Patents

Literature

40results about How to "Guaranteed perfect fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

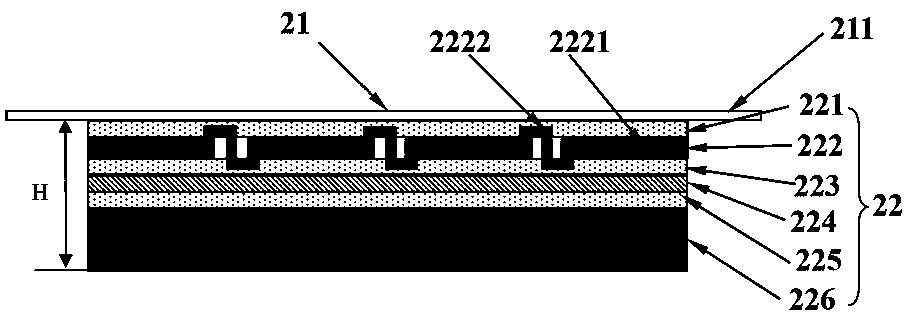

High-polymer modified asphalt waterproof roll for road and bridge and preparation method thereof

ActiveCN106739310AGuaranteed thicknessHigh temperature shear resistanceSynthetic resin layered productsLaminationBituminous waterproofingEngineering

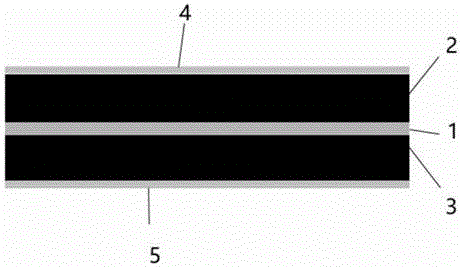

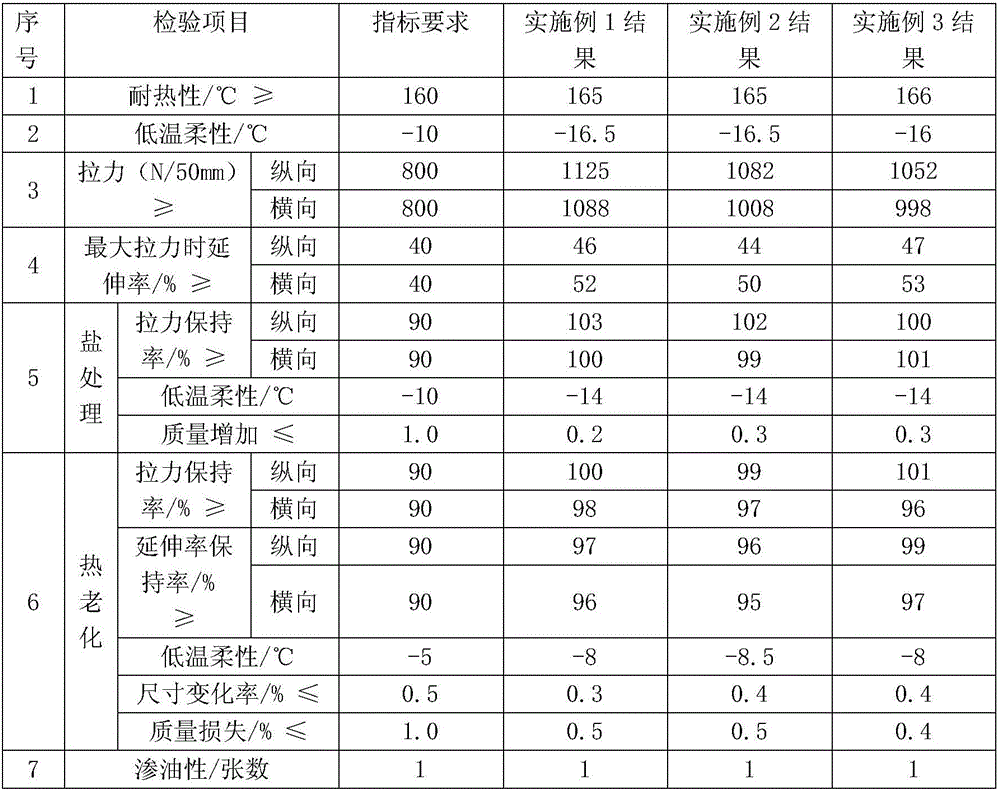

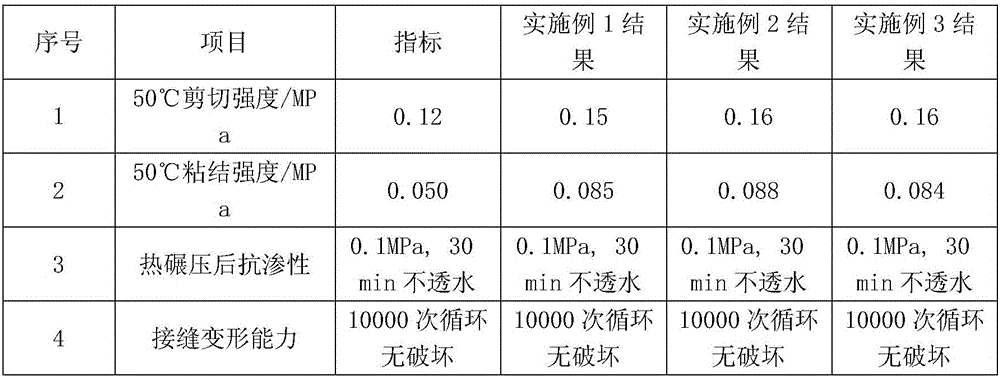

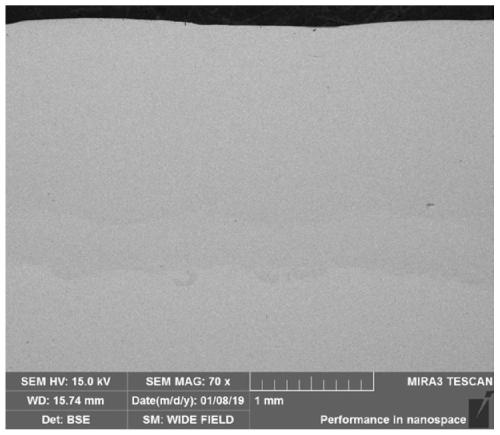

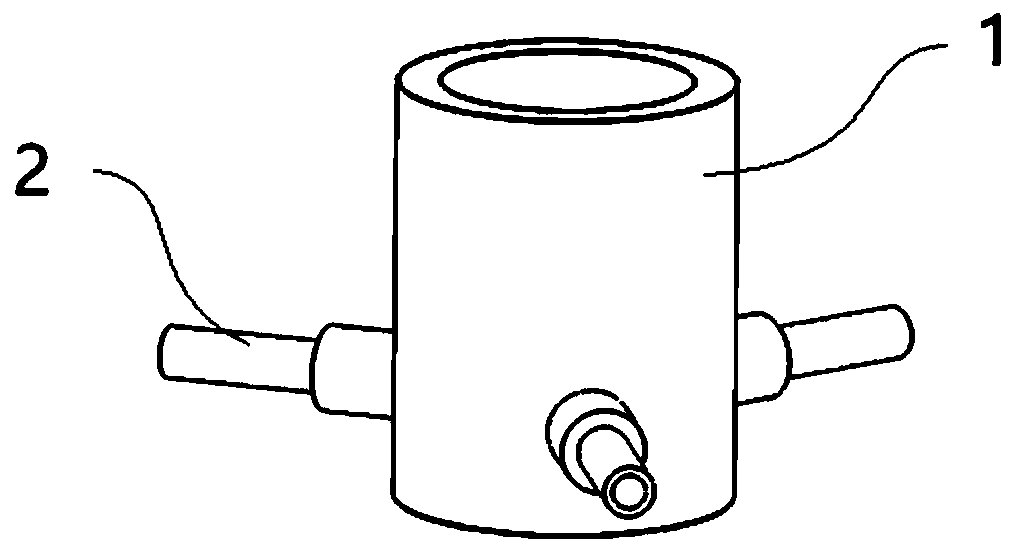

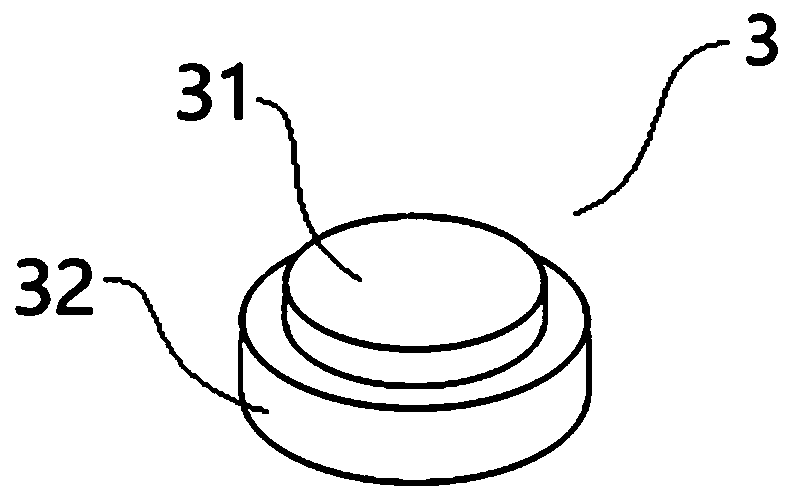

The invention relates to a high-polymer modified asphalt waterproof roll for roads and bridges. The high-polymer modified asphalt waterproof roll is manufactured in the way that a bank base layer (1) is used; modified asphalt coating and covering layers (2) and (3) are respectively bonded on the upper and lower surfaces of the bank base layer (1); an isolation layer (4) covers the upper surface of the modified asphalt coating and covering layer (2); an isolation layer (5) covers the lower surface of the modified asphalt coating and covering layer (3); each modified asphalt coating and covering layer is prepared from the following raw materials in percentage by mass: 38 to 44 percent of 90# asphalt, 11 to 17 percent of 200# asphalt, 5 to 8 percent of polypropylene, 1 to 3 percent of SBS, 4 to 6 percent of APAO, 2 to 3 percent of high-temperature modifiers, 15 to 17 percent of modification powder and 10 to 15 percent of filling materials. The product of the high-polymer modified asphalt waterproof roll has the advantages that the high-temperature resistant and low-temperature cracking resistant capability is high; the anti-aging capability is high; the joint deformation capability is high; the high-standard waterproof function is provided; meanwhile, the construction performance of the waterproof roll for roads and bridges is improved; the high-polymer modified asphalt waterproof roll is mainly used for pavement of cast asphalt concrete mixtures.

Owner:SHANGHAI ORIENTAL YUHONG WATERPROOF TECH

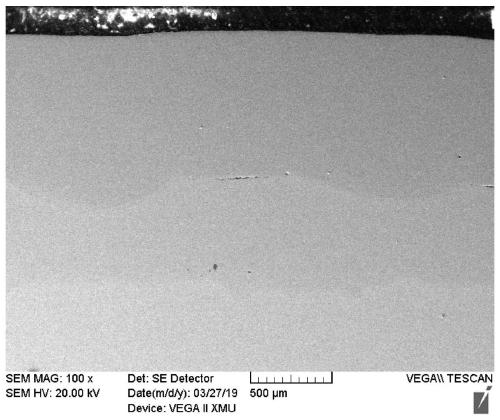

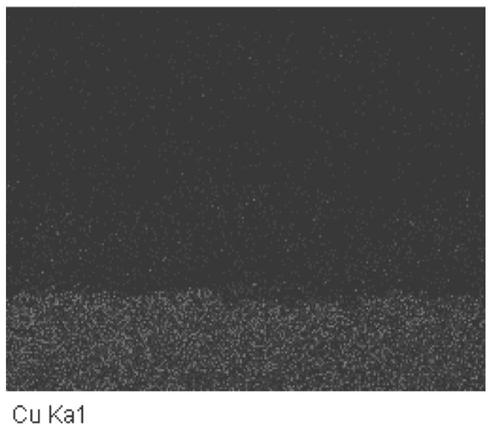

Metal-based material for preparation of crystallizer or tuyere as well as preparation method of metal-based material

ActiveCN110144582AImprove high temperature wear resistanceLower perfect fitMetallic material coating processesSurface engineeringAlloy

The invention discloses a metal-based material for the preparation of a crystallizer or a tuyere and belongs to the technical field of surface engineering. According to the metal-based material, a transition layer is innovatively arranged between a Cu or Cu alloy matrix and a high-abrasion-resistance working layer by the adoption of a metallurgical bonding method, and made of at least one of pureCo metal, pure Ni metal, pure Cr metal, pure Cu metal, pure Mo metal, pure Ag metal and a NiCr or MCrAlY alloy; through the transition layer, the functions of improving the laser absorption rate, lowering the matrix heat conductivity, and lowering the dilution rate can be achieved; due to the existence of the transition layer, the thickness of the working layer can be adjusted within a range of 0.01-3 mm and the formation of surface cracks can be avoided; furthermore, the ratio of the thickness of the transition layer to that of the high-abrasion-resistance working layer is 1:(1-3), so that the perfect bonding of the transition layer and the high-abrasion-resistance working layer can be guaranteed within the ratio range; the formation of a high-abrasion-resistance coating or coating product which is free of surface cracks and subjected to metallurgical bonding on the Cu or Cu alloy matrix can be improved; the reliability of the crystallizer or the tuyere can be improved; and the service life of the crystallizer or the tuyere can be prolonged.

Owner:XI AN JIAOTONG UNIV

Manufacturing method for surface type-P conductive diamond heat sink material

ActiveCN105331948AGood thermal conductivityGood mechanical strengthChemical vapor deposition coatingMicrowaveSurface roughness

The invention discloses a manufacturing method for a surface type-P conductive diamond heat sink material, and belongs to the technical field of diamond free-standing film application. A polished thick free-standing diamond film is adopted as a substrate, and a thin boron-doped diamond film with the type-P conductivity is deposited after microwave hydrogen plasma surface treatment is performed. Due to the fact that homoepitaxy growth is adopted, an epitaxial conductive layer and the substrate have the perfect attachment performance, and the interface resistance can be lowered to the minimum extent; and the microwave CVD technology is adopted for manufacturing the boron-doped diamond film, the thickness is controllable, the surface roughness is low, and the film conductivity is high. Hydrogen plasma is adopted in the middle for processing the surface of the substrate, atomic-size cleaning can be performed on the substrate, and epitaxial growth of the boron-doped diamond film is further facilitated through a formed hydrogen dangling bond. The surface type-P conductive diamond heat sink material can be used for the field of packaging of some high-power electronic devices needing heat sink material surface conduction.

Owner:UNIV OF SCI & TECH BEIJING

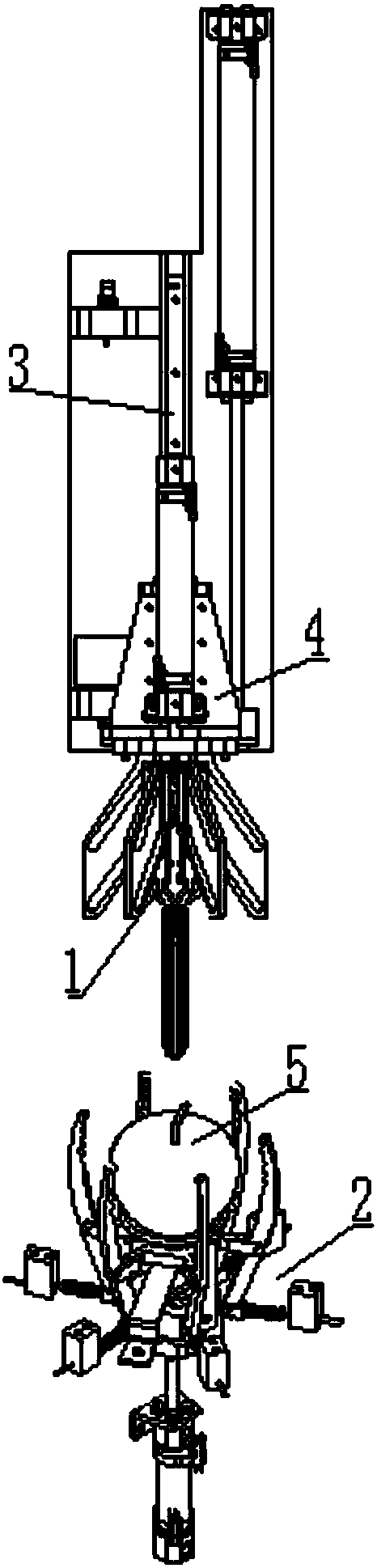

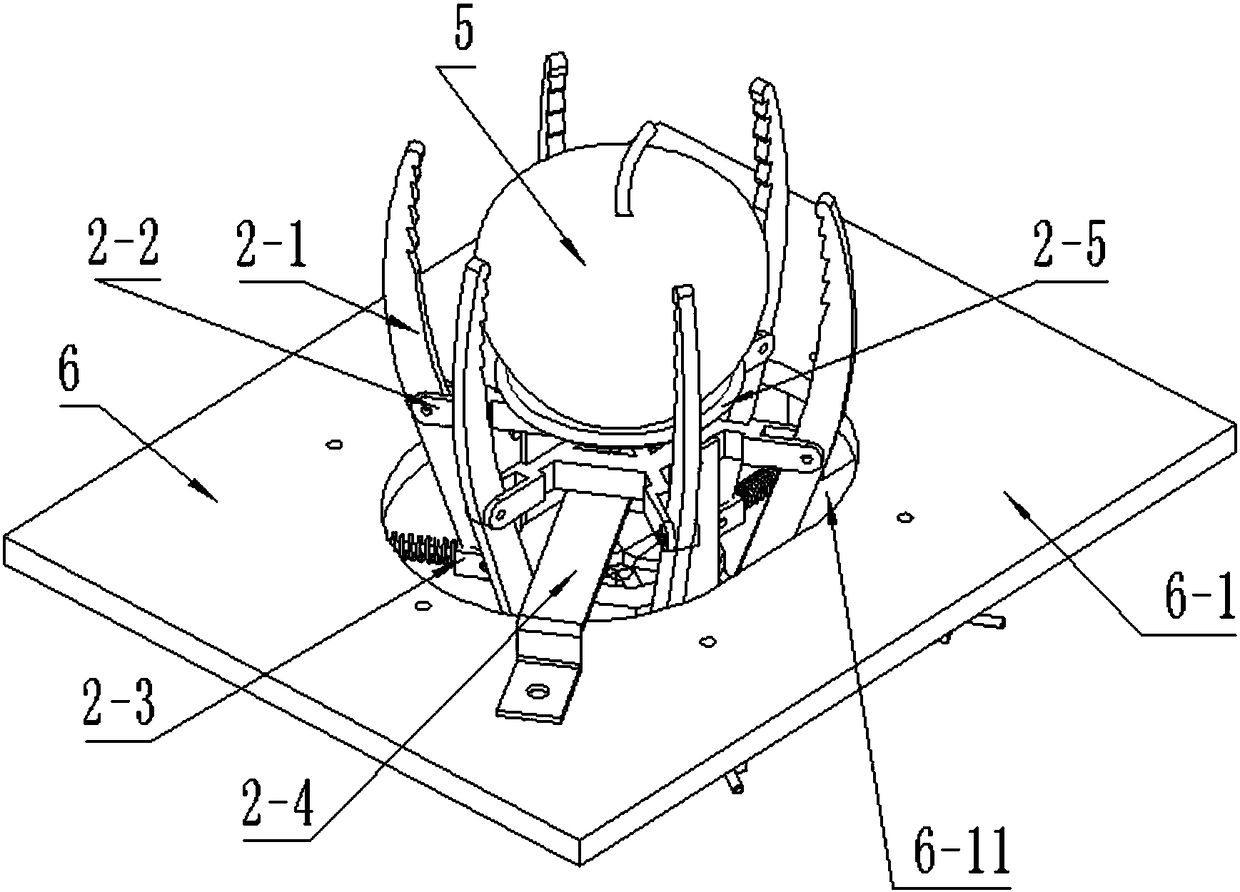

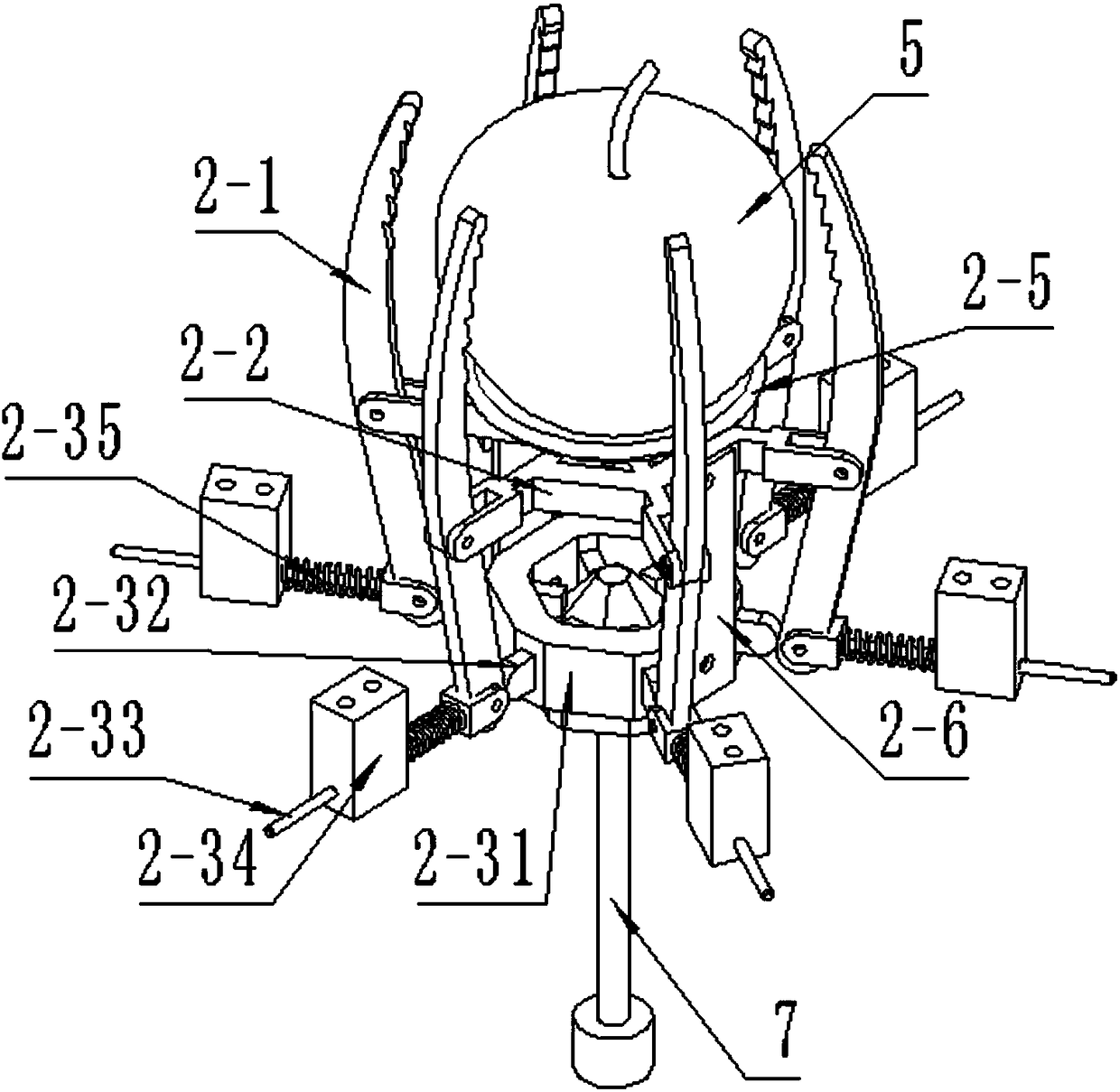

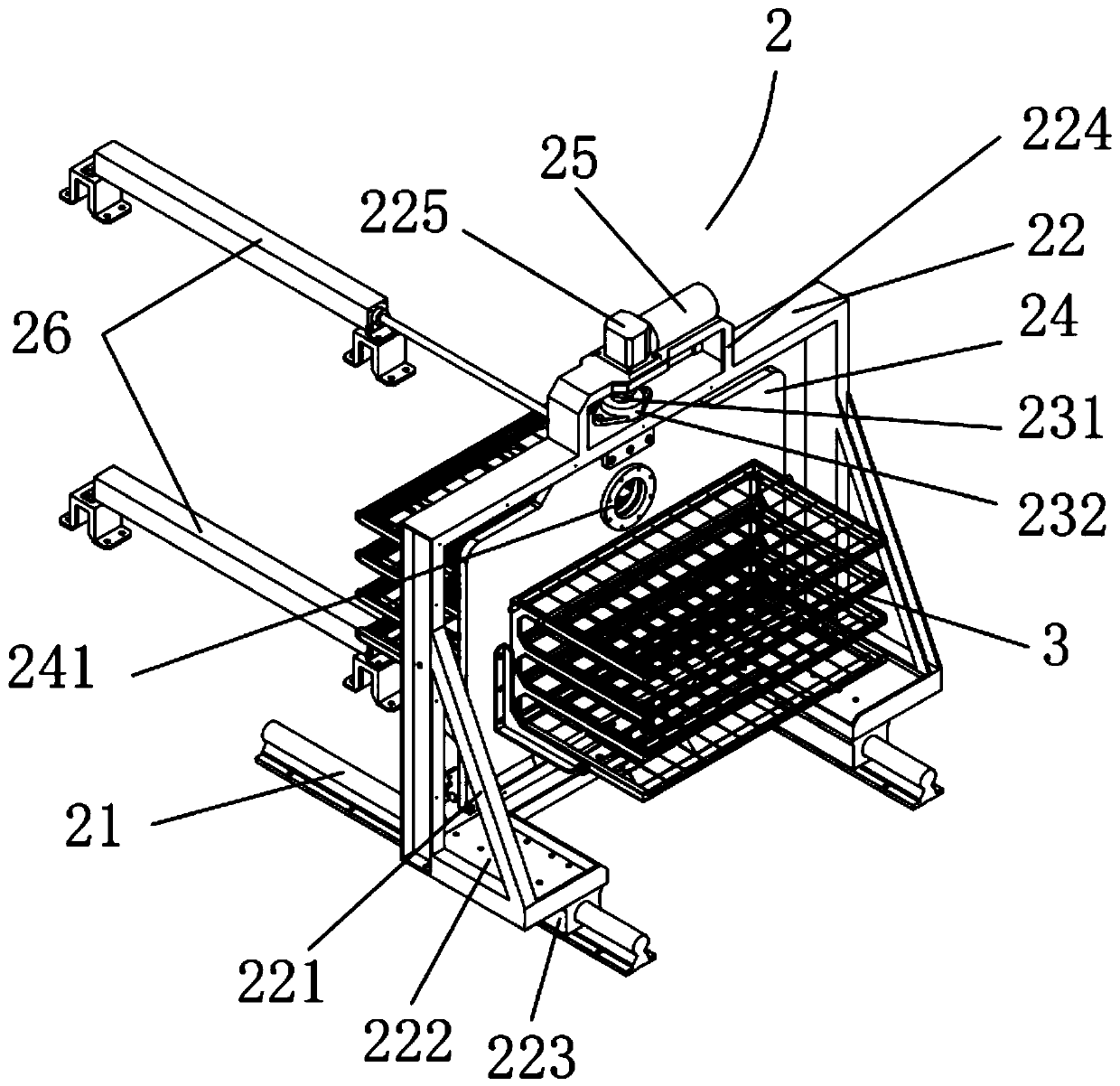

Bagging device used for bagging fruits with mesh bags

PendingCN108454967AEasy to flushGuaranteed impact timePackaging fruits/vegetablesWaste collection and transferBiomedical engineering

