Mold fitting device and method for splicing joints of prestressed ribbed superimposed sheets

A laminated slab and prestressed technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of long time for joint mold matching and difficulty in joint joint mold matching, and achieves Convenience for patchwork butt joint, accurate patchwork and avoid misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

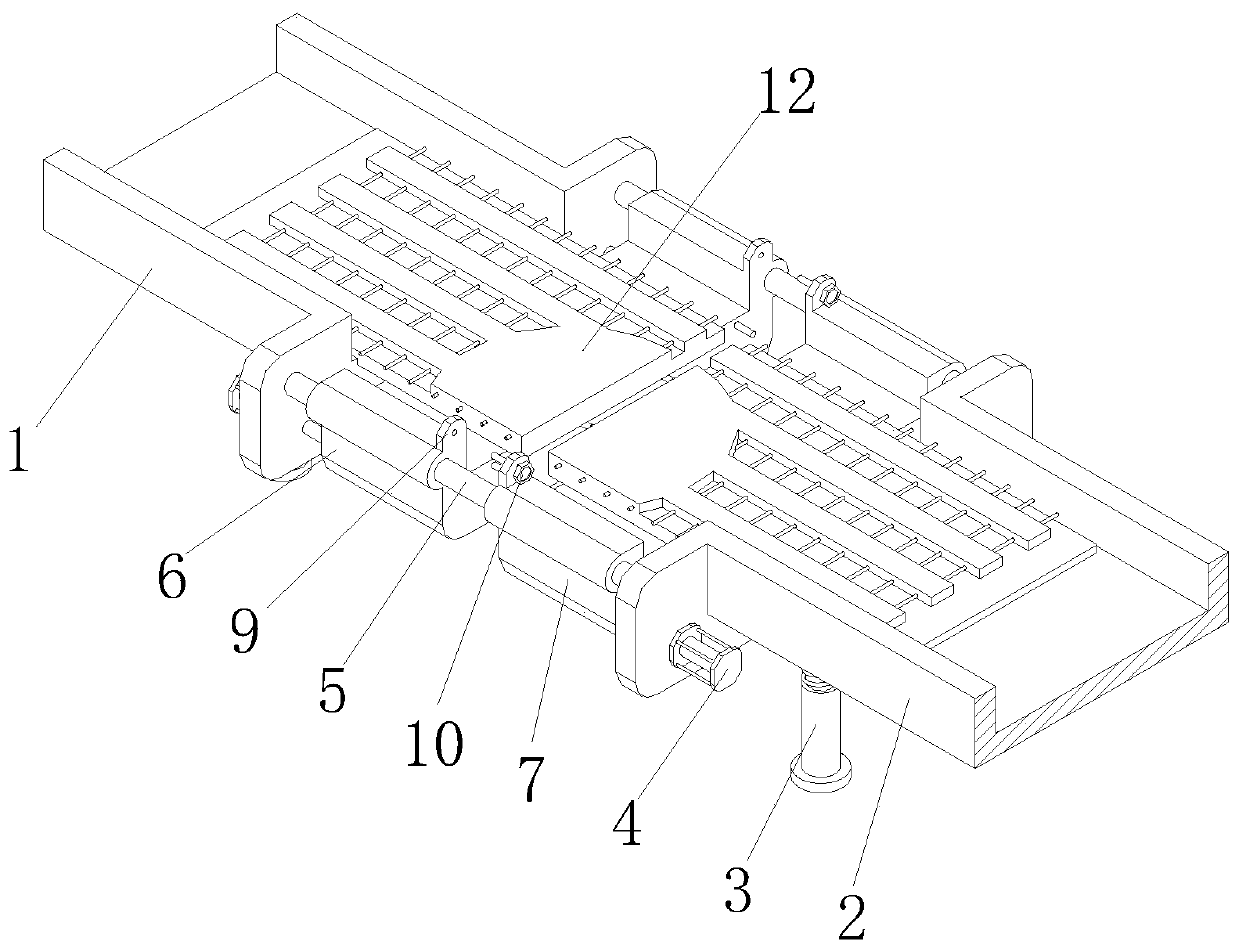

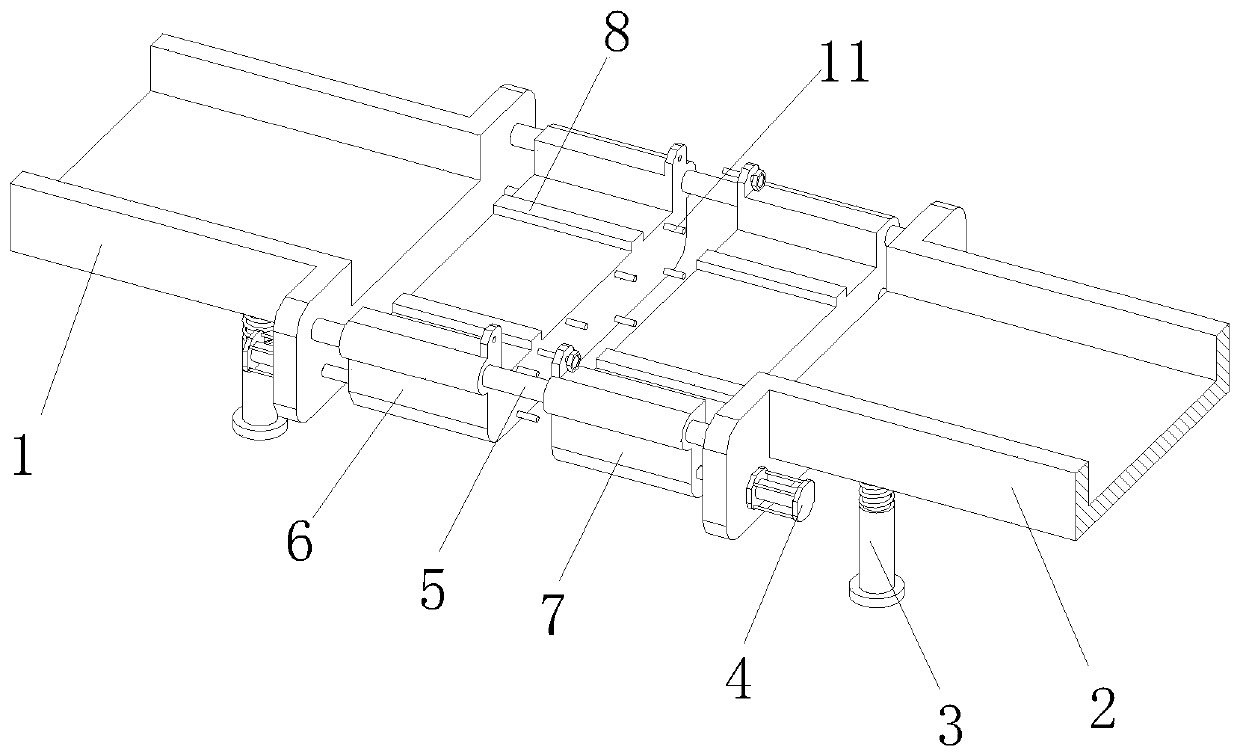

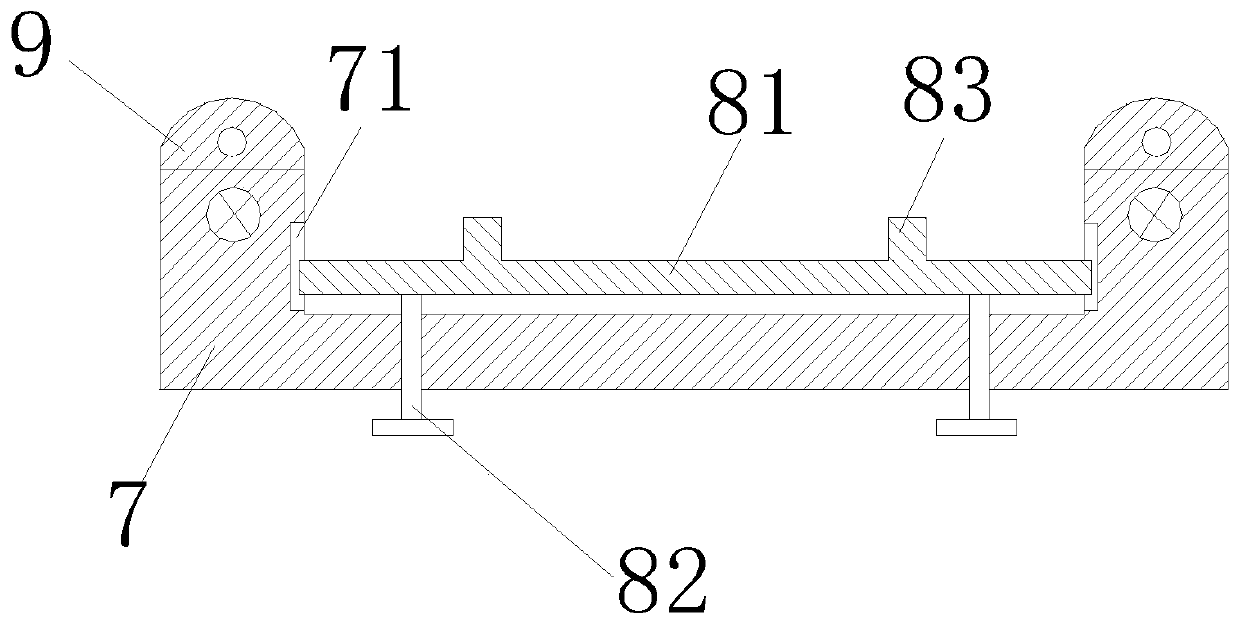

[0026] Embodiment 1: refer to Figure 1-3 As shown, a prestressed ribbed laminated plate seam matching device includes a first shelf 1 and a second shelf 2, and the bottoms of the first shelf 1 and the second shelf 2 are fixedly installed with several supporting bases 3. The bottom of the support base 3 is fixed with anti-skid