Microcomputer controlled electro-hydraulic servo multi-functional pressure-shear test machine

A technology of electro-hydraulic servo and microcomputer control, which is applied in the testing of machines/structural components, using stable tension/pressure to test the strength of materials, measuring devices, etc., which can solve the problem that the detection accuracy cannot meet the requirements and the load capacity of the testing machine is small , many testing items, etc., to achieve the effect of complete functions, high rigidity, and reasonable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

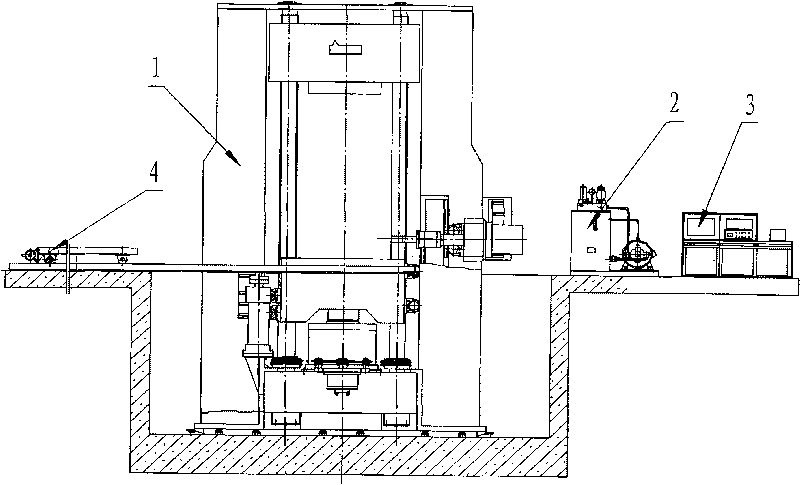

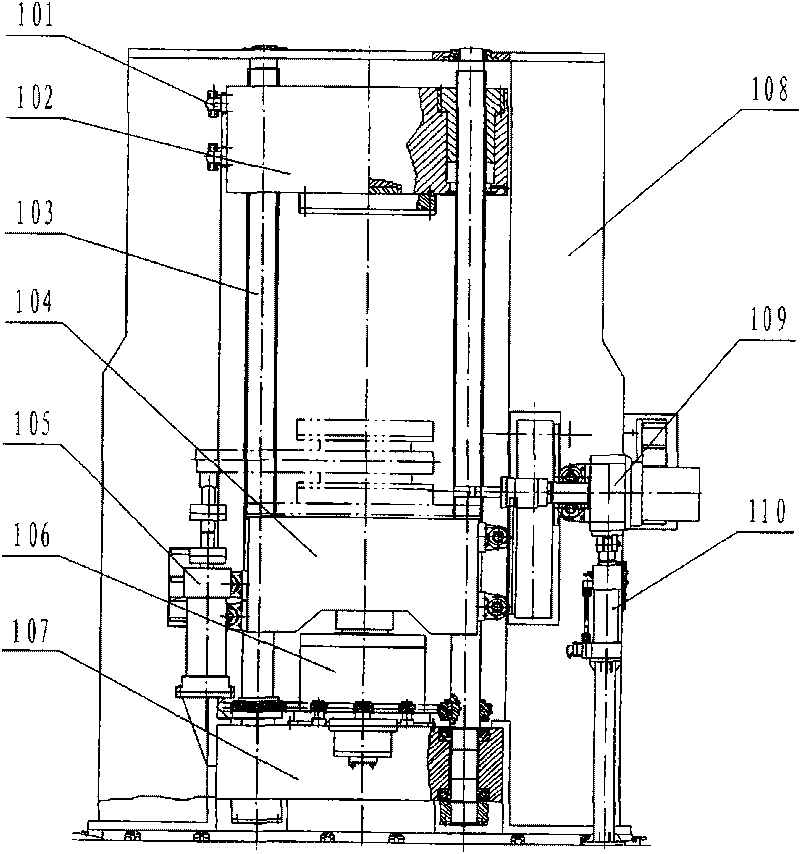

[0027] like figure 1 As shown, the present invention includes a host part 1 , a hydraulic system 2 , a control measurement system 3 and a sample transport trolley 4 . host part 1 as figure 2 As shown, it includes a load-bearing frame, and the load-bearing frame is composed of a frame 107, a lead screw 103, a movable beam 102, and a frame 108. Four frames 108 are installed on the four corners of the frame 107. The frame 108 is a shear-resistant The force frame is a square welded structure of equal strength with a small top and a large bottom. The lower end of the lead screw 103 is fixed on the machine base 107, the upper end is hinged with the top beam of the frame 108, the upper part of the lead screw 103 is equipped with a movable beam 102, and the side of the movable beam 102 is equipped with 8 locking oil cylinders 101, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com