Electrophoresis process after galvanizing

A process and electrophoresis technology, applied in hot-dip plating process, metal material coating process, electrolytic coating, etc., can solve the problems that cannot meet the daily environment, achieve good micro-abrasion performance, improve film hardness, and high anti-corrosion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

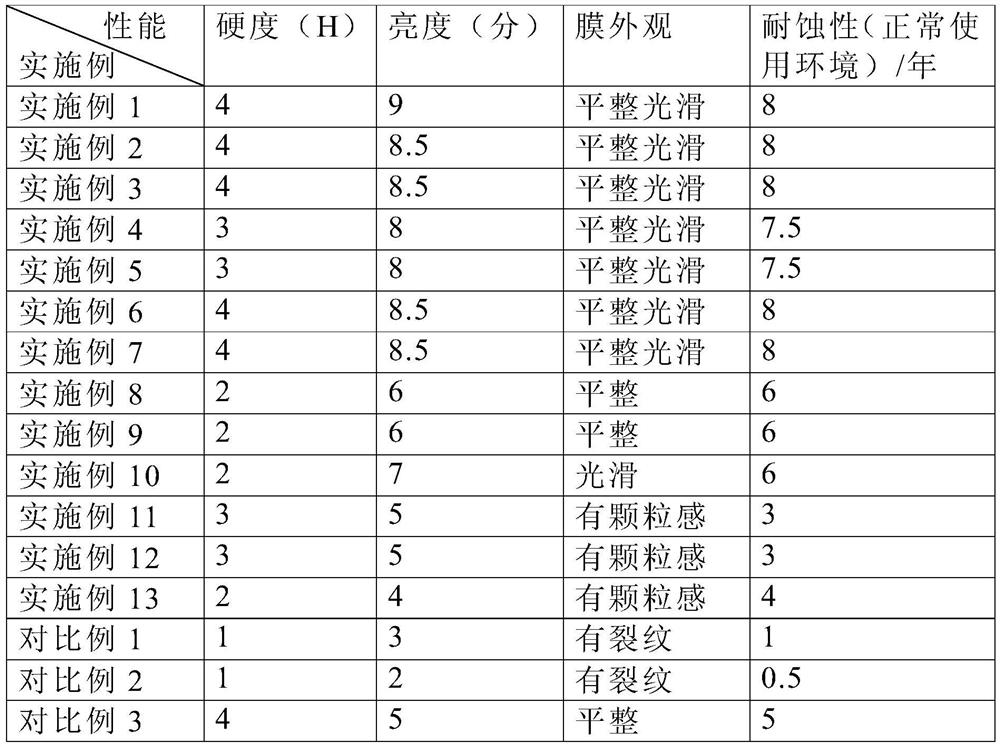

Examples

Embodiment 1

[0028] Pre-treatment: The alloy workpiece is degreased, hot water washed, rust removed, and cold washed in sequence. First, the alloy workpiece is tilted at 50°, and superheated steam is continuously sprayed upward from the bottom of the workpiece for 20 seconds, and then immersed in cold water at -1°C. Steam blowing and cold water immersion were performed 4 times, and then the alloy workpiece was soaked in an activator, wherein the activator included hydrogen fluoride 50g / L, fluoroboric acid 70g / L, perchloric acid 6g / L, sodium citrate 4g / L, polytetrafluoroethylene Vinyl fluoride particles 50g / L, undergo physical and chemical composite activation treatment;

[0029] Film production: galvanize the activated alloy workpiece to form a galvanized layer with a thickness of 5 μm, then phosphate at 80°C for 10 minutes to form a phosphating film, and then immerse it in 11% of the solid coating by mass percentage, liquid In the electrolytic solution with 89% solvent, add the compound p...

Embodiment 2

[0032] Pretreatment: The alloy workpiece is degreased, hot water washed, rust removed, and cold washed in sequence. First, the alloy workpiece is tilted at 40°, and superheated steam is continuously sprayed upward from the bottom of the workpiece for 10 seconds, then immersed in cold water at -2°C, and circulated. Steam blowing and cold water immersion were performed for 3 times, and then the alloy workpiece was soaked in an activator, wherein the activator included 25g / L hydrogen fluoride, 50g / L fluoroboric acid, 4g / L perchloric acid, 3g / L sodium citrate, polytetrafluoroethylene Vinyl fluoride particles 40g / L, undergo physical and chemical compound activation treatment;

[0033] Film production: galvanize the activated alloy workpiece to form a galvanized layer with a thickness of 5 μm, then phosphate at 80°C for 10 minutes to form a phosphating film, and then immerse it in 11% of the solid coating by mass percentage, liquid In the electrolytic solution with 89% solvent, add ...

Embodiment 3

[0036] Pre-treatment: The alloy workpiece is degreased, hot water washed, rust removed, and cold washed in sequence. First, the alloy workpiece is tilted 60°, and superheated steam is continuously sprayed upward from the bottom of the workpiece for 30 seconds, then immersed in cold water at 0°C, and the steam is circulated. Spraying and soaking in cold water for 5 times, and then soaking the alloy workpiece with activator, wherein the activator includes hydrogen fluoride 75g / L, fluoboric acid 90g / L, perchloric acid 8g / L, sodium citrate 5g / L, polytetrafluoroethylene Ethylene particles 60g / L, undergo physical and chemical compound activation treatment;

[0037] Film production: galvanize the activated alloy workpiece to form a galvanized layer with a thickness of 5 μm, then phosphate at 80°C for 10 minutes to form a phosphating film, and then immerse it in 11% of the solid coating by mass percentage, liquid In the electrolytic solution with 89% solvent, add the compound particle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com