High-wear-resistant conductive strong-bonding coating and preparation method thereof

A high wear-resistant, coating technology, applied in the direction of coating, metal material coating process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Embodiment 1 of the present invention provides a highly wear-resistant and electrically conductive strong bonding coating, specifically providing a nickel-silver alloy coating formed on the surface of a copper and / or aluminum substrate by metallurgical bonding, which includes forming on copper and / or aluminum Or the transition layer on the surface of the aluminum substrate, the nickel-silver alloy layer formed on the surface of the transition layer, the copper and / or aluminum substrate, the transition layer, and the nickel-silver alloy layer are all metallurgical bonds, wherein the material of the transition layer is pure Ni metal , at least one of pure Cr metal, NiCr or MCrAlY alloy, M represents Ni, Co or NiCo, and the material of the high wear-resistant nickel-silver alloy layer includes pure nickel and pure Silver powder, the ratio of the thickness of the transition layer to the thickness of the high wear-resistant nickel-silver alloy layer is 2:1-1:3. When the ratio...

Embodiment 2

[0041] Embodiment 2 of the present invention provides a method for preparing a highly wear-resistant and conductive strong bonding coating on the surface of a copper and / or aluminum substrate, the method comprising:

[0042] Step 1: Pretreat and preheat the surface of the copper and / or aluminum substrate. The pretreatment includes at least degreasing and sandblasting the surface of the copper and / or aluminum substrate. The preheating temperature is 40°C to 300°C. The preheating time is 30 minutes to 120 minutes;

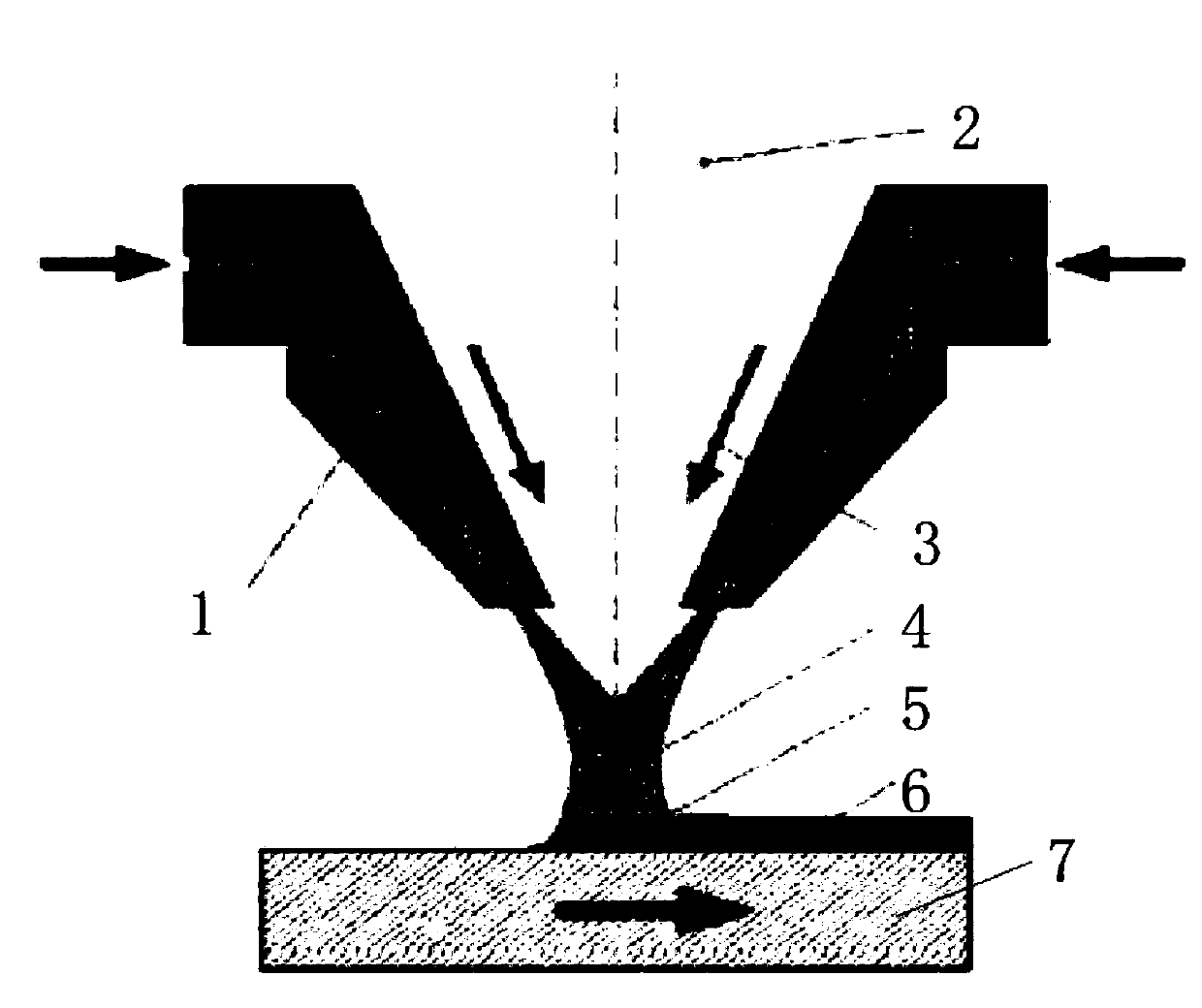

[0043] Step 2: Prepare a transition layer on the surface of the copper and / or aluminum substrate by using a coaxial powder feeding device with laser cladding technology, the material of the transition layer is at least one of pure Ni metal, pure Cr metal, NiCr or MCrAlY alloy Type, M represents Ni, Co or NiCo, and the transition layer is metallurgically bonded to the copper and / or aluminum substrate;

[0044] Specifically, a transition layer is prepared on the surfa...