The invention relates to a bagging device used for bagging fruits with mesh bags. The bagging device comprises a clamping separating assembly, a bag supporting assembly, a lifting mechanism and a rack, the lifting mechanism and the clamping separating assembly are installed on the rack, the bag supporting assembly is arranged above the clamping separating assembly and is installed on the lifting mechanism, and the lifting mechanism can drive the bag supporting assembly to move up and down; and the bag supporting assembly comprises a bag supporting mechanism and a bag supporting driving mechanism, the bag supporting mechanism comprises bag supporting claws capable of opening and closing in parallel, the clamping separating assembly comprises a clamping separating mechanism, the clamping separating mechanism comprises clamping separating claws, the bag supporting claws and the clamping separating claws are evenly distributed along a circle, and the clamping separating claws and the bag supporting claws are staggered in the circumferential direction. The overall structure is simple, and the bagging efficiency is high; and stress is even during supporting or clamping separation of a net bag, and the net bag can be prevented from being damaged by supporting or clamping.

Owner:烟台梦现自动化设备有限公司

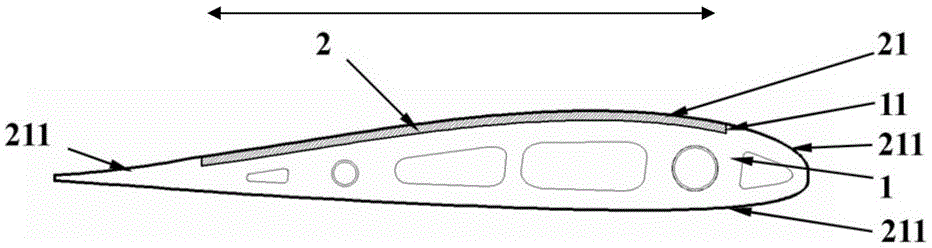

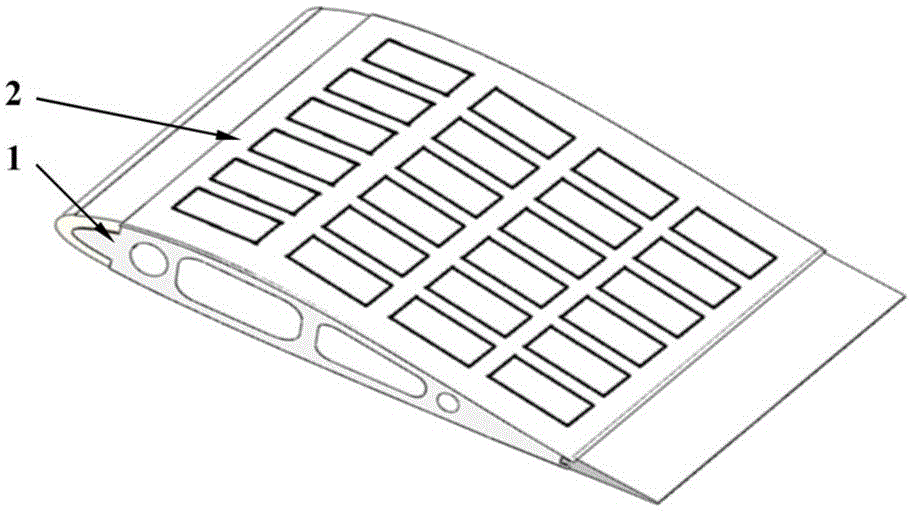

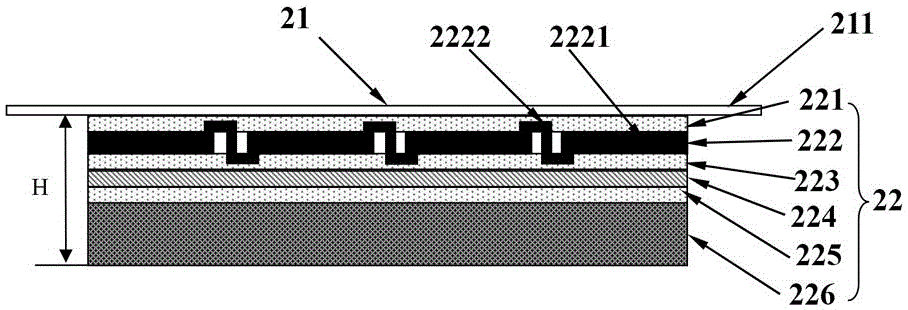

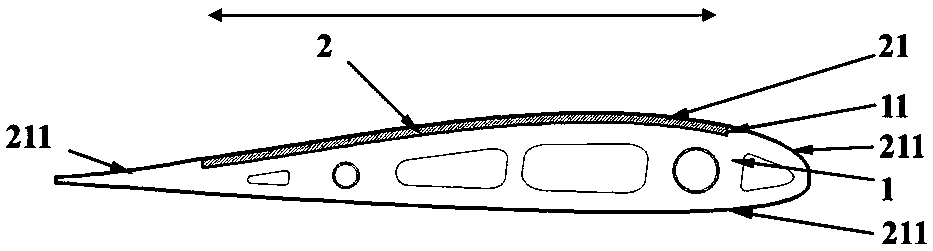

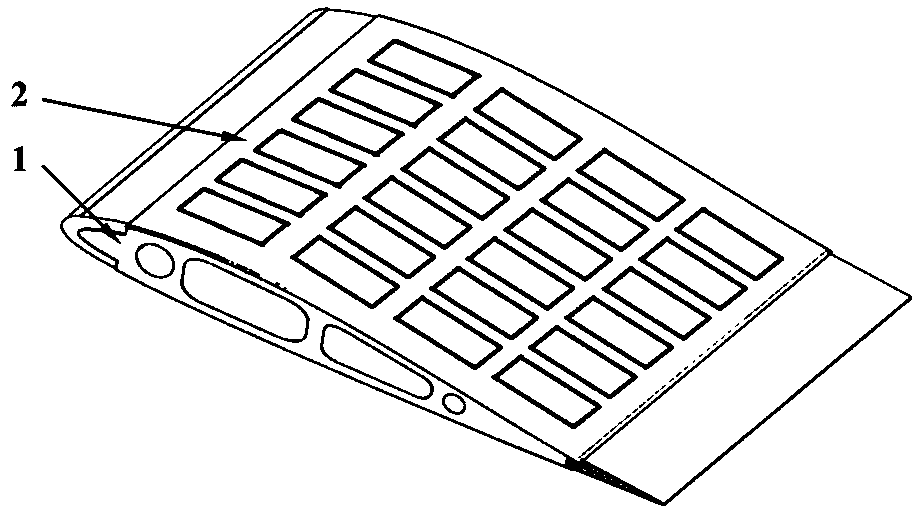

Solar-powered airplane wing and manufacturing method thereof

ActiveCN106379516AGood conformabilityImprove surface smoothnessFinal product manufactureWingsHigh surfaceSolar cell

The invention discloses a solar-powered airplane wing and a manufacturing method thereof. The solar-powered airplane wing comprises a wing framework and a flexible solar cell module, wherein the middle part of the upper surface of the wing framework is provided with a groove; the flexible solar cell module comprises a packaging skin and an assembly framework arranged on the lower surface of the packaging skin; the assembly framework is arranged in the groove; the packaging skin extends outwards along the two sides of the wing framework in the spanwise direction to form a coating side; and the coating side is coated on the wing framework. The manufacturing method comprises the following steps: S1: preparing the wing framework; S2: preparing the flexible solar cell module; and S3: assembling. The solar-powered airplane wing has the advantages of favorable conformal effects between the solar cell module and wing framework, high surface smoothness, excellent aerodynamic performance, light weight and the like. The preparation method has the advantages of convenient assembly, weight reduction and favorable reliability.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Red plum graft propagation method by using green plums as rootstocks

ActiveCN103283499AGuaranteed fertilizer efficiencyGuaranteed perfect fitHorticultureDiseaseRootstock

The invention discloses a red plum graft propagation method by using green plums as rootstocks. The red plum graft propagation method includes: selecting the green plums which are low in price, abundant in output and usually taken as waste by farmers as the rootstocks, subjecting the green plum rootstocks to pretreatment, scion treatment and grafting, and managing nutrient and water in later stages. By the aid of the red plum graft propagation method, perfect combination between the rootstocks and scions during graft propagation operation is guaranteed, survival rate of trees is increased while life time of the trees is prolonged by the aid of the pretreatment of the rootstocks and the scions, fertilizer efficiency of red plums is guaranteed to be sufficient rather than excessive by the aid of nutrient and water management in different periods in the later stages, growth cycle of red plum trees is shortened, growing quality and blooming quality of the trees are guaranteed, and disease resistance of plants is strengthened.

Owner:江苏知聚知识产权服务有限公司

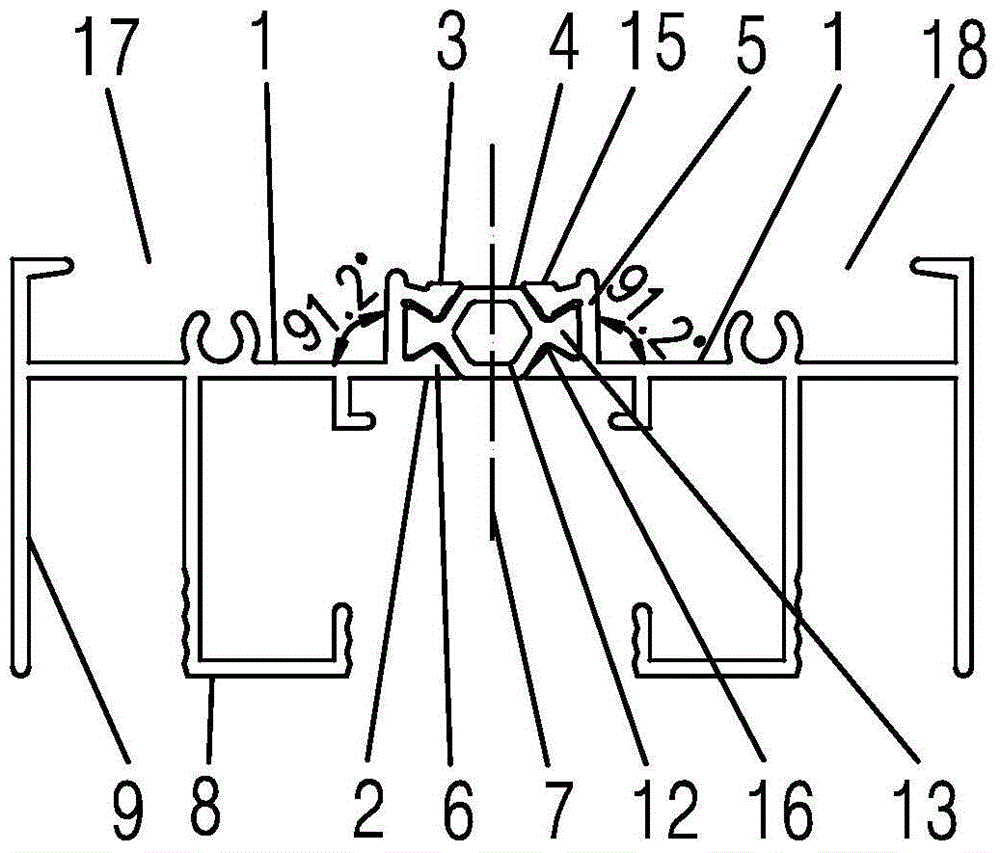

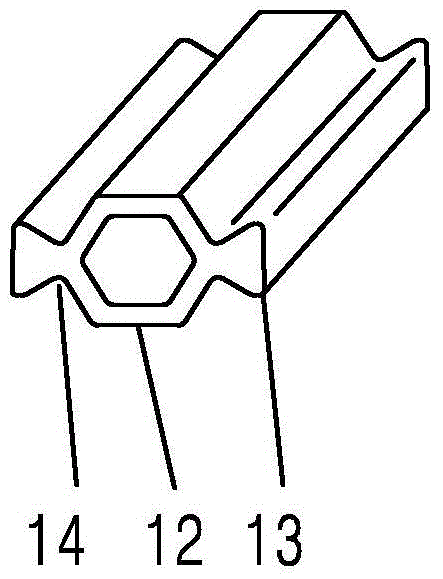

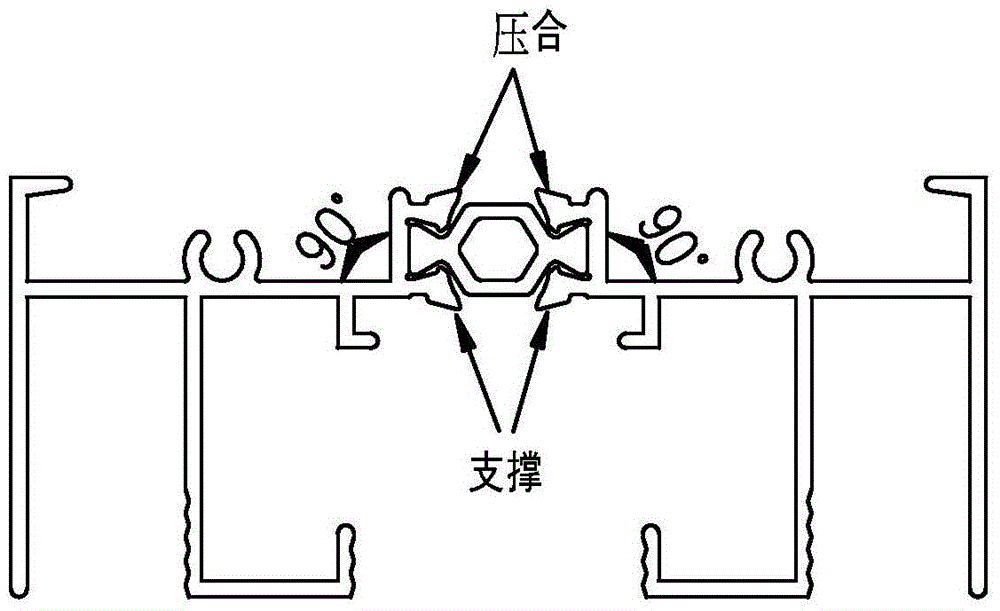

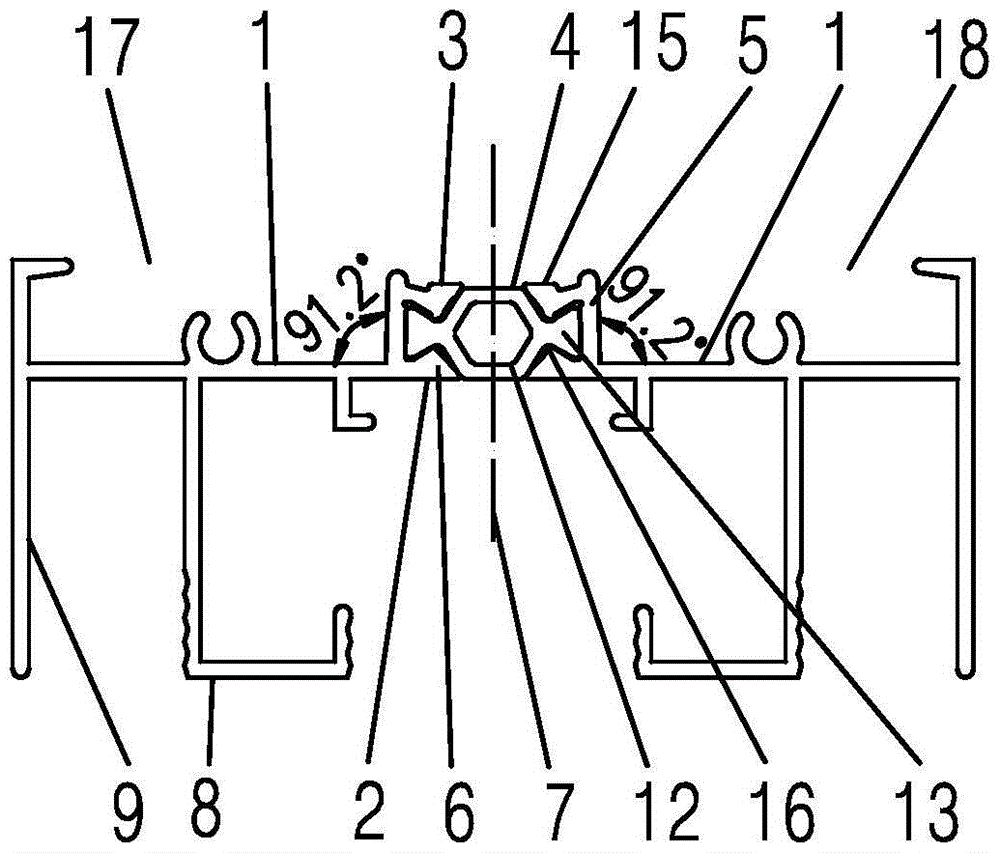

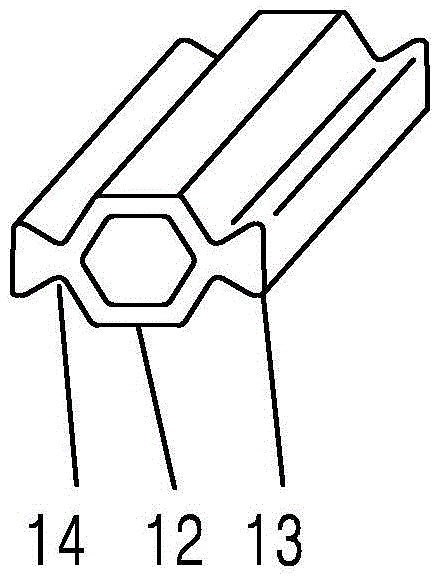

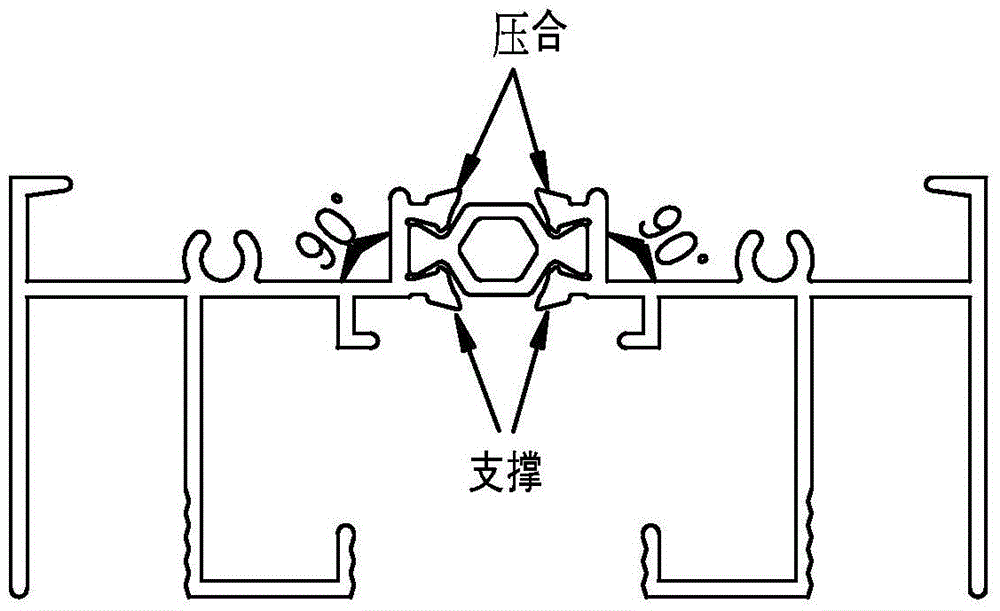

Strip-penetrating broken-bridge heat insulation building energy-saving section bar and machining process for section bar

The invention provides a strip-penetrating broken-bridge heat insulation building energy-saving section bar and a machining process for the section bar. The section bar is formed by single section bars at the inner side and the outer side and a hollow heat insulating strip between the two section bars, the hollow heat insulating strip is in bilateral symmetry centering on a vertical center line, one ends of tooth supports, adjacent to compression tooth rolling torsion surfaces, inwardly incline towards the direction of the vertical center line, included angles are 1 degree to 2 degrees, and compression tooth support surfaces are vertical to the vertical center line. According to the section bar, the cost is reduced, the machining is convenient, the section bar formed by machining is not deformed due to machining, standard-structure section bars capable of preventing structural deformation can be obtained via rolling combination of the single section bars, and the installation problem of the section bar due to deformation in a combination process is eliminated.

Owner:YICHANG HONGJIAN ALUMINUM IND

Overturning sliding cavity door structure, plasma vacuum cavity and plasma treatment equipment

PendingCN110184590AAvoid failureGuaranteed vacuum environmentElectric discharge tubesChemical vapor deposition coatingEngineeringMechanical engineering

The invention discloses an overturning sliding cavity door structure, a plasma vacuum cavity and plasma treatment equipment. The cavity door structure comprises a slide rail, a mounting rack slidablymounted on the slide rail and a cavity door rotatably connected in the mounting rack. Material rest trays are arranged on two sides of the cavity door, a vertical rotating shaft is mounted in the middle of the cavity door in a penetrating manner, the vertical rotating shaft is mounted in the mounting rack, and the vertical rotating shaft is driven by a driving mechanism A located on the top of themounting rack, the cavity door under the action of the driving mechanism A rotates in the mounting rack around the vertical rotating shaft, and the mounting rack is driven by an external driving mechanism B to slide; and the plasma vacuum cavity and the plasma treatment equipment adopt the overturning sliding cavity door structure. By arranging the rotary vacuum cavity door, the positions of thematerial rest trays can be exchanged, so that a purpose of changing in-out materials quickly is further achieved.

