; the service life of the paper forming die is prolonged; and the manufacturing automation level of thepaper forming die is improved, and the labor intensity of workers is greatly relieved.

Owner:CHENGDU BANKNOTE PRINTING +1

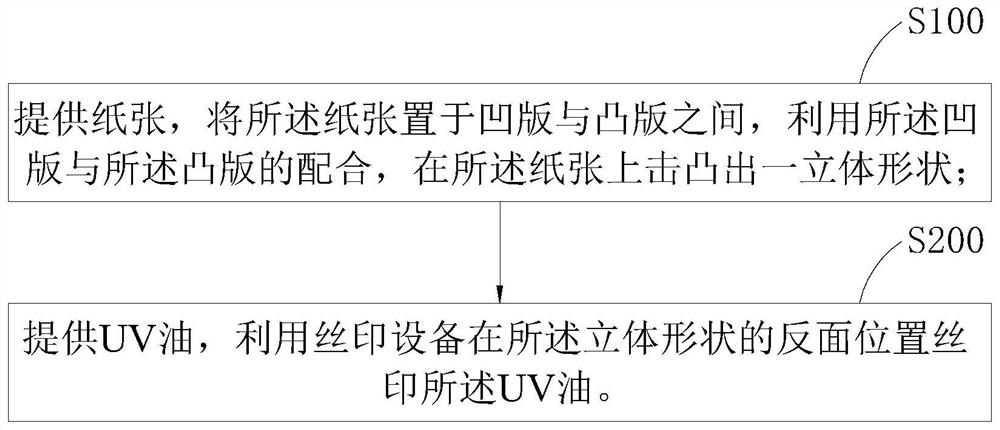

Thin paper embossing silk-screen printing process

InactiveCN112622465AGuaranteed three-dimensional effectOther printing apparatusScreen printingPolymer science

The invention belongs to the technical field of paper silk-screen printing, and particularly relates to a thin paper embossing silk-screen printing process. The process comprises the following steps that S100, paper is provided and placed between an intaglio plate and a relief plate, and a three-dimensional shape is embossed on the paper through cooperation of the intaglio plate and the relief plate; and S200, UV oil is provided and subjected to silk-screen printing on the reverse side of the three-dimensional shape through silk-screen printing equipment. The thin paper embossing silk-screen printing process is particularly suitable for the thin paper which is 200 g or below, during production, embossing is conducted on the paper through the intaglio plate and the relief plate, the three-dimensional shape is formed on the paper, and then silk-screen printing of the UV oil is conducted on the reverse side of the three-dimensional shape formed on the paper through the silk-screen printing equipment; in this way, the strength of the position of the three-dimensional shape is reinforced through the silk-screen UV oil, the three-dimensional shape can show the three-dimensional effect without other processes, meanwhile, the paper is not pressed to be deviated by a roller when passing through glue, and therefore the three-dimensional effect can be kept after the inclusion procedure is completed.

