Device and method for preparing bonding test sample piece

A bonding and sample technology, which is applied in the field of equipment for preparing bonding test samples, can solve the problems of the influence of test results and the inability to guarantee the coaxiality of two composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] join figure 1 , the bonding test sample includes an upper test piece 5 and a lower test piece 11 parallel to each other (the upper test piece and the lower test piece are made of composite materials, and the specifications are the same), one end of the upper test piece 5 and the lower test piece 11 Bonding by an adhesive (forming a glue layer 17 after curing).

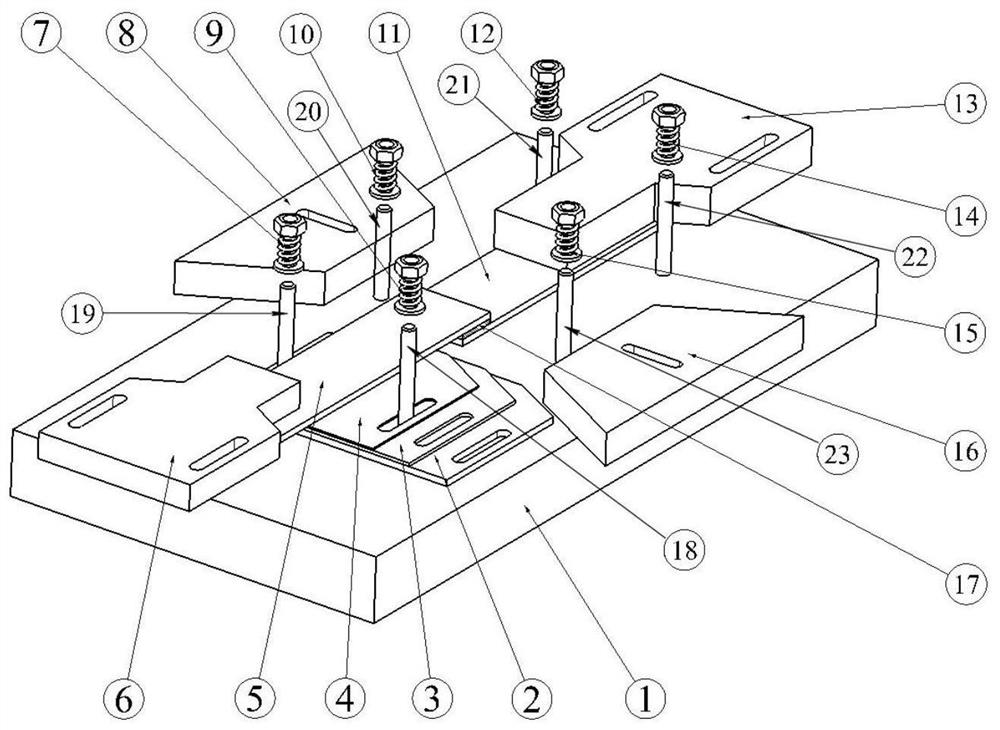

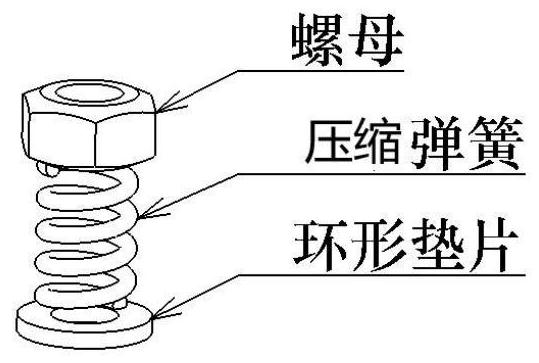

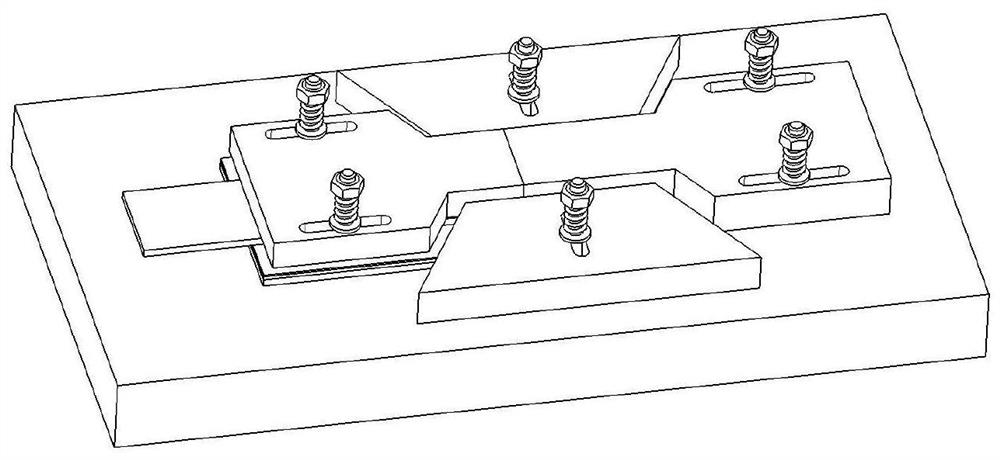

[0036] join Figure 1-Figure 3 , a device for preparing a bonding test sample, including a base 1, the base 1 is provided with a transverse limiter 8, a transverse limiter 2 16, a longitudinal limiter 6 and a longitudinal limiter Two 13, the first horizontal limit block 8, the second horizontal limit block 16 are used to limit the lateral positions of the upper test piece 5 and the lower test piece 11, and the second vertical limit block 13 is used to compress the lower test piece 11 , and the vertical positioning of the upper test piece 5, the longitudinal stopper-6 is used to compress the upper test piece 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com