Three-dimensional embroidery and making method thereof

A production method, three-dimensional embroidery technology, applied to embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc., can solve problems such as weak three-dimensional effects and difficulty in reaching, and achieve poor embroidery quality, poor expressiveness, and simple implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

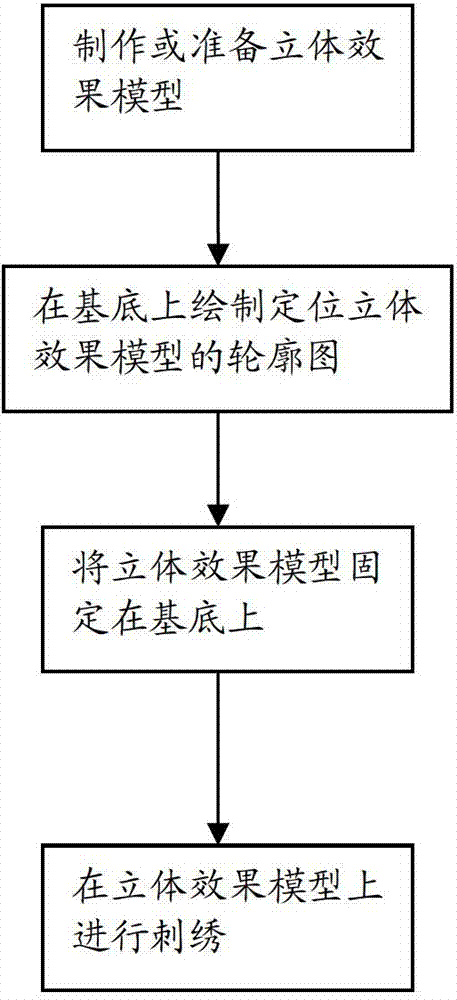

[0029] The three-dimensional embroidery production method described in this embodiment includes two steps:

[0030] Step 1: Prepare or make a three-dimensional three-dimensional effect model according to the embroidery pattern and the three-dimensional effect to be presented;

[0031] Step 2: Embroidery on the diorama.

[0032] Existing embroidery is carried out on flat textiles. The performance of the three-dimensional effect of embroidery is expressed through the light and shade expression techniques of the color of the embroidery thread at different levels and embroidery stitches. This method of expressing the three-dimensional effect is not only complicated 1. The labor intensity of the embroidery process is high, and the quality of the embroidery has a lot to do with the embroiderer's personal skills, so the quality is unstable. The most important thing is that the three-dimensional effect of the performance is very limited.

[0033] However, in this embodiment, before e...

Embodiment 2

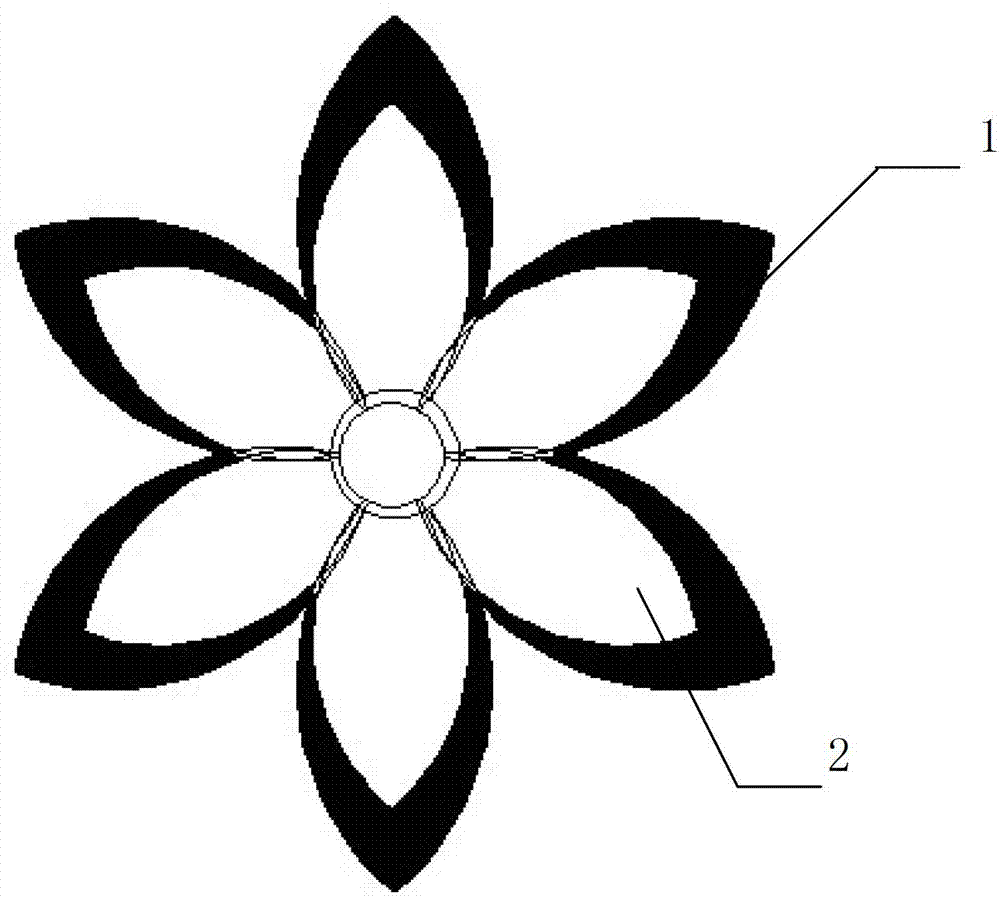

[0035] Based on the first embodiment, this embodiment also includes fixing the three-dimensional effect model on the base. The base may be textiles such as cloth and silk. The step of fixing the three-dimensional effect model on the base can be located before step 2 or after step 2. Fix a single three-dimensional embroidery on the base for composition to form a complete three-dimensional embroidery picture.

Embodiment 3

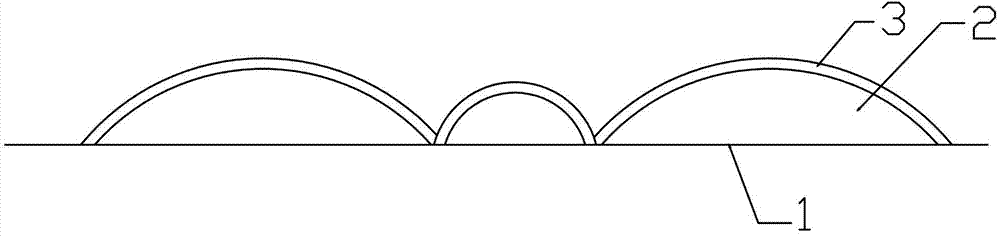

[0037] like figure 1 As shown, this embodiment, on the basis of the second embodiment, further includes drawing a contour map on the substrate that matches the outer contour of the desired fixed stereoscopic effect model before the stereoscopic effect model is fixed on the base. When it is necessary to express a complex picture composed of multiple independent three-dimensional embroidery on the base, the positioning and layout of each three-dimensional embroidery directly affect the aesthetics and quality of the embroidery picture. However, this embodiment avoids the above-mentioned problems simply and quickly by drawing the outline of the three-dimensional effect model on the base.

[0038] In addition, as a further improvement of this embodiment, the method of drawing the outline of the three-dimensional effect model in this embodiment is flat screen printing. It adopts the mature technology of flat screen printing, which is fast, easy and accurate in positioning.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com