Decorative part with 3D visual effect and manufacturing method thereof

A technology of visual effect and manufacturing method, applied in the field of decorative parts and decorative parts with 3D visual effect, can solve the problems of rough surface, easy to dirty, difficult to clean, low surface hardness, etc. Dot-shaped or column-shaped grating protrusions to ensure the effect of stereoscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

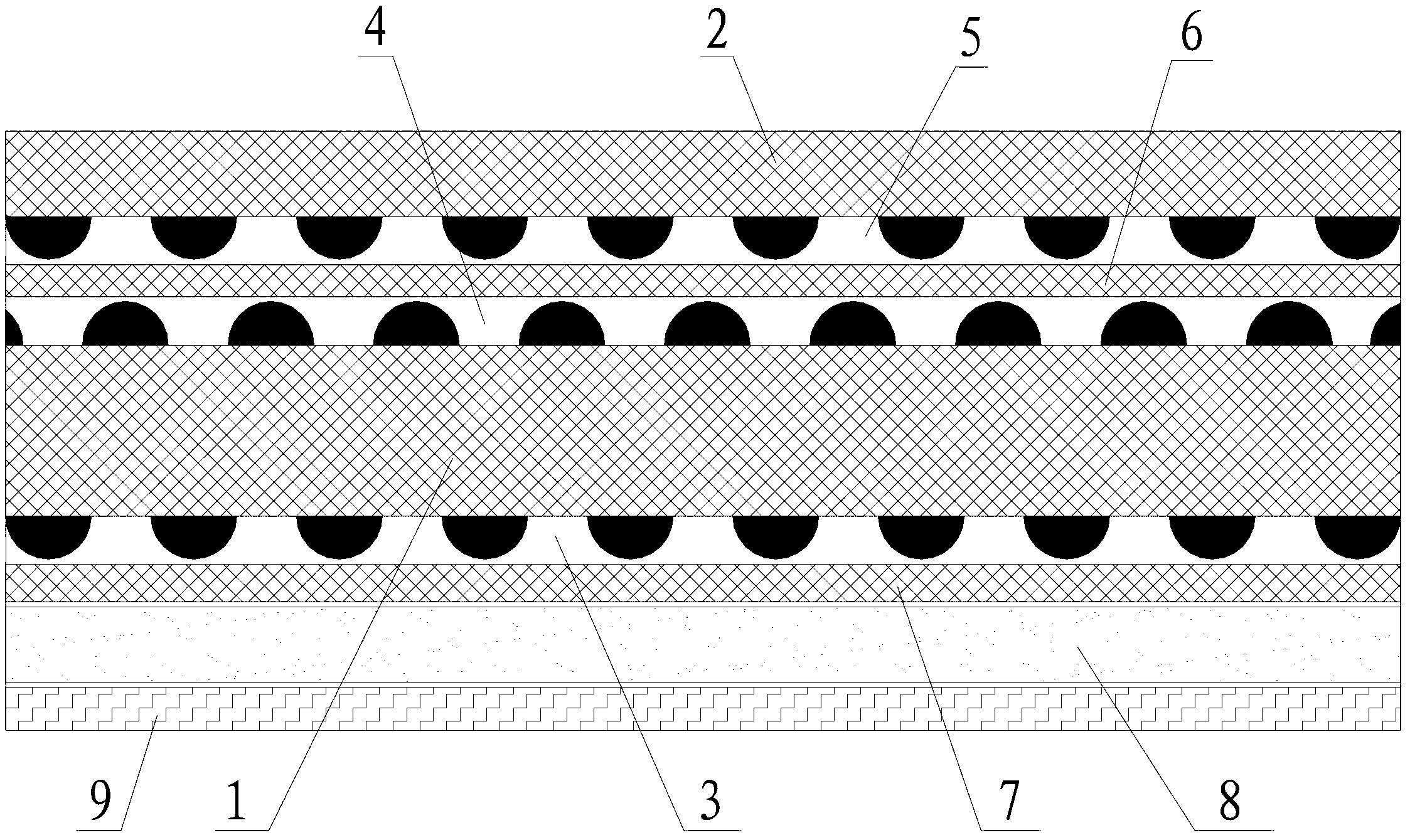

[0024] like figure 1 Shown is a decorative part with a 3D visual effect provided by the present invention, which provides a good three-dimensional visual effect, smooth and smooth outer surface, and is easy to clean, and a manufacturing method for the decorative part. A decorative piece with 3D visual effects, comprising a transparent substrate 1 and a transparent cover sheet 2; a graphic background layer 3 is printed on the lower surface of the transparent substrate 1, and a transparent refraction layer is printed on the upper surface Bump 4; transparent refraction dots 5 are printed on the lower surface of the transparent cover 2; the transparent substrate 1 and the transparent cover 2 pass through the upper surface of the transparent substrate and the lower side of the transparent cover The transparent glue 6 between the surfaces is bonded as a whole. A manufacturing method for producing said trim comprising the steps of,

[0025] 1) Make a transparent substrate 1, print ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com