High-dispersion flame-retardant ABS color masterbatch and preparation method thereof

A color masterbatch, high dispersion technology, applied in the production of bulk chemicals, etc., can solve the problems of many downstream molding processing components, high consumption of antioxidants, poor carrier flow performance, etc., to achieve low processing costs and shorten production. The effect of cycle and equipment friction is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

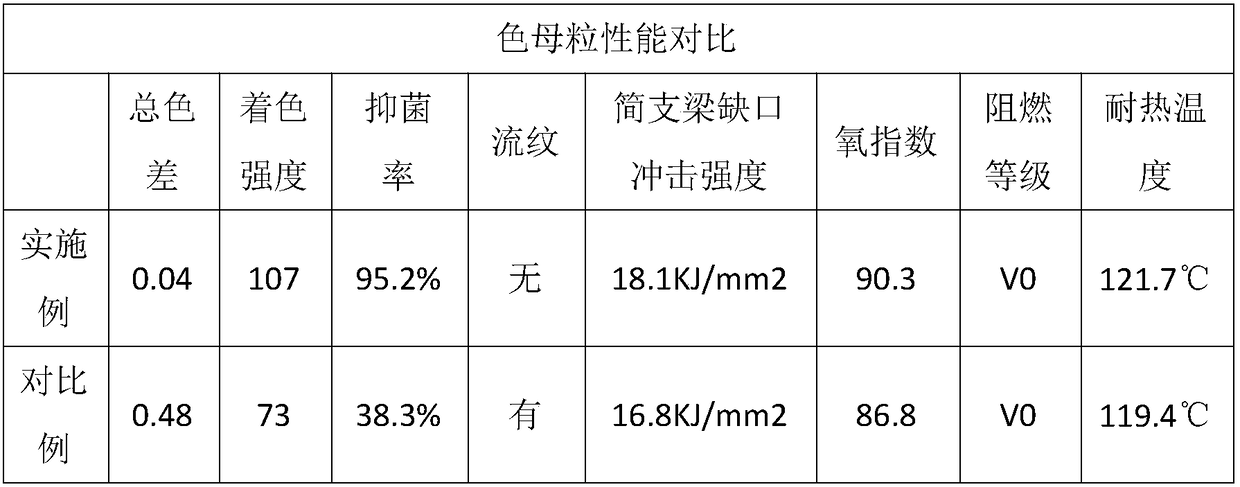

Examples

Embodiment

[0028] A high-dispersion flame-retardant ABS color masterbatch is made of the following raw materials in parts by weight:

[0029] 40 parts of polystyrene, 20 parts of inorganic pigment, 4 parts of composite dispersant, 10 parts of fiber, 6 parts of magnesium hydroxide flame retardant, 0.1 part of filler.

[0030] The inorganic pigment is carbon black.

[0031] The composite dispersant is prepared from dispersant YY-5023, maleic anhydride grafted polyethylene wax, and titanate coupling agent in a mass ratio of 2:2:1.

[0032] The fiber is composed of bamboo charcoal fiber and coconut charcoal fiber in a mass ratio of 2:1.

[0033] The filler is composed of calcium carbonate and calcium stearate in a mass ratio of 1:1.

[0034] A method for preparing highly dispersed flame-retardant ABS color masterbatch, comprising the following steps:

[0035] (1) Soak the inorganic pigment with 3 times deionized water for 1 day, then suction filter, wash the obtained filter residue 3 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com