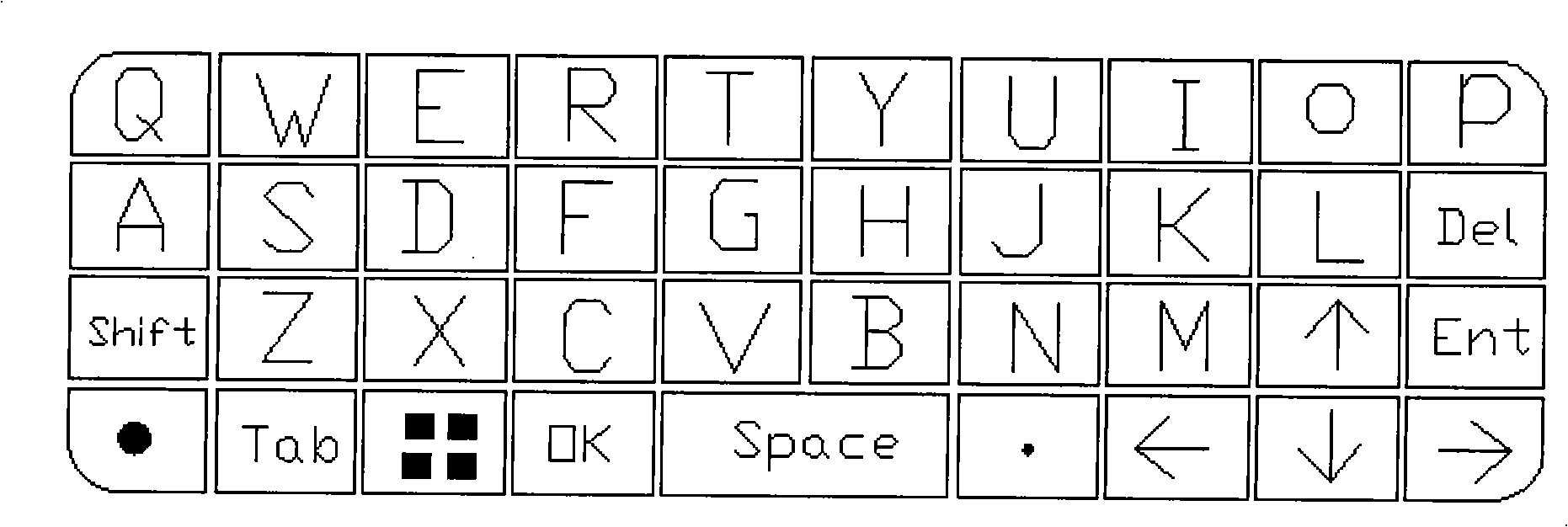

Ultra-thin QWERTY full keyboard and manufacturing method thereof

A manufacturing method and full keyboard technology, applied to electrical components, electric switches, circuits, etc., can solve problems such as weak rigidity and poor hand feeling, and achieve high production efficiency, good hand feel, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the technical means and effects of the present invention to achieve the intended purpose, the ultra-thin full QWERTY keyboard proposed by the present invention and its manufacturing method will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] figure 1 It is a schematic plan view of the ultra-thin full QWERTY keyboard of the present invention.

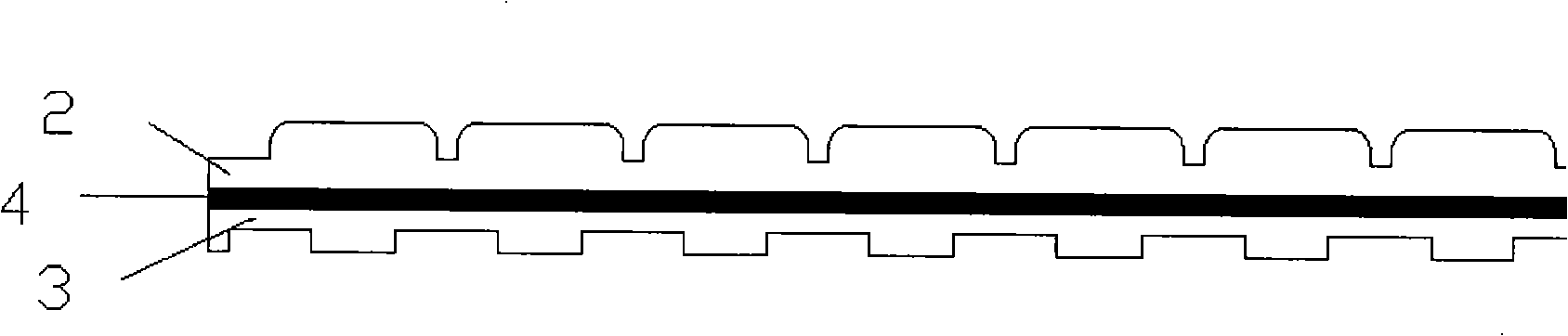

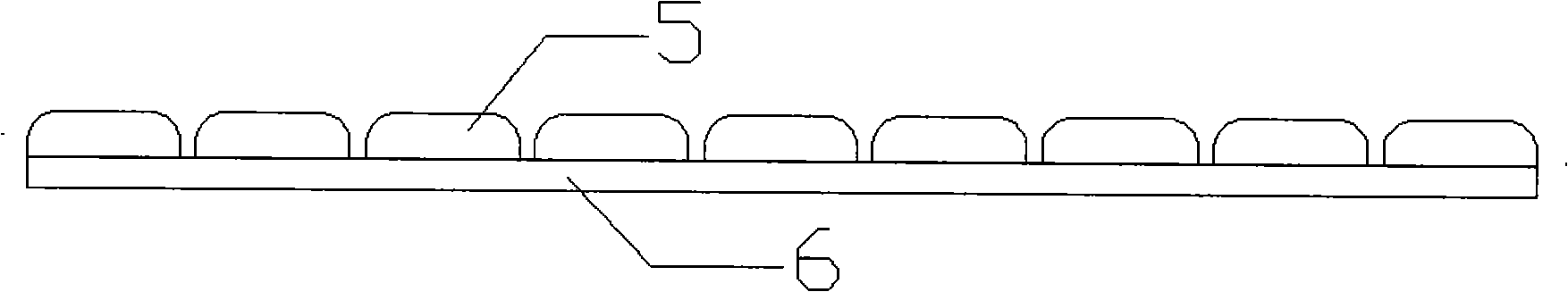

[0034] The first embodiment of the present invention is the manufacturing method of described ultra-thin full QWERTY keyboard, comprising the following steps:

[0035] Step 1, manufacturing the UV keycap layer 2 . Under the condition of ultraviolet light, the UV curable adhesive is cured and molded on the first plastic plate 6 through a hot pressing process, thereby forming the entire UV keycap layer 2, which is used to realize various functional keys, specifically including the following processes:

[0036] a. On the first plastic plate 6, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com