Owner:SUZHOU WEIPENG ELECTRICAL TECH CO LTD

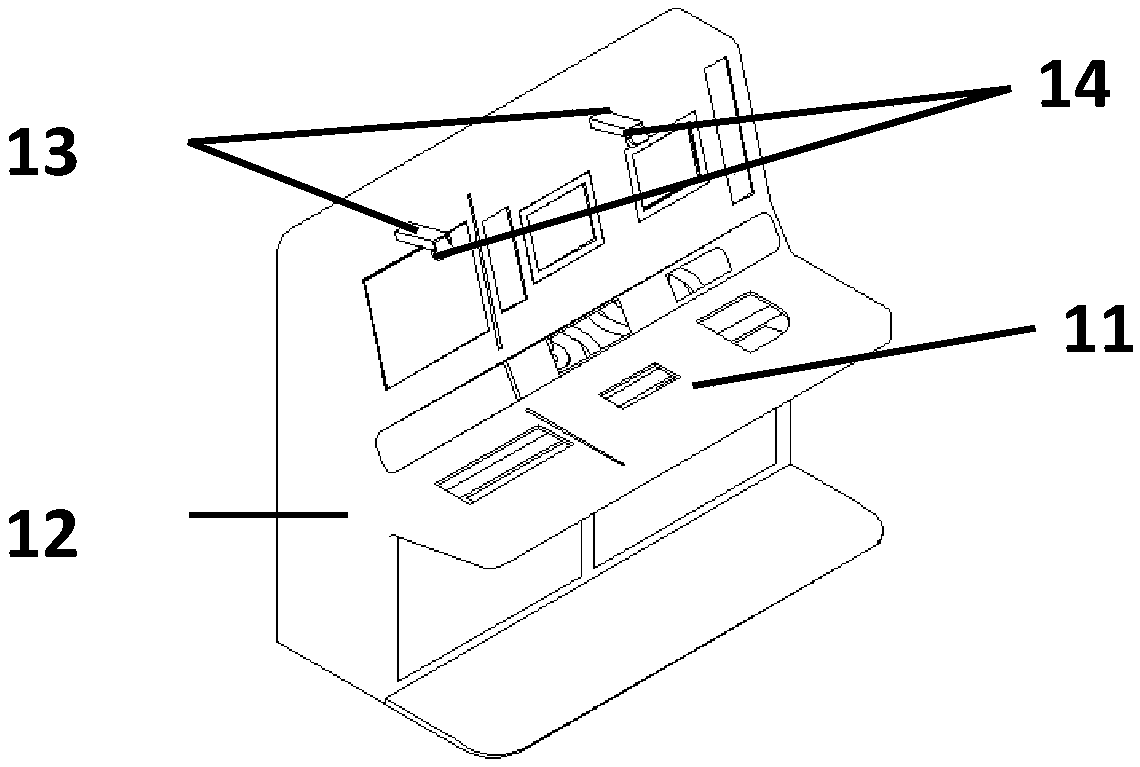

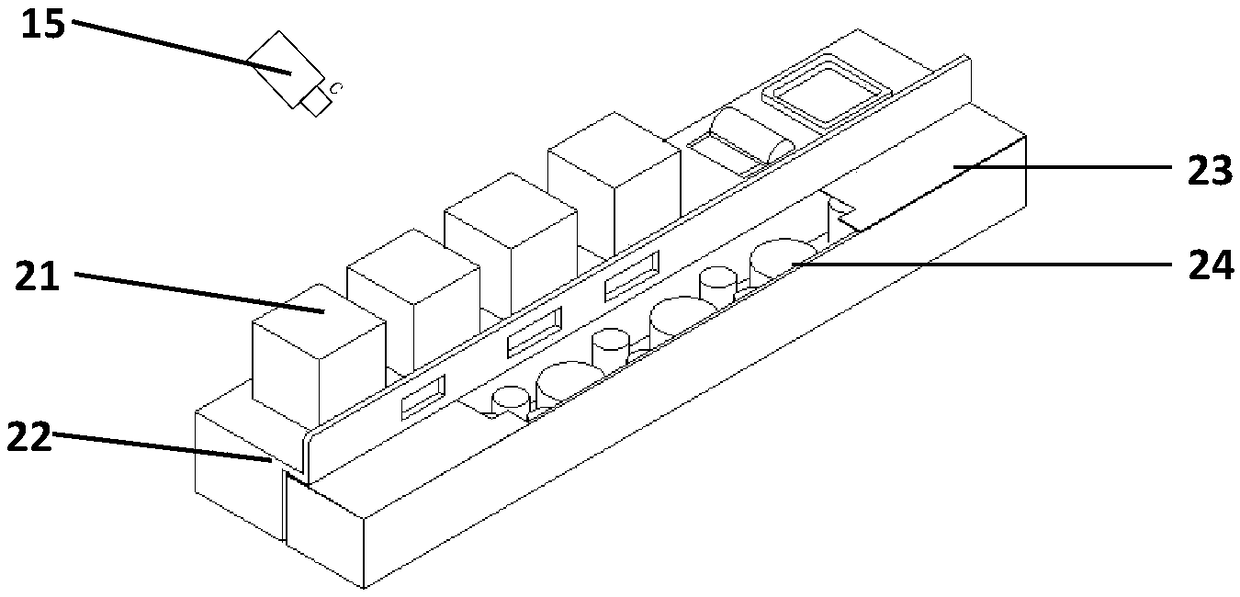

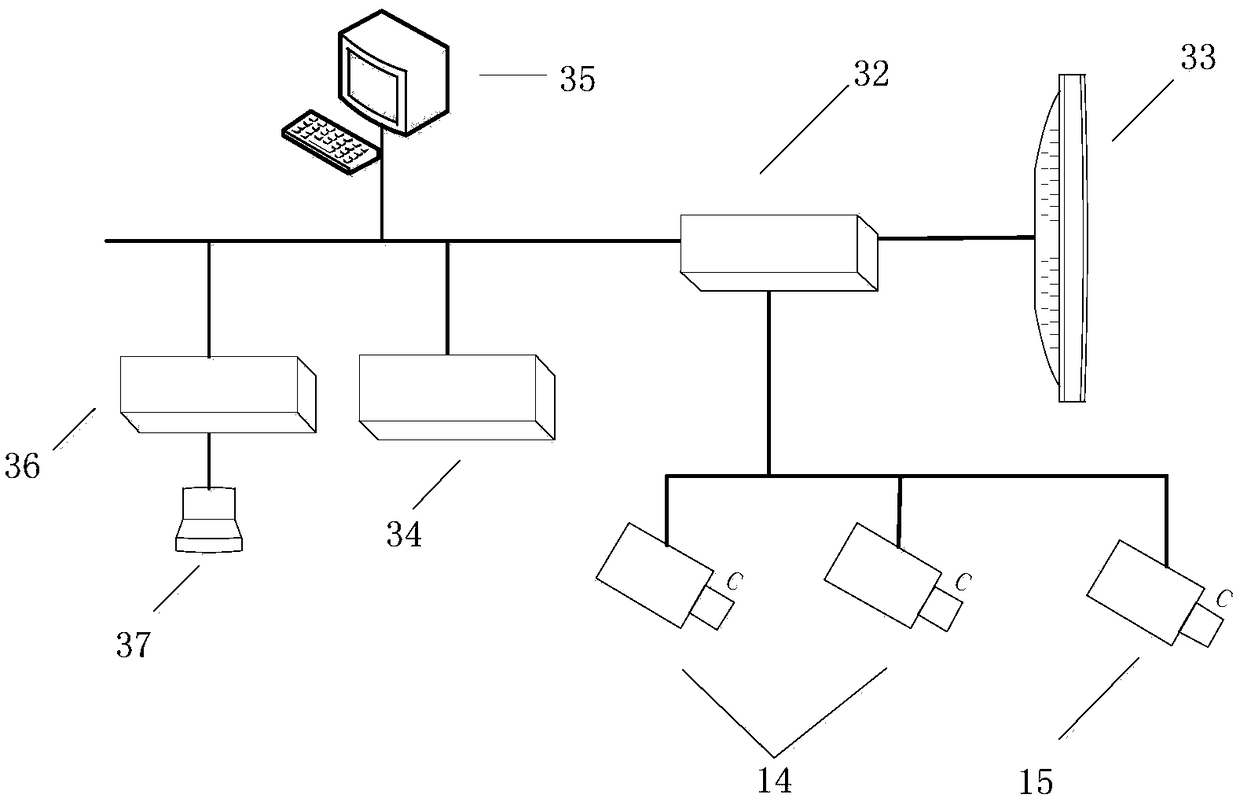

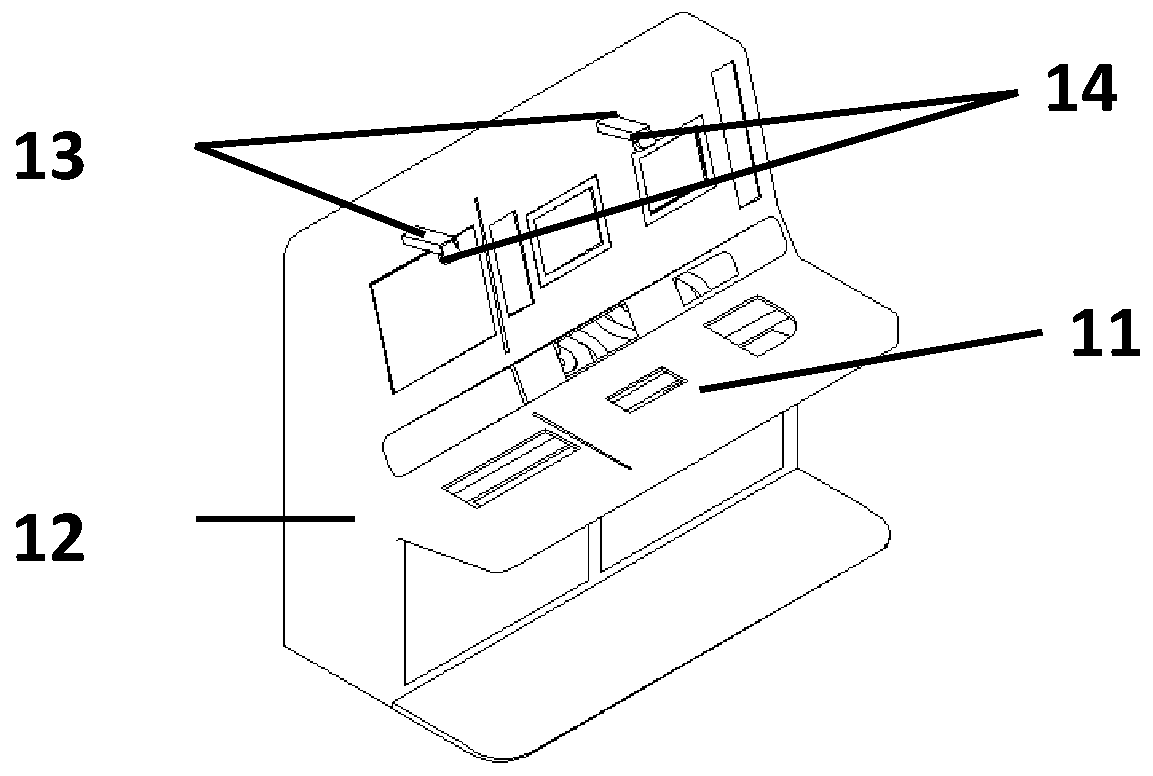

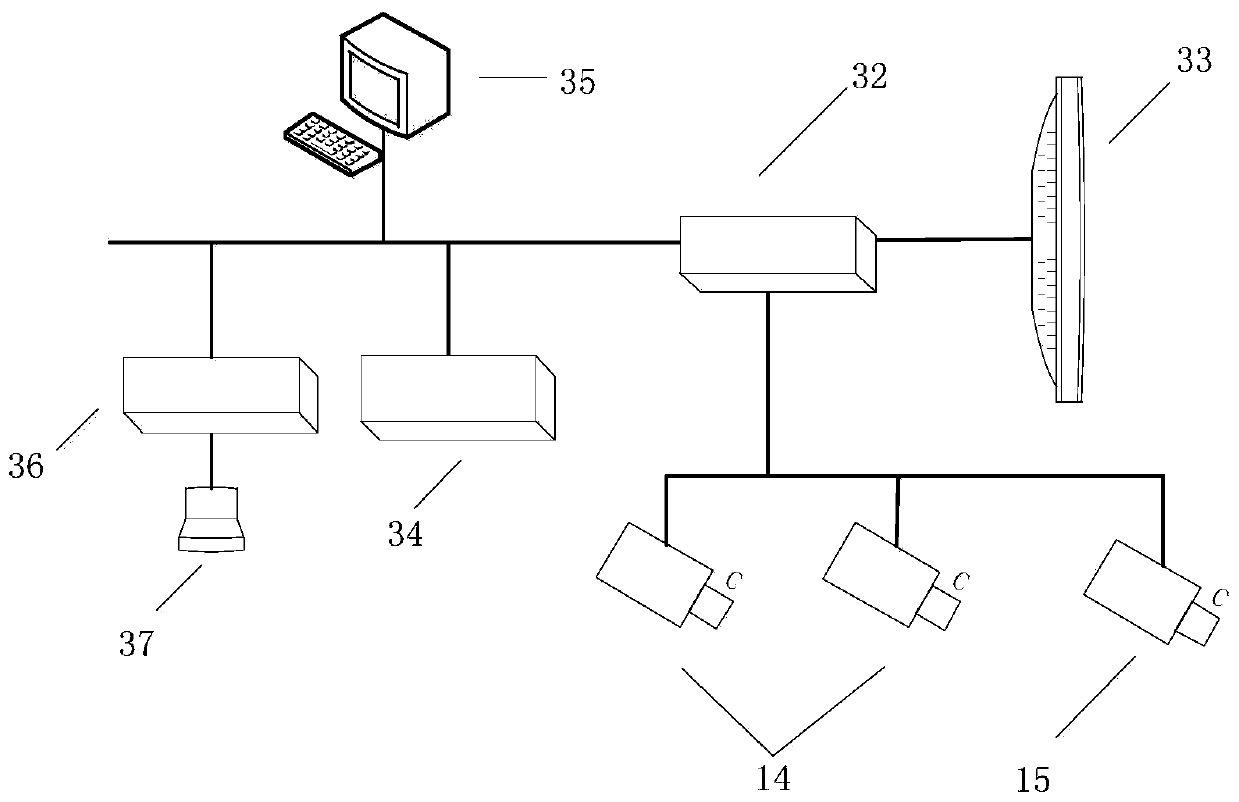

Platform and method for monitoring ground test launch control system

ActiveCN108873777AReduce the number of peopleGuaranteed perfect fitProgramme controlComputer controlControl systemDevice Panel

The invention relates to a platform and method for monitoring a ground test launch control system. The method comprises reasonably planning a ground single machine and cable network layout; acquiringthe display images of a status display and a central computer display, and the status image of a test launch control device panel; identifying a currently executed process step; calling a corresponding template from a template; performing matching; and determining that a current test status is normal if matching is successful, or giving an alarm if not. The platform rearranges cable positions by acable arrangement box, is provided with a wire duct, and is provided with an independent wiring space to help the concentration of respective single machines of a test launch control system and a monitoring and operation panel. The platform and method perform comprehensive judgment by identifying a first word and a color block length, ensure the accuracy of process identification, obtain the corresponding template through the process, and ensure the accurate monitoring of the device state by the matching of the template.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST +1

Preparation method for original auto seat cushion template of special car

InactiveCN103600674APerfect Coverage GuaranteedDoes not affect the functionBack restsThigh restsMaximum levelPolyvinyl chloride

The invention relates to preparation method for an original auto seat cushion template of a special car. The preparation method includes following steps: using a transparent PVC (polyvinyl chloride) film to cover an original auto seat, using a marking pen to record contour lines of different partition faces of the seat instead of an outer contour of the whole seat, using a three-dimensional cutting method to manufacture templates of different arc faces, respectively taking down a headrest, a front-row backrest, a seat, a rear-row backrest and the templates of the partition faces of the seat, and keeping a good record; and obtaining a corresponding template by the aid of the method, and then completing seat cushion products through processing. Corresponding openings are reserved for safety belts or other mechanical devices, center-close rear armrests or a split structure goes through plate-pressing separately and are connected by zippers. The preparation method has the advantages that perfect coverage of the seat of an original car can be guaranteed, used functions of the seat of the original car are not affected, perfect camber fit of the manufactured seat cushion products and the seat of the original car can further be guaranteed, and use demands of a car owner is met at a maximum level.

