Alternative multilayer graphene-rodlike ferric oxide composite material and hydrothermal synthesis method thereof

A technology of multi-layer graphene and composite materials, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of detachment, inability to play graphene and iron oxide composite materials, loss of activity, etc., and achieve raw material economy and good cycle performance , good volume deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Using ferrous sulfate as the iron source to prepare alternating multilayer graphene-rod iron oxide composite materials.

[0034] Take 50mg graphene dry powder and ultrasonically disperse it in 70ml water solution, and then add 0.56g FeSO4·4H to the solution 2 O and 0.27g CH 3 COONa·3H 2 O, stir quickly for 30 minutes, the solution is black; transferred to a 100ml reactor, hydrothermally heated at 100°C for 8h, then hydrothermally heated at 180°C for 24h, centrifuged and washed after reaction, washed with alcohol three times, washed three times with water, and dried at 80°C Dry to obtain the reaction product. The prepared product was uniformly mixed with carbon black and PTFE according to the ratio of 70:20:10, and then formed into a film on a pair of rollers, and then pressed on a copper mesh as the working electrode, and the lithium sheet was used as the counter electrode to form a button cell. Charge and discharge test.

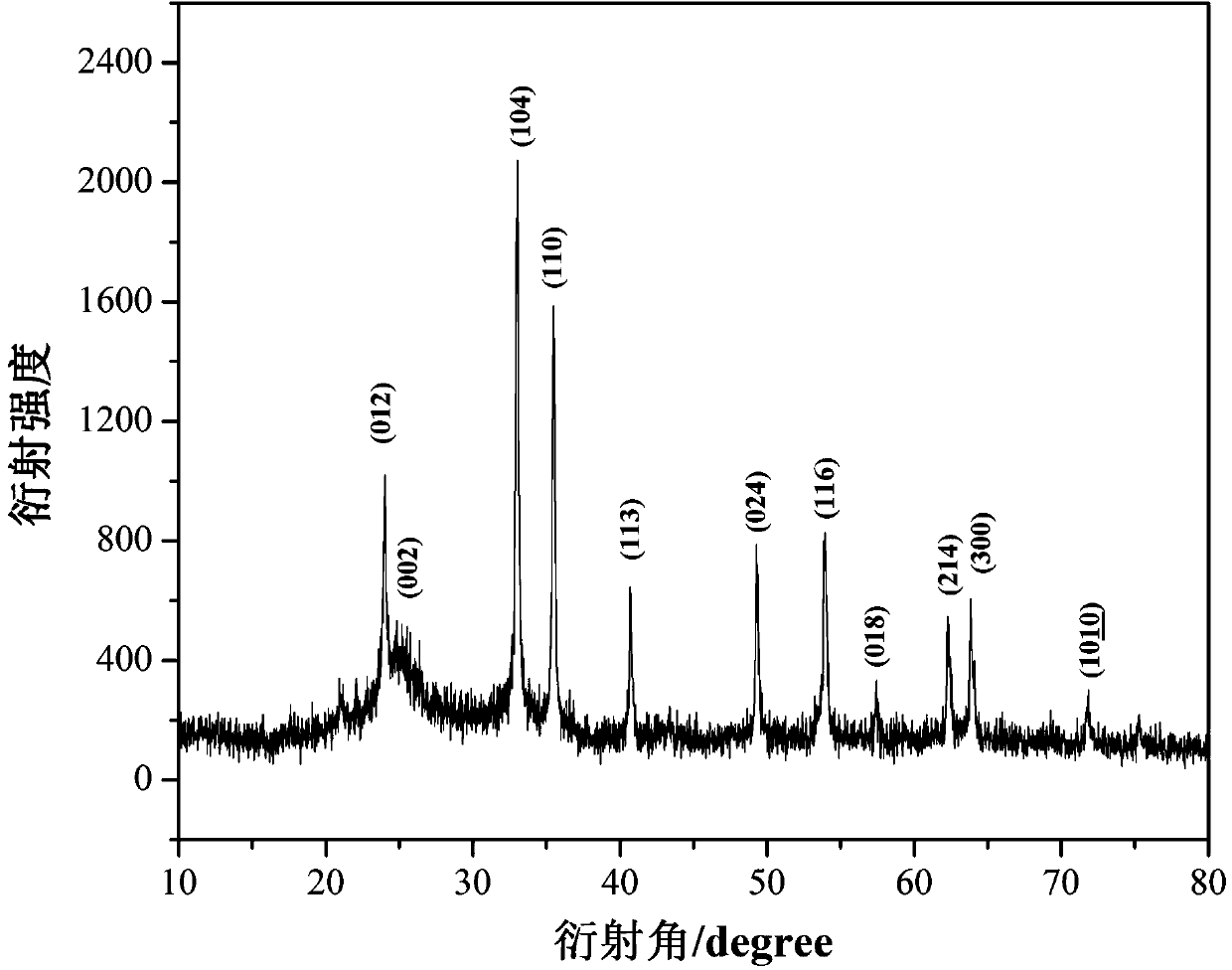

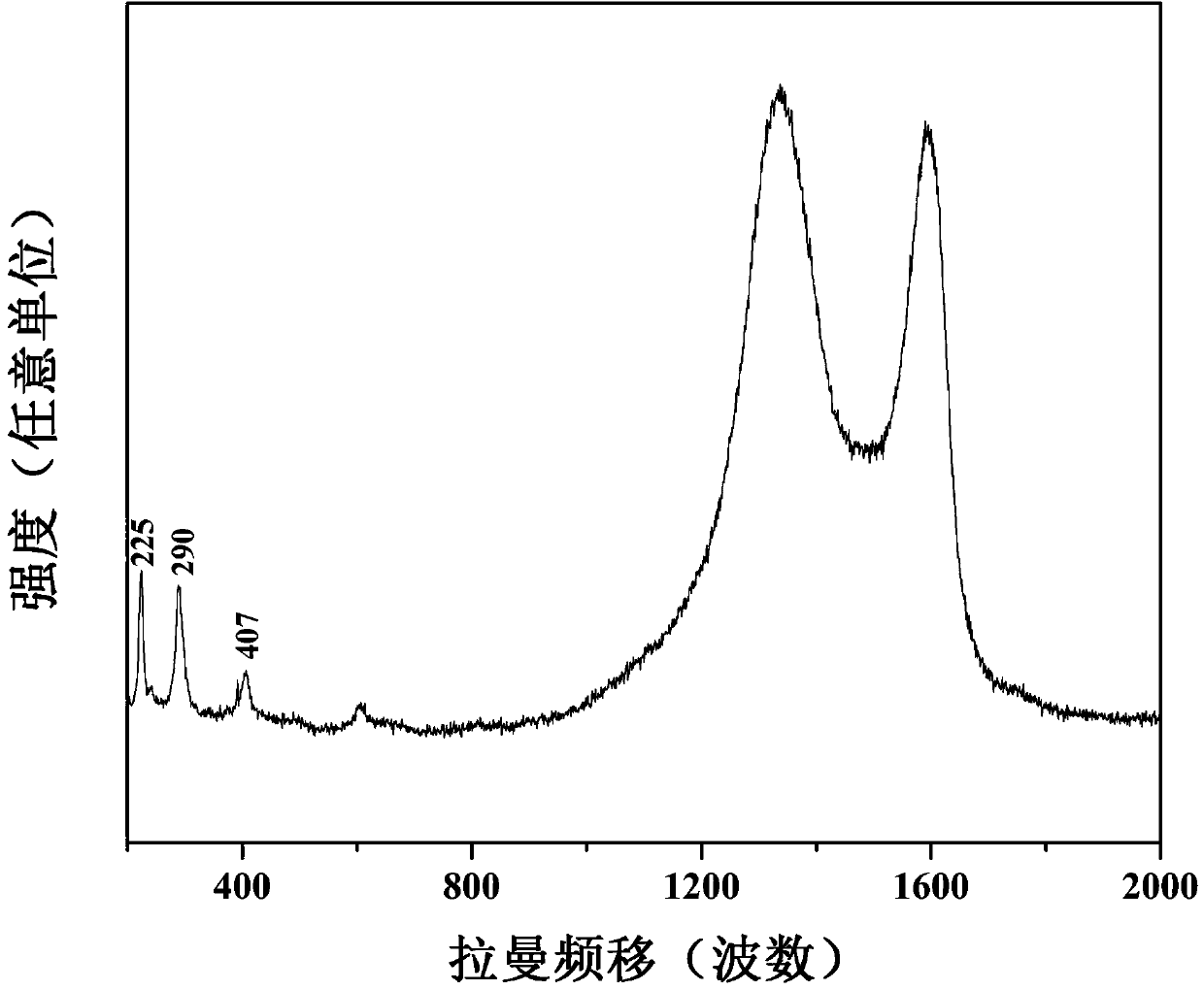

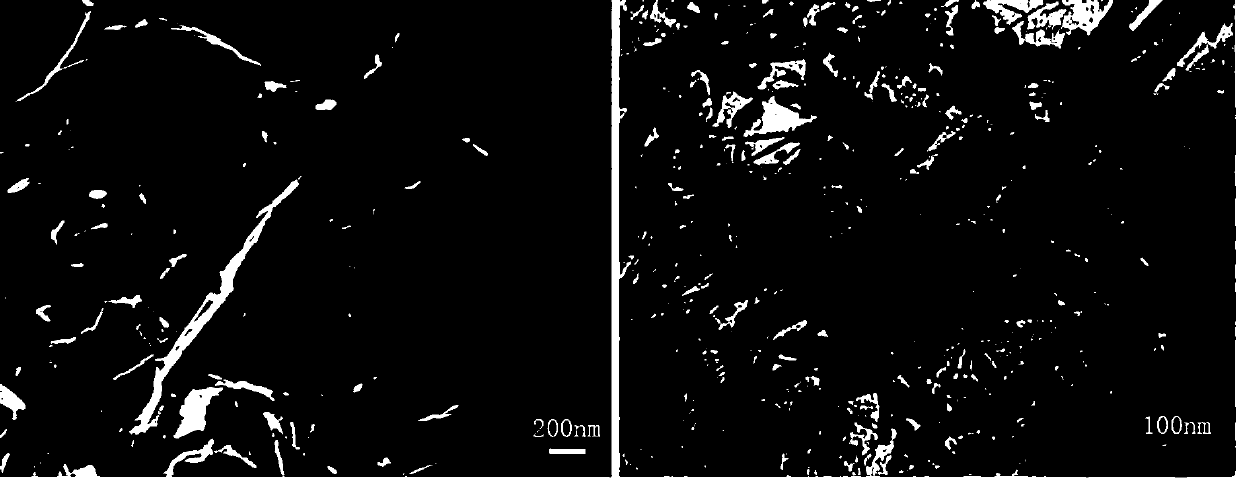

[0035] The XRD of the prepared product ...

Embodiment 2

[0037] Example 2: Using ferrous nitrate as iron source to prepare alternating multilayer graphene-rod iron oxide composite material.

[0038] Take 100mg graphene dry powder and ultrasonically disperse it in 120ml aqueous solution, and then add 0.6g Fe(NO 3 ) 2 And 0.41g CH 3 COONa·3H 2 O, stir quickly for 30 minutes, the solution is black; transfer to a 150ml reactor, hydrothermally heat at 100°C for 10h, then at 200°C for 24h, centrifuge and wash after reaction, wash with alcohol three times, wash three times with water, and dry at 80°C Dry to obtain the reaction product. After testing, the specific discharge capacity of the composite material reached 1063.2mAh / g in the second cycle.

Embodiment 3

[0039] Example 3: Using ferrous oxalate as iron source to prepare alternating multilayer graphene-rod iron oxide composite material.

[0040] Take 80mg graphene dry powder and ultrasonically disperse it in 100ml aqueous solution, and then add 0.43g FeC to the solution 2 O 4 And 0.8g CH 3 COONa, quickly stirred for 30 minutes, the resulting solution was black; transferred to a 120ml reactor, hydrothermally heated at 90°C for 10 hours, then hydrothermally heated at 180°C for 24 hours, after the reaction, centrifuged washing, alcohol washing three times, water washing three times, and 80°C drying Dry to obtain the reaction product. After testing, the specific discharge capacity of the composite material reached 1011.6mAh / g in the second cycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com