Owner:DONGGUAN MYS ENVIRONMENTAL PROTECTION TECH

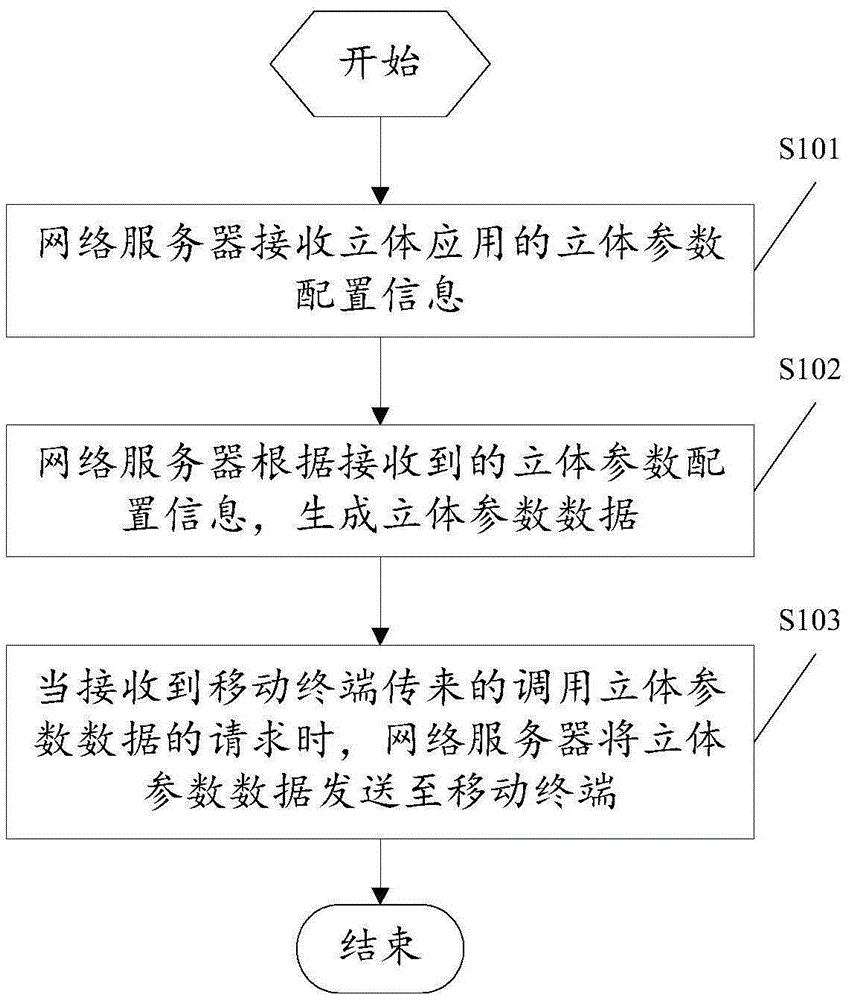

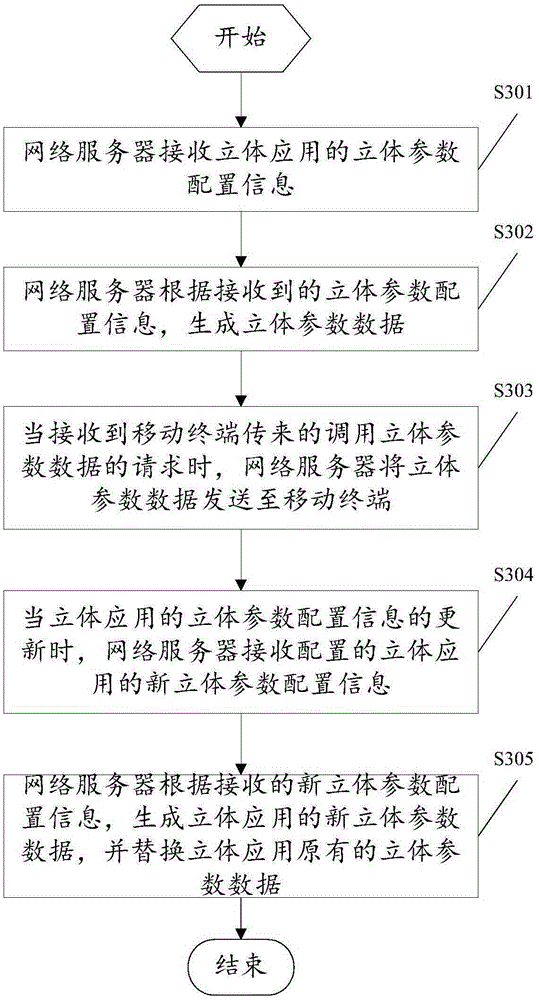

Three-dimensional application starting method, device and system applied to mobile terminal

InactiveCN106254409AImprove experienceGuaranteed three-dimensional effectSubstation equipmentProgram loading/initiatingNetwork serviceComputer engineering

The invention discloses a three-dimensional application starting method, device and system applied to a mobile terminal. The three-dimensional application starting method comprises the steps that the mobile terminal sends a request command of three-dimensional parameter data to a network server when receiving a starting command of a three-dimensional application; the mobile terminal receives three-dimensional parameter data sent by the network server; the mobile terminal starts the three-dimensional application in a three-dimensional manner according to the received three-dimensional parameter data. By applying the technical scheme disclosed by the invention, use requirements of the three-dimensional application can be met without improving the interactivity of the existing mobile terminal one the one hand, and a user of the mobile terminal does not need to debug three-dimensional parameters any more on the other hand, so that the user experience of using the three-dimensional application at the mobile terminal is improved.