Owner:浙江联享科技有限公司

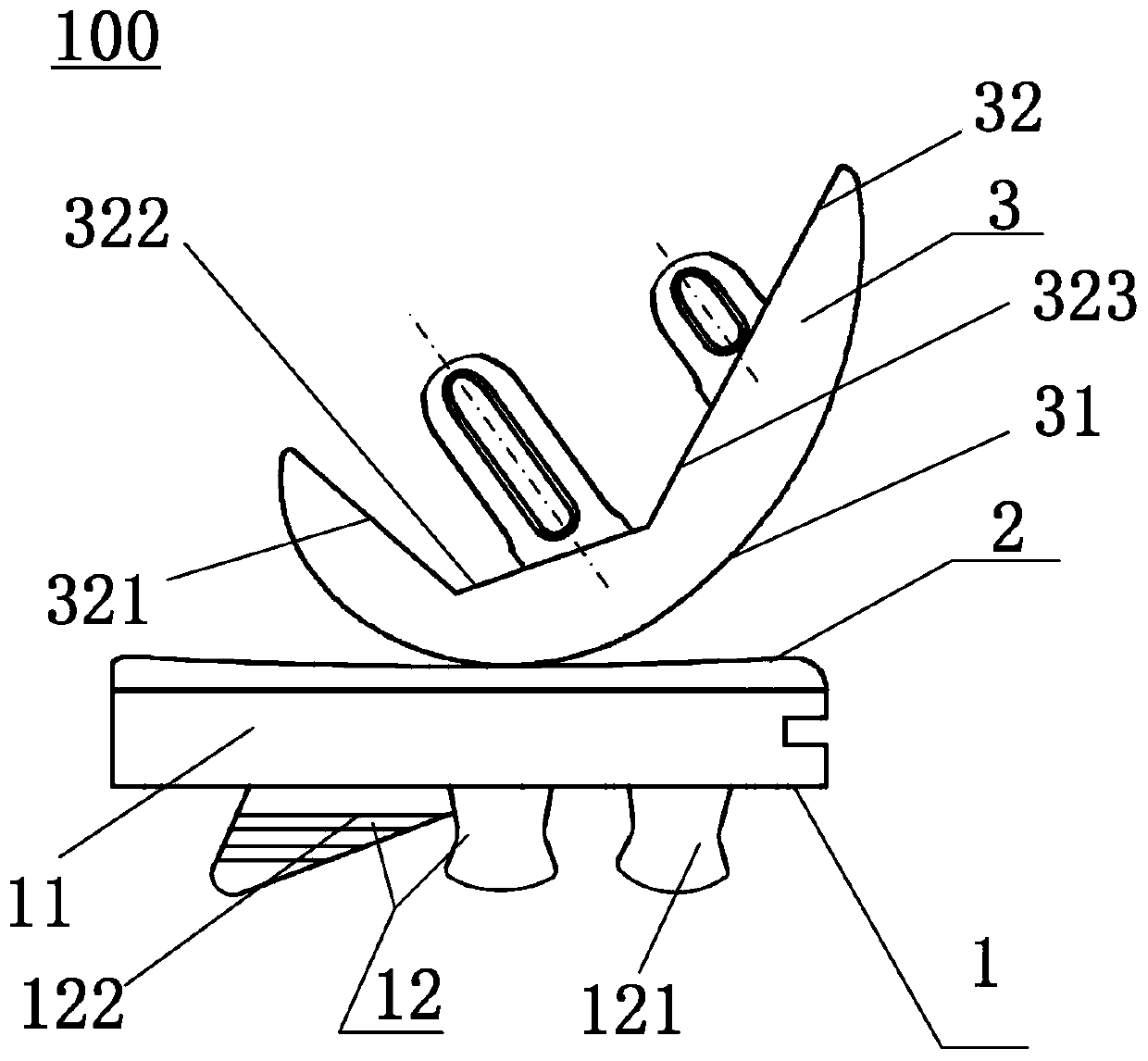

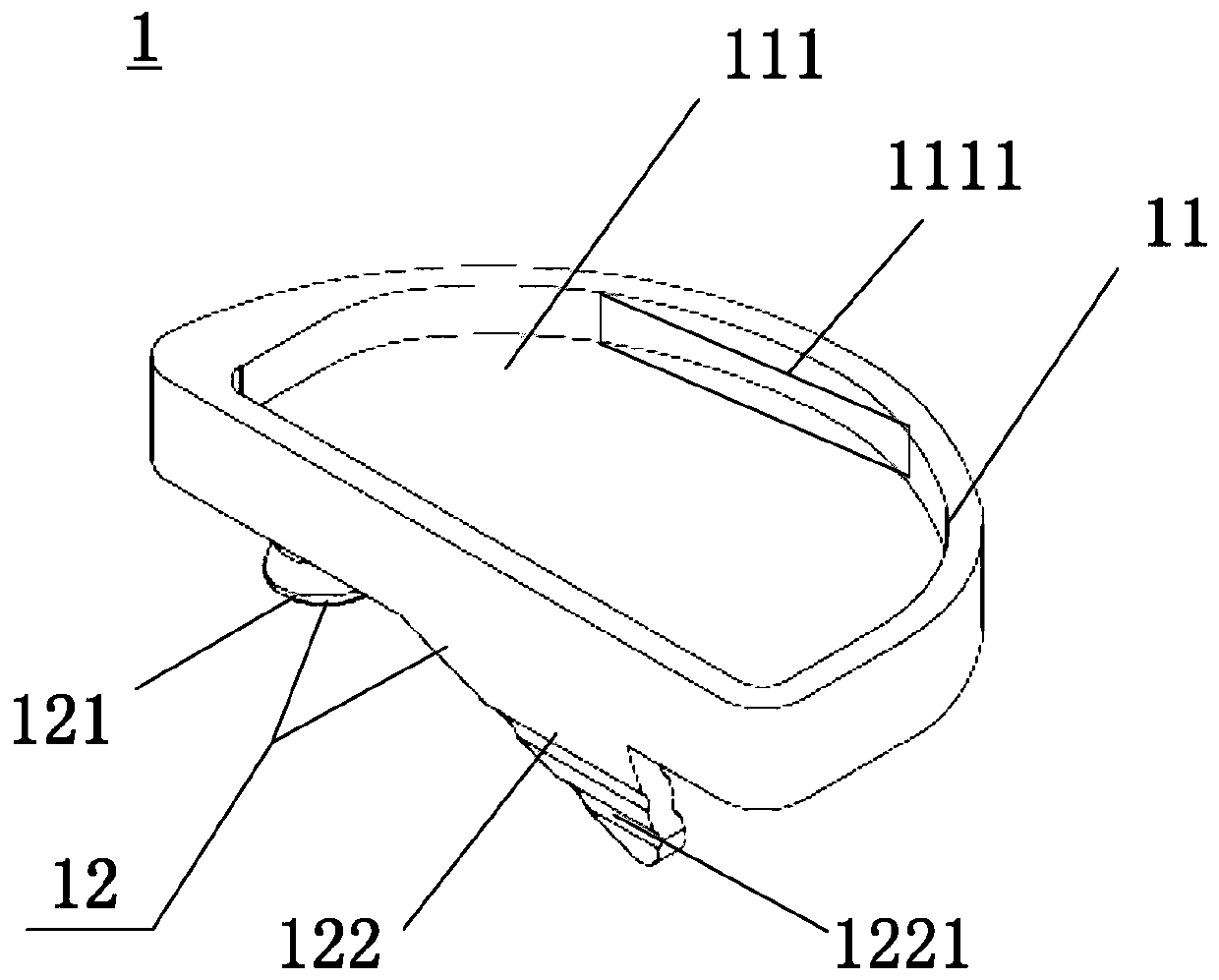

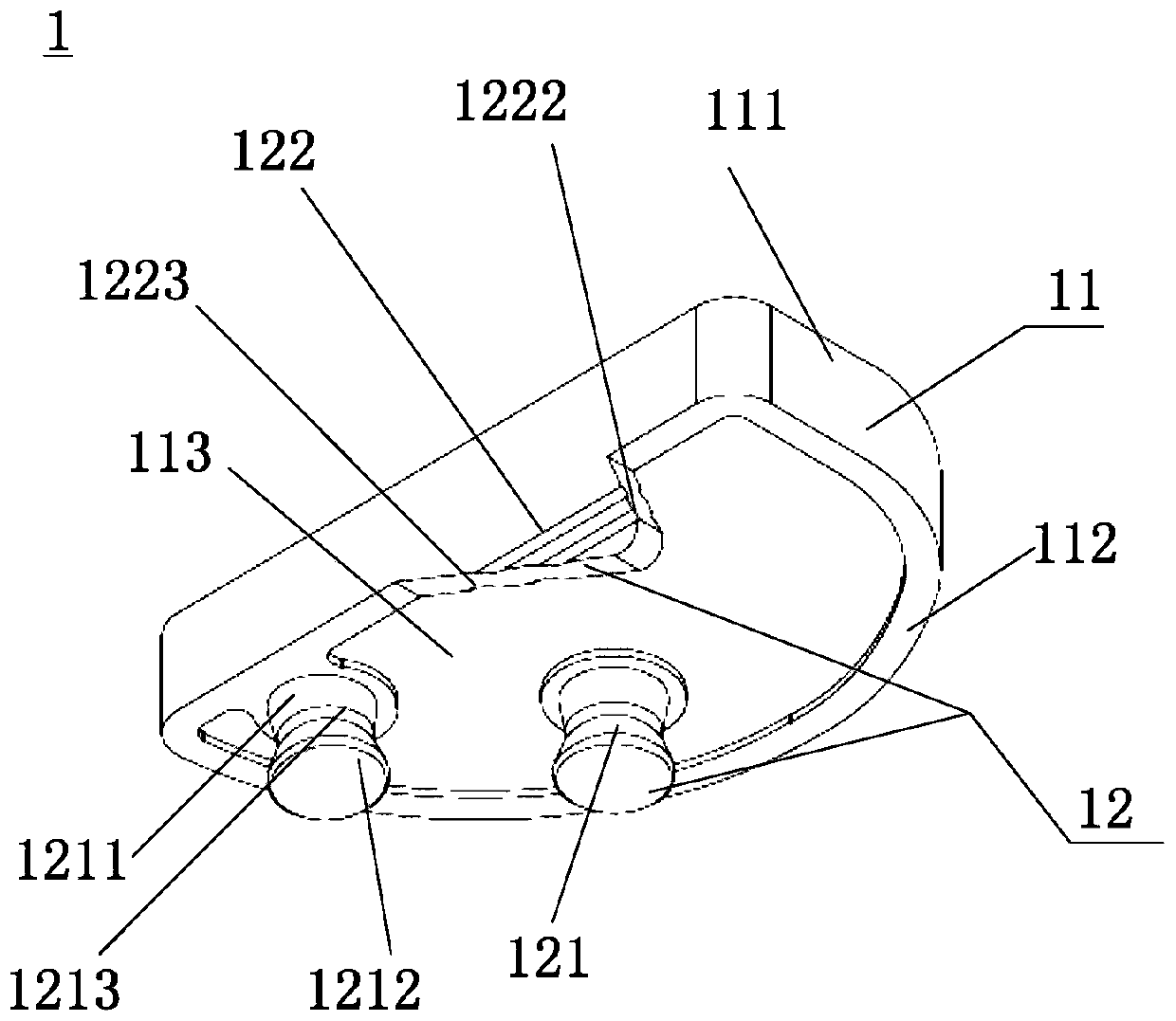

Tibia platform support and single-condyle knee joint applying tibia platform support

PendingCN110786969ASimple structureExtended service lifeJoint implantsKnee jointsKnee JointArthroplasty knee

The invention relates to the field of medical instruments, and discloses a tibia platform support and a single-condyle knee joint applying the tibia platform support. The single-condyle knee joint applying the tibia platform support comprises a first platform part, as well as a connecting part which is fixed on a bottom surface of the first platform part; the connecting part comprises at least onefixed column and at least one panel which are arranged, with interval between, on the bottom surface of the first platform part; and the panel has a tapered width from the bottom surface of the firstplatform part to a direction that is away from the bottom surface. The single-condyle knee joint applying the tibia platform support disclosed by the invention is capable of realizing better fixationwith human bone tissue, so that the single-condyle knee joint has improved stability after a single-condyle knee replacement surgery; and thus, normal kinematics of the knee joint can be ensured.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

Process for improving plating thickness of zinc-nickel-plated low area

ActiveCN109402685AImprove complexation abilityImprove uniformityVacuum evaporation coatingSputtering coatingAlloyBiological activation

The invention belongs to the technical field of metal surface treatment, and particularly relates to a process for improving the plating thickness of a zinc-nickel-plated low area. The process comprises the following steps: pre-treatment, specifically, an alloy workpiece is subjected to de-oiling, hot washing, derusting and cold washing treatment in sequence, and then is subjected to physical activation and chemical activation in sequence; film formation, specifically, magnesium metal is evaporated on the activated alloy workpiece, sealing treatment is carried out, and then the workpiece is immersed in electrolyte for electroplating treatment to obtain a film-coated workpiece; and post-treatment, specifically, the film-coated workpiece is rinsed with clean water, leached with cold water, and dried to obtain the finished alloy workpiece. By using the magnesium metal as a pre-plating, the weight of the plating is greatly reduced, and through simple boiling water sealing and sodium silicate heat sealing treatment, the inertness of the magnesium plating and the corrosion resistance of the plating are improved.

Owner:NINGBO YADA METAL SURFACE TREATMENT

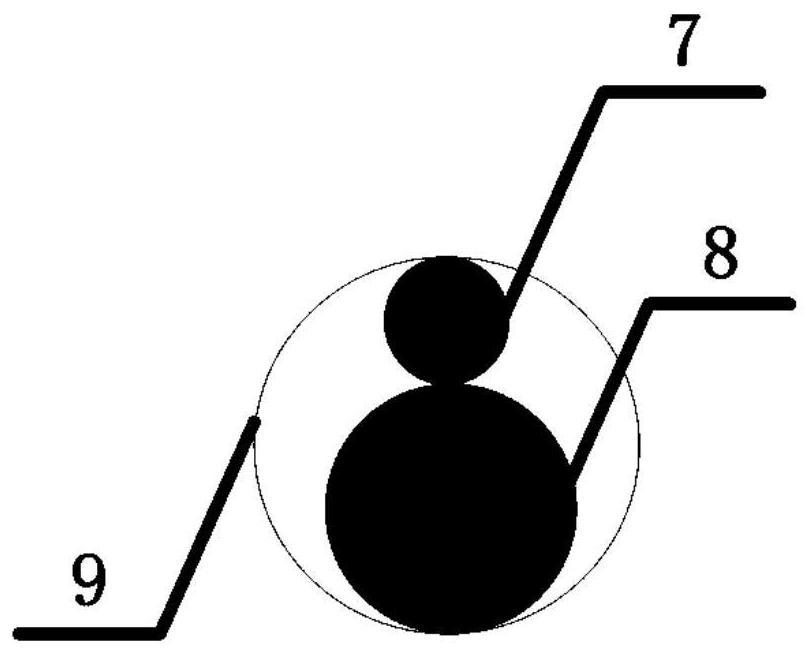

Clamping tool applied to manufacturing of spherical surface curved crystal and manufacturing method

ActiveCN109702909ACoaxial Consistency GuaranteeGuaranteed Optical ResolutionWorking accessoriesFine working devicesMicrometerEngineering

The invention relates to a clamping tool applied to manufacturing of a spherical surface curved crystal and a manufacturing method. The clamping tool comprises a sleeve assembly, an external metal clamping piece and a micrometer caliper, wherein the external metal clamping piece is of a half frame structure, the sleeve assembly is clamped in a half frame of the external metal clamping piece, and the micrometer caliper is connected with the sleeve assembly; and the sleeve assembly comprises a metal sleeve, a metal base, a metal pressing block and a metal cushion block, wherein the metal sleeveis used for containing a spherical base and a crystal material, the metal sleeve is connected with a metal air suction nozzle, the metal base and the metal pressing block are arranged at the two endsof the metal sleeve and are in contact with the spherical base, and the metal cushion block is arranged between the metal pressing block and the external metal clamping piece and is connected with themicrometer caliper. Compared with the prior art, the clamping tool and the manufacturing method have the advantages of being simple, reliable, low in cost and the like, and the optical resolution ofa final optical element is ensured.

Owner:TONGJI UNIV

Solar-powered aircraft wing and manufacturing method thereof

ActiveCN106379516BGood conformabilityImprove surface smoothnessFinal product manufactureWingsHigh surfaceSolar cell

The invention discloses a solar-powered airplane wing and a manufacturing method thereof. The solar-powered airplane wing comprises a wing framework and a flexible solar cell module, wherein the middle part of the upper surface of the wing framework is provided with a groove; the flexible solar cell module comprises a packaging skin and an assembly framework arranged on the lower surface of the packaging skin; the assembly framework is arranged in the groove; the packaging skin extends outwards along the two sides of the wing framework in the spanwise direction to form a coating side; and the coating side is coated on the wing framework. The manufacturing method comprises the following steps: S1: preparing the wing framework; S2: preparing the flexible solar cell module; and S3: assembling. The solar-powered airplane wing has the advantages of favorable conformal effects between the solar cell module and wing framework, high surface smoothness, excellent aerodynamic performance, light weight and the like. The preparation method has the advantages of convenient assembly, weight reduction and favorable reliability.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

