Production process and production system of digital art ceramic tile

A technology of digital art and production technology, which is applied in the field of digital art tile production technology and production system, can solve the problems of limited pattern layer effect and contrast range, high price, complicated production process, etc., and solve the problem of complicated production process and production process Simple and easy to implement, the effect of ensuring image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

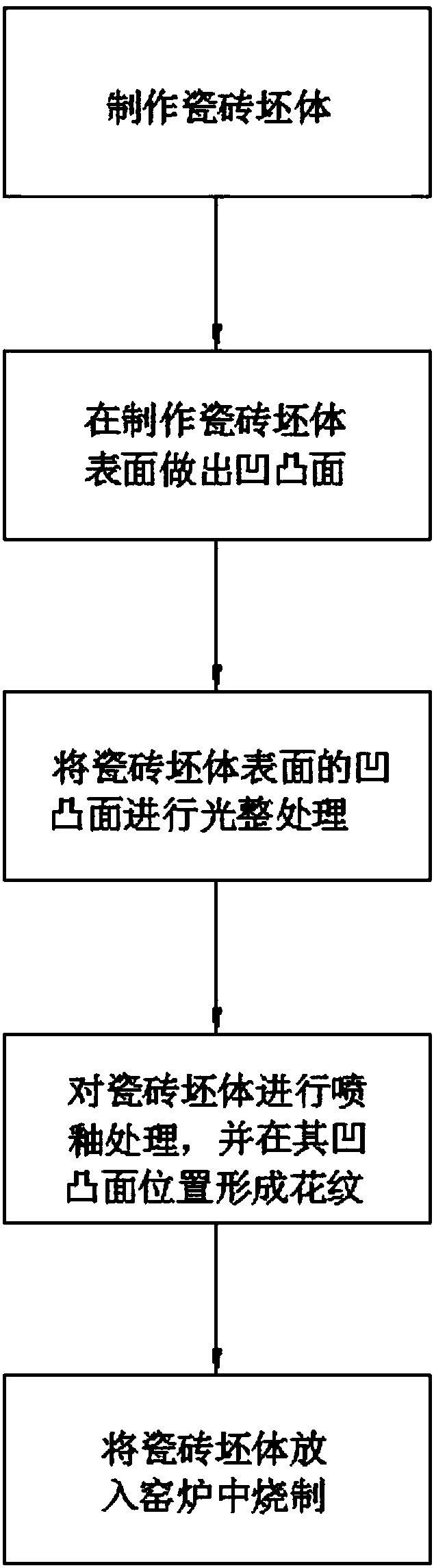

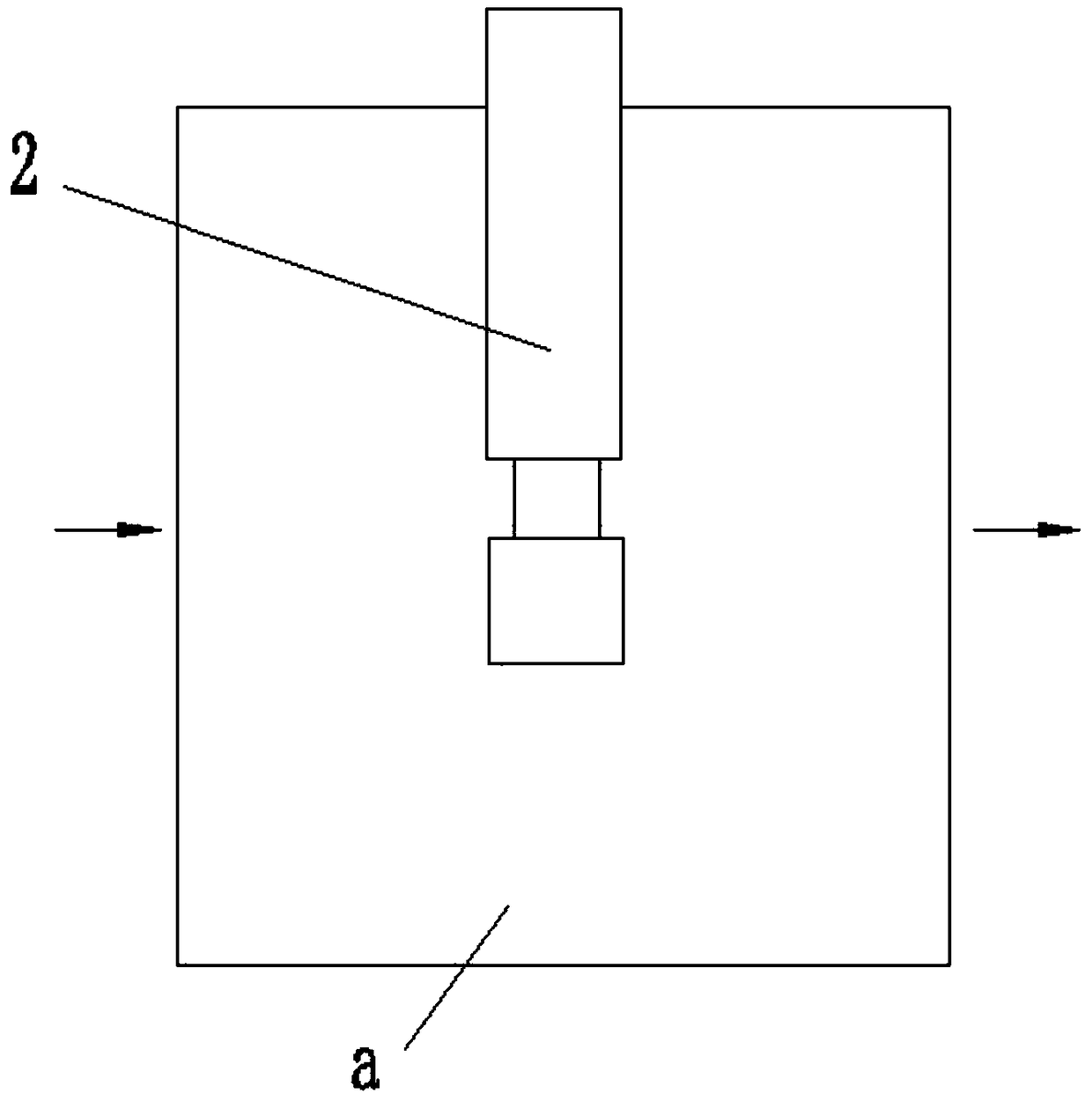

[0037] see figure 1 and image 3 , the digital art tile production process of the present embodiment, comprises the following steps:

[0038] S1. The ceramic tile body a is pressed and formed;

[0039] S2. Make a concave-convex surface on the surface of the ceramic tile body a;

[0040] In this embodiment, part of the material on the surface of the tile body a is removed by material reduction, so as to make a concave-convex surface on the surface of the tile body a;

[0041] S3. Finishing the concave-convex surface on the surface of the ceramic tile body a;

[0042] The finishing treatment in this embodiment is polishing;

[0043] S4. Perform glaze spraying treatment on the ceramic tile body a, and form patterns on its concave-convex surface;

[0044] The step S4 of this embodiment specifically includes the following steps:

[0045] a. The ceramic tile body a is sprayed with glaze to fill the pores of the tile body a to form a bottom layer on the surface of the tile body...

Embodiment 2

[0059] see figure 1 and image 3 , the digital art tile production process of the present embodiment, comprises the following steps:

[0060] S1. The ceramic tile body a is pressed and formed;

