Gantry vertical type numerical control single-head milling machine machining center

A milling machine processing, gantry technology, applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the continuous finishing of large and medium-sized parts cannot be applied, and achieve rapid continuous processing, good rigidity, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

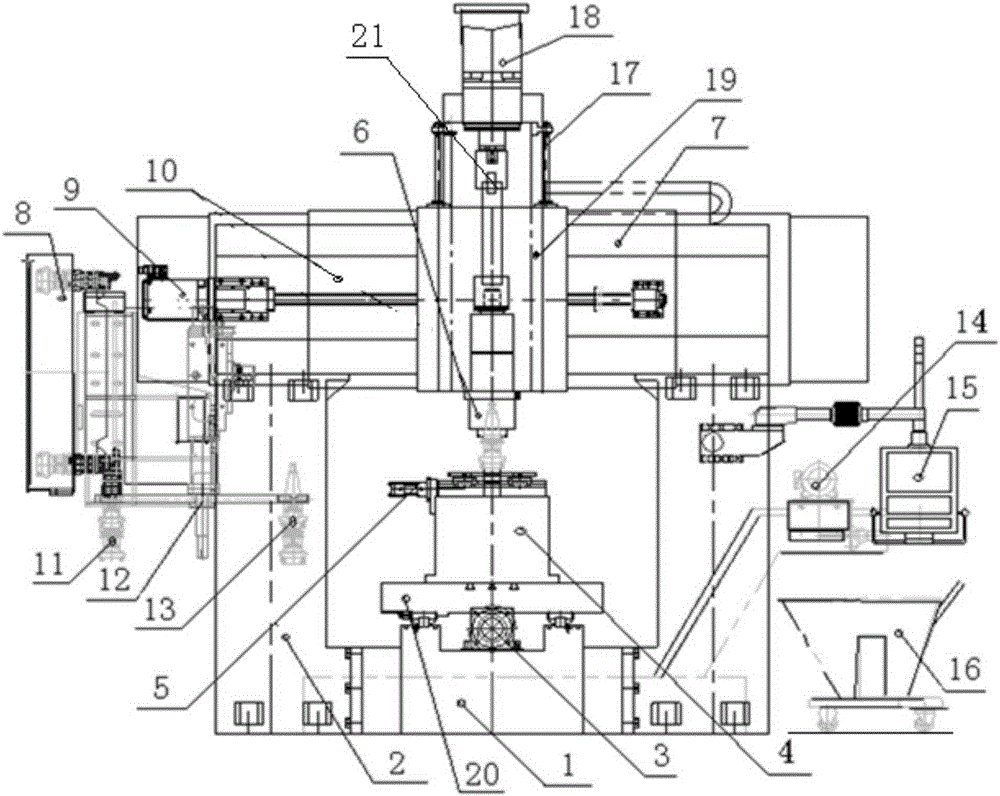

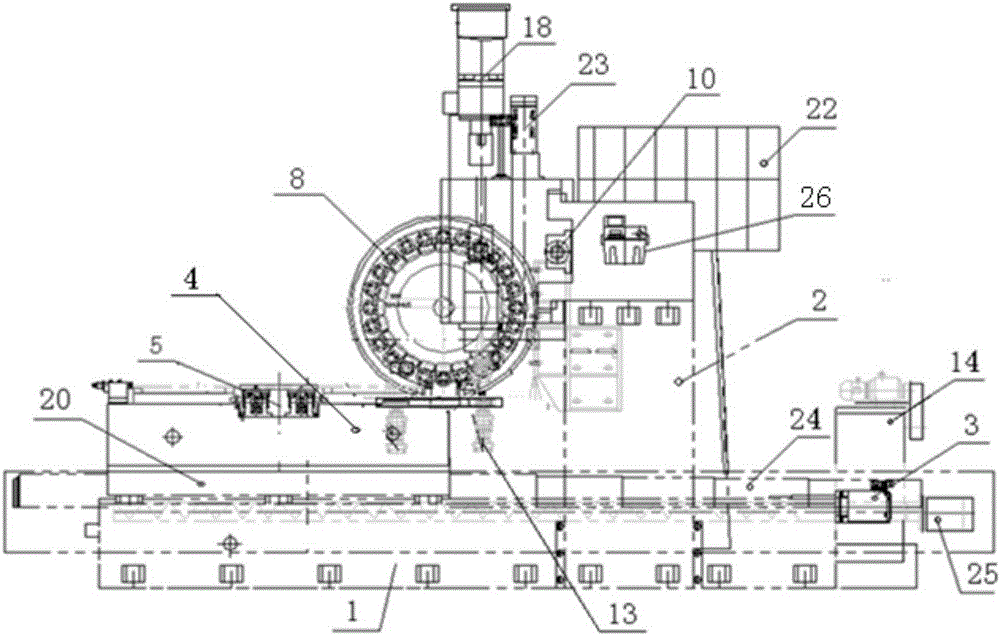

[0028] see figure 1 , figure 2 , image 3 As shown, the gantry vertical CNC single-head milling machine machining center of the present invention includes a base 1, a gantry column 2, an X-axis main slide table 20, a workpiece platform 4, a fixture 5, a spindle milling head 6, a fixed beam 7, a circular Disc cutter magazine 8, numerical control system 15 and other components, the operation of numerical control system 15 is realized through the manipulation screen. An X-axis main slide 20 and an X-axis servo motor 3 and a ball screw for driving the X-axis main slide 20 are arranged above the base 1 .

[0029] A gantry column is arranged on both sides of the base 1, a tool change mechanism 12 is installed above the left side of the gantry column 2, and a fixed beam 7 is arranged above the gantry column, and a cross beam 7 is arranged on the fixed beam 7. CNC slide table, the cross CNC slide table is Y-axis slide table 10 and Z-axis slide table 19, Y-axis slide table 10 and Z...