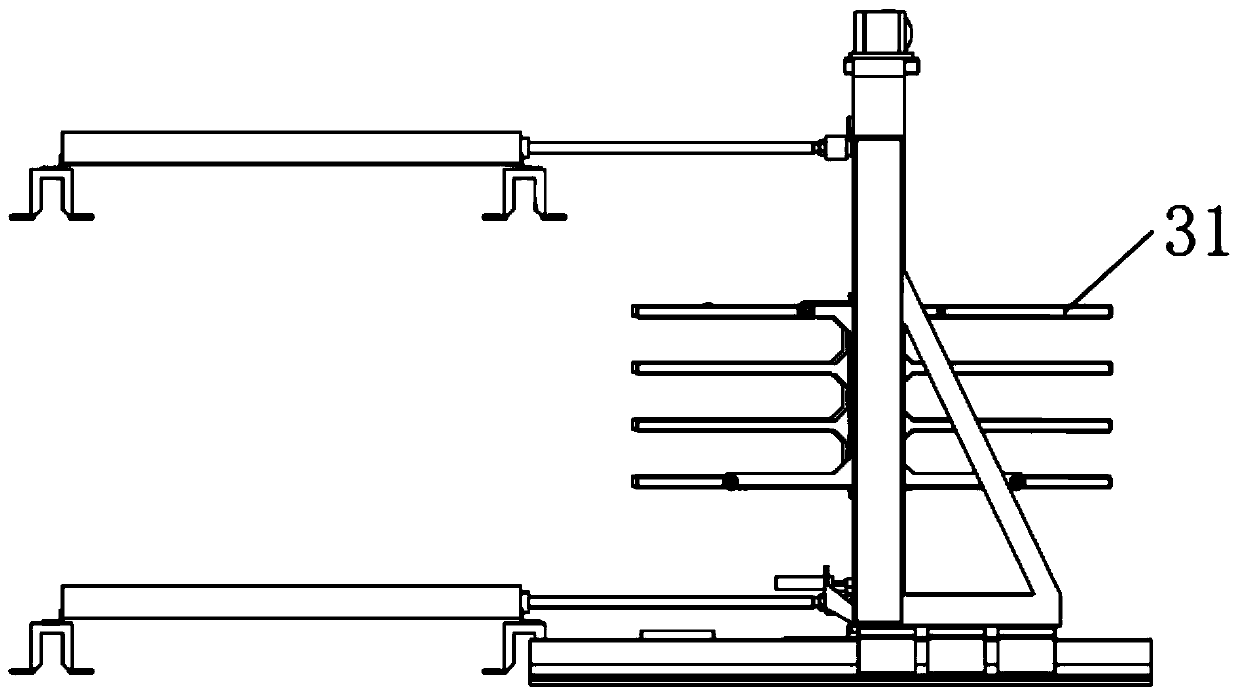

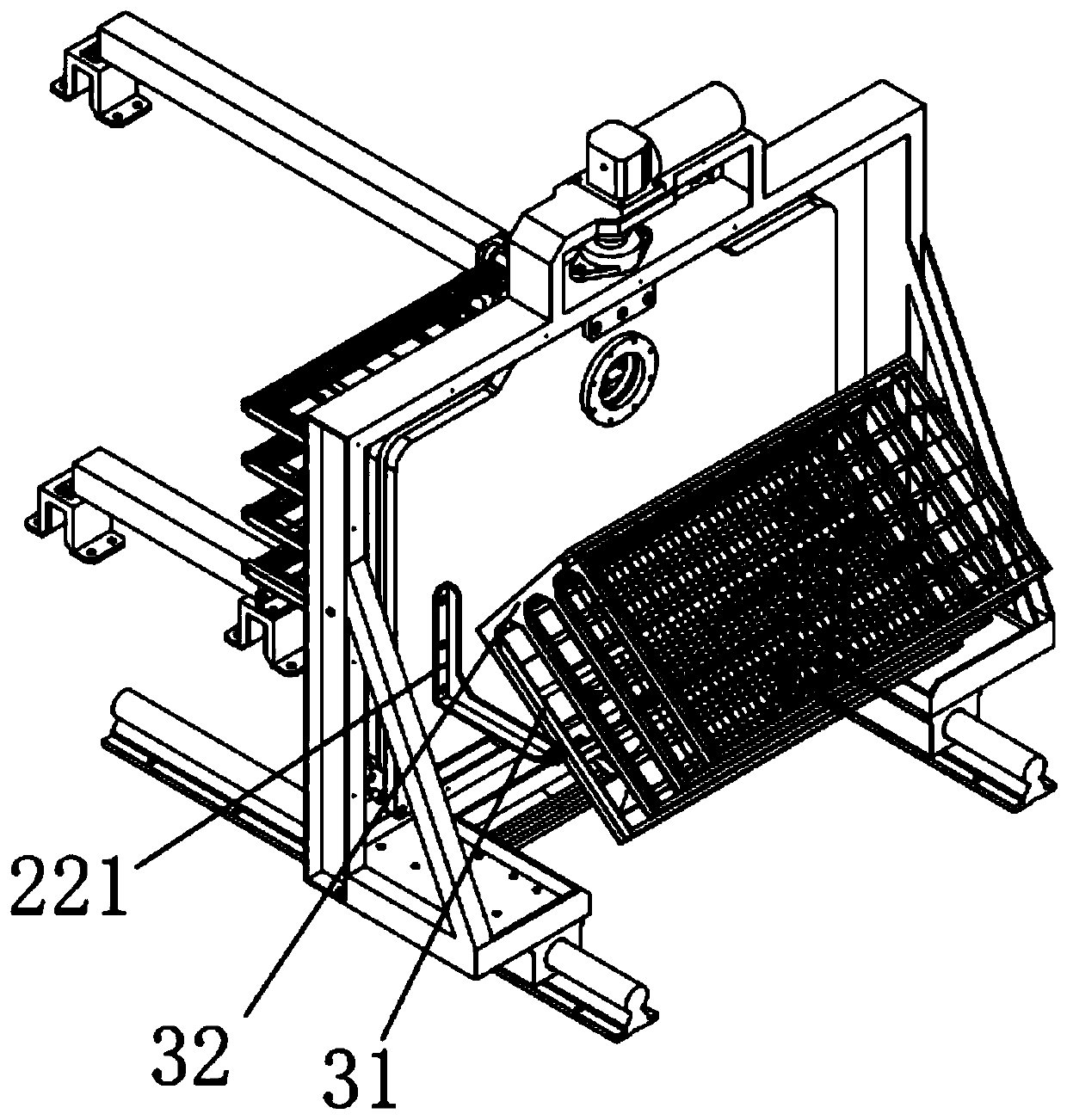

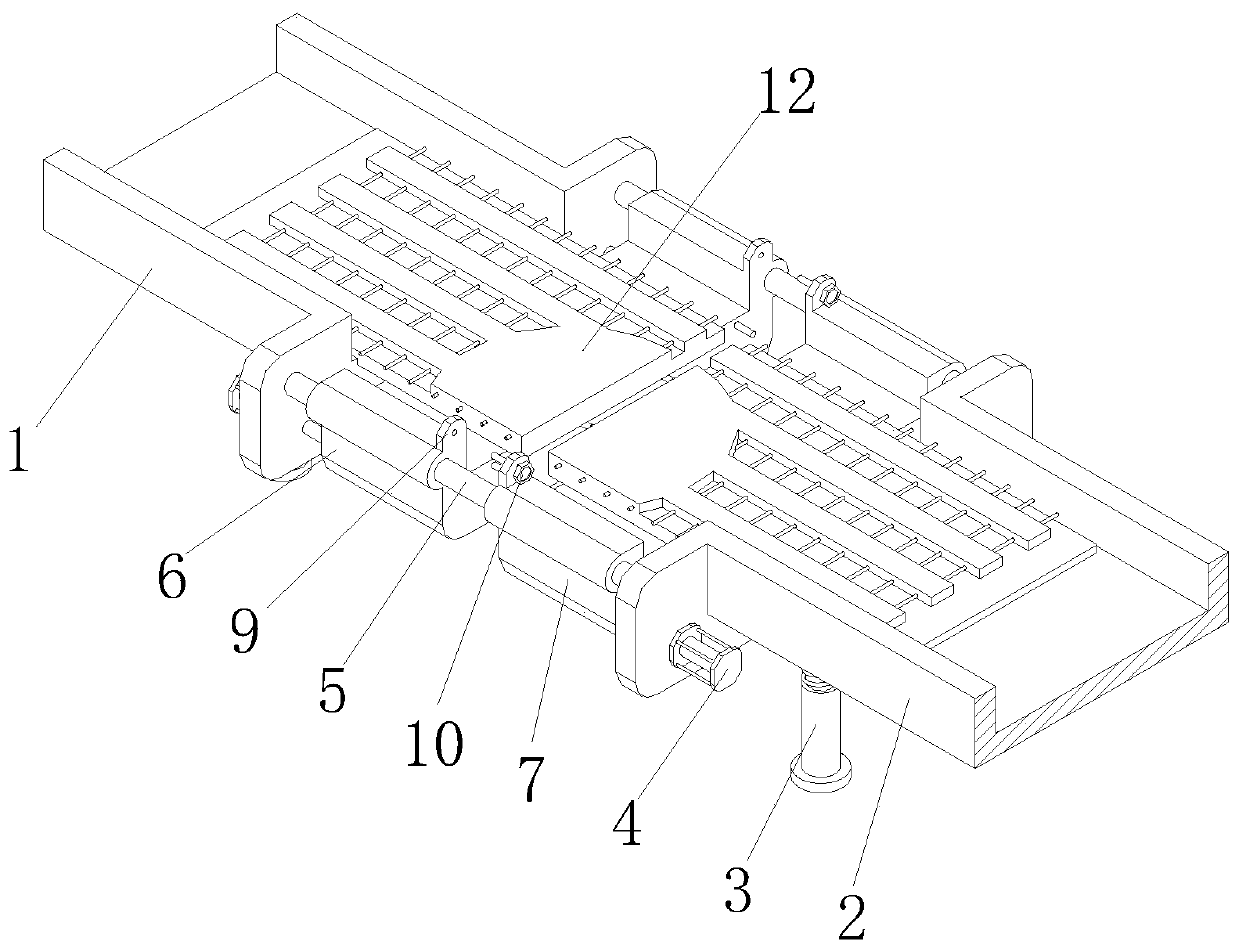

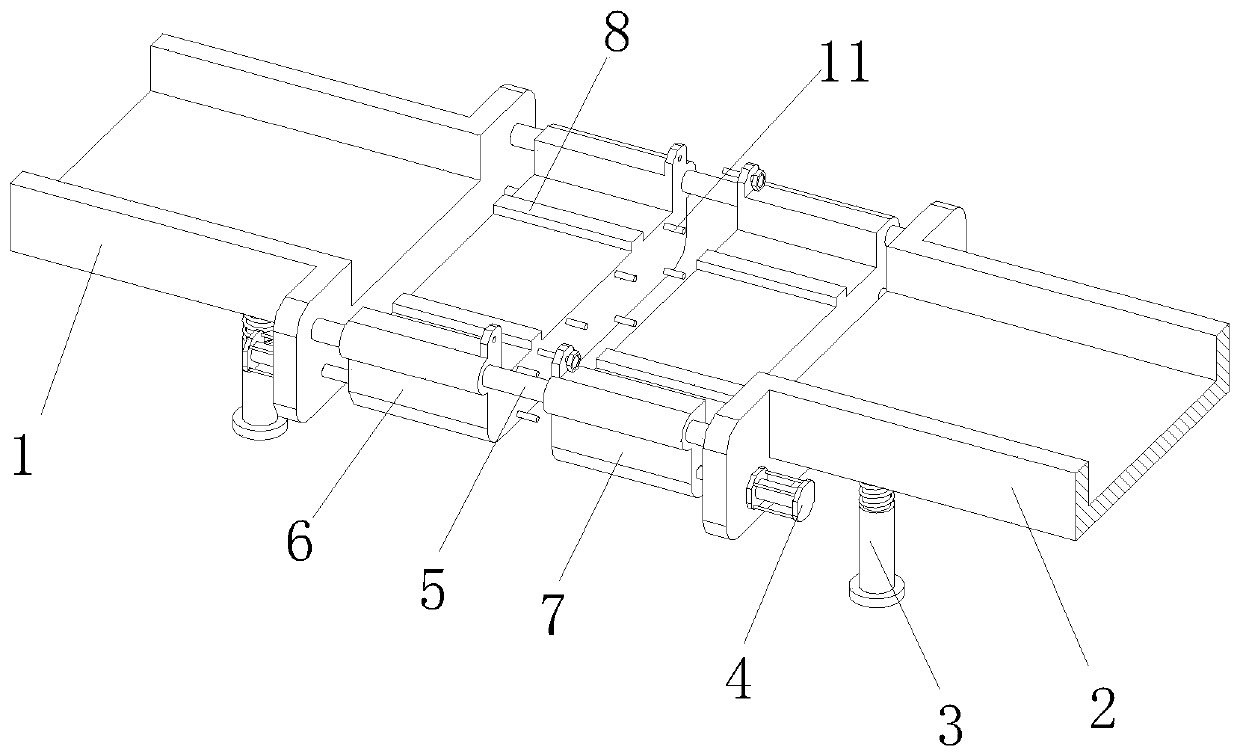

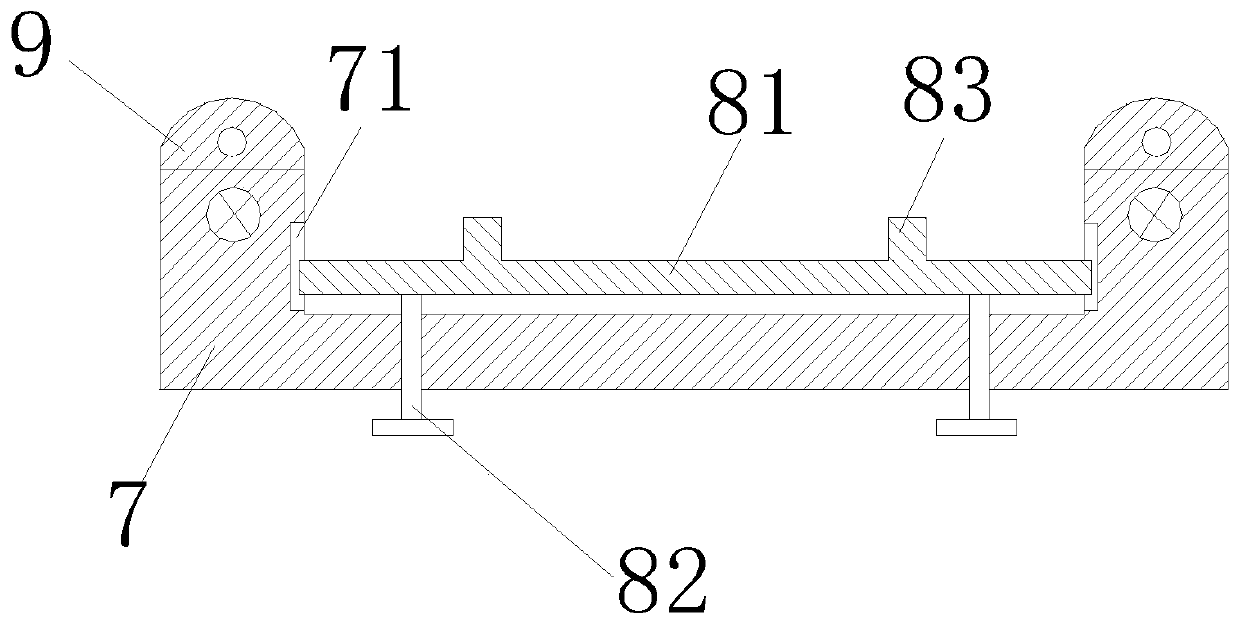

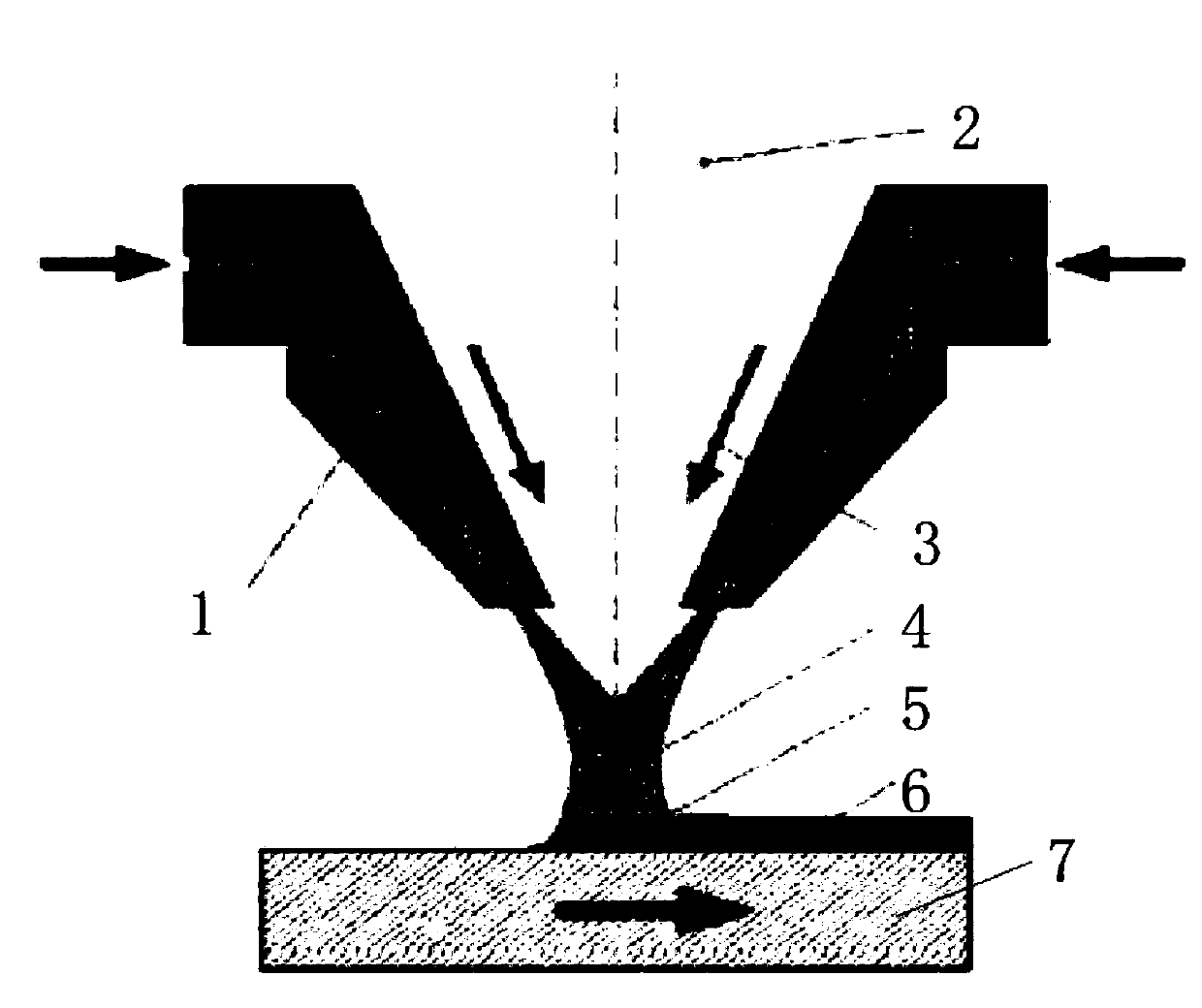

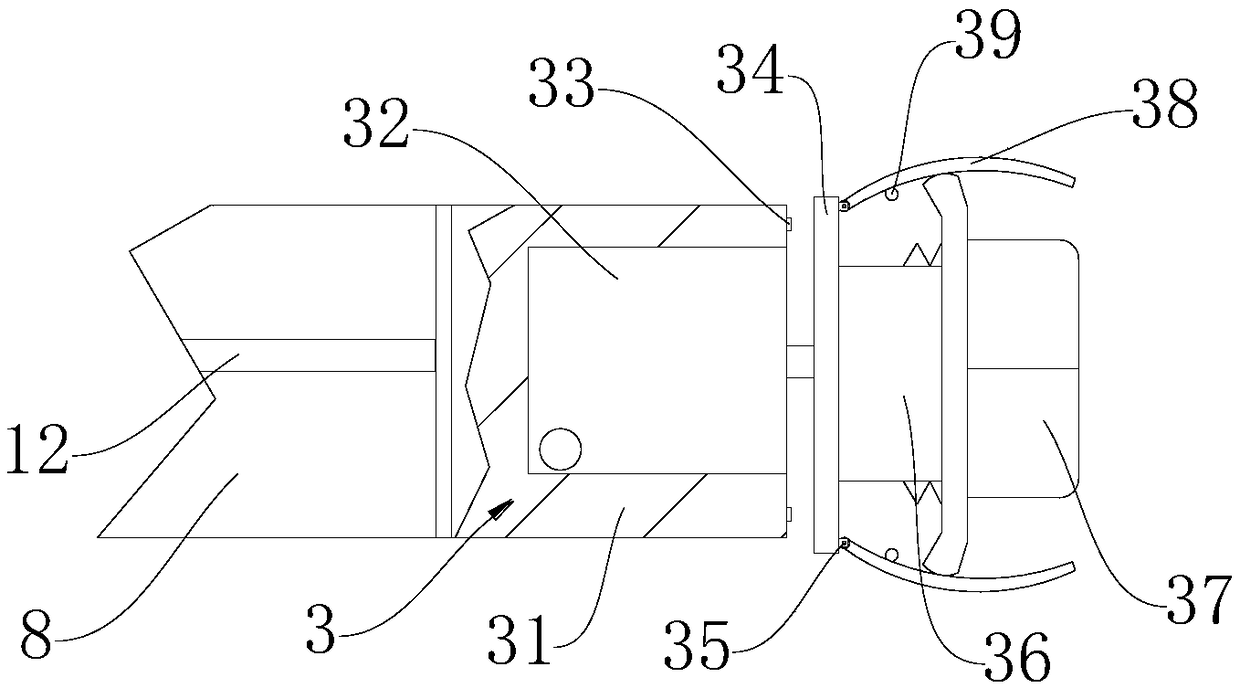

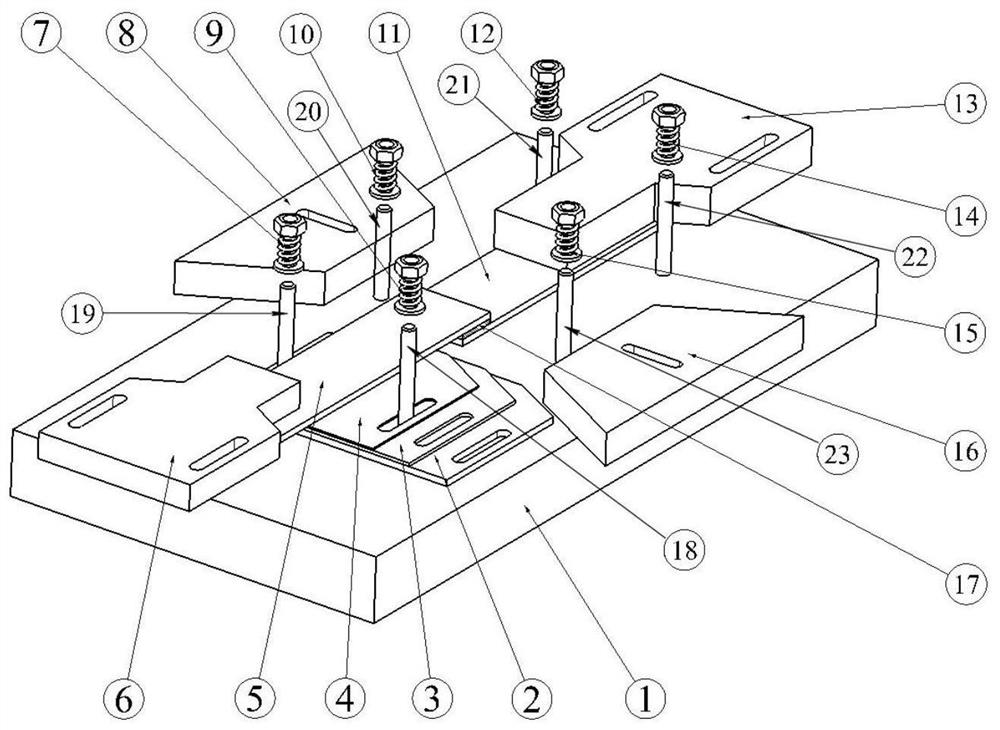

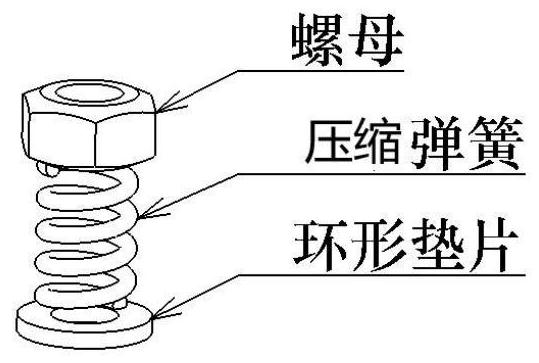

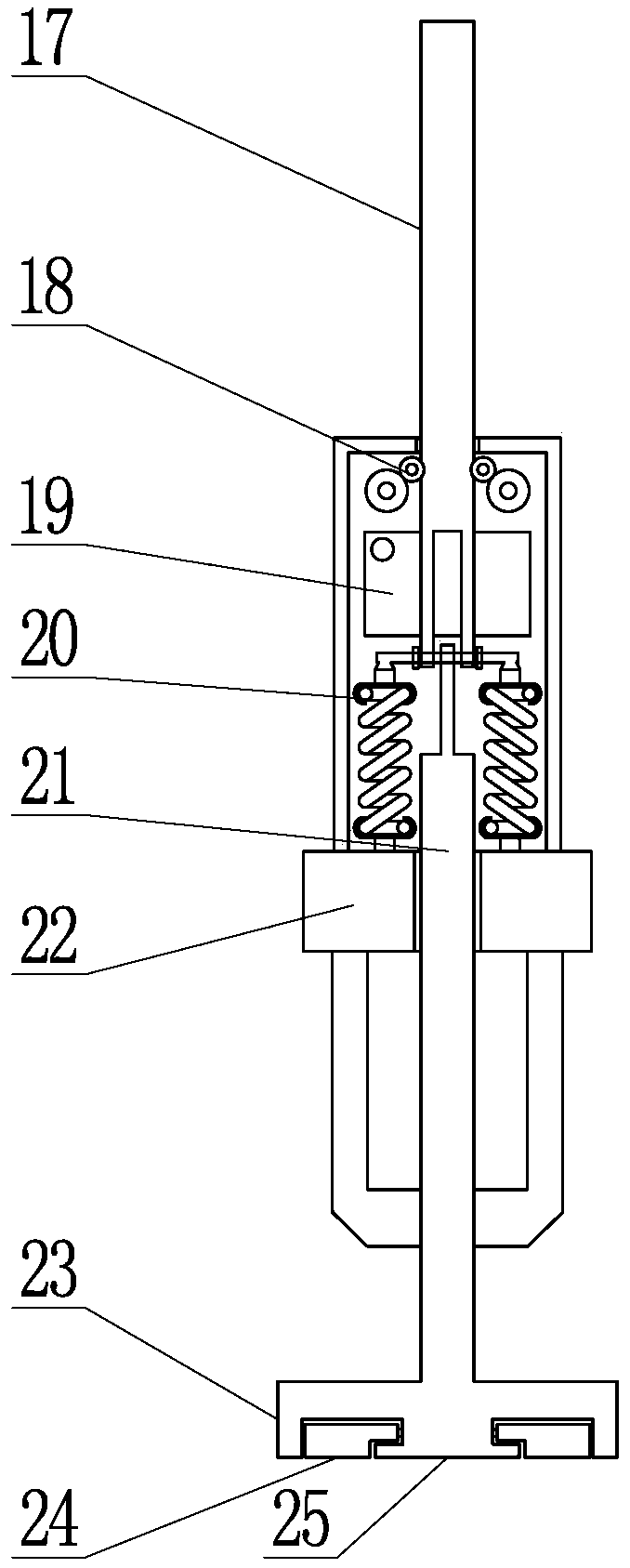

Mold fitting device and method for splicing joints of prestressed ribbed superimposed sheets

ActiveCN110206299AGuaranteed perfect fitConvenient patchwork butt jointForms/shuttering/falseworksEngineeringSplice joint

The invention relates to the technical field of building construction, in particular to a mold fitting device for splicing joints of prestressed ribbed superimposed sheets. The mold fitting device includes a first frame plate and a second frame plate, a plurality of supporting bases are fixedly installed at the bottoms of the first frame plate and the second frame plate, two mutually symmetrical guide rods are arranged between the first frame plate and the second frame plate, a first mold plate is arranged at the end, on the first frame plate, of the guide rods, a second mold plate is arrangedat the end, on the second frame plate, of the guide rods, telescopic air cylinders are fixedly and correspondingly installed on both sides of the bottom ends of the first frame plate and the second frame plate, the first mold plate and the second mold plate are provided with butt mechanisms correspondingly, the butt mechanisms are fixedly connected with the first frame plate and the second frameplate correspondingly, and the superimposed sheets are placed at the top ends of the butt mechanisms correspondingly. The mold fitting device has the advantages that mold fitting of the splicing joints of the superimposed sheets is more easy and accurate, thus the working efficiency is greatly improved, and the practical applicability is high.

Owner:CHINA MCC17 GRP

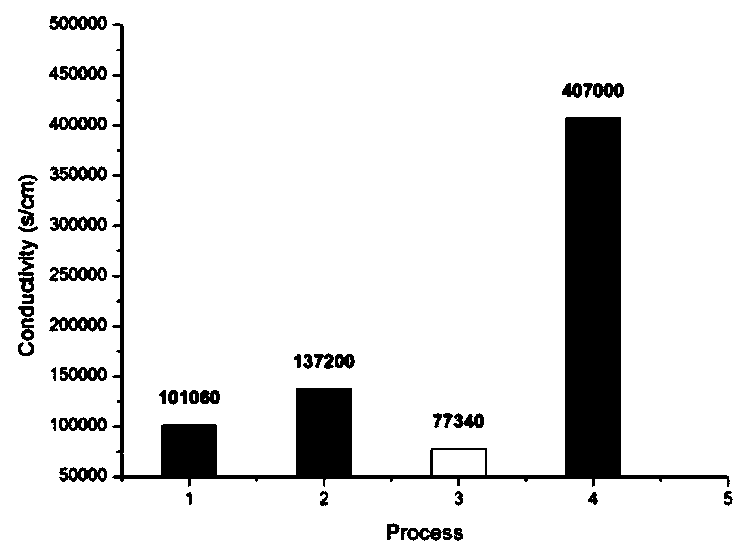

High-wear-resistant conductive strong-bonding coating and preparation method thereof

InactiveCN110791754AIncrease profitLow thermal conductivityMetallic material coating processesSurface engineeringConductive materials

The invention discloses a high-wear-resistant conductive strong-bonding coating and a preparation method thereof, and belongs to the technical field of surface engineering. According to the coating and the preparation method thereof, a transition layer is creatively arranged between the surface of a copper and / or aluminum substrate and a nickel-silver alloy layer in a metallurgical bonding mode, the transition layer has the effects of improving the laser absorptivity, reducing the thermal conductivity of the substrate and decreasing the dilution rate, perfect bonding between the transition layer and the high-wear-resistant nickel-silver alloy layer can be guaranteed, formation of the high-wear-resistant coating and a coating product which are free of surface cracks and are metallurgicallybonded on the surface of the copper and / or aluminum substrate is improved, the problem that a layer of nickel-silver alloy coating which is metallurgically bonded with the the substrate and has high bonding strength, high surface wear resistance and good conductivity is prepared on the surface of a copper or aluminum substrate can be solved, the service life of conductive materials such as copperand aluminum is prolonged, and it is guaranteed that under the condition that the nickel-silver alloy coating and the substrate are metallurgically bonded, efficient green processing, zero emission oftoxic and harmful substances and high material utilization rate can be realized in the production process.