[0061] S2. Make a concave-convex surface on the surface of the ceramic tile body a;

[0062] In this embodiment, a concave-convex surface is made on the surface of the ceramic tile body a by means of material addition;

[0063] S3. Finishing the concave-convex surface on the surface of the ceramic tile body a;

[0064] The finishing treatment in this embodiment is polishing;

[0065] S4. Perform glaze spraying treatment on the ceramic tile body a, and form patterns on its concave-convex surface;

[0066] The step S4 of this embodiment specifically includes the following steps:

[0067] a. The ceramic tile body a is sprayed with glaze to fill the pores of the tile body a to form a bottom layer on the surface of the tile body a;

[0068] b. Carry out online inkjet printing and col...

Embodiment 3

[0081] see figure 1 and image 3 , the digital art tile production process of the present embodiment, comprises the following steps:

[0082] S1. The ceramic tile body a is pressed and formed;

[0083] S2. Make a concave-convex surface on the surface of the ceramic tile body a;

[0084] In this embodiment, part of the material on the surface of the tile body a is removed by material reduction, so as to make a concave-convex surface on the surface of the tile body a;

[0085] S3. Finishing the concave-convex surface on the surface of the ceramic tile body a;

[0086] The finishing treatment in this embodiment is polishing;

[0087] S4. Perform glaze spraying treatment on the ceramic tile body a, and form patterns on its concave-convex surface;

[0088] The step S4 of this embodiment is specifically: spray the infiltrating glaze on the tile body a, and the glaze ink penetrates into the tile body a to form a three-dimensional pattern pattern;

[0089] S5. Put the ceramic ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com