Composite fiber material and preparation method, device and application of material

A composite fiber, unwinding device technology, applied in application, medical science, clothing and other directions, can solve the problems of poor three-dimensional retention of single-layer fiber products, affecting permeability and aesthetics, affecting air permeability and dryness, etc., to increase the level of three-dimensional feeling, improving breathability, and improving dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

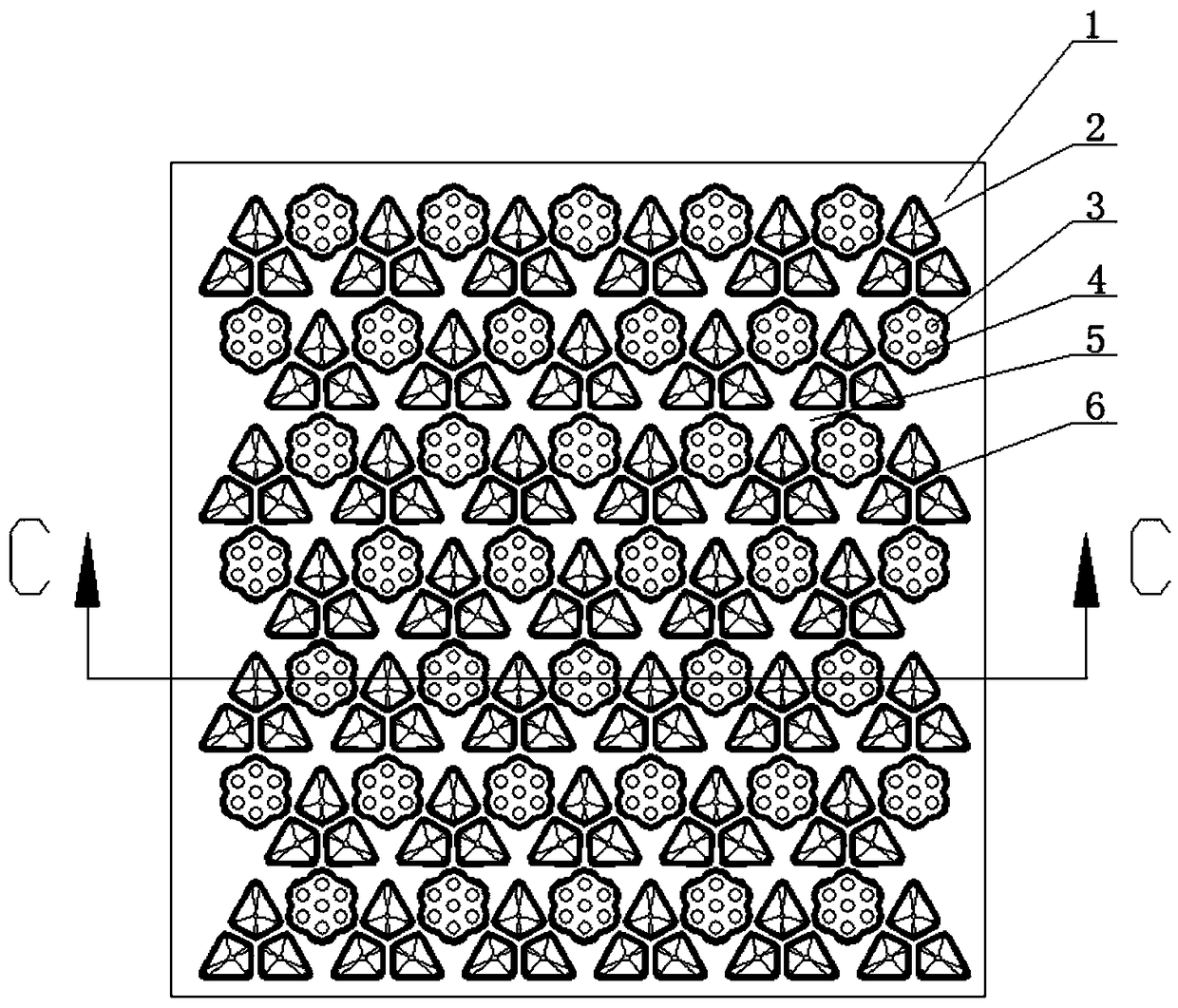

