Coloring technological method for aluminum alloy shell cases

A process method, aluminum alloy technology, applied in anodic oxidation, electrolytic coating, electrophoretic plating, etc., can solve the problems of single coloring, easy to fall off, light color, etc., and achieve the effect of uniform coloring, not easy to fall off, and deep color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

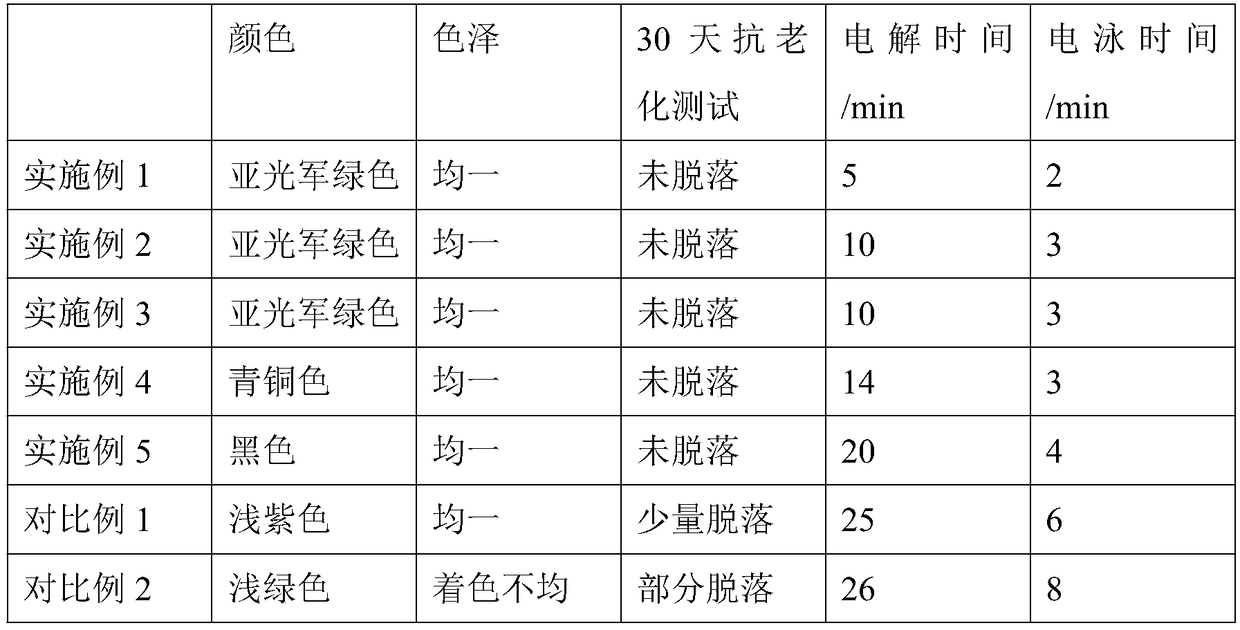

Examples

Embodiment 1

[0037] S1. Anodizing: put the extruded shell into the anodizing solution, the anodizing solution is prepared according to sulfuric acid 18%, YX-I 0.1%, YX-II 0.1%; direct current anodizing for 10min, the current density is 0.6Adm 2 , to form a 22um thick protective layer on the surface of the shell;

[0038] S2. Coloring and sealing: put the anodized cartridge case obtained in step S1 into a coloring solution with a temperature of 18°C, a pH value of 2, and a voltage of 5V, and electrolyze it for 5 minutes. After washing with water, put it into a nickel salt with a concentration of 3%. The holes were sealed in the solution for 1 min. Wherein, the coloring solution contains 23 g / L of stannous sulfate, 7 g / L of copper sulfate, and 50 g / L of sulfuric acid.

[0039] S3. Electrophoretic painting: put the cartridge casing after the sealing treatment in step S2 into the temperature of 20°C and pH of 7.8, containing 3 parts of water-soluble acrylic transparent varnish, 3 parts of sty...

Embodiment 2

[0042] S1. Anodizing: Put the extruded shell into the anodic oxidation solution, the anodic oxidation solution is prepared by sulfuric acid 20%, YX-I 1%, YX-II 0.5%; direct current anodization for 12min, the current density is 0.8Adm 2 , to form a 28um thick protective layer on the surface of the shell;

[0043] S2. Coloring and sealing: put the anodized cartridge casing obtained in step S1 into a coloring solution with a temperature of 20°C, a pH value of 4, and a voltage of 10V, and electrolyze it for 10 minutes. After washing, put a nickel salt with a concentration of 4%. The holes were sealed in the solution for 2 min. Among them, the coloring solution contains 33 g / L of stannous sulfate, 7 g / L of copper sulfate pentahydrate, and 55 g / L of sulfuric acid.

[0044] S3. Electrophoretic painting: put the cartridge casing after the sealing treatment in step S2 into the temperature of 24° C., pH 8, containing 5 parts of water-soluble acrylic transparent varnish, 4 parts of styr...

Embodiment 3

[0047]S1. Anodizing: Put the extruded cartridge case into an anodic oxidation solution, which is prepared by sulfuric acid 25%, YX-I 1.5%, YX-II 1%; direct current anodic oxidation for 28min, current density is 0.8Adm 2 , to form a 30um thick protective layer on the surface of the shell;

[0048] S2. Coloring and sealing: put the anodized cartridge casing obtained in step S1 into a coloring solution with a temperature of 20°C, a pH value of 4, and a voltage of 10V, and electrolyze it for 10 minutes. After washing with water, put a nickel salt with a concentration of 4%. The holes were sealed in the solution for 3 min. Among them, the coloring liquid contains copper sulfate pentahydrate 43g / L, stannous sulfate 8g / L, sulfuric acid 65g / L.

[0049] S3. Electrophoretic painting: put the cartridge casing after the sealing treatment in step S2 into a temperature of 24°C and a pH of 8, containing 5 parts of water-soluble acrylic transparent varnish, 4 parts of styrene, 3 parts of but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com