Method for forming end insulation of stator coil by vacuum pressure impregnation

A vacuum pressure impregnation, stator coil technology, applied in laying solid insulation, manufacturing motor generators, electrical components, etc., can solve the problems of uneven resin curing speed, unfavorable manufacturing method for rapid coil manufacturing, and large temperature difference between mold and coil, etc. To achieve the effect of uniform pressure, good rigidity and uniform wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

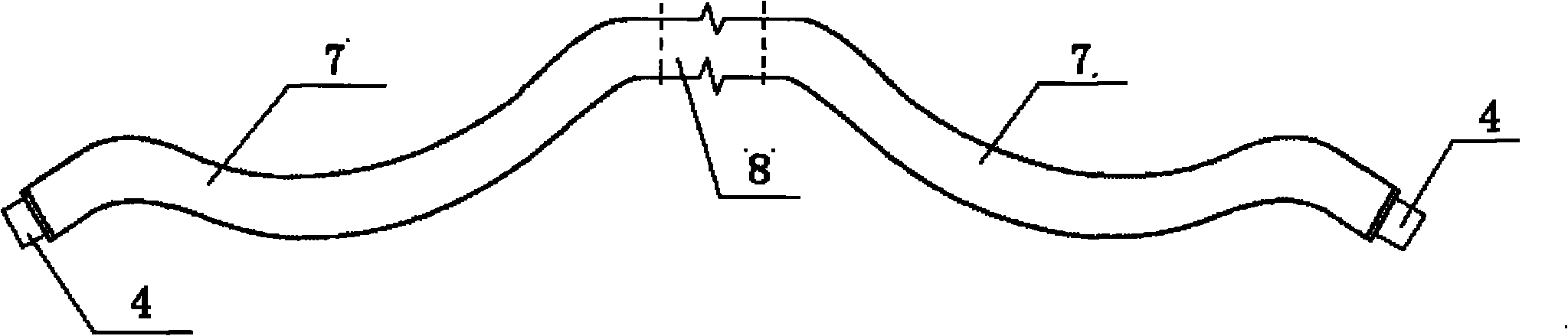

[0019] Such as figure 1 As shown, it is the front view of the stator coil. The stator coil needs to be cured after vacuum pressure impregnation treatment. Among them, the middle part 8 of the stator coil is cured by a traditional fixed mold, and the end part 7 of the stator coil is cured by the following method.

