Strip-penetrating broken-bridge heat insulation building energy-saving section bar and machining process for section bar

A technology for bridge-breaking heat insulation and energy-saving profiles, which is applied to buildings, building components, building structures, etc., can solve the problems of closing deformation, affecting the appearance, and the installation and coordination of profiles cannot fit the installation, and achieve the effect of preventing excessive stretching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

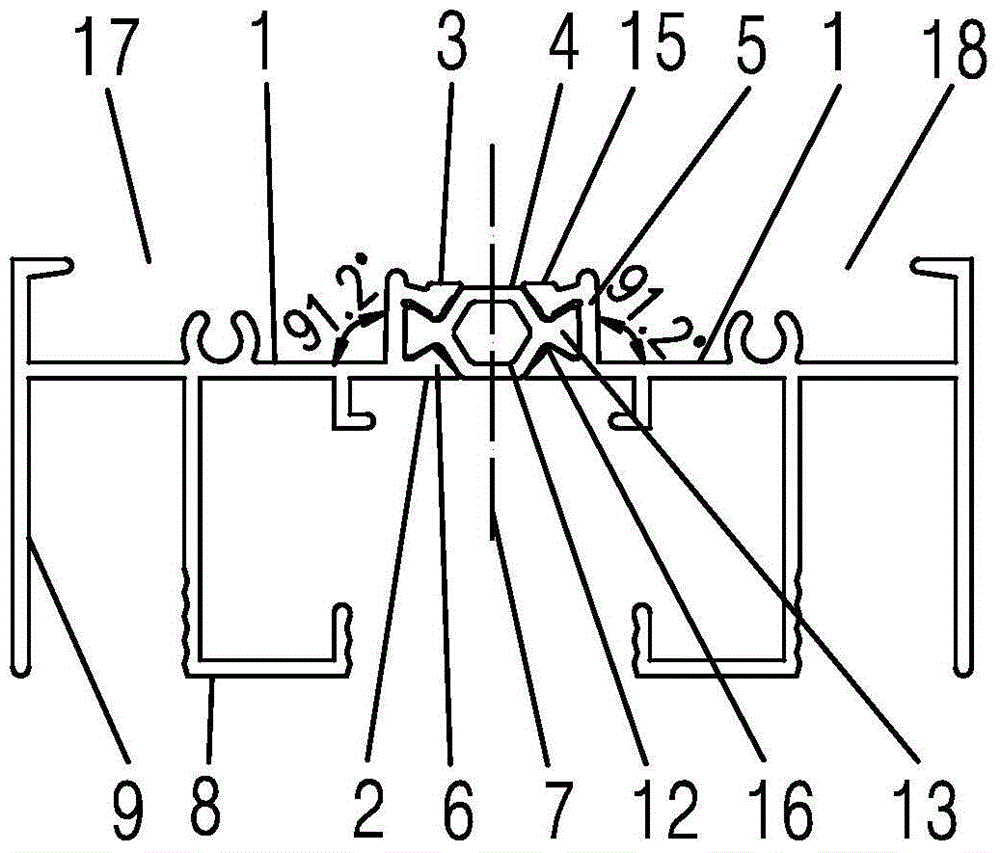

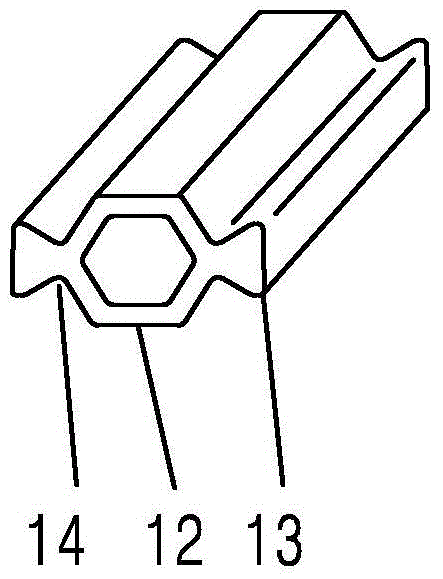

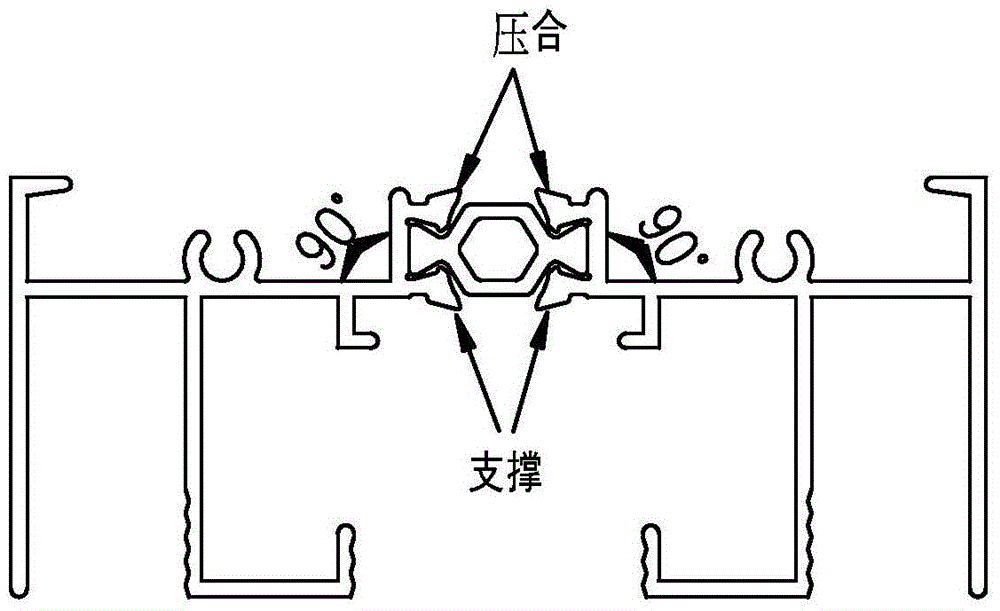

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments: the structures of the energy-saving profiles for the energy-saving buildings with broken bridges through strips are various, and all can be composed of single profiles on both sides of the inner and outer sides and only one between the single profiles on both sides. The hollow heat insulation strip consists of 4; figure 1 The single profile in the embodiment is provided with an outer side rib 9, a skeleton rib 1 arranged inside the side rib and perpendicular to the side rib, and an upper material fixing rib 8 integrally arranged on the lower side of the skeleton rib , the anti-collision tooth block integrally arranged on the lower side of the skeleton tendon, the screw hole seat integrally arranged on the upper side of the skeleton tendon, and the compression teeth integrally arranged on the inner end of the skeleton tendon. A large number of profile str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com