Owner:XI AN JIAOTONG UNIV

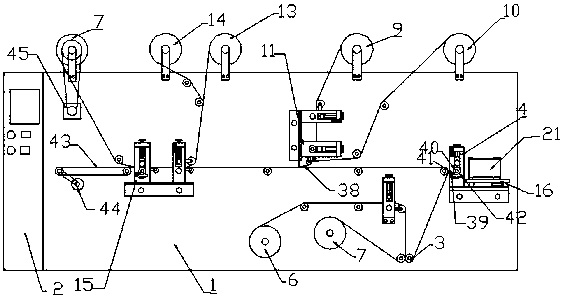

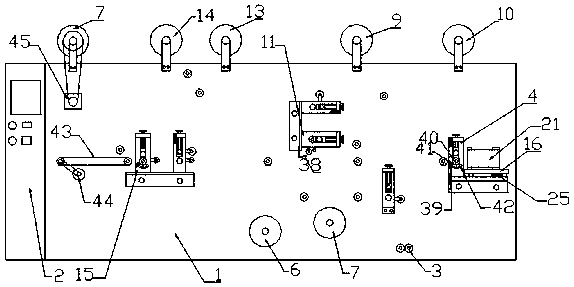

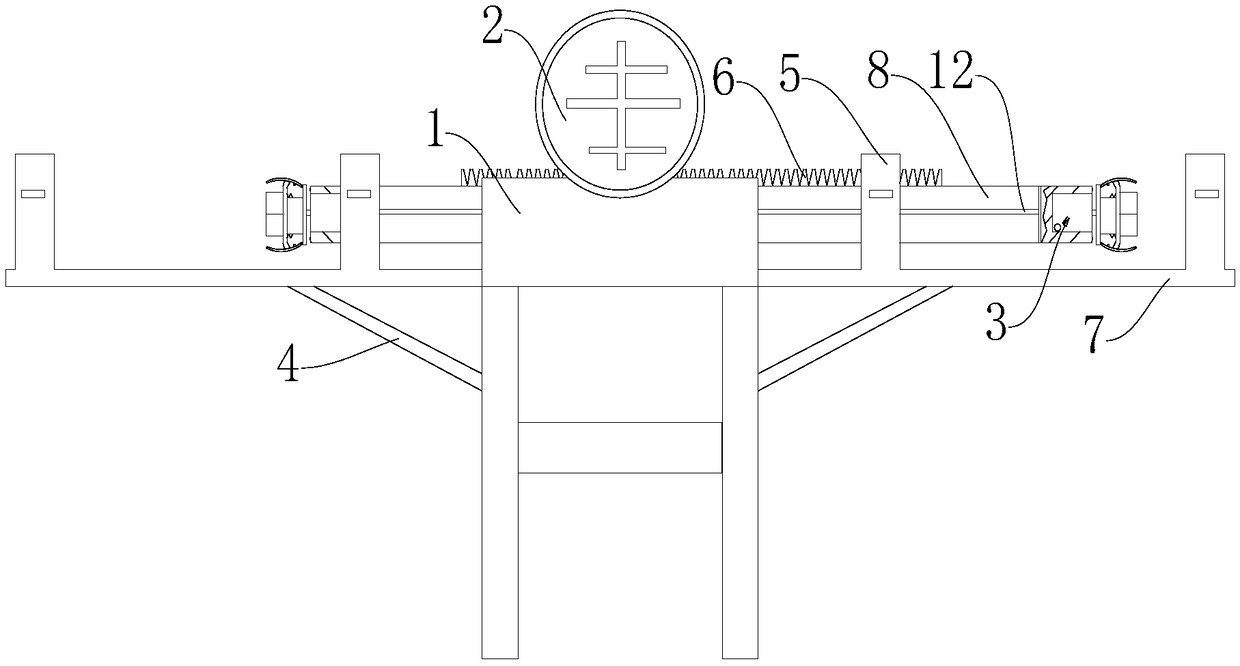

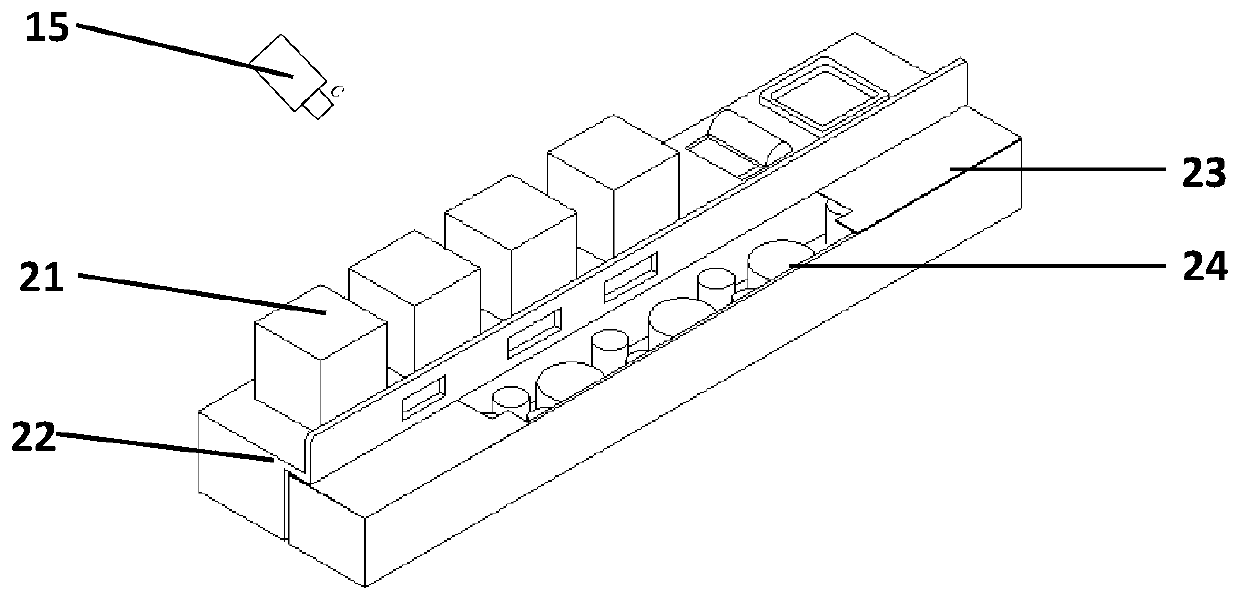

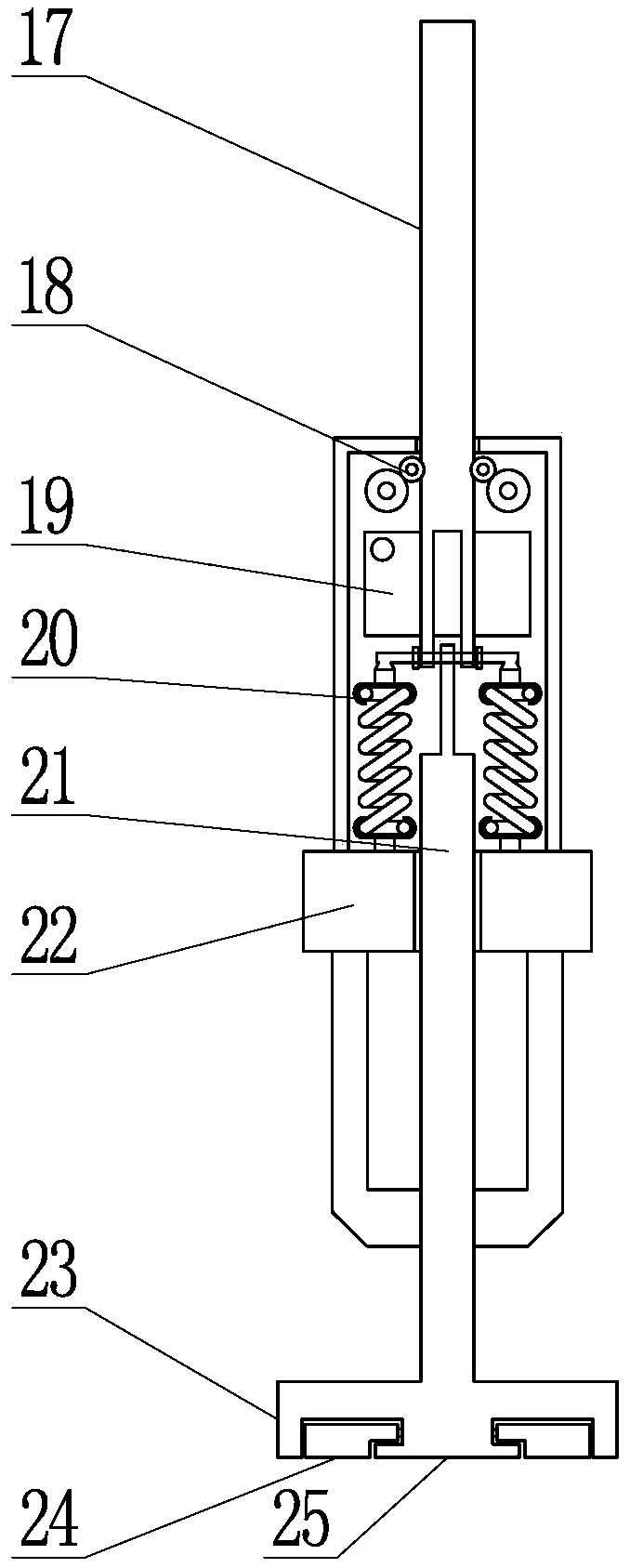

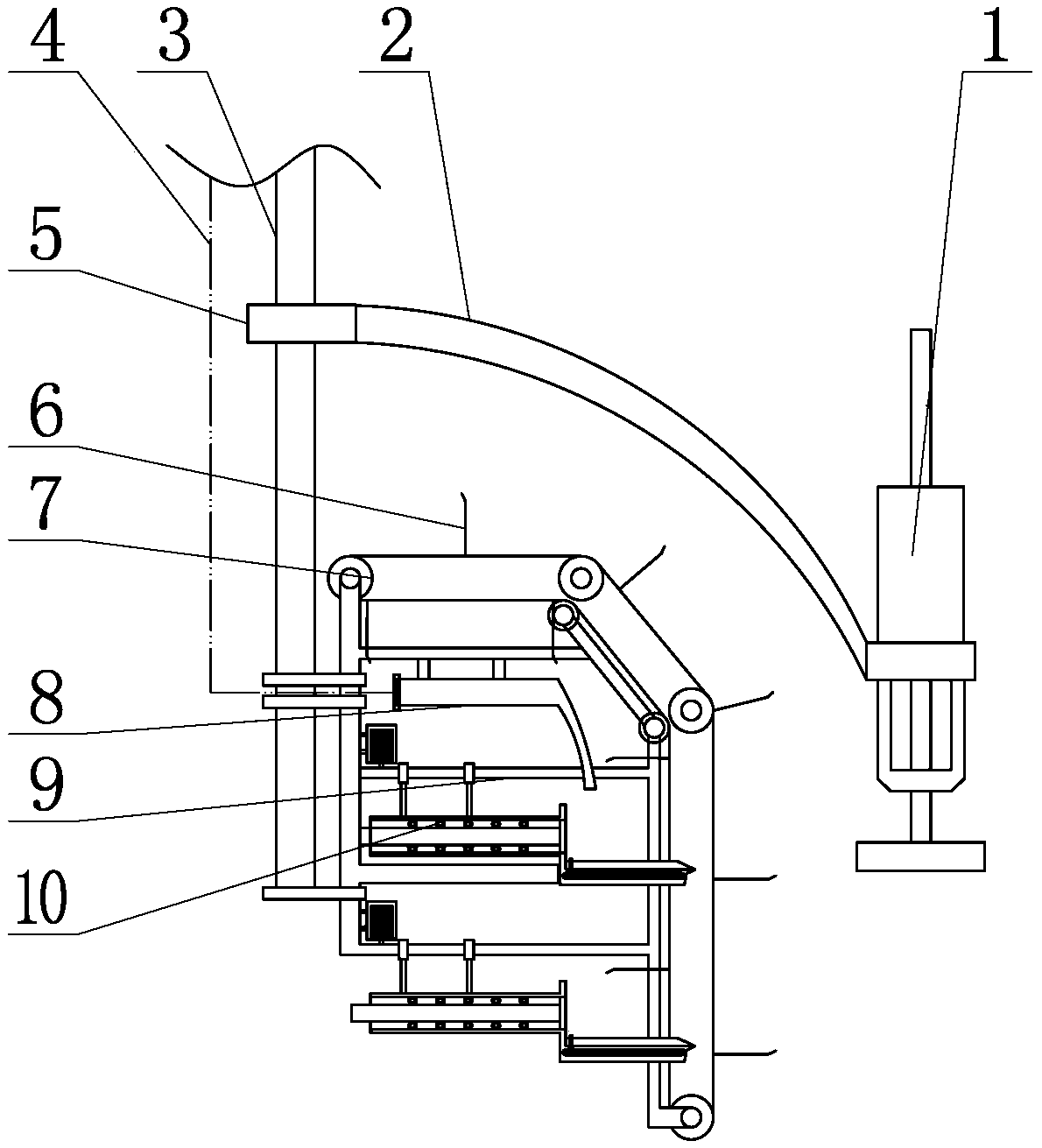

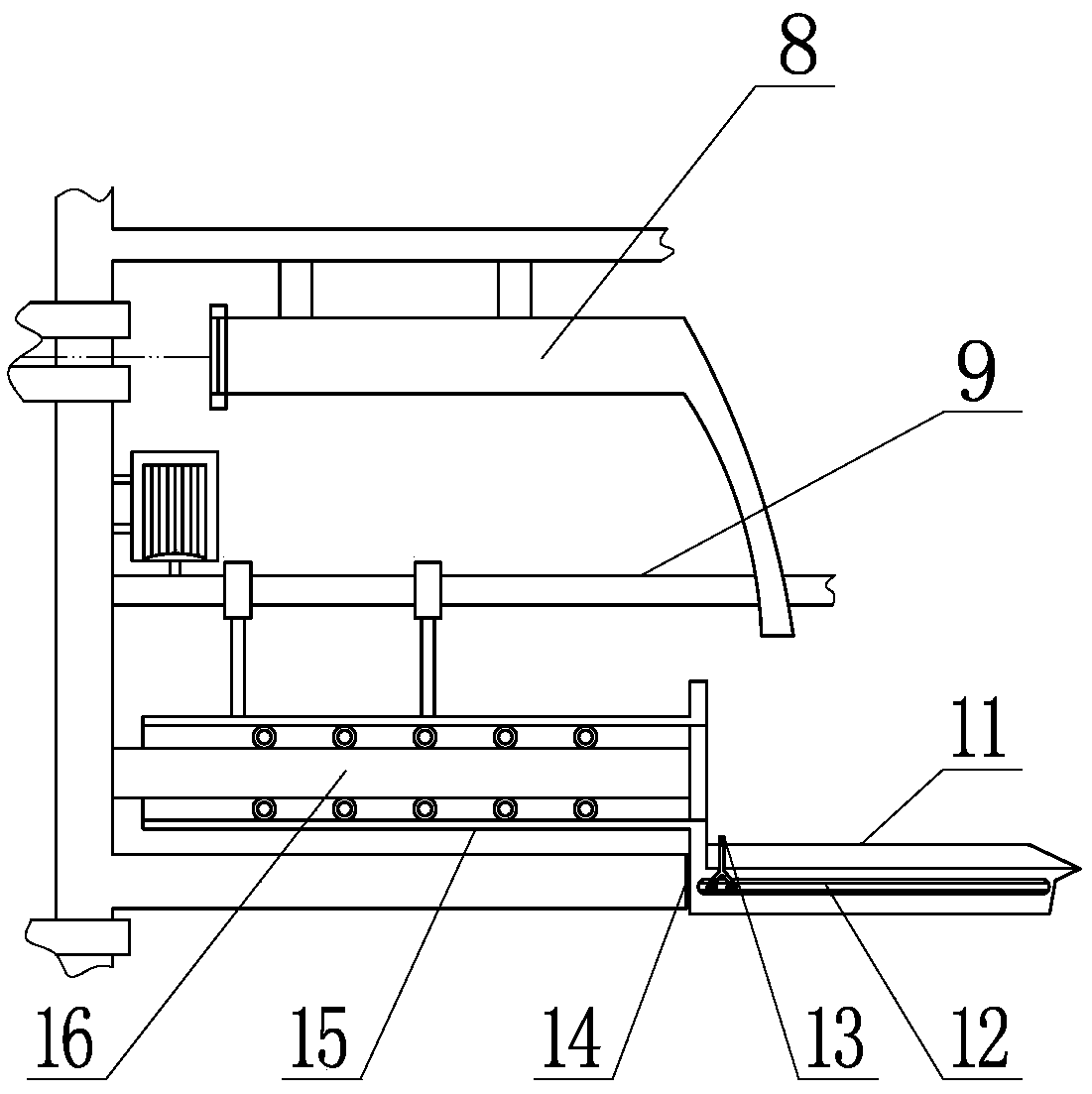

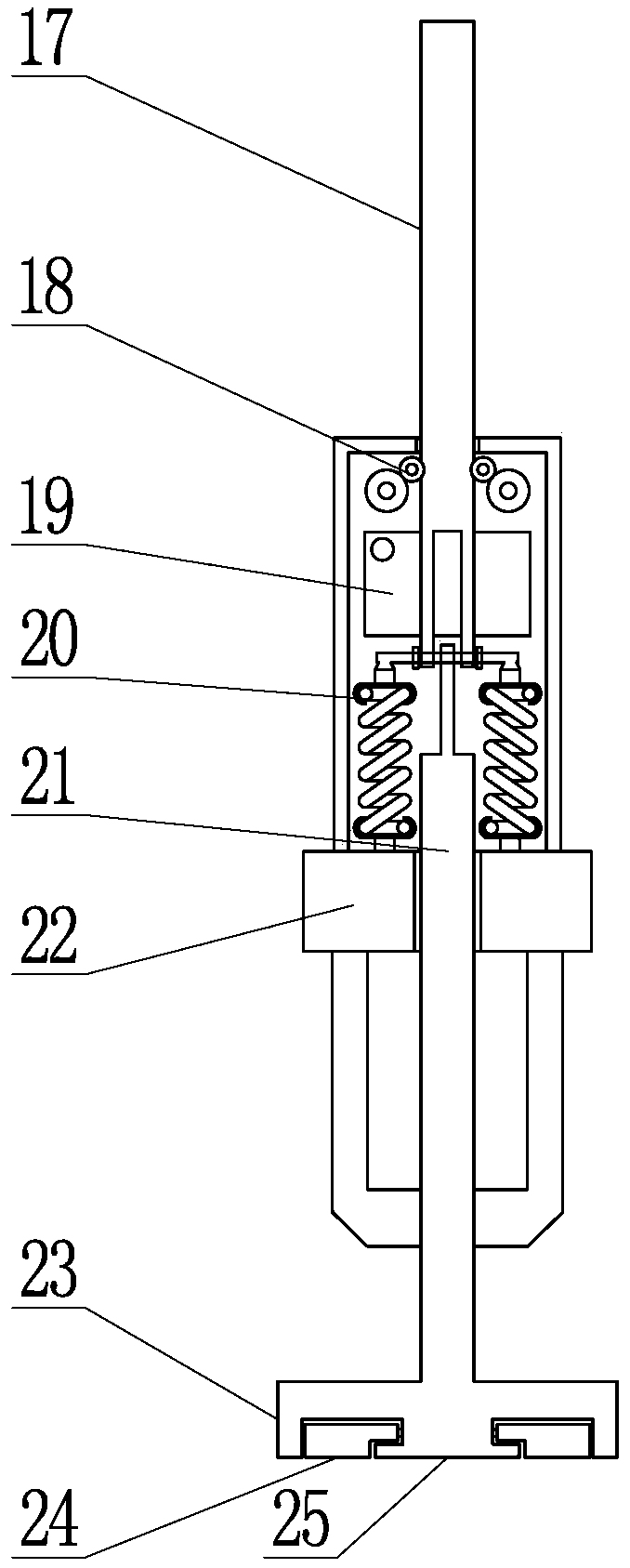

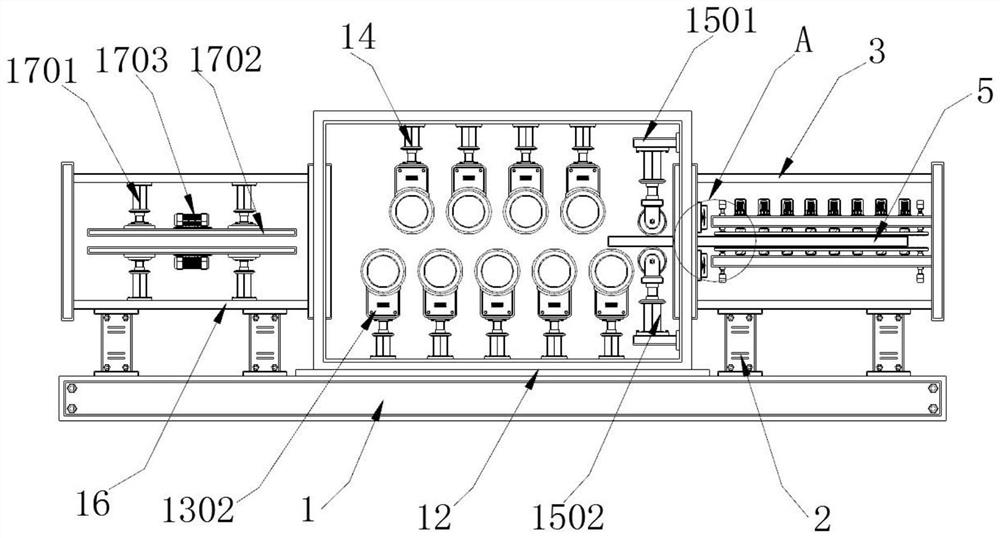

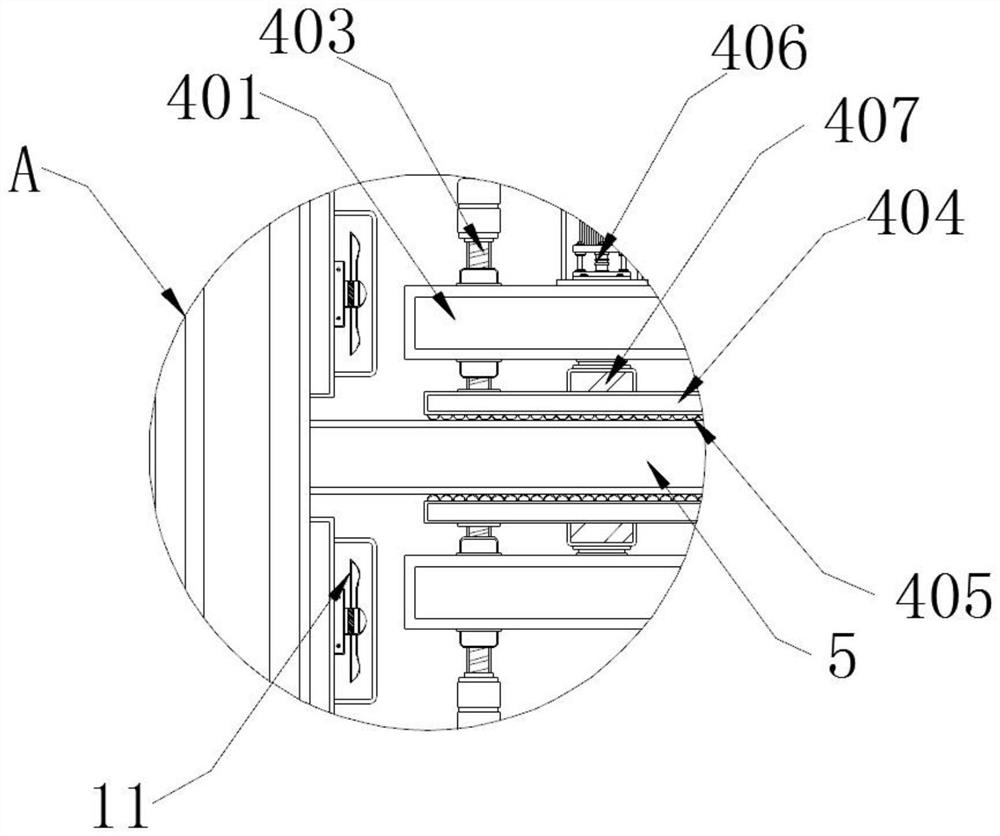

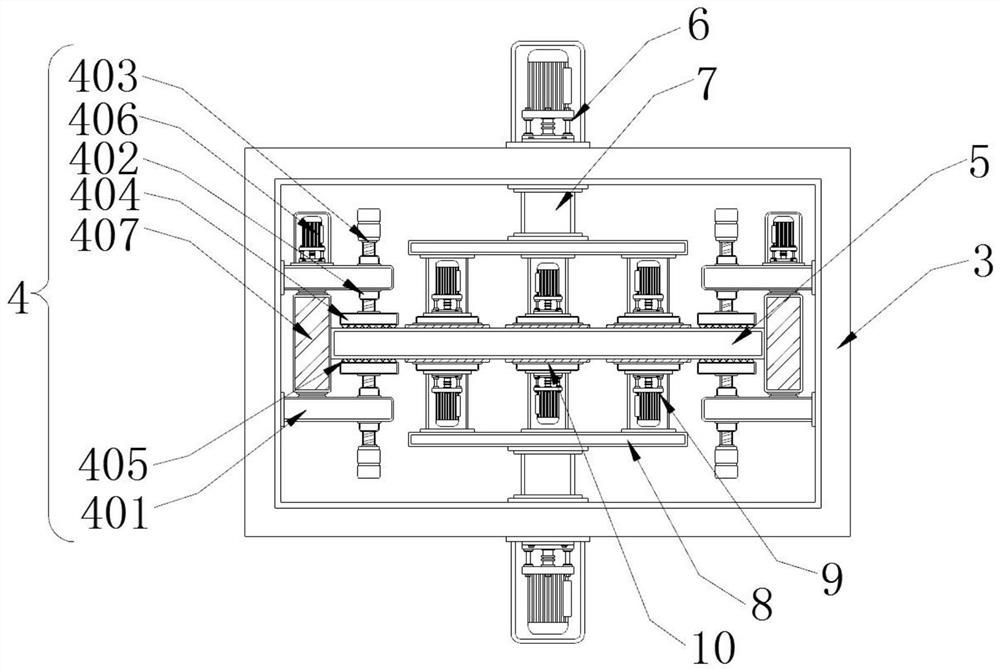

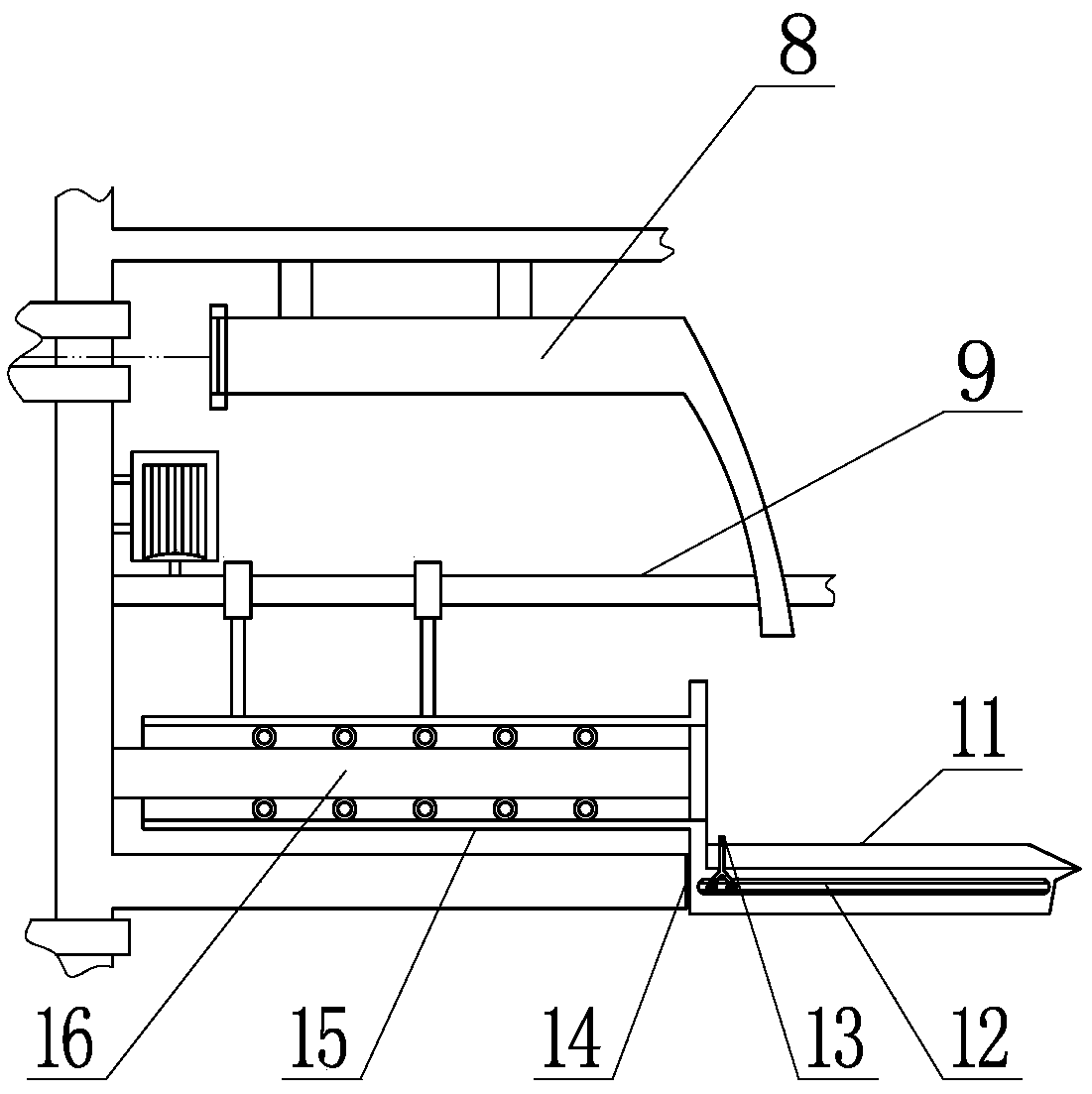

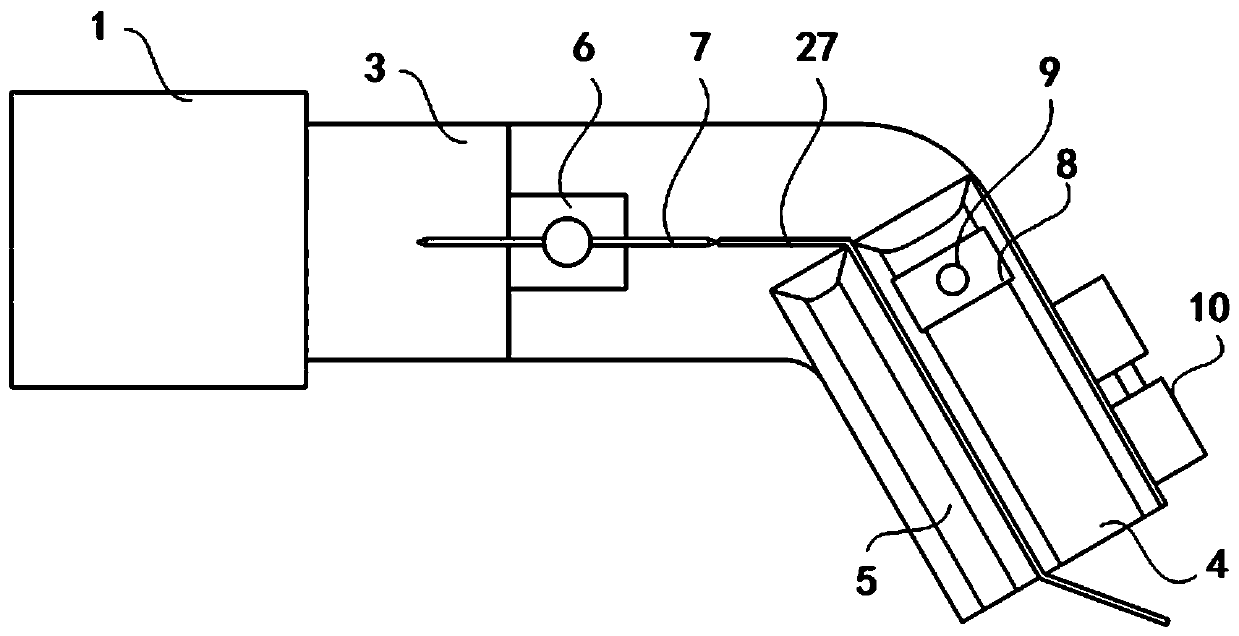

Anorectal patch composite forming machine

ActiveCN109925123AIncrease productivityGuaranteed perfect fitAdhesive dressingsEngineeringTherapeutic effect

The invention discloses an anorectal patch composite forming machine comprising a frame. The frame comprises a cotton processing zone, a base laying zone and a fitting shearing zone. The cotton processing zone is provided with a cotton shearing machine and a transmission motor. The base laying zone comprises a base discharging roller and a scrap recycling roller, wherein the fitting shearing zoneis provided with a first shearing machine, a first discharging roller, a second discharging roller and a second shearing machine. Raw materials on each layer are laid by layers, and finally the rapidformation of the haemorrhoid patch can be achieved in the one-step press fit mode by the shearing machine. At the same time, the consistency between the layers is ensured to avoid the misalignment. Ashaping frame ensures the consistency of the central ridge of the patch and improves the forming effect, so that the therapeutic effect of the patch is improved.

