Glaze coloring agent for waterborne woodenware coating and preparation method thereof

A color wipe, water-based technology, applied in the direction of coating, can solve the problems of inability to combine water-based primers, poor compatibility of water-based coatings, swelling of wood surface, etc., to achieve excellent color fixing effect, uniform coloring, and interlayer bonding. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

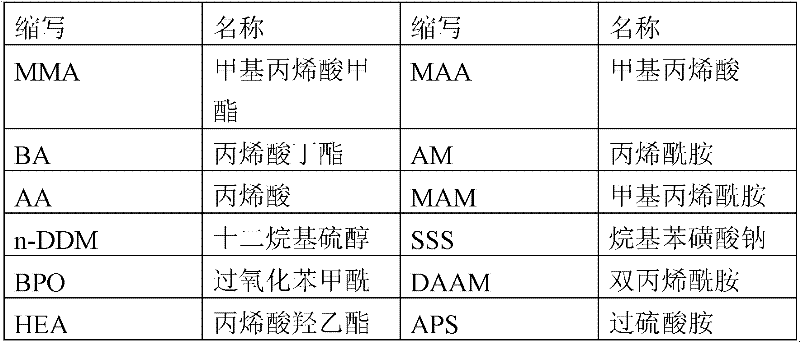

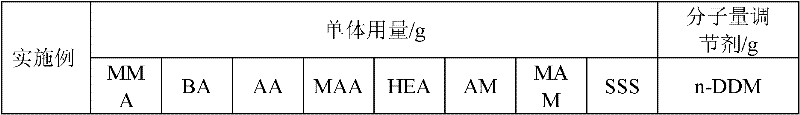

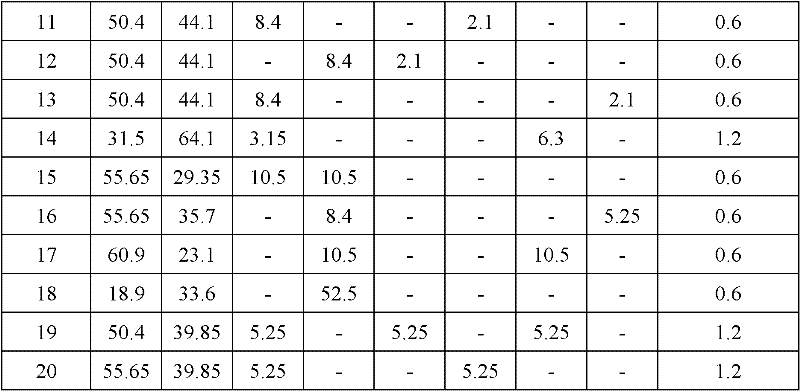

[0027] Preparation of Acrylate Polymer Emulsion

[0028]Under the protection of nitrogen, add 2.52g of reactive emulsifier allyl polyethoxysulfonate (SE-10N) into a 500mL four-neck flask equipped with a thermometer, stirring device, reflux cooler and dropping funnel , 78mL deionized water (DI), start stirring at 600 rpm, add seed monomer after 5 minutes, including: 4.54g butyl acrylate, 6.81g methyl methacrylate, 0.25g methacrylic acid and 10mL containing acrylamide 1g of water (DI) solution, pre-emulsified for 15 minutes, heated up to 82°C and reflux occurred, added 10mL of initiator water (DI) solution containing 0.32g ammonium persulfate to initiate polymerization, until no reflux occurred, began to drop The remaining monomer mixture, including: 40.82g of butyl acrylate, 61.24g of methyl methacrylate, 2.27g of methacrylic acid and 35mL of water (DI) solution containing 9.07g of acrylamide, while adding 40mL of 0.32g of persulfuric acid Ammonium water (DI) solution, the dro...

Embodiment 21

[0037] Preparation of Acrylate Polymer Emulsion

[0038] Under the protection of nitrogen, add 2.52g of reactive emulsifier allyl polyethoxysulfonate (SE-10N) into a 500mL four-neck flask equipped with a thermometer, stirring device, reflux cooler and dropping funnel , 78mL deionized water (DI), start stirring at 600 rpm, add seed monomer after 5 minutes, including: 3.53g of butyl acrylate, 2.27g of methyl methacrylate, 0.13g of methacrylic acid and 0.5g of acrylamide , pre-emulsified for 15 minutes, heated up to 82°C and refluxed, added 10mL of initiator water (DI) solution containing 0.32g ammonium persulfate to initiate polymerization, until no reflux occurred, began to drop the remaining monomer mixture, including : butyl acrylate 67.03g, methyl methacrylate 43.09g and methacrylic acid 2.39g, 40mL water (DI) solution containing 0.32g ammonium persulfate and 35mL water (DI) solution containing 9.58g acrylamide were added dropwise , the dropping time is 2 hours. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com