Water-based acrylic anti-corrosion coating and preparing method thereof

A water-based acrylic and anti-corrosion coating technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of slow drying speed, poor corrosion resistance, poor adhesion, etc., to achieve good salt spray resistance, convenient construction, and reduce air bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

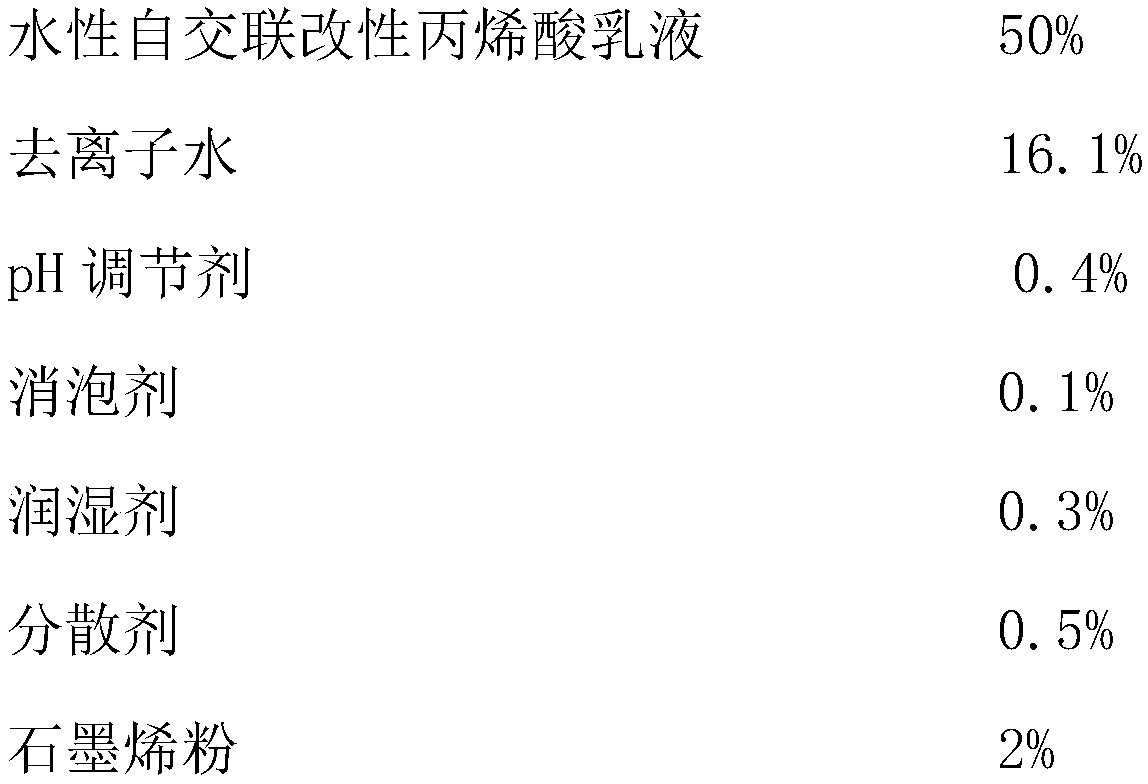

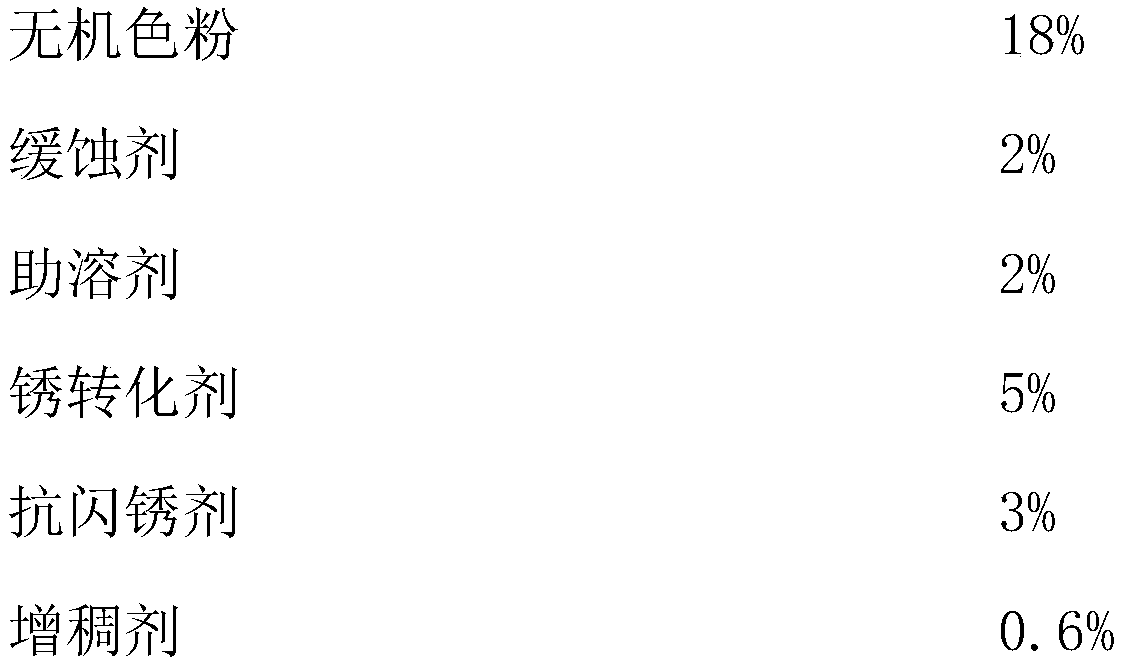

[0028] A kind of waterborne acrylic anticorrosion paint, comprises the component of following mass percentage:

[0029]

[0030]

[0031] Among them, the aqueous self-crosslinking modified acrylic emulsion is a mixture of XK-87 and XK-82, and the volume ratio is 2:1; the pH regulator is a mixture of dimethylethanolamine and ammonia water, and the volume ratio is 1:1; The defoamer is Tego Airex 902; the wetting agent is Tego Twin 4100; the dispersant is Tego Dispres 750W; the cosolvent is a mixture of dipropylene glycol methyl ether and alcohol ester-12, the volume ratio is 3:4; the rust conversion agent is Ferrocyanic acid; the anti-flash rust agent is zinc molybdate; the thickener is a mixture of PUR40, RM-8W, and OMG-0625, and the volume ratio is 1:1:1.

[0032] The preparation method of the waterborne acrylic acid anticorrosion coating in embodiment 1, comprises the steps:

[0033] a. Add water-based acrylic emulsion, deionized water, pH regulator, corrosion inhibito...

Embodiment 2

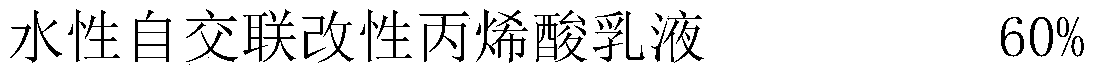

[0039] A kind of waterborne acrylic anticorrosion paint, comprises the component of following mass percentage:

[0040]

[0041]

