Solar-powered airplane wing and manufacturing method thereof

A technology for a solar-powered aircraft and a manufacturing method, applied in the field of solar cells, can solve the problems of reducing the load of the solar-powered aircraft, difficult to adapt to the wing fit, large mass, etc., so as to improve the flight aerodynamic performance and reliability, improve the conformal effect and Effects of surface smoothness, good flexibility and bendability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

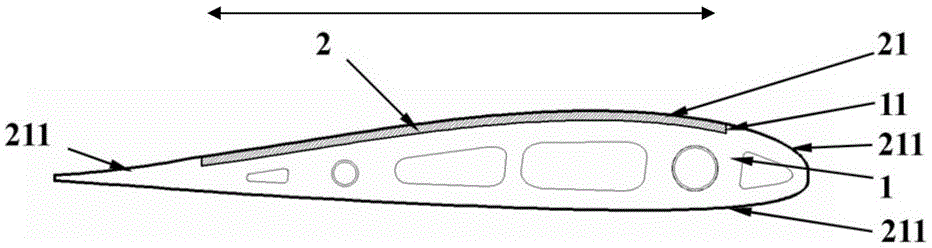

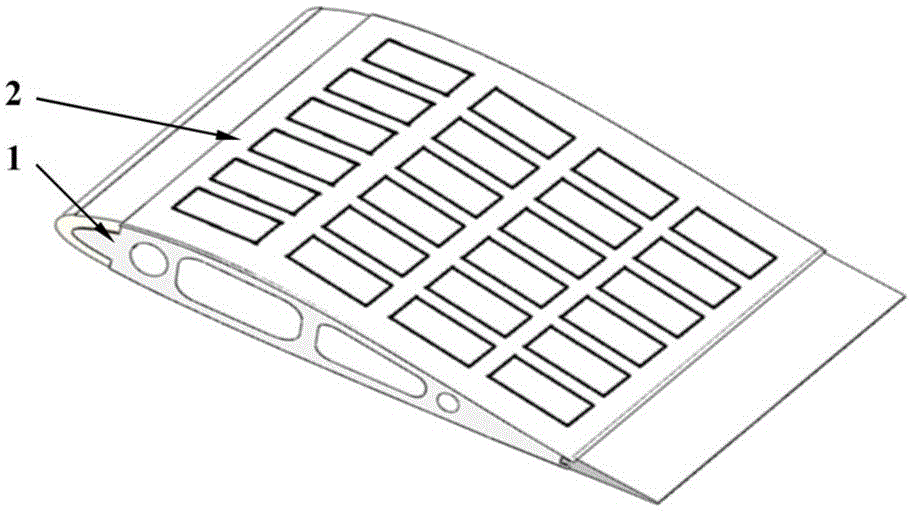

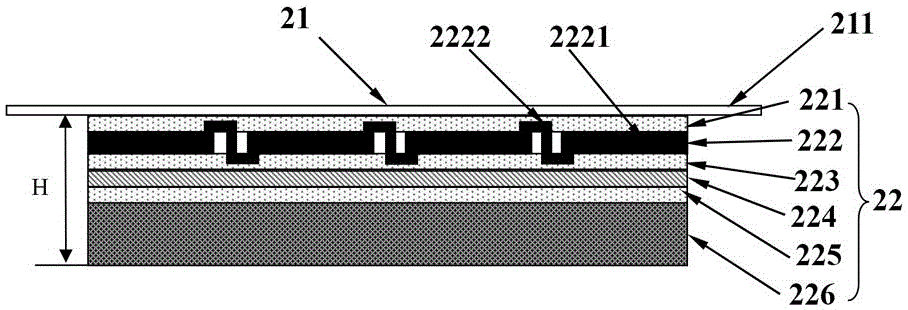

[0045] Such as figure 1 and figure 2 As shown, the solar aircraft wing of the present embodiment includes a wing frame 1 and a flexible solar cell assembly 2, the middle part of the upper surface of the wing frame 1 is provided with a groove 11, and the flexible solar cell assembly 2 includes an encapsulation skin 21 and a device. The component framework 22 on the lower surface of the package skin 21, the component framework 22 is located in the groove 11, and the package skin 21 is along the wingspan direction of the wing frame 1 (such as figure 1 (shown by the arrow) extends outwards to form a wrapping edge 211 , and the wrapping edge 211 wraps on the wing frame 1 . That is, the surface skin of the flexible solar cell module 2 extends to the surface skin of the wing frame 1. This structure greatly improves the conformal effect of the solar cell module and the wing frame and the surface smoothness of the wing, and greatly improves the solar energy. Flight aerodynamic perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com