Composite flame retardant insulation water-proof seal adhesive tape and its preparing method

A waterproof sealing, composite flame-retardant technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of non-existence and other problems, and achieve the effect of convenient coating, strong conformability and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

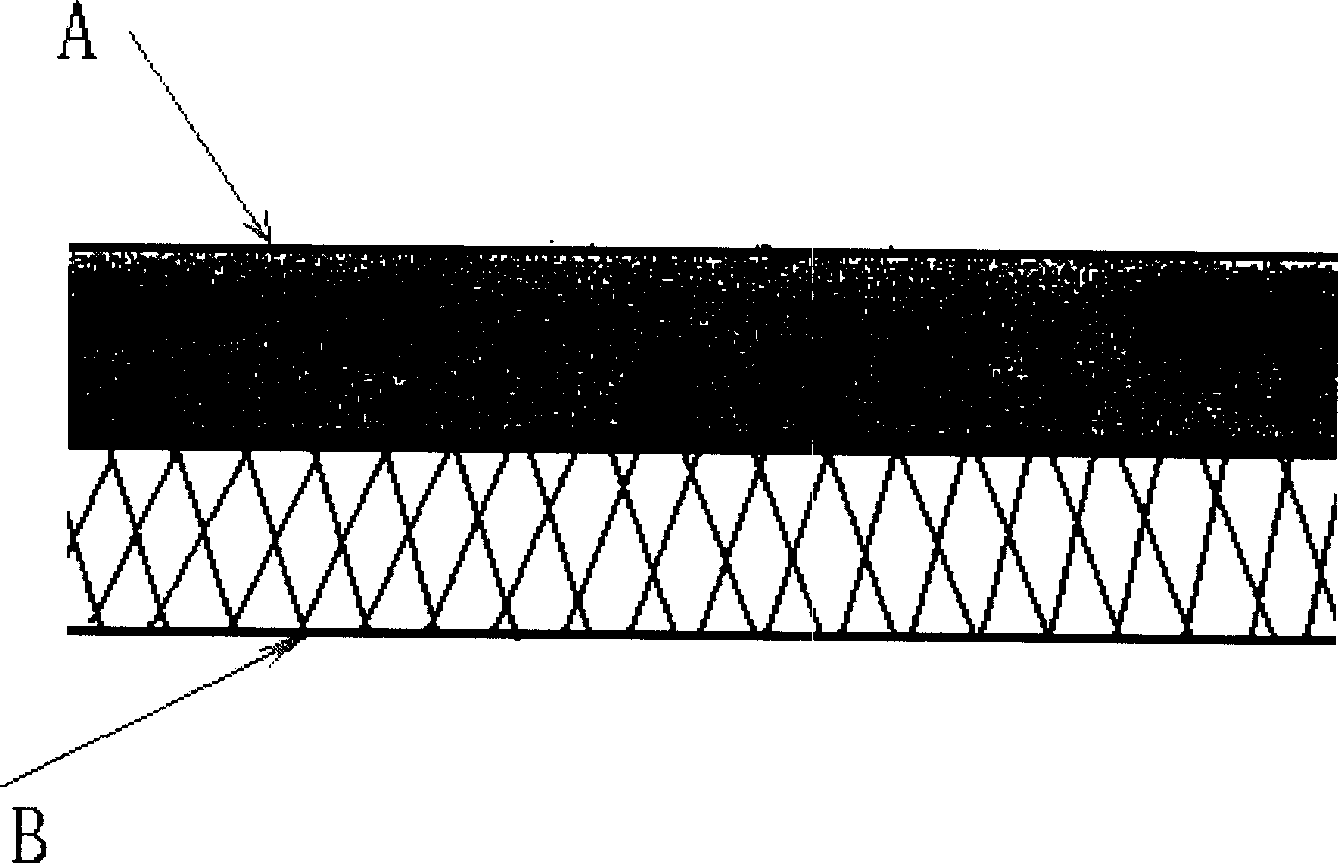

Image

Examples

Embodiment 1

[0012] The composition raw materials of the outer flame-retardant insulating elastic material A are weighed according to the following proportions (parts by weight): 30 parts of EPDM4045, 40 parts of CPE, 10 parts of fly ash, 8 parts of viscous engine oil, and 10 parts of decabromodiphenyl ether , 10 parts of pentabromotoluene, 6 parts of antimony oxide, 3 parts of carbon black, 3 parts of paraffin, 1 part of stearic acid, 0.5 part of antioxidant RD, 0.5 part of antioxidant 1010, 1 part of accelerator TMTD; In the open mill, knead repeatedly at 140 ° C until it is completely melted and mixed; then put it on a three-roll calender at 130 ° C, the distance between the rolls is 0.1 cm; pull it at a speed of 1 m / min and cut it into a width of 5 cm. layer strip.

[0013] The composition raw materials of inner flame-retardant sealing waterproof self-adhesive material B are weighed according to the following ratio (parts by weight): 20 parts of polyisobutylene, 18 parts of terpene res...

Embodiment 2

[0016] The raw materials of the outer layer flame-retardant insulating elastic material A are weighed according to the following proportions (parts by weight): 50 parts of EPDM4045, 60 parts of CPE, 20 parts of fly ash, 15 parts of sticky machine oil, 15 parts of decabromodiphenyl ether, 15 parts of pentabromotoluene, 10 parts of antimony oxide, 8 parts of carbon black, 8 parts of paraffin, 3 parts of stearic acid, 2 parts of antioxidant RD, 1.5 parts of antioxidant 1010, 3 parts of accelerator TMTD; In the open mill, knead repeatedly at 160 ° C until it is completely melted and mixed; then put it on a three-roll calender at 130 ° C, with a rolling distance of 0.3 cm; pull it at a speed of 1 m / min and cut it into an outer layer with a width of 5 cm Strip.

[0017] The composition raw material of internal flame-retardant sealing waterproof self-adhesive material B is weighed according to the following proportioning (parts by weight): 30 parts of polyisobutylene, 22 parts of ter...

Embodiment 3

[0020] The composition raw materials of the outer flame-retardant insulating elastic material A are weighed according to the following proportions (parts by weight): 40 parts of EPDM4045, 50 parts of CPE, 15 parts of fly ash, 12 parts of sticky machine oil, and 13 parts of decabromodiphenyl ether , 13 parts of pentabromotoluene, 8 parts of antimony oxide, 6 parts of carbon black, 6 parts of paraffin, 1.5 parts of stearic acid, 1 part of antioxidant RD, 1 part of antioxidant 1010, and 1 part of accelerator TMTD; In the open mill, knead repeatedly at 150°C until it is completely melted and mixed; then put it on a three-roll calender at 130°C, with a rolling distance of 0.2cm; pull it at a speed of 1m / min and pay attention to cutting into a width of 5cm. layer strip.

[0021] The composition raw materials of inner layer flame-retardant sealing waterproof self-adhesive material B are weighed according to the following proportioning (parts by weight): 25 parts of polyisobutylene, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com