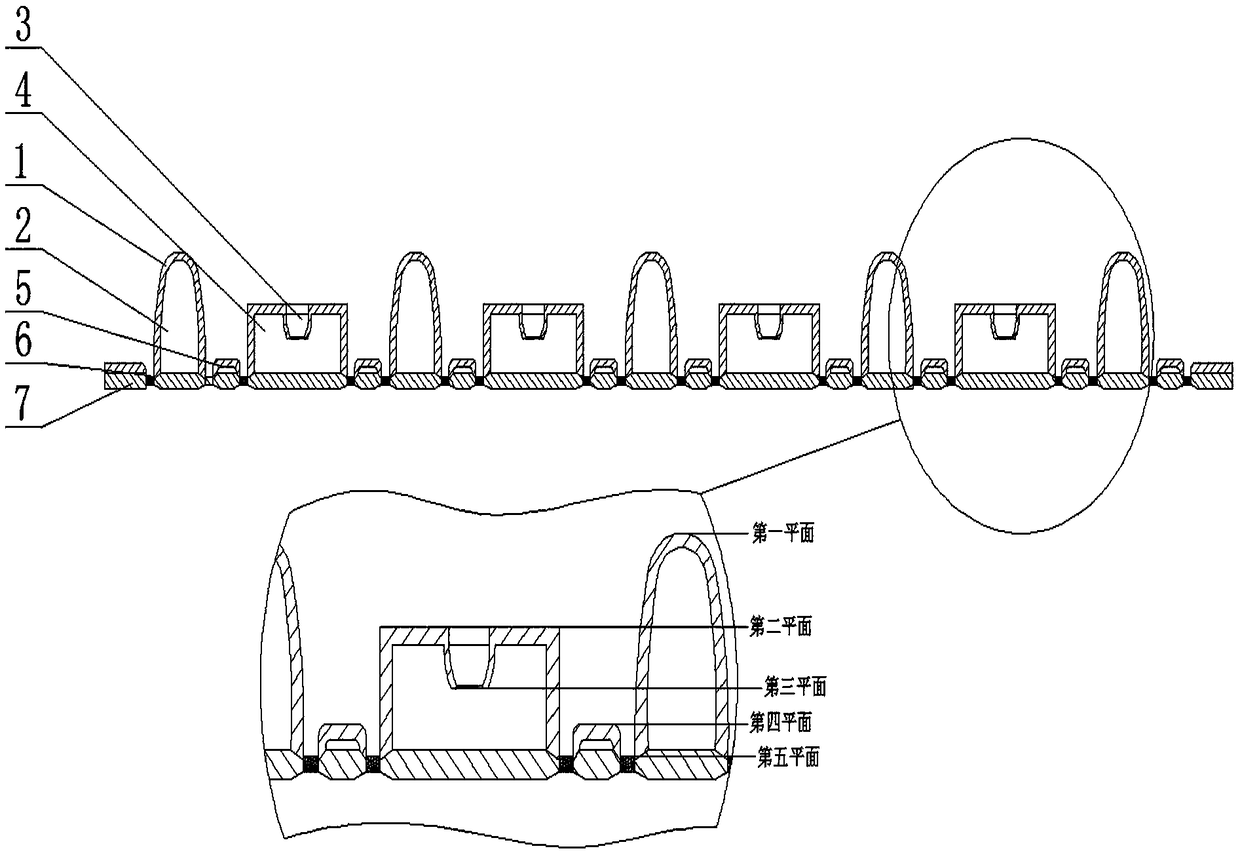

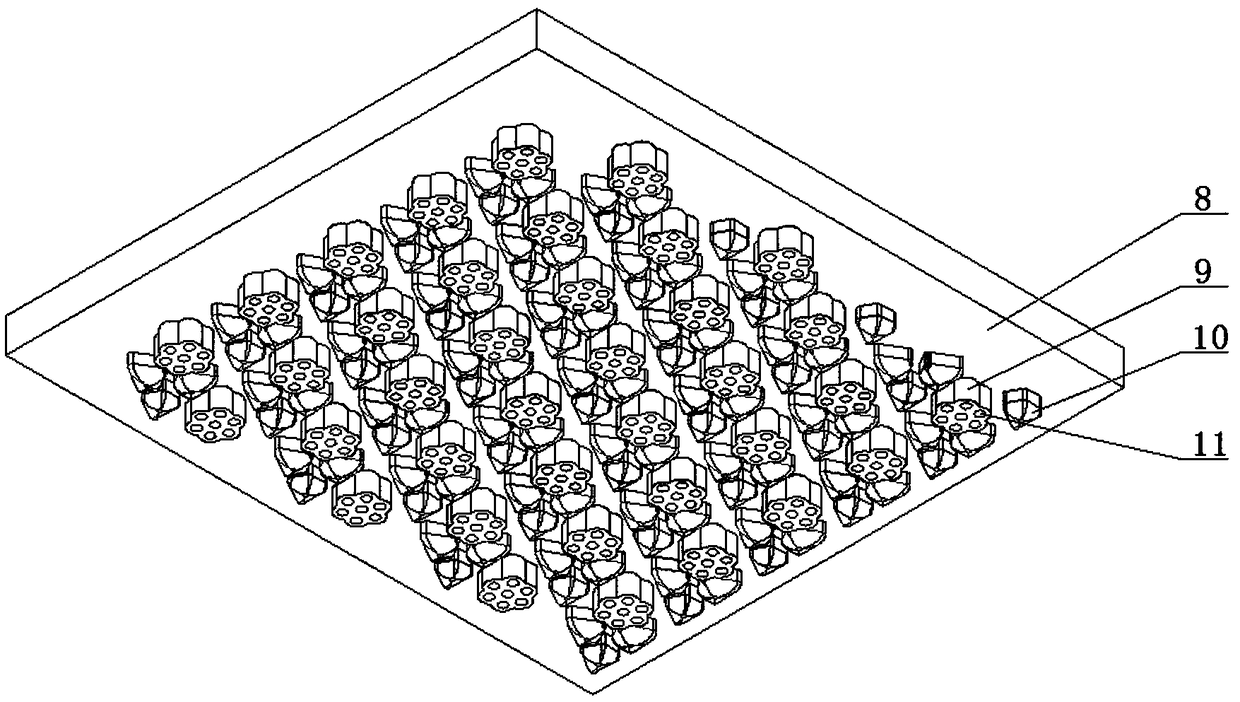

[0042] A composite fiber material such as figure 1 Shown: including the bottom layer 7 and the surface layer 1, the bottom layer 7 and the surface layer 1 are bonded by the bonding part 6, and upwardly protruding bumps are distributed on the surface layer 1, and the bumps include arc-shaped bumps 2, Vertical bumps 4 and natural semi-bumps 5, the vertical bumps 4 are provided with one or more pinholes 3, such as figure 2 As shown: the first plane is formed between the arc-shaped bumps 2, the second plane is formed between the vertical bumps 4, the third plane is formed between the bottom layers of the pinholes 3, and the natural semi-bumps A fourth plane is formed between 5, and a fifth plane is formed between the adhesive parts 6, and the heights of the first plane, the second plane, the third plane, the fourth plane and the fifth plane are different.

[0043] The pinhole 3 is in the shape of an inverted cone or a cylinder.

[0044] The heights of the first plane, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com