Embodiment 2

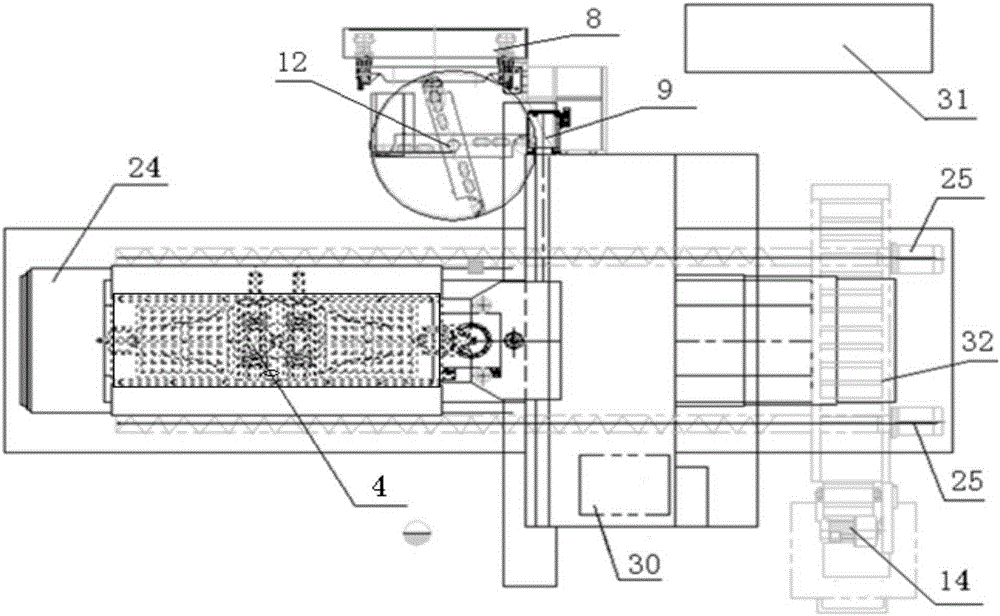

[0036] According to the second embodiment of the present invention, the milling machine processing center also includes a machine tool guide rail protection device, the main guide rail X-axis shield 24 is arranged above the guide rail of the X-axis main slide table 20 above the base 1, and the fixed beam 7 The outer side of the Y-axis guide rail is also provided with a protective cover. Preferably, the protective cover device is a fully enclosed stainless steel telescopic protective cover.

[0037] The machine tool auxiliary device of the present invention also includes a lubricating system, a magnetic automatic chip removal system and a coolant system. The machine tool adopts the centralized lubrication 26 device, and selects the Bechier lubrication station. The milling machine machining center is equipped with a magnetic automatic chip removal system. The chip removal system is composed of auger chip removal channels arranged on both sides of the X-axis main slide table 20. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com