Owner:SUPERD CO LTD

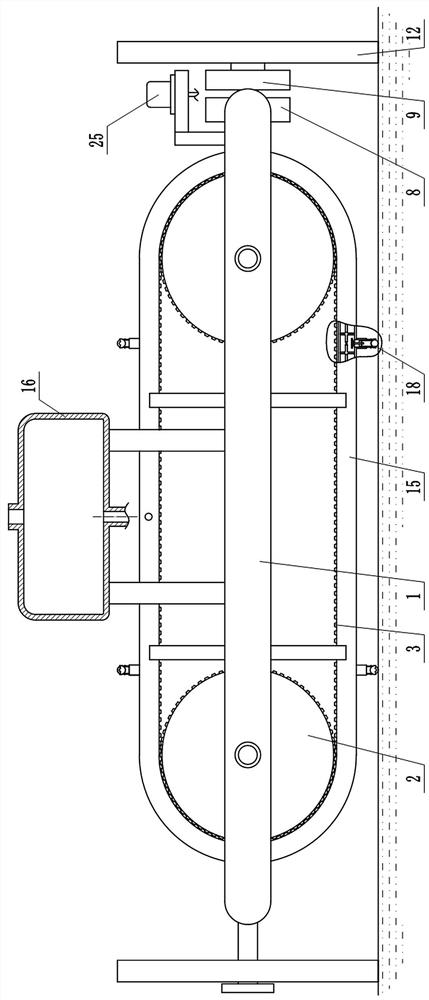

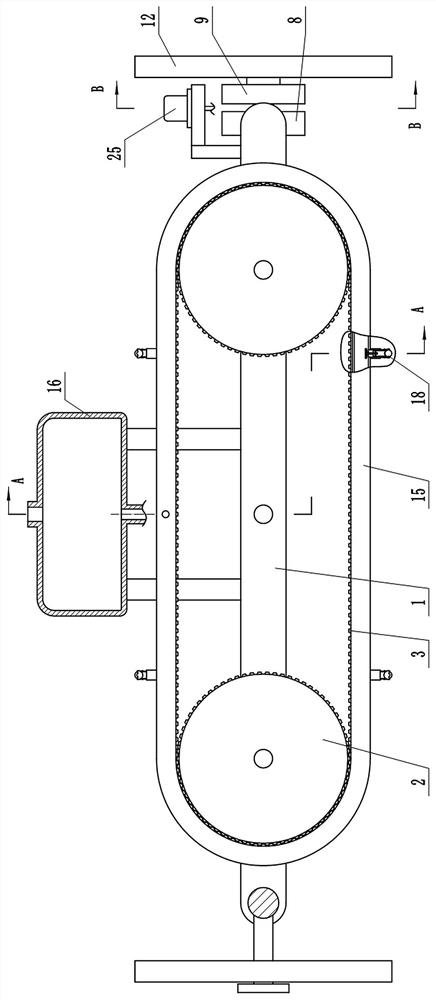

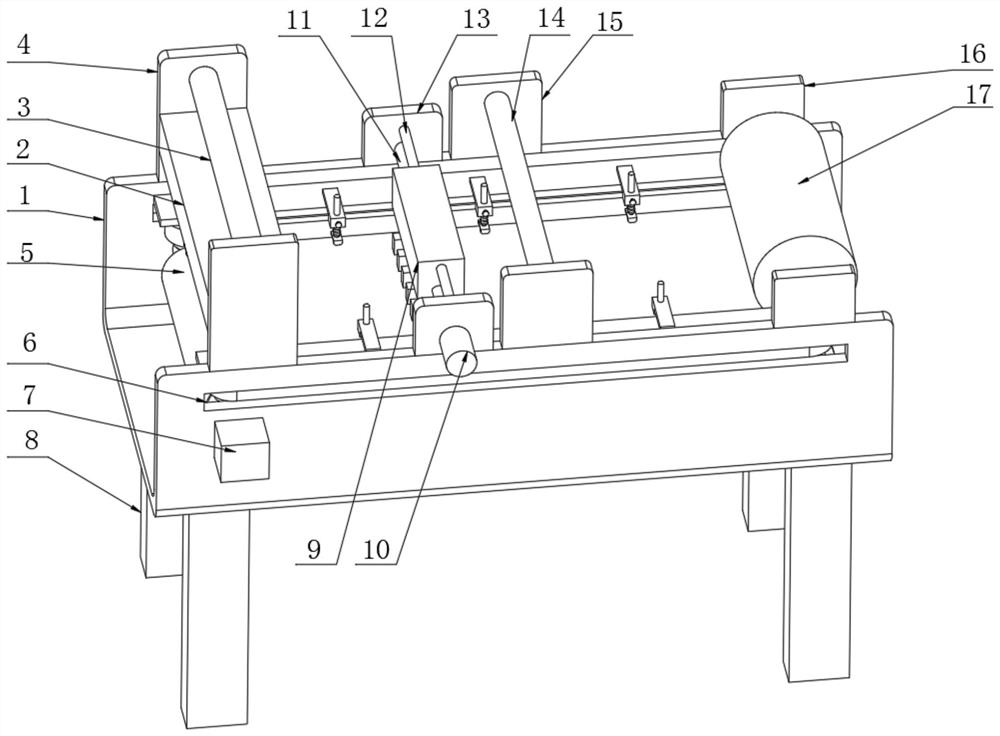

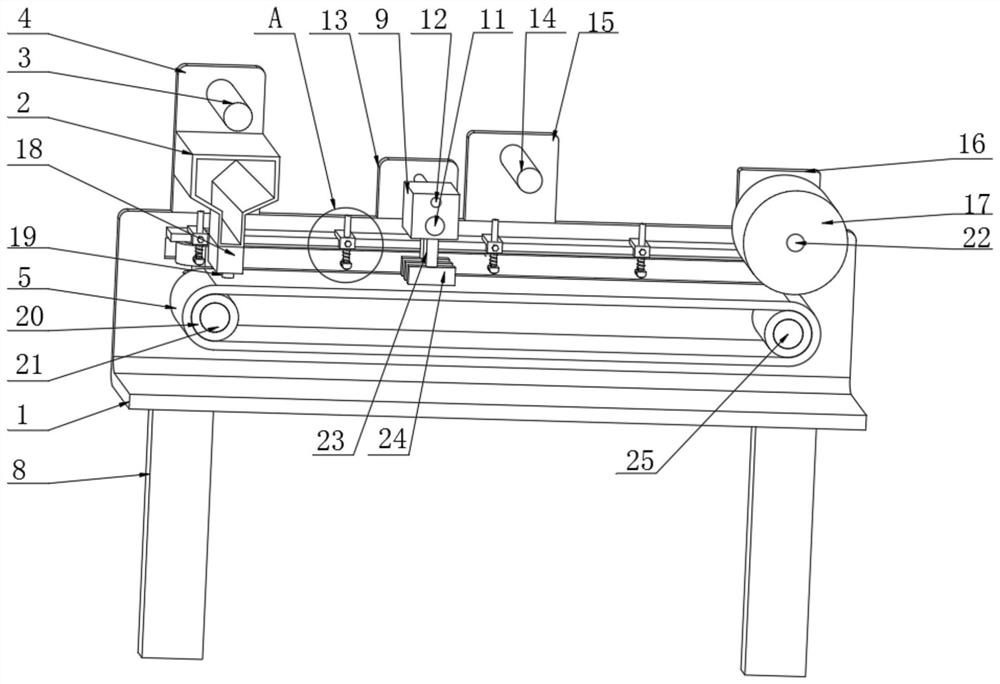

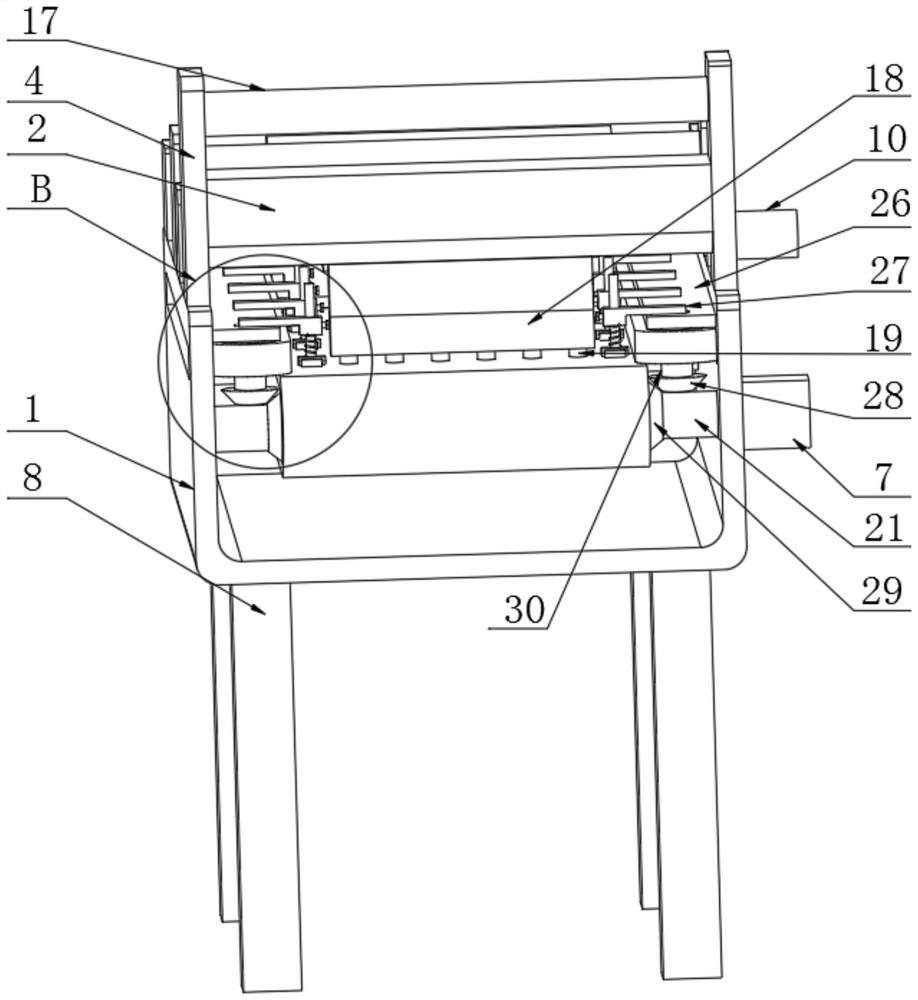

An interior decoration wiring harness outlining device

ActiveCN112746722BControl speedControl positive and negativeDecorative surface effectsPretreated surfacesGear wheelEngineering

The present invention provides a wiring harness outline device for interior decoration, which effectively solves the problem in the prior art that when decorating walls and floors, the distance between the drawn oblique lines is not uniform, which affects the viewing effect in the later stage; it solves the problem The technical solution is to include a frame, a pulley is arranged on the frame, a synchronous belt is arranged between two pulleys on the pulley, and a rolling brush is arranged on the synchronous belt; a planetary gear mechanism is arranged on the rear side of the frame, and a second gear mechanism is arranged on the left side of the sun gear. A bevel gear, a second bevel gear is