High-polymer modified asphalt waterproof roll for road and bridge and preparation method thereof

A technology of asphalt waterproofing membrane and polymer modification, applied in asphalt coatings, chemical instruments and methods, bridges, etc. Small attenuation, improved service life, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

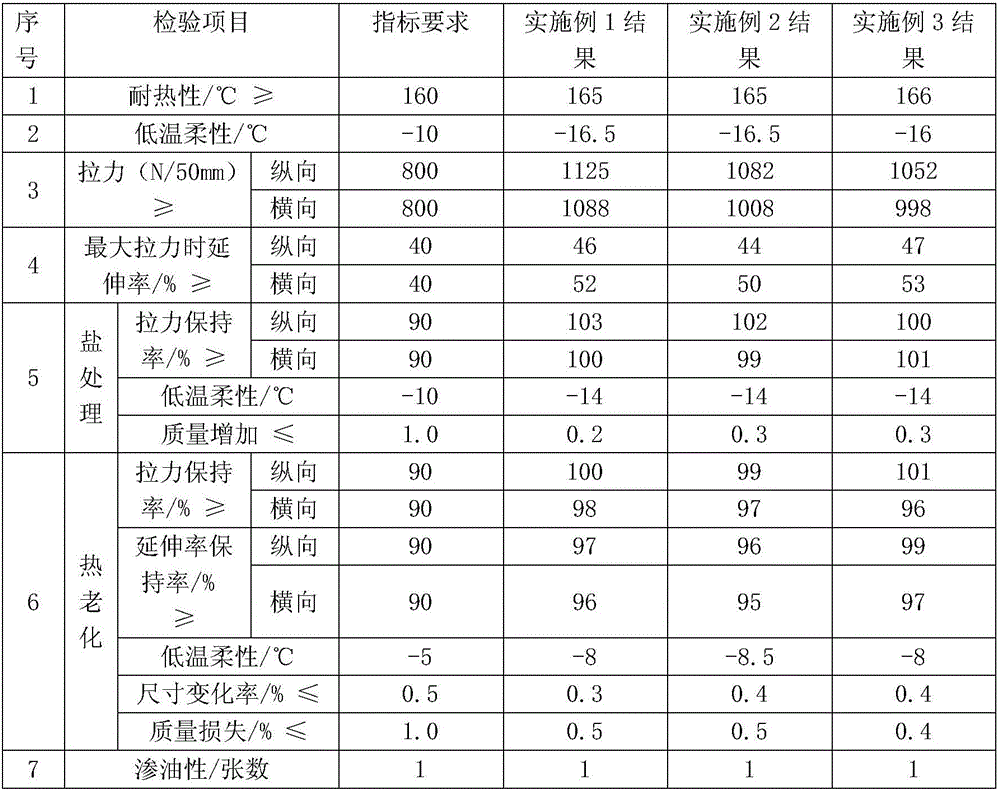

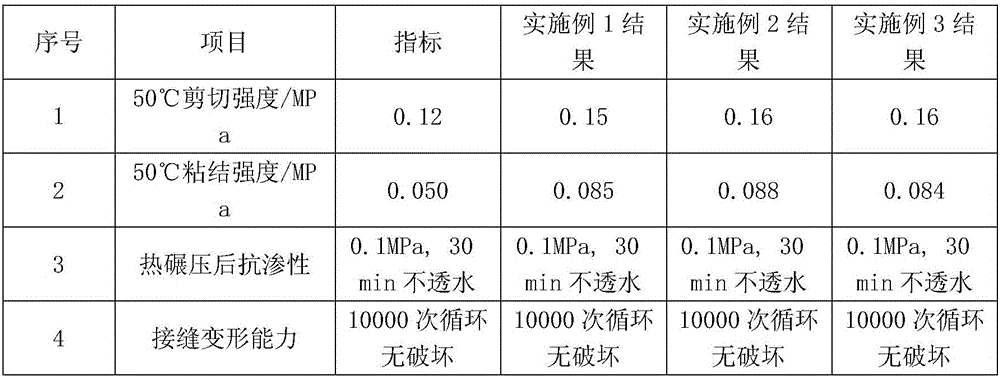

Examples

Embodiment 1

[0024] 1. Formula of modified asphalt

[0025] 2600kg 90# asphalt, 1000kg 200# asphalt, 425kg IPP, 80kg SBS, 350kg APAO, 300kg high temperature modifier, 1100kg modified powder, 900kg heavy calcium.

[0026] 2. Preparation of modified asphalt

[0027] (1) Pour in 2600kg 90# asphalt and 1000kg 200# asphalt in sequence according to the ratio, and heat up to 150-170°C.

[0028] (2) Add 425kg IPP and 80kg SBS to swell at 150-170°C for 1-2 hours.

[0029] (3) Grind with a colloid mill for 1-2 hours, and raise the temperature to 190-195°C.

[0030] (4) Add 350kg APAO and stir for 30min.

[0031] (5) Add 300kg of high-temperature modifier, and continue grinding with a colloid mill for 30 minutes.

[0032] (6) Add 1100kg of modified powder and 900kg of heavy calcium, and stir at high speed for 60-90min.

[0033] (7) Inspection, after passing the test, put it into the storage tank and prepare for on-line production.

[0034] 3. High polymer modified asphalt waterproof membrane fo...

Embodiment 2

[0038] 1. Formula of modified asphalt

[0039] 2650kg 90# asphalt, 950kg 200# asphalt, 425kg IPP, 70kg SBS, 340kg APAO, 250kg high temperature modifier, 1050kg modified powder, 900kg heavy calcium.

[0040] 2. Preparation of modified asphalt for road and bridge

[0041] (1) Pour in 2650kg of 90# asphalt and 950kg of 200# asphalt in sequence according to the ratio, and heat up to 150-170°C.

[0042] (2) Add 425kg IPP and 70kg SBS to swell for 1-2 hours when the temperature is 150-170°C.

[0043] (3) Grind with a colloid mill for 1-2 hours, and raise the temperature to 190-195°C.

[0044] (4) Add 340kg APAO and stir for 30min.

[0045] (5) Add 250kg of high-temperature modifier, and continue grinding with a colloid mill for 30 minutes.

[0046] (6) Add 1050kg of modified powder and 900kg of heavy calcium, and stir at high speed for 60-90min.

[0047] (7) Inspection, after passing the test, put it into the storage tank and prepare for on-line production.

[0048] 3. High po...

Embodiment 3

[0052] 1. Formula of modified asphalt

[0053] 2900kg 90# asphalt, 950kg 200# asphalt, 425kg IPP, 100kg SBS, 350kg APAO, 200kg high temperature modifier, 1100kg modified powder, 1000kg heavy calcium.

[0054] 2. Preparation of modified asphalt for road and bridge

[0055] (1) Pour in 2900kg 90# asphalt and 950kg 200# asphalt in sequence according to the ratio, and heat up to 150-170°C.

[0056] (2) Add 425kg IPP and 100kg SBS to swell at 150-170°C for 1-2 hours.

[0057] (3) Grind with a colloid mill for 1-2 hours, and raise the temperature to 190-195°C.

[0058] (4) Add 350kg APAO and stir for 30min.

[0059] (5) Add 200kg of high-temperature modifier, and continue grinding with a colloid mill for 30 minutes.

[0060] (6) Add 1100kg of modified powder and 1000kg of heavy calcium, and stir at high speed for 60-90min.

[0061] (7) Inspection, after passing the test, put it into the storage tank and prepare for on-line production.

[0062] 3. High polymer modified asphalt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com