pads. There are two mutually symmetrical guide rods 5 between the first shelf 1 and the second shelf 2. The two guide rods 5 are respectively located on the first shelf 1. The two ends of the two guide rods 5 are respectively fixedly connected with the corresponding first shelf 1 and the second shelf 2, and the guide rod 5 is provided with a first template 6 at one end of the first shelf 1. A template 6 is clamped on the guide rod 5, and is slidably connected with the guide rod 5, and the guide rod 5 is located at one end of the second shelf plate 2 to be provided with a second template 7, and the second template 7 is clamped on the guide rod 5, and Sli...

Embodiment 2

[0029] Embodiment 2: refer to Figure 1-3 As shown, a prestressed ribbed laminated joint joint mold matching method includes the following steps:

[0030] Step 1: Control the telescopic cylinder 4 so that the first formwork 6 and the second formwork 7 are close to the corresponding first shelf 1 and second shelf 2;

[0031] Step 2: Place the two laminated plates on the first template 6 and the second template 7 respectively, and then control the telescopic cylinder 4 so that the first template 6 and the second template 7 slide toward each other;

[0032] Step 3: When there is only a gap between the two laminated plates, turn the adjusting bolt 82 to make the sliding plate 81 move slightly up and down until the two laminated plates are on a parallel line;

[0033] Step 4: Continue to control the telescopic cylinder 4 so that the first formwork 6 and the second formwork 7 slide toward each other until the first formwork 6 and the second formwork 7 fit together, and then tighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com