Owner:四川艾医生医疗科技有限公司

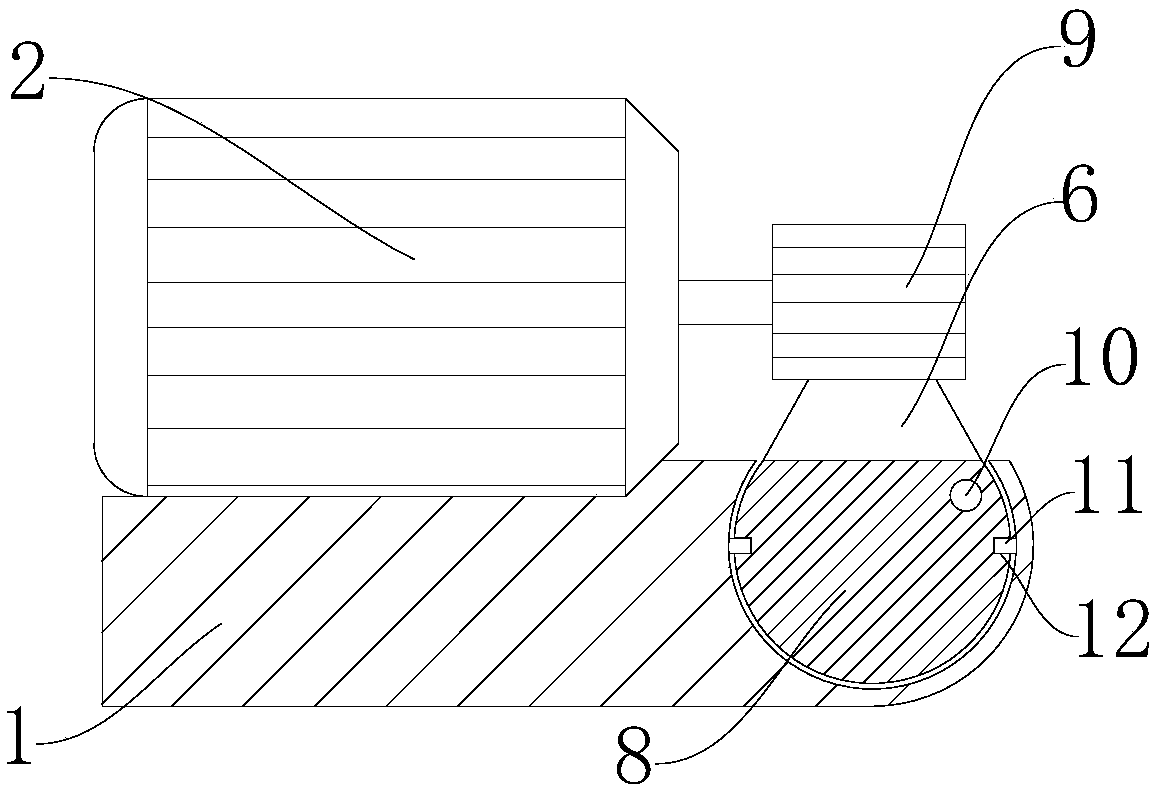

Plastic pipeline inner wall reprocessing device

InactiveCN108788957ASimple structureImprove efficiencyRevolution surface grinding machinesGrinding drivesEngineeringMotor drive

The invention discloses a plastic pipeline inner wall reprocessing device which comprises a base. A motor is arranged at the top end of the base. A drive gear is arranged at the output end of the motor. A processing rod is arranged inside the base and penetrates through the left end and the right end of the base. A high-pressure air pipe is arranged inside the processing rod and penetrates throughthe processing rod. A rack is arranged on the upper surface of the middle section of the processing rod and engaged with the drive gear. Limiting grooves are formed in the front and rear side faces of the processing rod; limiting blocks are arranged at the positions, opposite to the limiting grooves, of the interior of the base; the limiting blocks and the limiting grooves are matched; and processing heads are arranged at the left end and the right end of the processing rod. When the plastic pipeline inner wall reprocessing device is used, a plastic pipeline needing to be processed is horizontally put on a plastic pipeline support, the left end and the right end of the plastic pipeline are clamped by plastic pipeline clamps, and therefore the plastic pipeline can be fixed relative to theplastic pipeline support, then the motor drives the drive gear to slightly rotate, the drive gear and the rack are engaged to transmit power to the rack, and the plastic pipeline inner wall reprocessing device is simple in structure and high in efficiency.

Owner:东至县科创塑料制品有限公司

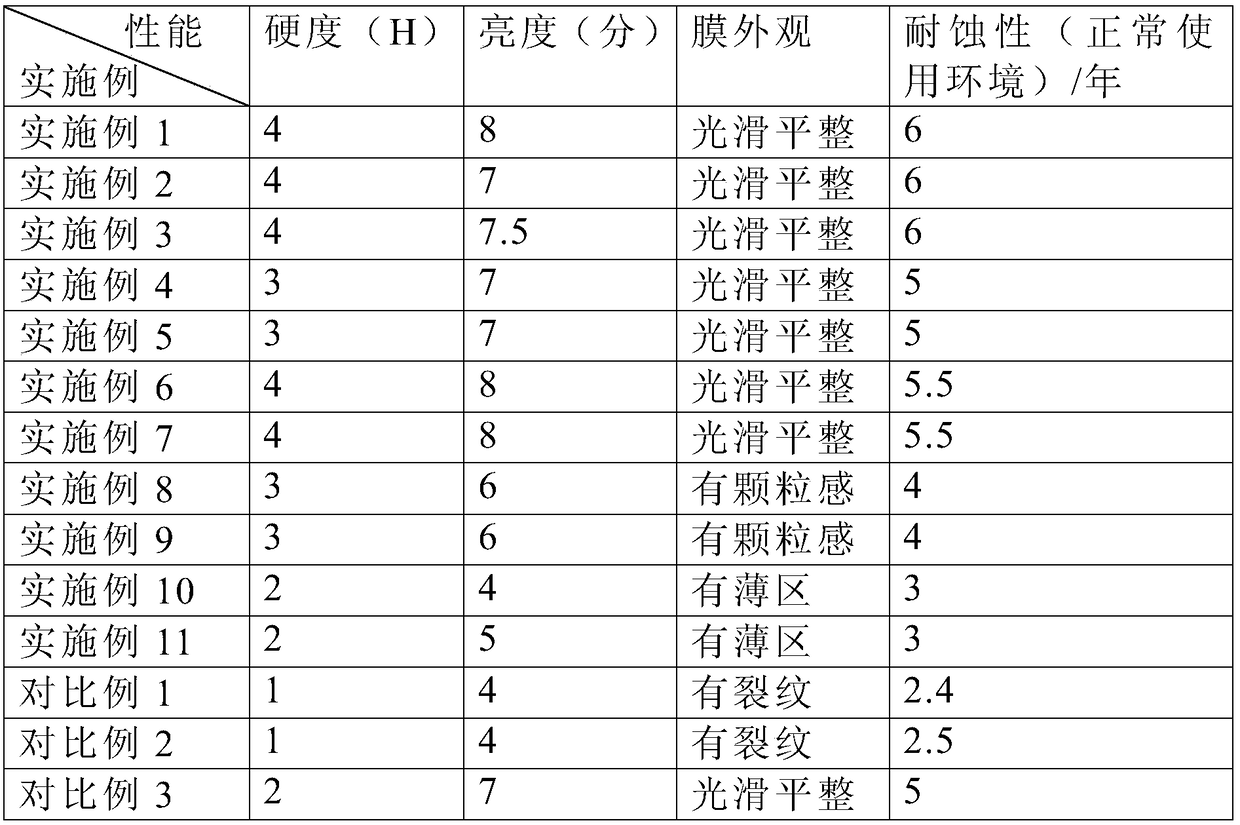

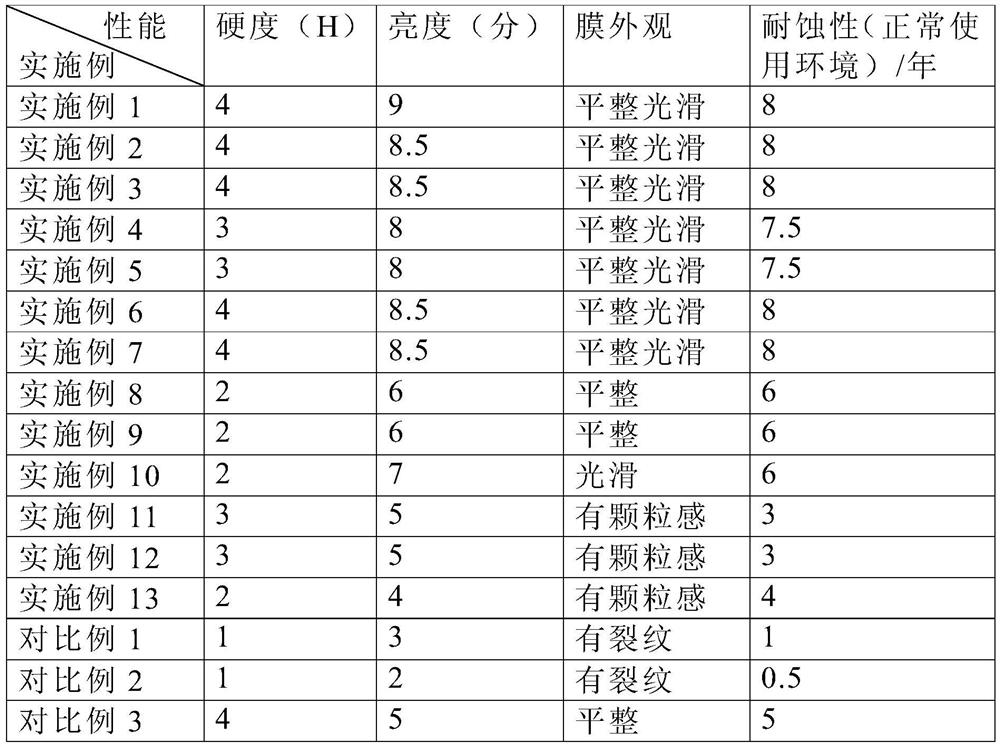

Electrophoresis process after galvanizing

ActiveCN109055880BNo anodic dissolutionImprove anti-corrosion performanceHot-dipping/immersion processesElectrolytic coatingsElectrolytic agentElectrophoreses

The invention belongs to the technical field of metal surface processing, an particularly relates to an electrophoresis technology after galvanizing. The electrophoresis technology comprises the following steps that pre-processing is conducted, specifically, an alloy workpiece is sequentially subjected to oil removing, hot washing, rust removing and cold washing, and is subjected to physical activation and chemical activation; mold manufacturing is conducted, specifically, the alloy workpiece after activation is subjected to galvanization and phosphorization, and then is immersed in phosphorization to conduct anodic electrophoresis processing to obtain mold workpiece; and post-processing is conducted, specifically, the mold workpiece is subjected to clean water washing, cold washing and drying to obtain an alloy workpiece finished product. When an electrophoresis coating is formed at the alloy workpiece, the workpiece is cathode, and anodic dissolution does not occur, and therefore theworkpiece surface and a phosphating film can be protected from being damaged. The alloy workpiece surface is subjected to galvanization and phosphorization, and then the electrophoresis coating is applied, and therefore the metal can be protected. The paint is of high price and high quality, the anti-corrosion performance is high, the weather-proof performance is high, and the environmental protection performance is high.

Owner:NINGBO YADA METAL SURFACE TREATMENT

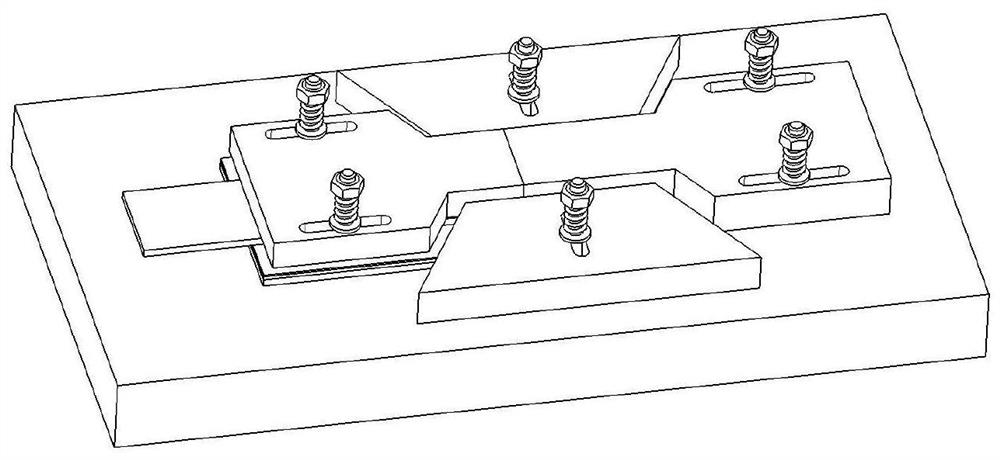

Device and method for preparing bonding test sample piece

PendingCN111829855ASimple structureImprove manufacturabilityPreparing sample for investigationUsing mechanical meansTest sampleStructural engineering

The invention discloses a device and a method for preparing a bonding test sample piece, which can accurately control coaxiality, the adhesive layer width and thickness of a bonding test piece and manufacture a standard bonding test sample piece. The device comprises a base, wherein a first transverse limiting block, a second transverse limiting block, a first longitudinal limiting block and a second longitudinal limiting block are arranged on the base, the first transverse limiting block and the second transverse limiting block are used for limiting transverse positions of the upper test piece and the lower test piece, the second longitudinal limiting block is used for pressing the lower test piece and longitudinally positioning the upper test piece, the first longitudinal limiting blockis used for pressing the upper test piece and the bonding position of the upper test piece and the lower test piece, at least one positioning cushion block is cushioned below the longitudinal limitingblock I, the total thickness of the positioning cushion block is equal to the sum of the thicknesses of adhesive layers at the bonding positions of the longitudinal limiting block II and the bondingtest sample, and one end, corresponding to the lower test piece, of the positioning cushion block is a positioning surface and is used for being matched with the end surface of the lower test piece tolongitudinally position the lower test piece.

Owner:重庆恩斯特龙通用航空技术研究院有限公司

A ground test launch control system monitoring platform and monitoring method

ActiveCN108873777BReduce the number of peopleGuaranteed perfect fitProgramme controlComputer controlDisplay deviceCable net

The invention relates to a platform and method for monitoring a ground test launch control system. The method comprises reasonably planning a ground single machine and cable network layout; acquiringthe display images of a status display and a central computer display, and the status image of a test launch control device panel; identifying a currently executed process step; calling a corresponding template from a template; performing matching; and determining that a current test status is normal if matching is successful, or giving an alarm if not. The platform rearranges cable positions by acable arrangement box, is provided with a wire duct, and is provided with an independent wiring space to help the concentration of respective single machines of a test launch control system and a monitoring and operation panel. The platform and method perform comprehensive judgment by identifying a first word and a color block length, ensure the accuracy of process identification, obtain the corresponding template through the process, and ensure the accurate monitoring of the device state by the matching of the template.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST +1