Embodiment 3

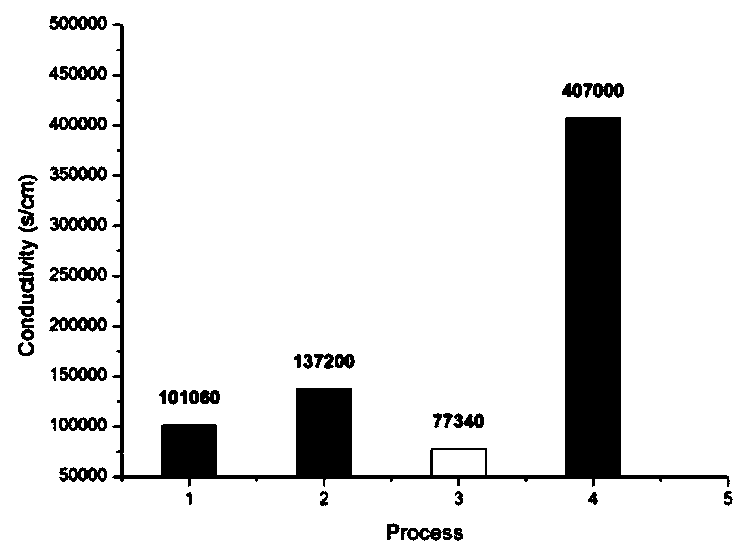

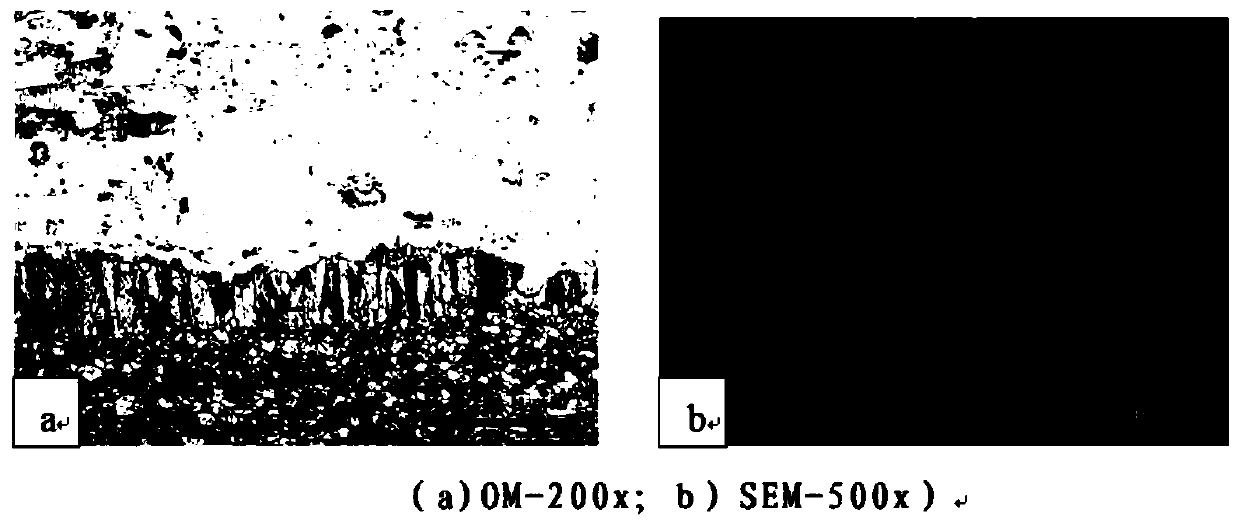

[0052] Embodiment 3 of the present invention provides a comparative test analysis result of the highly wear-resistant and conductive strong-bonding coating of the above-mentioned embodiment 1 prepared by using the different preparation processes of the above-mentioned embodiment 2, wherein, specifically, it is chromium-zirconium copper with a thickness of 20mm The wear-resistant conductive coating was prepared by laser cladding nickel-silver alloy powder with different process parameters on the surface of the substrate. The equipment used in the preparation process includes: a 6-axis robot system, a 4KW fiber laser, a core diameter of 100 μm, and a laser cladding powder feeder (the coaxial powder feeder is the powder feeding part of the laser cladding powder feeder). The specific preparation process parameters adopted by sample 1, sample 2 and sample 3 are shown in Table 1 below:

[0053] Table 1: Different process parameters used for different samples

[0054]

[0055] Ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com