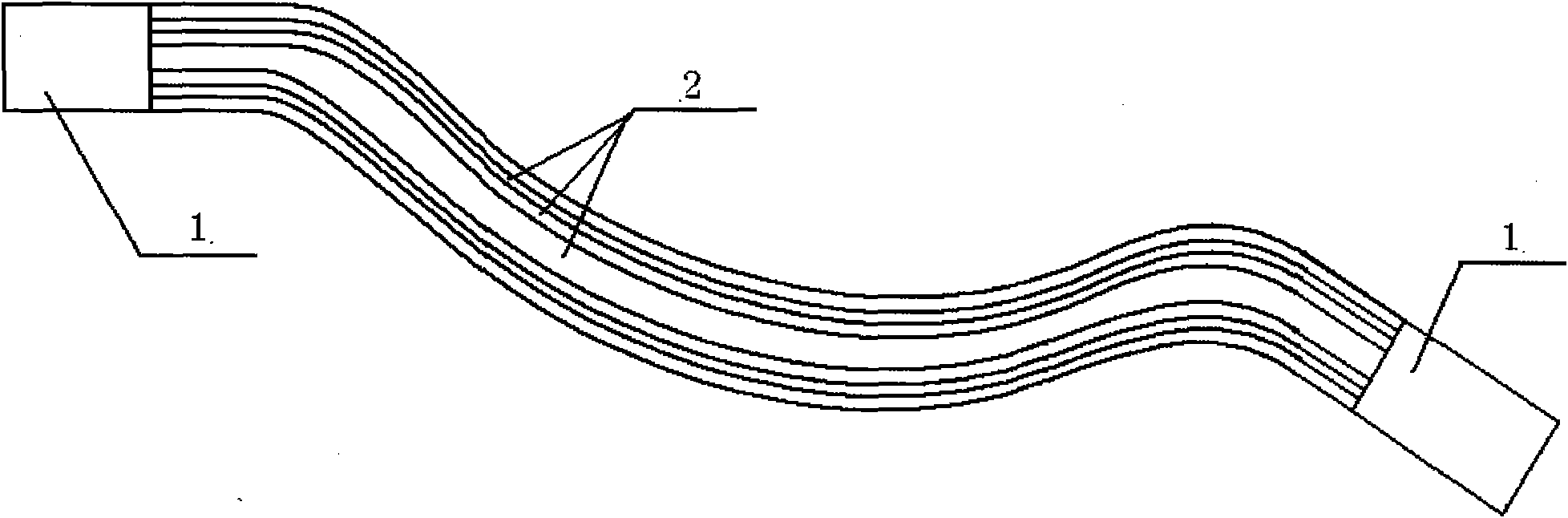

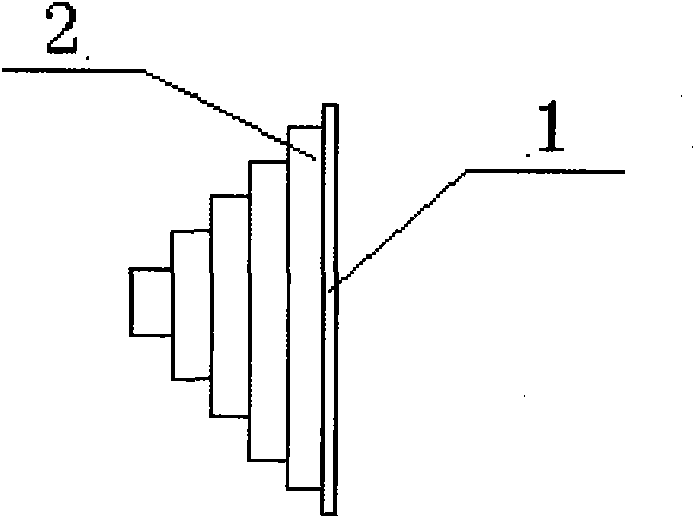

[0020] The first step is to cut the liner aluminum plate 1 according to the shape of the four sides of the stator coil end 7, the thickness of the liner aluminum plate 1 is 1 mm, and the width is between the width of the gelled coil 4 and the width of the stator coil 5 after insulation. The two ends of the backing aluminum plate 1 are 50mm longer than the ends 7 of the stator coil; cut the 2-thick unvulcanized neoprene rubber plate 2 into long strips, and the length of the unvulcanized neoprene rubber plate 2 is the same as that of the backing aluminum plate 1. The width of the first layer of unvulcanized neoprene rubber plate 2 of the liner aluminum plate 1 is 1mm s...

Embodiment 2

[0025] Such as figure 1 As shown, it is the front view of the stator coil. The stator coil needs to be cured after vacuum pressure impregnation treatment. Among them, the middle part 8 of the stator coil is cured by a traditional fixed mold, and the end part 7 of the stator coil is cured by the following method.

[0026] The first step is to cut the liner aluminum plate 1 according to the shape of the four sides of the stator coil end 7, the thickness of the liner aluminum plate 1 is 2 mm, and the width is between the width of the gelled coil 4 and the width of the stator coil 5 after insulation. Both ends of the backing aluminum plate 1 are 75mm longer than the end 7 of the stator coil; cut the 4mm thick unvulcanized neoprene rubber plate 2 into strips, the length of the unvulcanized neoprene rubber plate 2 is consistent with the liner aluminum plate 1, and it is close to the The width of the first layer of unvulcanized neoprene rubber plate 2 of the liner aluminum plate 1 is...

Embodiment 3

[0031] Such as figure 1 As shown, it is the front view of the stator coil. The stator coil needs to be cured after vacuum pressure impregnation treatment. Among them, the middle part 8 of the stator coil is cured by a traditional fixed mold, and the end part 7 of the stator coil is cured by the following method.

[0032] The first step is to cut the liner aluminum plate 1 according to the shape of the four sides of the stator coil end 7, the thickness of the liner aluminum plate 1 is 3mm, and the width is between the width of the gelled coil 4 and the width of the stator coil 5 after insulation. The two ends of the pad aluminum plate 1 are 100mm longer than the stator coil end 7; the 6mm thick unvulcanized neoprene rubber plate 2 is cut into strips, and the length of the unvulcanized neoprene rubber plate 2 is consistent with the liner aluminum plate 1. The width of the first layer of unvulcanized neoprene rubber plate 2 of the liner aluminum plate 1 is 5mm smaller than the wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com