Overturning sliding cavity door structure, plasma vacuum cavity and plasma treatment equipment

A processing equipment, sliding technology, applied in the direction of gaseous chemical plating, metal material coating process, discharge tube, etc., can solve the problems of production requirements that cannot meet the increasing demand, low production process efficiency, etc., to achieve replacement and maintenance. Effects of a vacuum environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

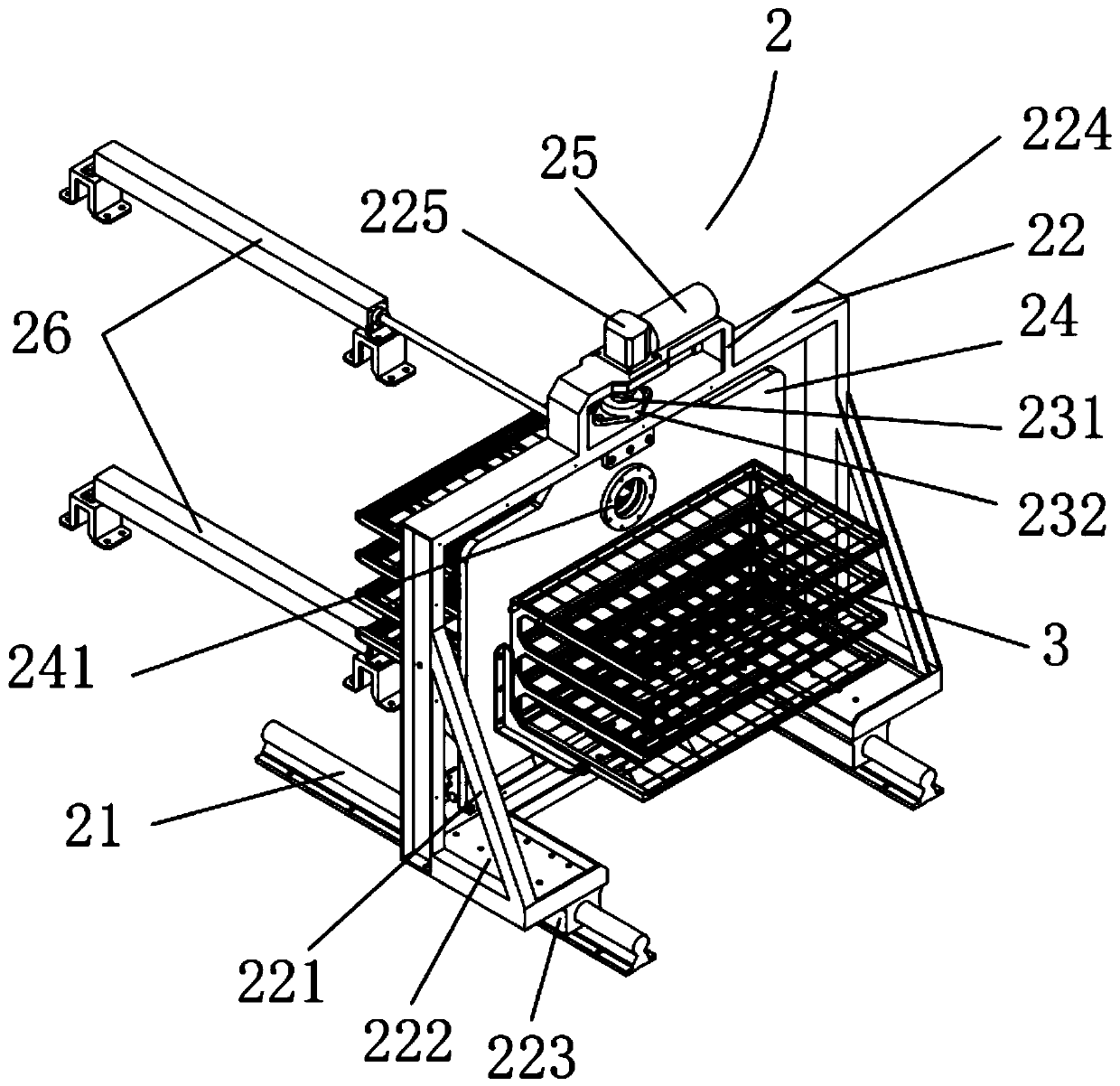

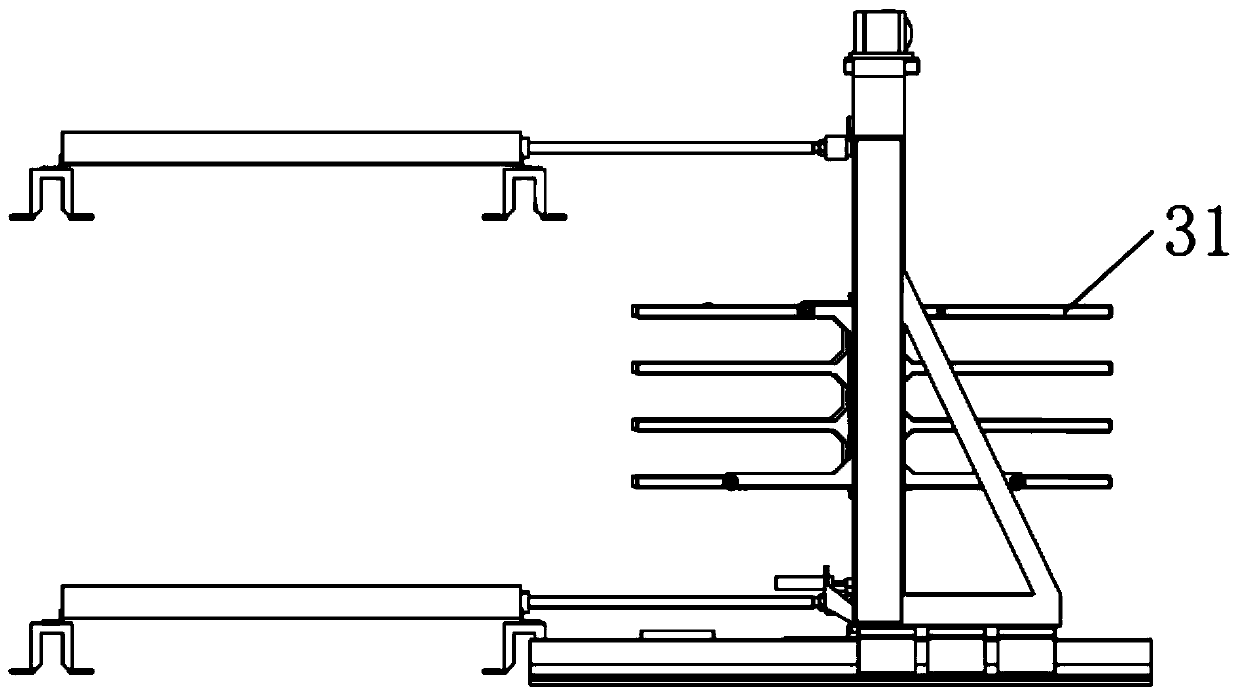

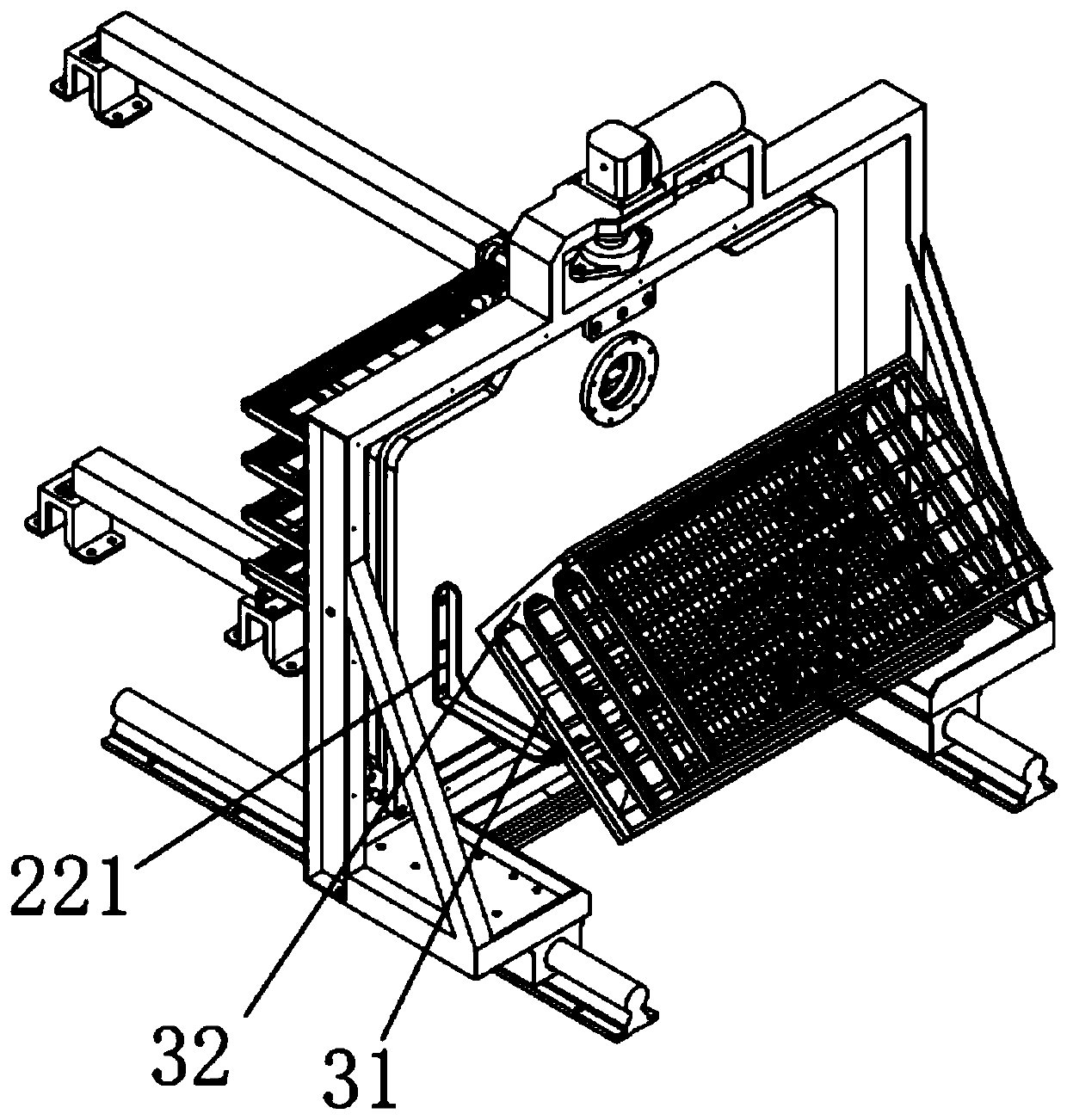

[0031] The present invention provides a flip-sliding cavity door structure 2, such as Figure 1-3 Said, including slide rail 21, the installation frame 22 that is slidably installed on the slide rail 21 and the chamber door 24 that is rotatably connected to the inside of the installation frame 22, the chamber door 24 both sides are provided with material shelf tray 3, and the chamber door 24 middle part wears There is a vertical rotation shaft 231, and the vertical rotation shaft 231 is installed