Two-sided lathe bed miller

A bed, double-sided technology, applied in the field of double-sided bed milling machines, can solve problems such as affecting processing efficiency, reducing transmission rigidity, reducing cutting rigidity and strength, etc., to improve processing efficiency, large three-way travel, and good rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

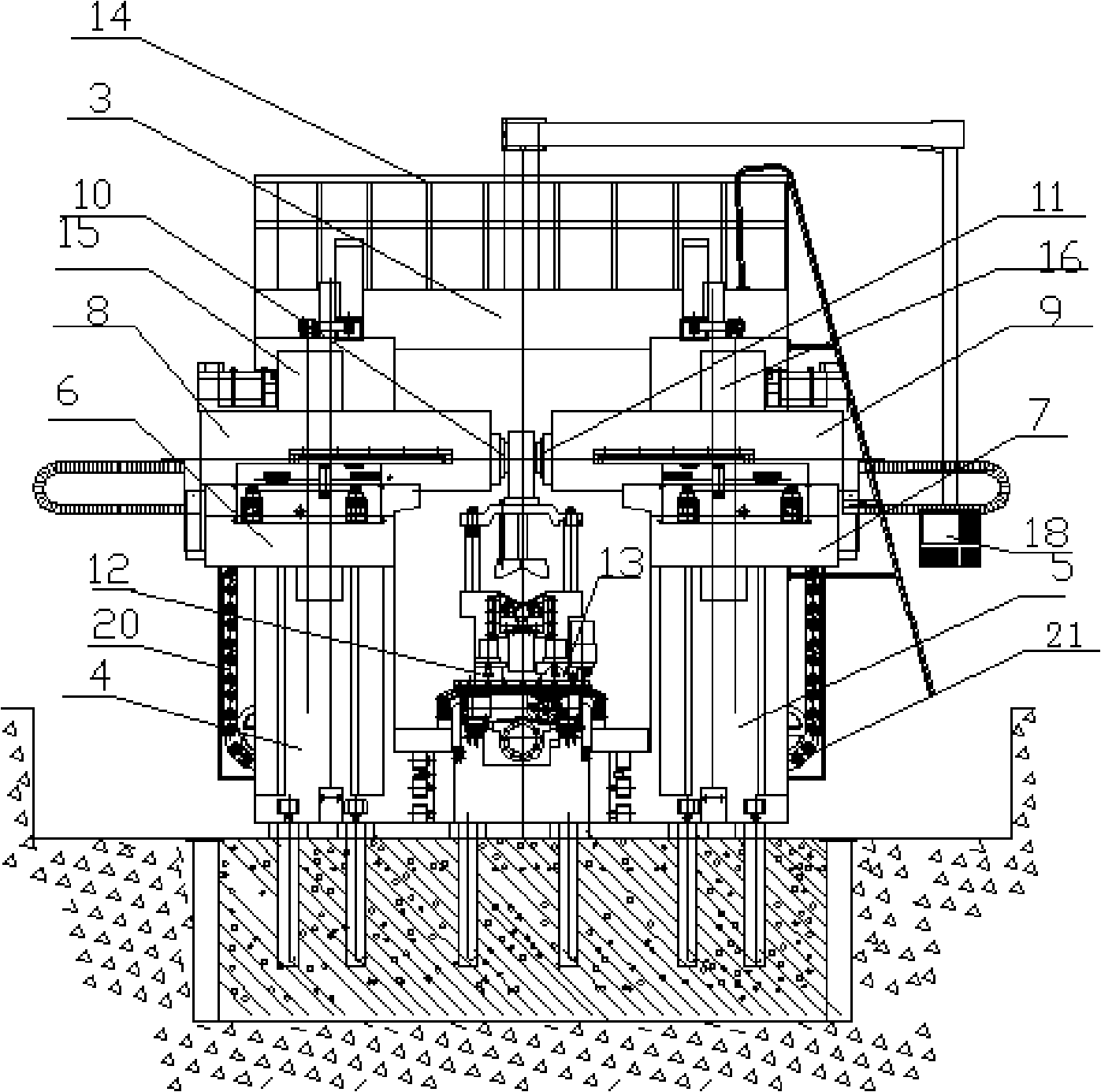

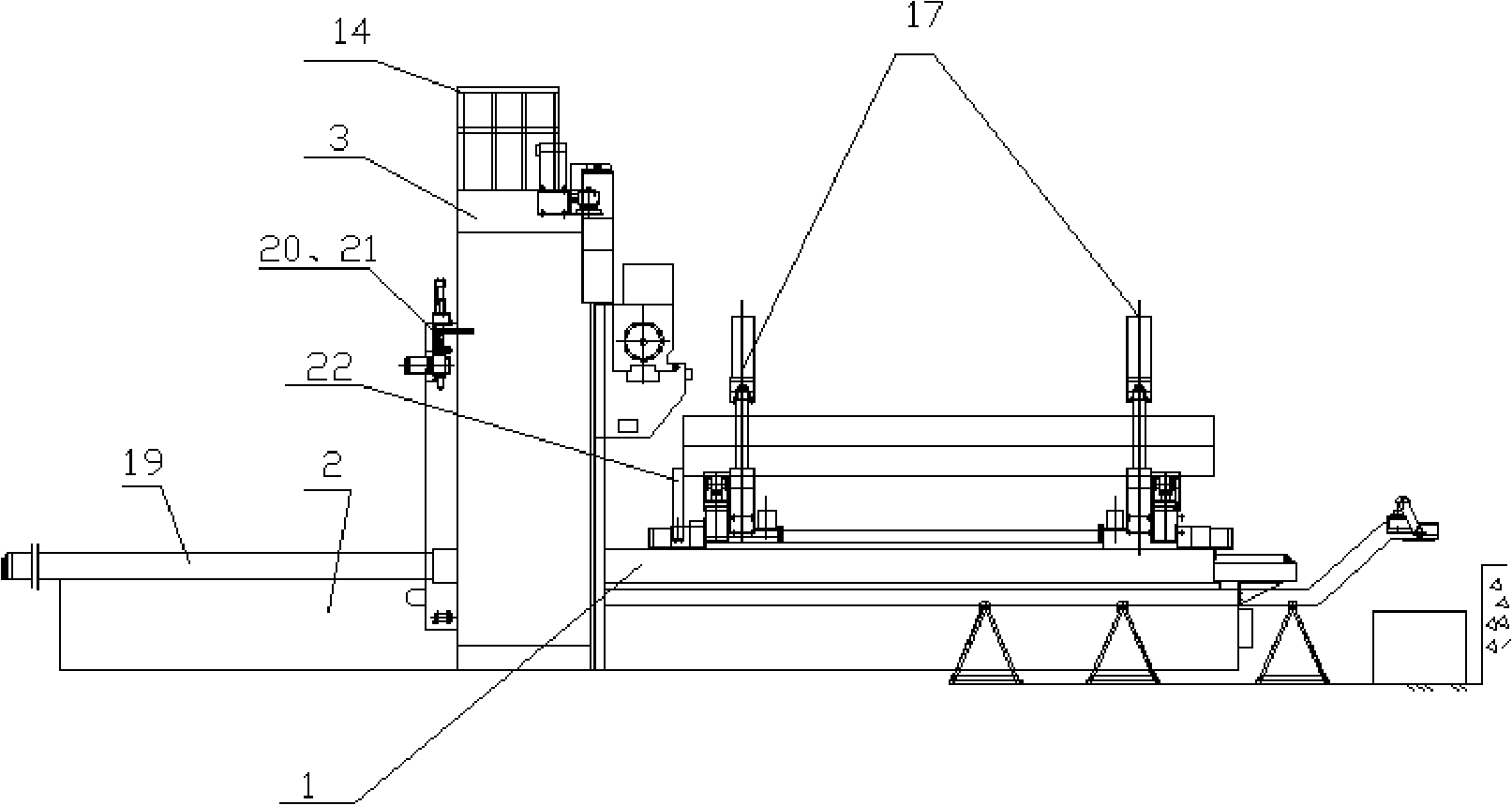

[0018] The double-sided bed milling machine of the present invention includes a bed 2, a workbench 1 that moves left and right along the guide rail along the guide rail on the bed 2, and two sets of milling units arranged on both sides of the bed 2, such as figure 1 , figure 2 shown.

[0019] exist figure 1 Among them, each milling unit includes column, slider, ram and horizontal spindle. According to the orientation, the left milling unit includes left column 4, left slider 6, left ram 8 and left horizontal spindle 10, and the right milling unit The unit includes a right column 5, a right sliding seat 7, a right ram 9 and a right horizontal main shaft 11. The left column 4 and the right column 5 are vertically fixed, and the tops of the two are connected with a beam 3 to form a high-rigidity gantry frame, and a guardrail 14 is arranged on the beam 3 . exist figure 2 Among them, the right sides of the left column 4 and the right column 5 are provided with parallel vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com