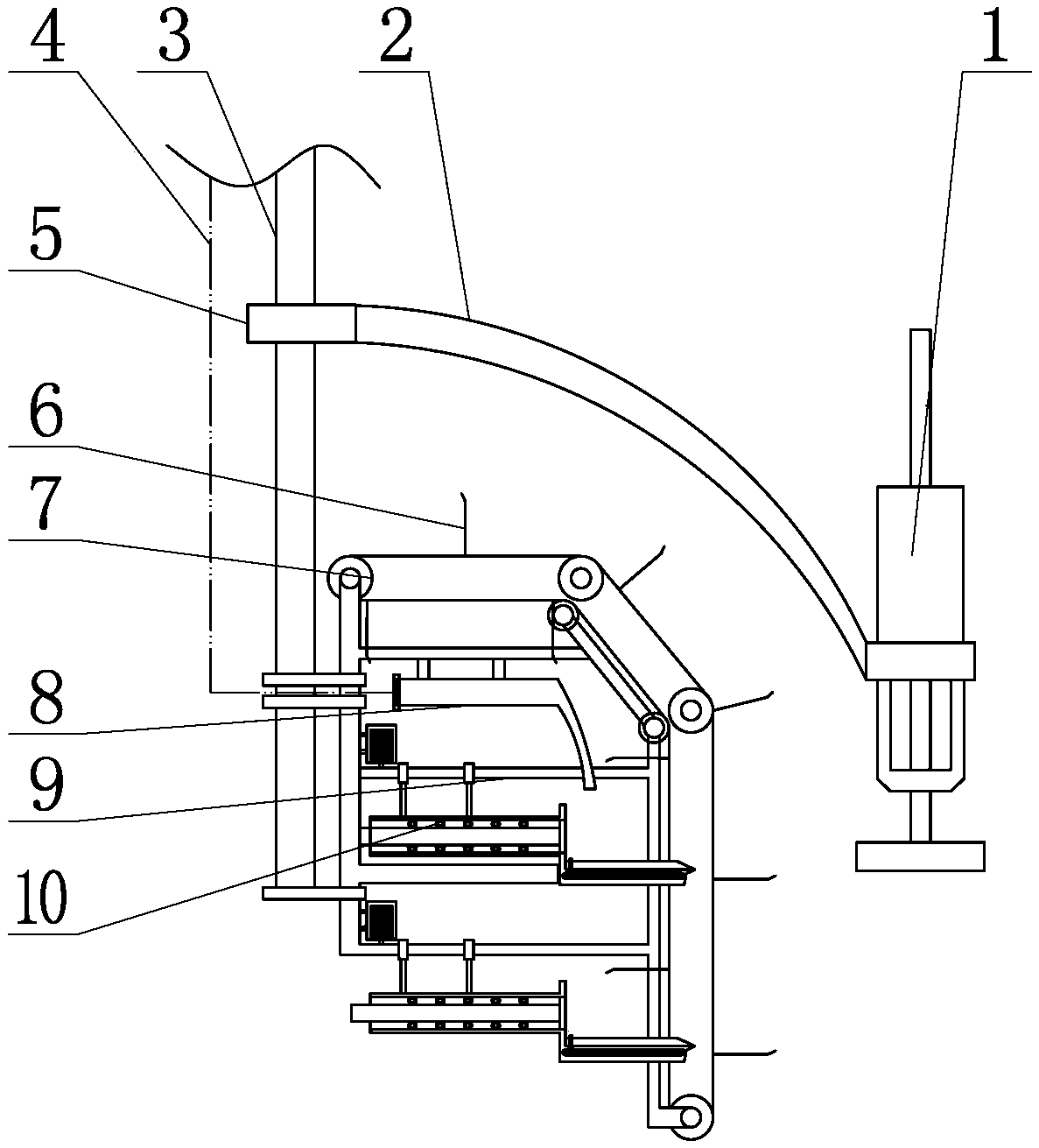

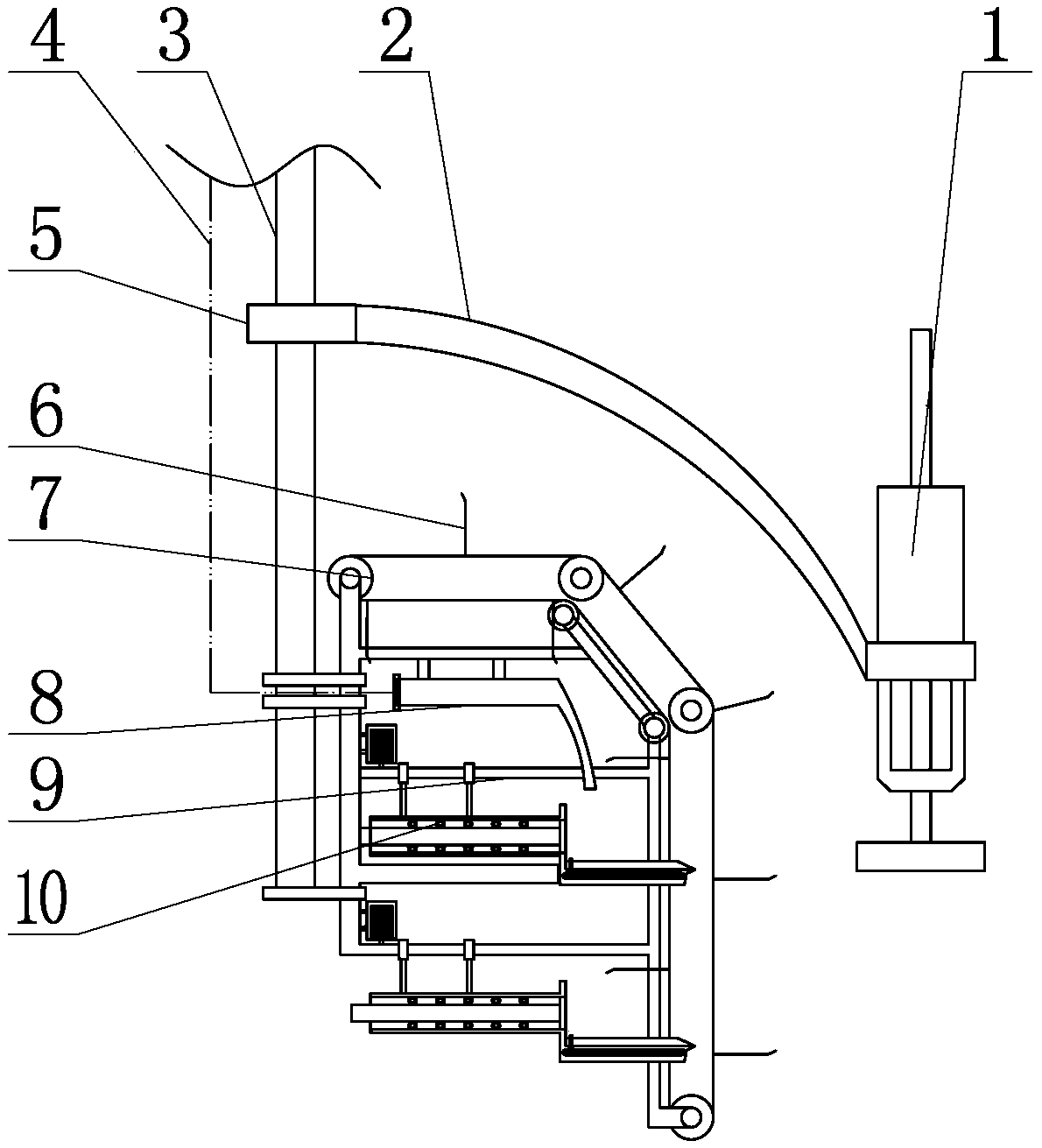

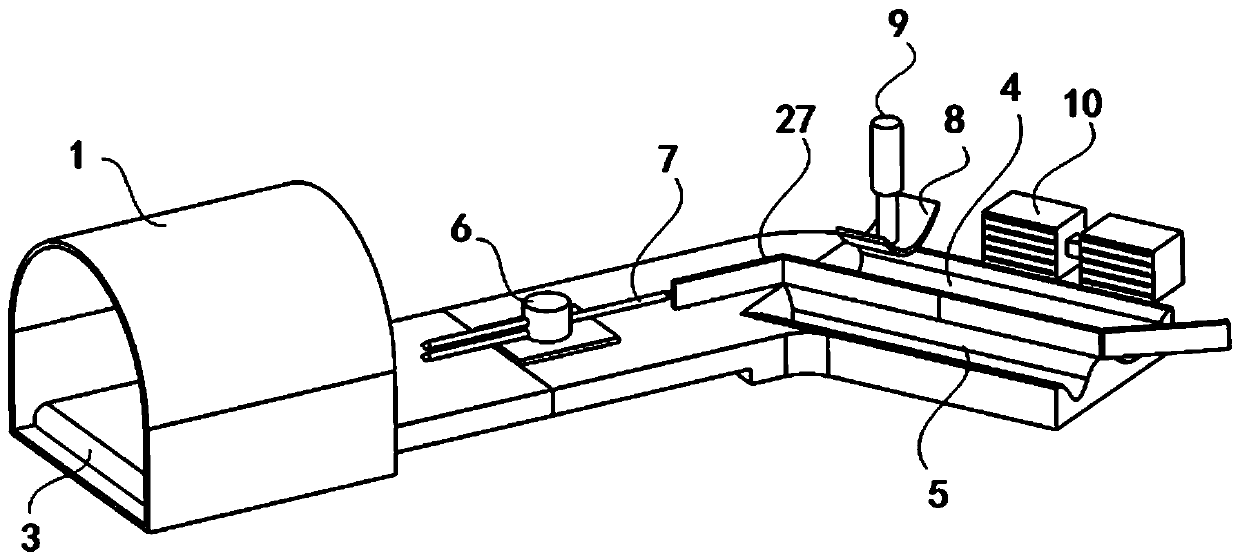

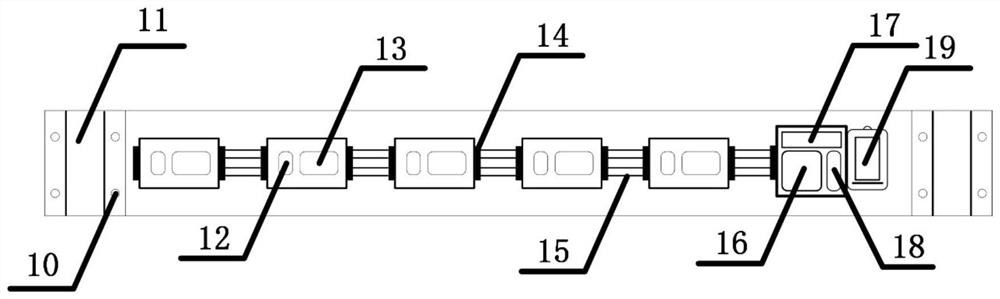

Automatic building device for circulating fluidized bed boiler hearth refractory bricks

ActiveCN107676811AGuaranteed pass rateImprove construction qualityFluidized bed combustionCasings/liningsBrickFluidized bed

The invention discloses an automatic building device for circulating fluidized bed boiler hearth refractory bricks and belongs to the field of refractory material construction equipment. The automaticbuilding device is characterized by comprising a main rack, a brick conveying device, a brick pushing device and a beating device; the brick conveying device is arranged between the beating device and the brick pushing device; the brick pushing device can push building materials on the brick conveying device to the needed position; and then the beating device can be used for beating the buildingmaterials compactly. By means of the automatic building device for the circulating fluidized bed boiler hearth refractory bricks, the building construction efficiency of refractory bricks in the circulating fluidized bed boiler building process can be greatly improved, and the automatic building device is high in automation degree and capable of obviously saving manpower.

Owner:SHANDONG YAOHUA REFRACTORY MATERIAL SCI & TECH CO LTD

A circulating fluidized bed boiler furnace refractory brick conveying process and equipment

ActiveCN108036356BGuaranteed pass rateImprove construction qualityFluidized bed combustionCasings/liningsBrickBoiler furnace

Owner:SHANDONG YAOHUA REFRACTORY MATERIAL SCI & TECH CO LTD

A stress-relieving high-speed rail car group manufacturing body leveling device

ActiveCN113909335BAvoid size deviationReduce distractionsShaping toolsMetal-working feeding devicesHydraulic cylinderWindage

The invention discloses a leveling device for manufacturing a body of a stress-relieving high-speed rail vehicle group, which relates to the technical field of high-speed rail production. A feeding box is arranged on the top of the right side of the feeding box, the inner two sides of the feeding box are connected with a limit push component, and the inner side of the limit push component is arranged with a steel plate of the vehicle group. In the present invention, the vertical arrangement of the upper leveling components is the same as that of the lower leveling components, and can be combined into a straight line with the same radian as the lower leveling components through the working energy of the second hydraulic cylinder. When leveling, the steel plate of the train group can be leveled into a steel plate with a specified radian. Because the high-speed rail body considers the wind resistance, most of them have a certain radian. All the required steel plates of the vehicle group are flattened into the required shape, which is beneficial to improve the flexibility of the equipment.

Owner:深圳市华明博机电设备工程有限公司

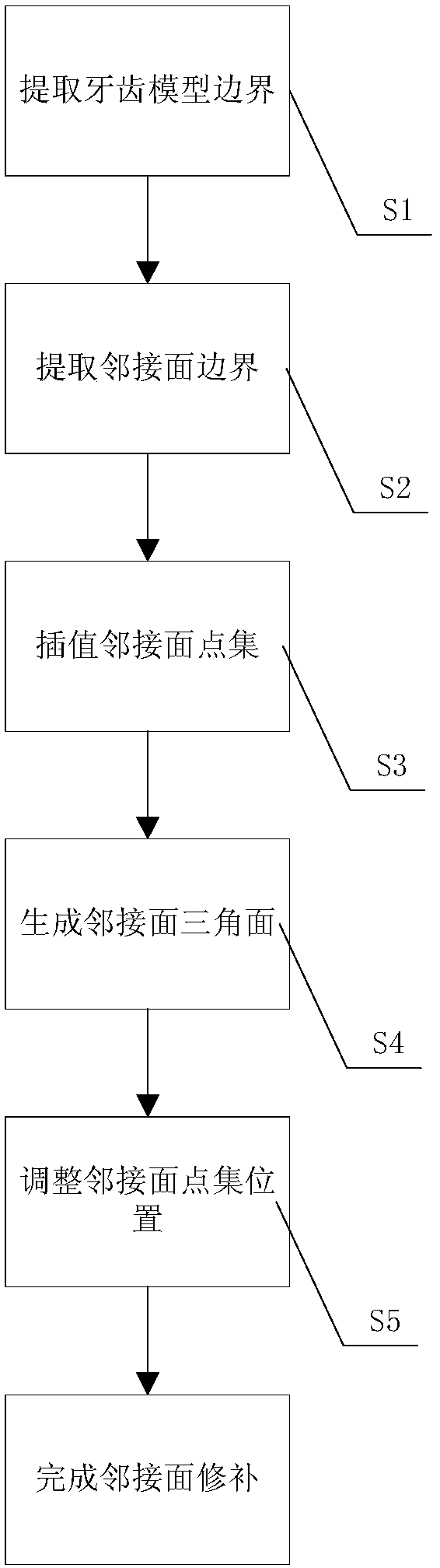

A method for repairing the adjacent surface of the crown in a three-dimensional tooth model

ActiveCN106228616BAccurately restore 3D anatomical featuresGuaranteed perfect fitImage data processingClosed loopAbutment

The invention discloses a method of repairing the adjacent sides of a dental crown in a 3D tooth model, comprising the following steps: extracting a boundary point set of a tooth model from a database; extracting left and right adjacent side boundary point sets of the tooth model from the boundary point set; and for both the left boundary and the right boundary, performing the following steps: interpolating points between the begin and end points of the left or right boundary according to a certain distance to get a closed-loop boundary point set; calculating the center of mass of the closed-loop boundary to make the closed-loop boundary point set gather to the center of mass so as to interpolate a point set V; generating a triangular face set based on the closed-loop boundary point set and the point set V; and calculating the center of mass of the tooth model, and adjusting the position of the point set V according to the center of mass to make the position consistent with the curvature trend of the tooth model. The contact relationship of the adjacent sides of adjacent teeth partially missing due to tooth segmentation can be restored accurately.

Owner:INNOVATIVE MATERIAL & DEVICES

Energy-saving profiles and profile processing technology for heat-insulated buildings with strips and broken bridges

The invention provides a strip-penetrating broken-bridge heat insulation building energy-saving section bar and a machining process for the section bar. The section bar is formed by single section bars at the inner side and the outer side and a hollow heat insulating strip between the two section bars, the hollow heat insulating strip is in bilateral symmetry centering on a vertical center line, one ends of tooth supports, adjacent to compression tooth rolling torsion surfaces, inwardly incline towards the direction of the vertical center line, included angles are 1 degree to 2 degrees, and compression tooth support surfaces are vertical to the vertical center line. According to the section bar, the cost is reduced, the machining is convenient, the section bar formed by machining is not deformed due to machining, standard-structure section bars capable of preventing structural deformation can be obtained via rolling combination of the single section bars, and the installation problem of the section bar due to deformation in a combination process is eliminated.

Owner:YICHANG HONGJIAN ALUMINUM IND

An automatic building equipment for refractory bricks in the hearth of a circulating fluidized bed boiler

ActiveCN107676811BGuaranteed pass rateImprove construction qualityFluidized bed combustionCasings/liningsBoiler furnaceFluidized bed

Owner:SHANDONG YAOHUA REFRACTORY MATERIAL SCI & TECH CO LTD

Processing technology of explosion-proof glass cover used for charging cabinet

InactiveCN109233192AGood explosion-proofImprove fire resistanceLamination ancillary operationsLaminationGlass coverEngineering

The invention relates to a processing technology of an explosion-proof glass cover used for a charging cabinet, and belongs to the technical field of coal mine equipment. The processing technology ofthe explosion-proof glass cover used for the charging cabinet comprises the following steps: firstly, manufacturing a composite material frame; secondly, manufacturing double-layer explosion-proof glass; thirdly, putting the double-layer explosion-proof glass in the composite material frame; fourthly, sealing glue at the joint of the composite material frame and the double-layer explosion-proof glass to manufacture the explosion-proof glass cover used for the charging cabinet; and fifthly, checking the explosion-proof glass cover used for the charging cabinet, taking products with cracks and glue failures as inferior-quality products, and taking others as qualified products to be put in storage. According to the processing technology of the explosion-proof glass cover used for the chargingcabinet provided by the invention, the explosion-proof glass cover used for the charging cabinet prepared from the composite material frame and the double-layer explosion-proof glass is good in explosion-proof and fireproof performances, internal conditions of the charging cabinet are observed conveniently, and when overheating fire occurs, a user can discover and treat fire at first time, so that the safety is improved.

Owner:镇江市南方工矿器材有限公司

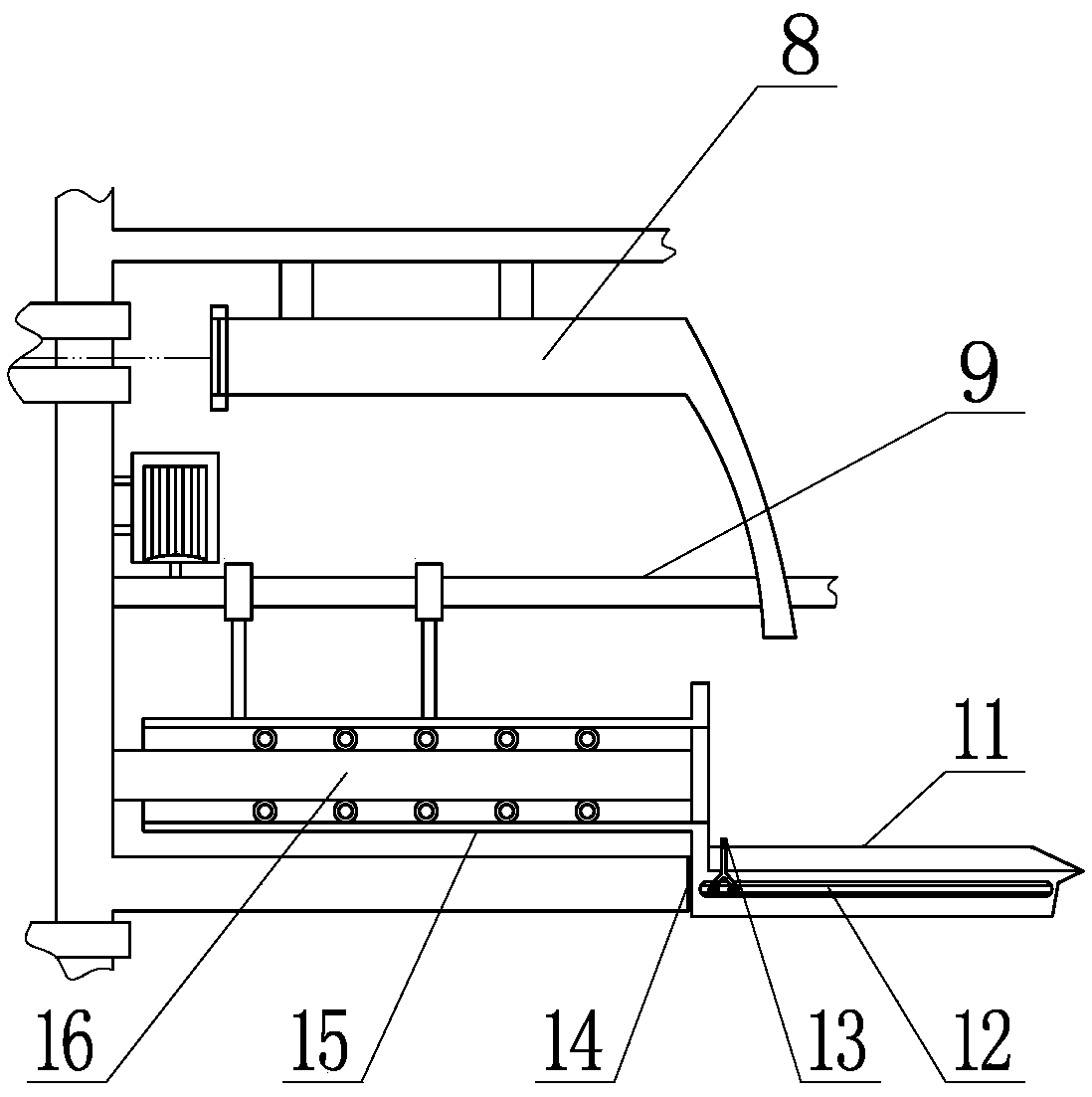

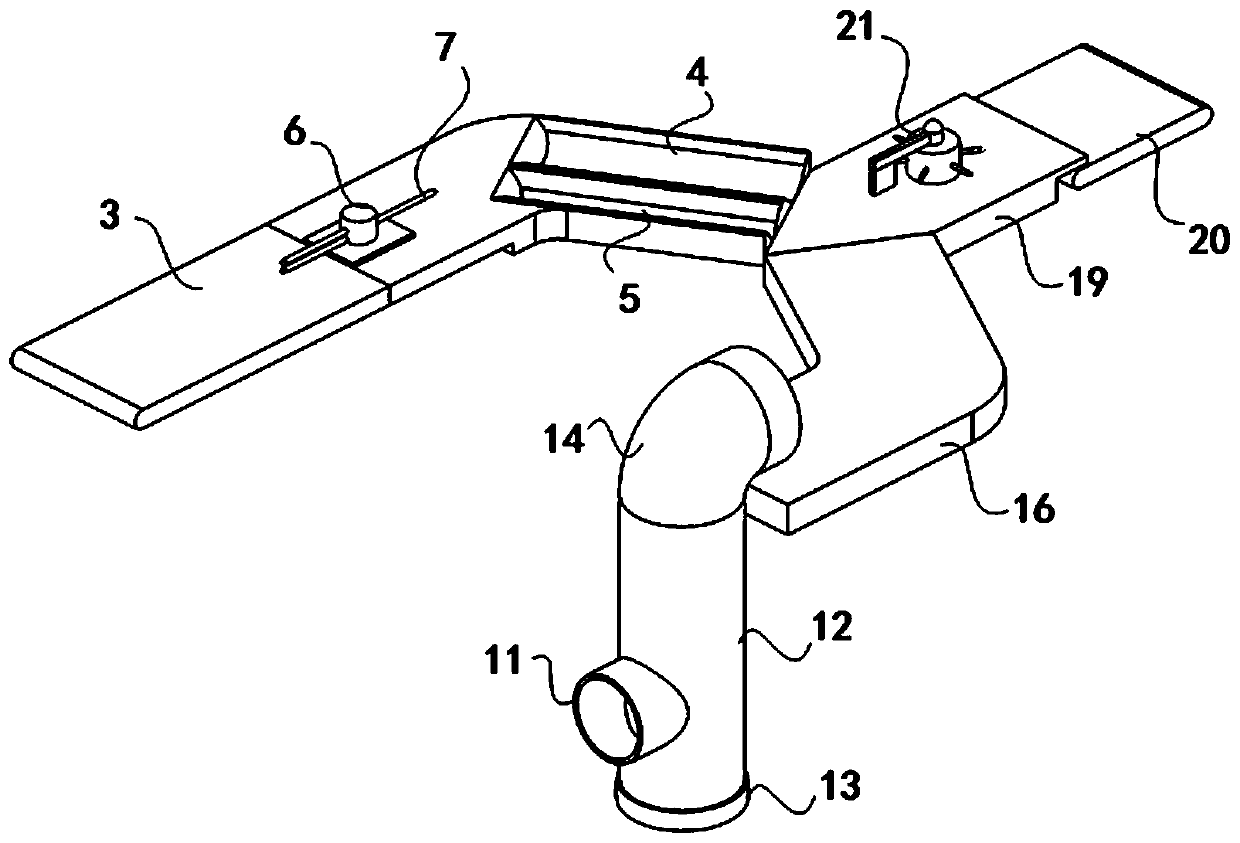

Health tea production processing equipment with mixing function

PendingCN110214832AConducive to a reasonable ratioImprove fault tolerancePre-extraction tea treatmentBlack teaEngineering

The invention relates to health tea production processing equipment with a mixing function. The equipment comprises a lycium chinense treatment mechanism, a tea leaf treatment mechanism, a mixing mechanism and a control mechanism. The lycium chinense treatment mechanism comprises a first input end, a camera shooting assembly is arranged in the first input end, a first conveying belt is arranged behind the first input end and comprises a main conveying belt body, a sub conveying belt body and a stirring assembly, and a U-shaped press plate and a first lifting assembly are arranged on the upperportion of the first conveying belt; the tea leaf treatment mechanism comprises a second input end and an L-shaped conveying cavity, a draught fan is arranged at the bottom of the L-shaped conveying cavity, a first spraying assembly is arranged at the top of the L-shaped conveying cavity, and a first idler wheel assembly is arranged on the upper portion of the second conveying belt; the mixing mechanism comprises an operation table and a third conveying belt, a wheel disc assembly is arranged in the center of the operation table, a hole formation pin is arranged on the side face of the wheel disc assembly, a second spraying assembly is arranged at the rear side of the wheel disc assembly, and a second idler wheel assembly is arranged behind the second spraying assembly. According to the health tea production processing equipment, lycium chinense and black tea can be automatically mixed into health tea which can be directly brewed.

Owner:吉丽雄

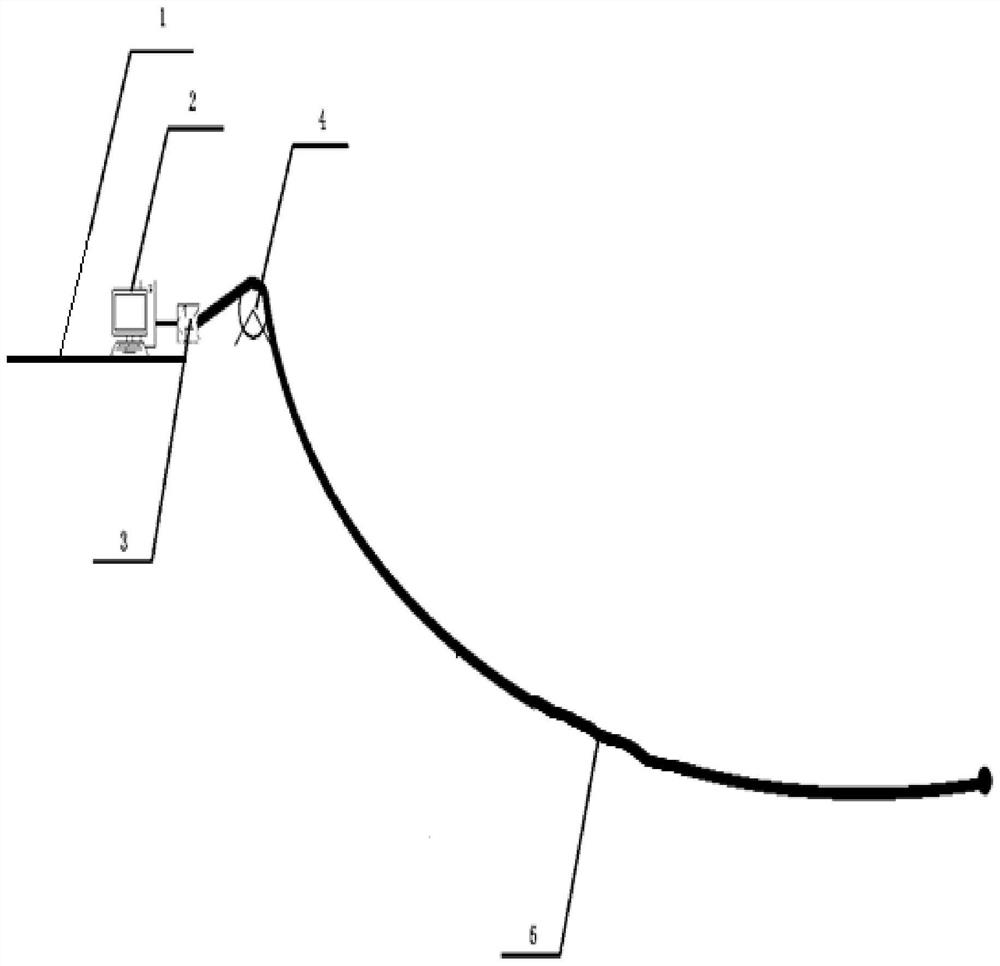

High-precision real-time monitoring system for long-distance submarine cable positioning and deformation

ActiveCN109374000BRealize remote real-time positioning self-check functionImprove stabilityNavigation by speed/acceleration measurementsElectrical/magnetic solid deformation measurementConvertersFlexible circuits

The invention relates to the technical field of ocean observation, in particular to a high-precision real-time monitoring system for positioning and deformation of long-distance submarine cables. Including the monitoring host computer; the monitoring host computer is set on the shore and connected to the photoelectric converter; the detection system includes a flexible circuit board, and a number of MEMS module components connected in series through the 485 bus connection line are welded on the flexible circuit board. The components include TTL to 485 bus module and MEMS acceleration sensor module; there is also a four-wire 485 connection port between the 485 bus connection line and the MEMS module components; the 485 bus connection line is connected to the central controller, and the central controller is connected to the electro-optic modulator. The invention can realize the positioning and real-time monitoring of the deformation of the submarine cable, realize the remote real-time positioning and self-checking function of the submarine cable, and can be used to improve the stability and fault repair ability of the submarine cable.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com