Preparation method of water-based low-temperature printed environment-friendly polyurethane synthetic leather

A polyurethane and synthetic leather technology, used in textiles, papermaking, clothing, footwear, etc., can solve the problems of poor durability, material cannot be stored for a long time, and high cost of material loss, and achieves increased durability and good durability. , the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

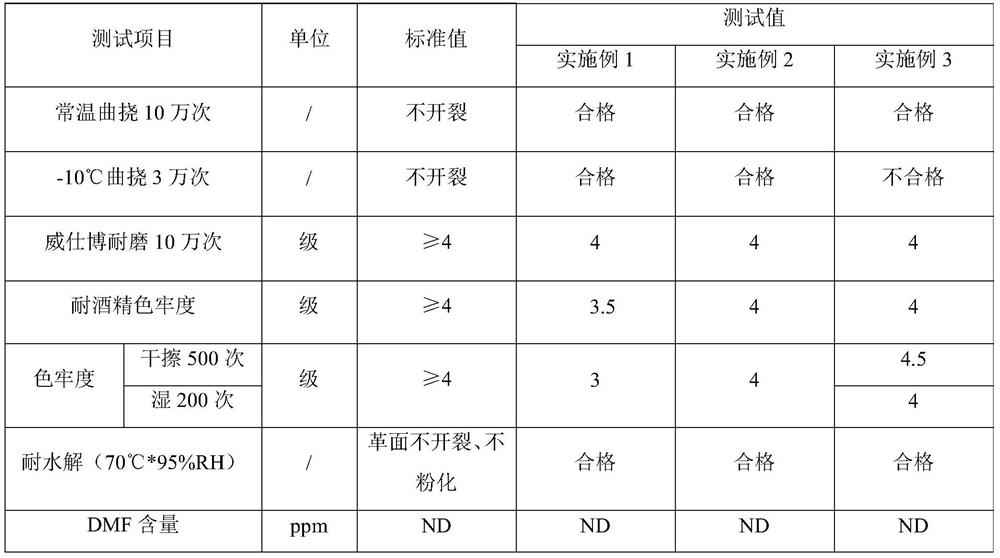

Examples

Embodiment 1

[0026] 1. Coat polyurethane YF-0304A surface layer slurry on the release paper with a coating thickness of 0.15mm and dry at 115°C for 1.5min to obtain a surface layer composite film; the components of the polyurethane slurry are composed in parts by mass As follows, YF-0304A: 100, anti-yellowing additive AL-UV: 0.5, 6080B: 1, dark blue paste SL-500: 8.

[0027] 2. Evenly coat the adhesive layer slurry on the surface layer composite film, the coating thickness is 0.25mm, and dry at 90°C for 2 minutes, and the coating retains a certain degree of adhesion; the polyurethane slurry components are in parts by mass The number composition is as follows: polyol BasfA material 100, isocyanate AL-5040B material 50, organic gold tin catalyst AL-5508 0.5, amine catalyst AL-2958: 0.1.

[0028] 3. After laminating the cloth base material on the adhesive layer, dry it at 145° C. for 4 minutes, peel off the release paper after drying and aging, and obtain a semi-finished leather crust.

[00...

Embodiment 2

[0031] 1. Coat polyurethane YF-0304A surface layer slurry on the release paper with a coating thickness of 0.15mm and dry at 115°C for 1.5min to obtain a surface layer composite film; the components of the polyurethane slurry are composed in parts by mass As follows: YF-0304A: 100, AL-UV: 0.5, 6080B: 1, dark blue paste SL-500: 8.

[0032] 2. Evenly coat the adhesive layer slurry on the surface layer composite film, the coating thickness is 0.25mm, and dry at 90°C for 1min, and the coating retains a certain degree of adhesion; the polyurethane slurry components are in parts by mass The number composition is as follows: polyol BasfA material 100, isocyanate AL-5040B material 50, organotin AL-5508 catalyst 0.5, amine catalyst AL-29580.1.

[0033] 3. After laminating the cloth base material on the adhesive layer, dry it at 130° C. for 6 minutes, peel off the release paper after drying and aging, and obtain a semi-finished leather crust.

[0034] 4. Print polyurethane slurry on th...

Embodiment 3

[0036] 1. Coat the polyurethane surface layer slurry on the release paper, the coating thickness is 0.15mm, and dry at 115°C for 1.5min to obtain the surface layer composite film; the components of the polyurethane slurry are composed as follows in parts by mass: YF -0304A: 100, AL-UV: 0.5, 6080B: 1, dark blue paste SL-500: 5.

[0037] 2. Evenly coat the adhesive layer slurry on the surface layer composite film, the coating thickness is 0.25mm, and dry at 90°C for 2 minutes, and the coating retains a certain degree of adhesion; the polyurethane slurry components are in parts by mass The number composition is as follows: polyol BasfA material 100, isocyanate AL-5040B material 50, organotin catalyst AL-5508:0.5, amine catalyst AL-2958:0.1.

[0038] 3. After laminating the cloth base material on the adhesive layer, dry it at 145° C. for 4 minutes, peel off the release paper after drying and aging, and obtain a semi-finished leather crust.

[0039] 4. Print polyurethane slurry on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com