A circulating fluidized bed boiler furnace refractory brick conveying process and equipment

A circulating fluidized bed and boiler furnace technology, which is applied to fluidized bed combustion equipment, combustion equipment, lighting and heating equipment, etc., can solve the problem that the uniformity of construction quality cannot be guaranteed as a whole, it is difficult to enter the construction area, and the construction operation is safe. Accidents and other problems, to achieve the effect of promoting the overall construction quality, improving the overall construction quality, and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

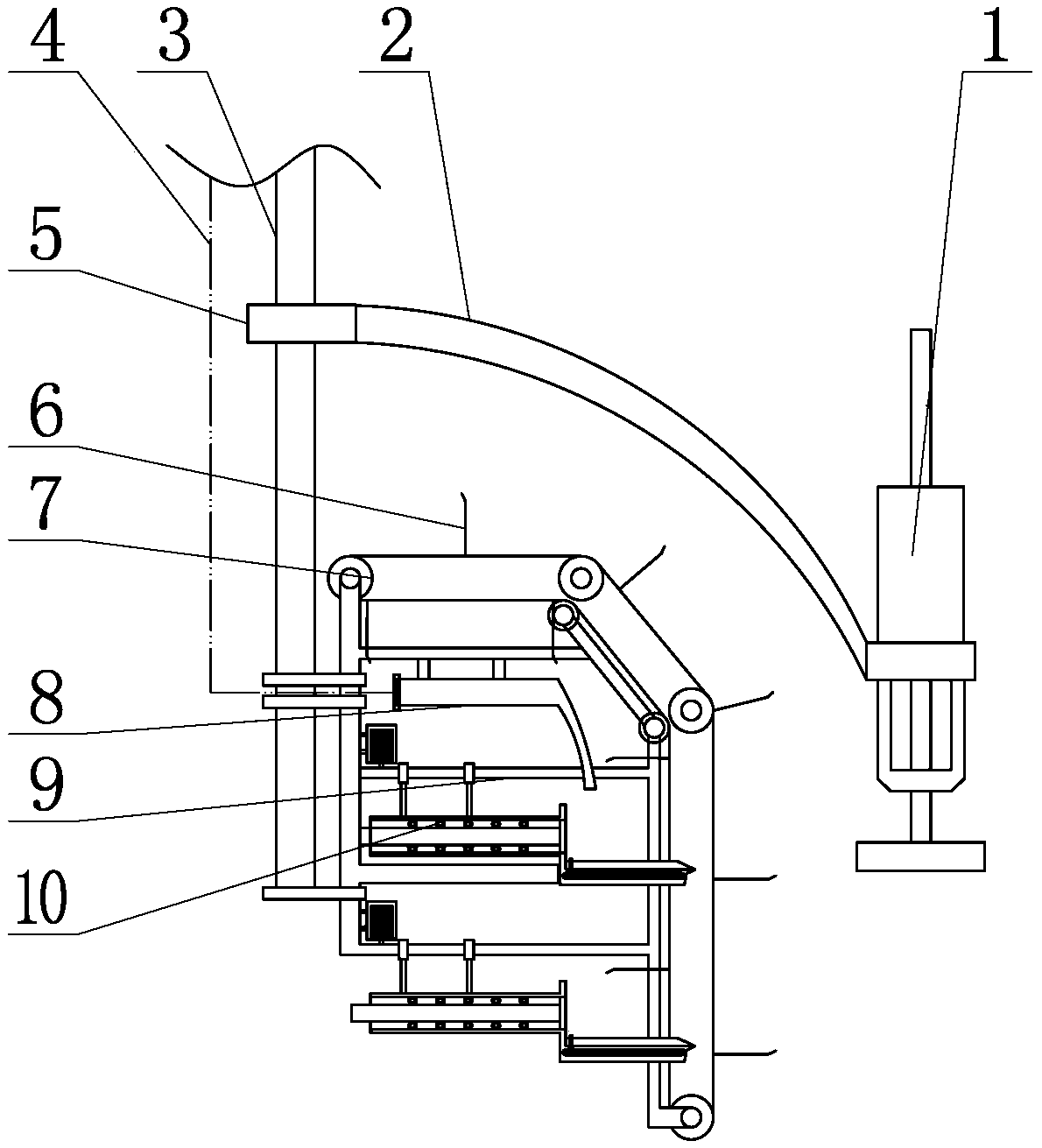

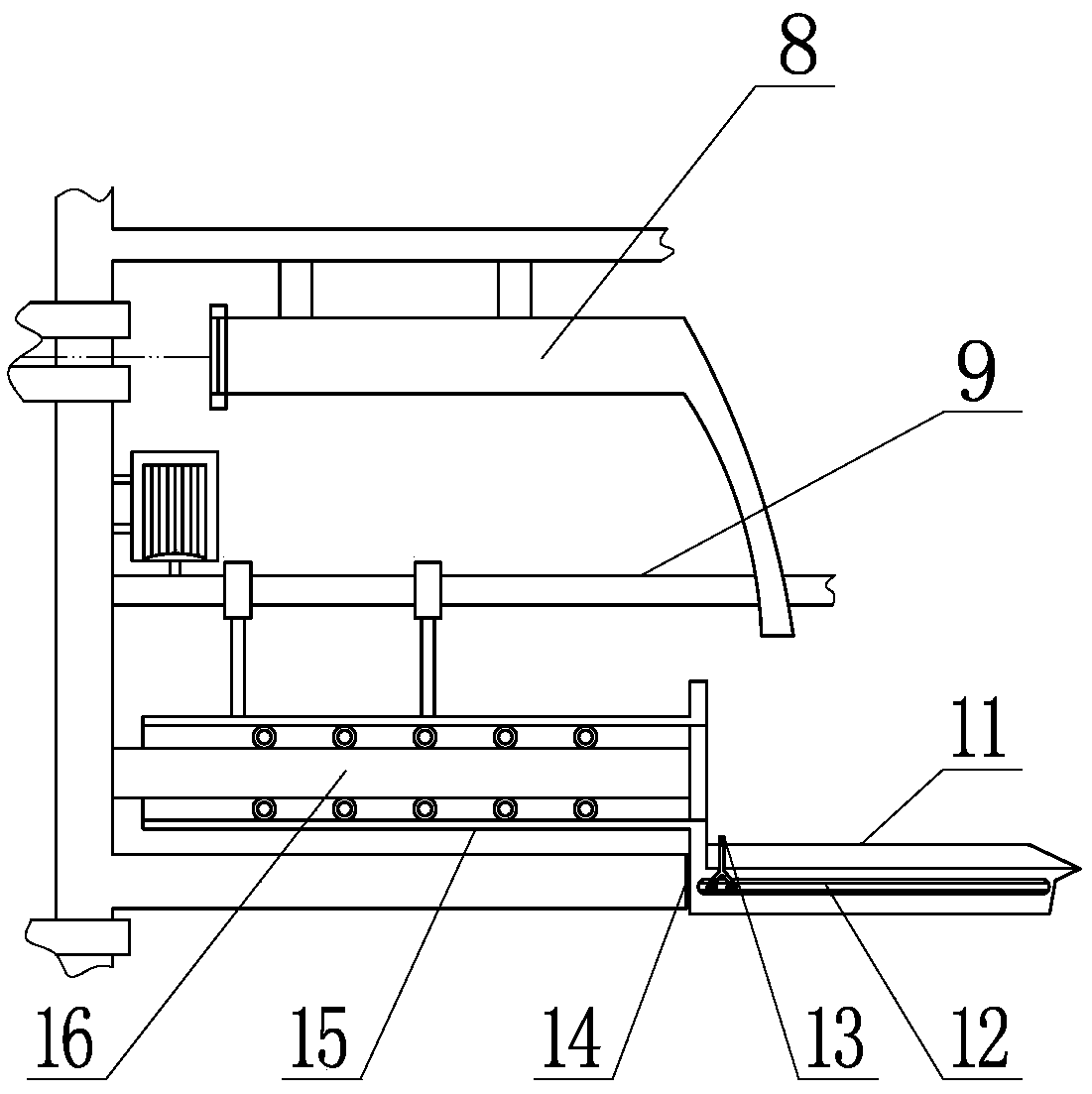

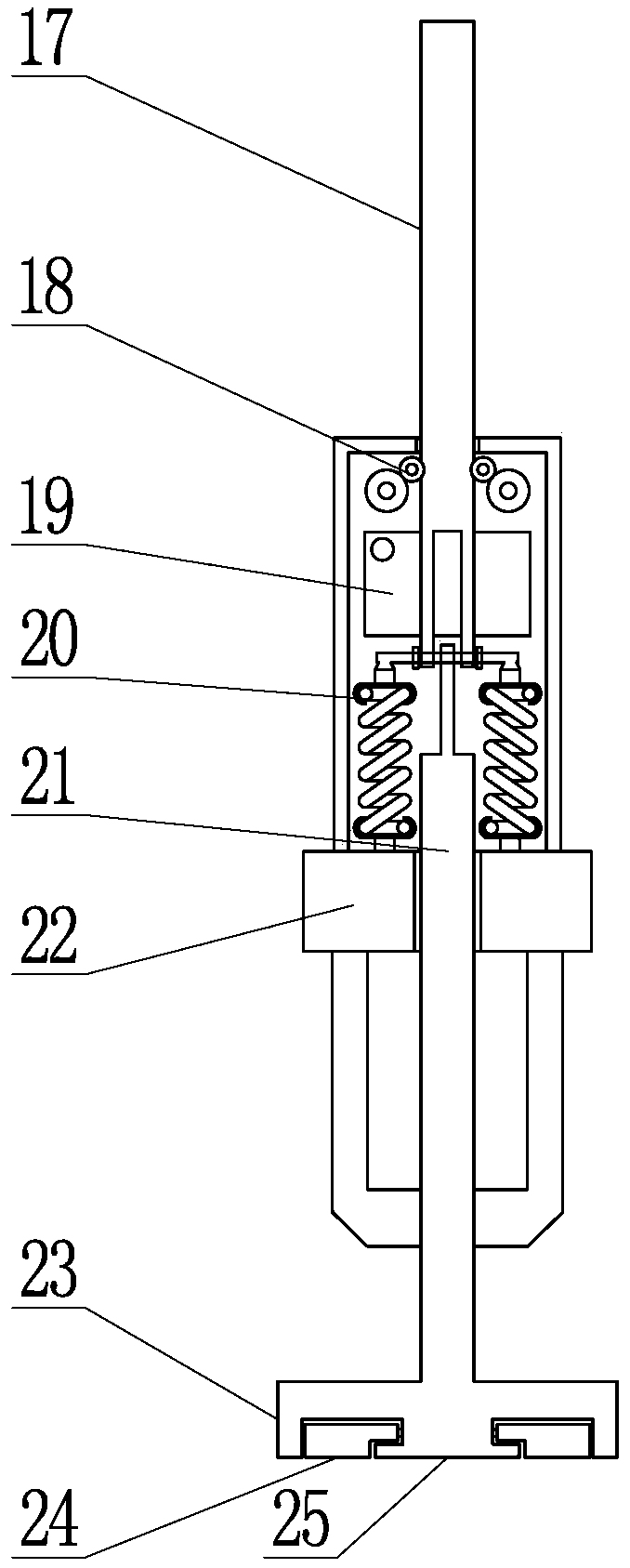

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] A circulating fluidized bed boiler furnace refractory brick conveying and laying process according to the present invention is characterized in that it includes the following steps:

[0040] (1) Conveying: use the brick conveying device to convey the refractory bricks into the furnace;

[0041] (2) Brick pushing: Use the brick pushing device to push the refractory bricks to the laying position, and at the same time push the refractory bricks to attach the adhesive to the laying surface;

[0042] (3) Beating: Use the hammering device to hammer and tighten the refractory bricks at the laying position to complete the work.

[0043] Such as figure 1 As shown, a special equipment for conveying refractory bricks in the hearth of a circulating fluidized bed boiler includes four parts: the main frame, the brick conveying device, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com