arranged on the pulley on the right side, a cylinder is arranged at the right end of the ring gear, a first friction wheel is arranged at the right end of the cylinder, a second friction wheel is arranged on the right side of the first friction wheel, the first friction plate and the second friction wheel There is a small friction wheel between the two friction discs, and a wheel is connected to the right end of the second friction wheel; the invention has an ingenious structure, which can outline the standard oblique lines or grid lines required by users according to certain rules, and can follow the pre-designed route Outline, in the process of outlining, ensure that the distance between lines is evenly distributed, easy to operate, and strong in adaptability.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

Stable camera support for news transmission

InactiveCN114110324AGuaranteed three-dimensional effectGuaranteed flatnessStands/trestlesCamera body detailsControl theoryRetaining ring

The invention discloses a stable camera support for news transmission, which structurally comprises a fixed seat, an operation board, a camera, a support main body, a push rod and a chassis, the fixed seat is connected to the chassis and is connected with the push rod, the push rod and the operation board are arranged on the support main body, the camera is arranged in the support main body, and the camera is arranged in the support main body. A position adjusting device and a supporting handle are arranged on the power assisting body, the position adjusting device and the supporting handle are matched on the binding buckle, when the rubber surrounding pad is pushed and dragged by a push rod and a support hole, due to upward pushing of the push rod, a penetrating claw can be opened along the surface of a force application block through the supporting handle, and the supporting handle is supported on an inner limiting channel; and the retaining ring positioning driving position adjusting device is pressed on the surface of the colloid surrounding pad in an up-and-down reciprocating manner, so that the stereoscopic impression and flatness of the colloid surrounding pad on the surface of the camera are ensured.