[0042]The water-based self-crosslinking modified acrylic emulsion is a mixture of XK-87 and XK-82, the volume ratio is 1:1; the pH regulator is ammonia water; the defoamer is a mixture of Byk-024 and Byk028, the volume The ratio is 1:2; the wetting agent is a mixture of TegoTwin 4000, Tego Twin 4100, and Tego Wet 245, the volume ratio is 1:1:1; the dispersant is TegoDispres755W; the cosolvent is both dipropylene glycol methyl ether and alcohol ester-12 The mixture, the volume ratio is 3:4; the rust conversion agent is tannic acid; the anti-flash rust agent is zinc molybdate; the thickener is the mixture of PUR40, RM-8W, OMG-0625, PUR62, PUR65, the volume ratio is 1 :1:1:1:1.

[0043] The preparation method of the water-based acrylic anti-corrosion coating in Example 2 is the same as that in Example 1, and the viscosity of the prepared water-...

Embodiment 3

[0045] A kind of waterborne acrylic anticorrosion paint, comprises the component of following mass percentage:

[0046]

[0047]

[0048] Among them, the water-based self-crosslinking modified acrylic emulsion is A640; the pH regulator is a mixture of 2-amino-2-methyl-1-propanol, dimethylethanolamine, and ammonia water, and the volume ratio is 1; 2:1; defoamer It is a mixture of TegoAirex 901, TegoAirex 902, Byk-024 and Byk028, the volume ratio is 1:1:1:1; the wetting agent is Tego Wet 245; the dispersant is Tego Tego’s TegoDispres 750W, TegoDispres 735W mixture, The volume ratio is 2:1; the cosolvent is a mixture of dipropylene glycol methyl ether and alcohol ester-12, and the volume ratio is 3:4; the rust converting agent is a mixture of ferrocyanic acid and tannic acid, and the volume ratio is 1:1; the anti-flash rust agent is zinc molybdate; the thickener is a mixture of RM-8W, OMG-0625, and PUR62, and the volume ratio is 1:1:1.

[0049] The preparation method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com