inside the installation frame 22. The vertical rotation shaft 231 is driven by the driving mechanism A25 located at the top of the installation frame 22. The rotating shaft 231 rotates inside the installation frame 22, and the installation frame 22 is driven to slide by the driving mechanism B26 located outside it.

[0032] Preferably, both ends of the vertical rotating shaft 231 pass through the chamber door 24 and are mounted on the top and bottom ends of the installation frame 22 t...

Embodiment 2

[0041] The invention provides a vacuum cavity, such as Figure 4-5 As shown, the cavity body 1 and the cavity door structure 2 are included. The cavity door structure 2 is any one of the cavity door structures in the embodiment 1. The edge of the inlet and outlet 11 of the cavity body is provided with a sealing ring 12. The sliding door structure of the cavity The rail is perpendicular to the plane where the entrance and exit of the chamber body are located, and the installation frame is fixed on the outside of the entrance and exit, and is parallel to the plane where the entrance and exit are located. The shape of the chamber door matches the entrance and exit. Under the action of the driving mechanism B, the door structure makes the door and the inlet and outlet closely fit, and the inner wall of the chamber body and the door form a vacuum chamber. The chamber door can be rotated 360° in the horizontal direction along the vertical rotation axis in the installation frame, so ...

Embodiment 3

[0046] The present invention provides a plasma vacuum chamber. On the basis of the vacuum chamber provided in Embodiment 2, a positive pole and a negative pole that are relatively distributed and connected to an external power supply are added inside the chamber body. The positive pole and the negative pole are located in the chamber body. At the top and bottom of the inner side, the positive and negative electrodes are energized to generate plasma; or, the cavity body is not provided with positive and negative electrodes, and can be directly connected to an external plasma generator, and the external plasma generator can generate plasma directly. Fill in the vacuum chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com