Owner:LIAONING NORMAL UNIVERSITY

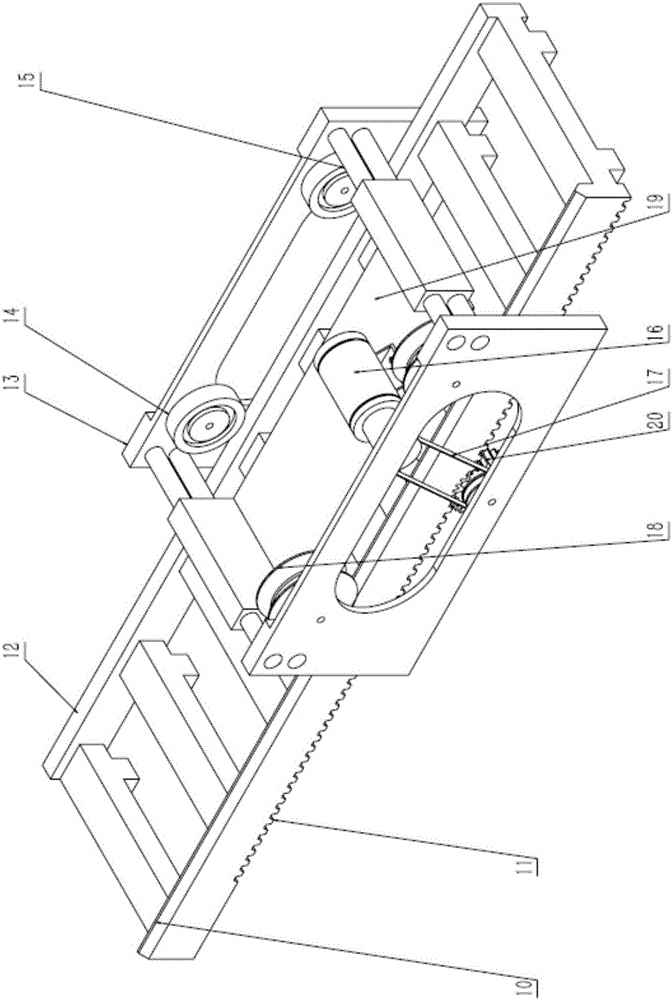

Processing technology and processing device for three-dimensional touch colorful leather pattern automobile interior trim panel

InactiveCN114475030AStereoscopic preservationGuaranteed three-dimensional effectPattern printingRotary pressesProcessing costIndustrial engineering

The invention discloses a processing technology and a processing device for a three-dimensional touch colorful leather pattern automobile interior trimming panel. According to the technical scheme, the processing technology comprises the following specific steps: S1, preparation before printing; s2, adjusting a printing machine; s3, performing trial printing; s4, batch printing; s5, film covering; s6, hot-pressing and compounding; 2, a conveying assembly and a deviation rectifying mechanism are arranged at the top of the U-shaped base (1), and a smearing mechanism is arranged at the top of the U-shaped base; the processing technology and the processing device for the three-dimensional touch colored dermatoglyph automotive trim panel have the beneficial effects that through the improved dermatoglyph plate technology, dermatoglyph is printed on an ABS plate, an anti-scraping transparent protective film is compounded, the film can also ensure that the printing stereoscopic impression is preserved for a long time, and the processing technology and the processing device have the advantages that the processing technology is simple and convenient, and the processing technology is suitable for popularization and application. And meanwhile, the normal leather pattern plate is compounded on the automotive trim panel in a hot-pressing manner, so that the stereoscopic impression of the leather patterns can be obviously kept, the stereoscopic impression of the leather patterns is always kept, the processing cost is low, the processing procedures are reduced, and the processing pollution is reduced.

Owner:扬州市邗江扬子汽车内饰件有限公司

Dyeing and finishing process of cotton fabric

PendingCN112095357AGuaranteed three-dimensional effectEasy to useSingeingDyeing processTextile printerPolymer science

The invention discloses a dyeing and finishing process of a cotton fabric. The process comprises the following steps of A, putting an original cotton blank on a singeing machine for singeing treatment; B, padding the singed cotton blank in bleaching liquid for 3-5 hours at room temperature, then steaming a padded cotton fabric, and finally washing the steamed cotton fabric with water; C, putting the cotton fabric obtained in the step B into a caustic soda solution to be soaked for 3-7 min; D, preparing coating printing size, and performing coating printing on the cotton fabric obtained in thestep C by using the coating printing size; and E, baking the cotton fabric obtained in the step D. The use of coating printing has the advantages of simplicity in use and convenience in process, the printed fabric has the advantages of high light fastness and clear contour lines, and the stereoscopic impression of patterns with dark-color bottom and light-color florets can be guaranteed.

Owner:江苏派逊服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com