Automatic sugar spraying system

A sugar liquid and nozzle technology, applied in the field of automatic sugar spraying system, can solve the problems of difficult to maintain stable sugar liquid concentration, short shelf life, low quality control level, etc., achieve stable and uniform coloring effect, fast drying speed, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

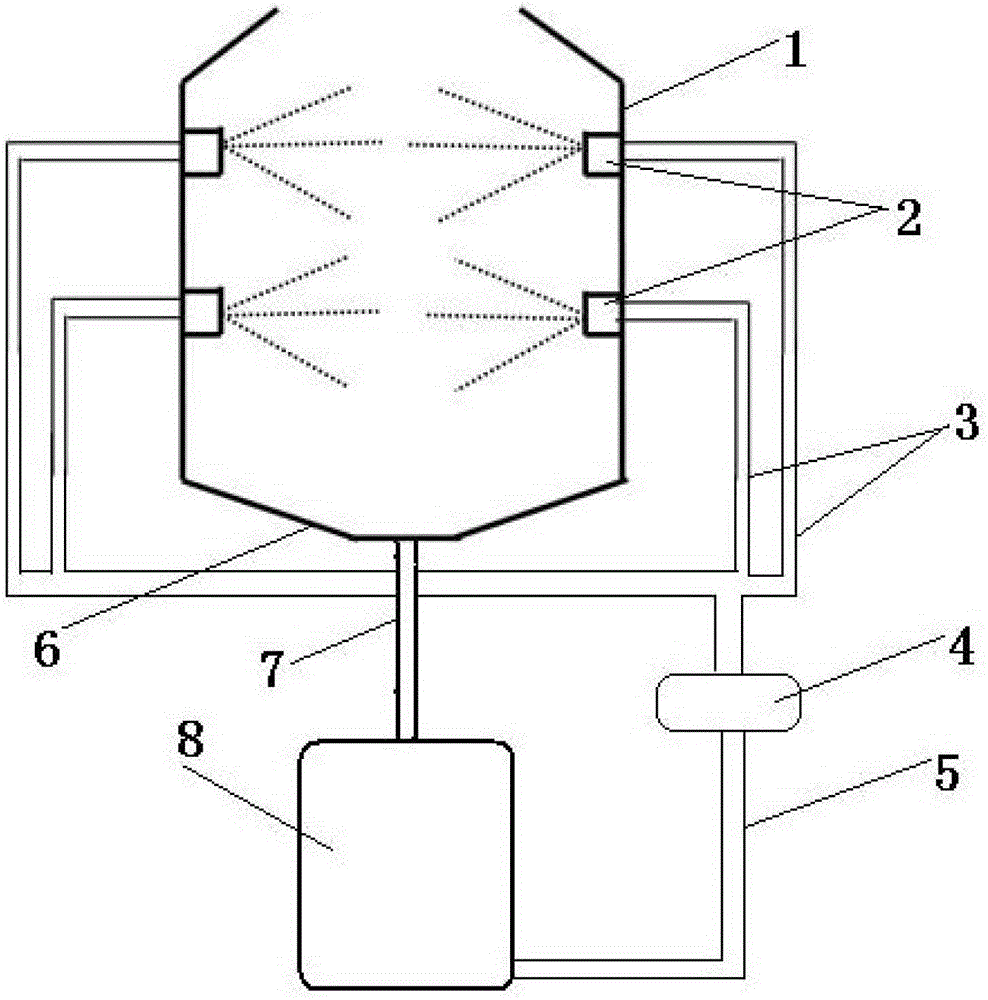

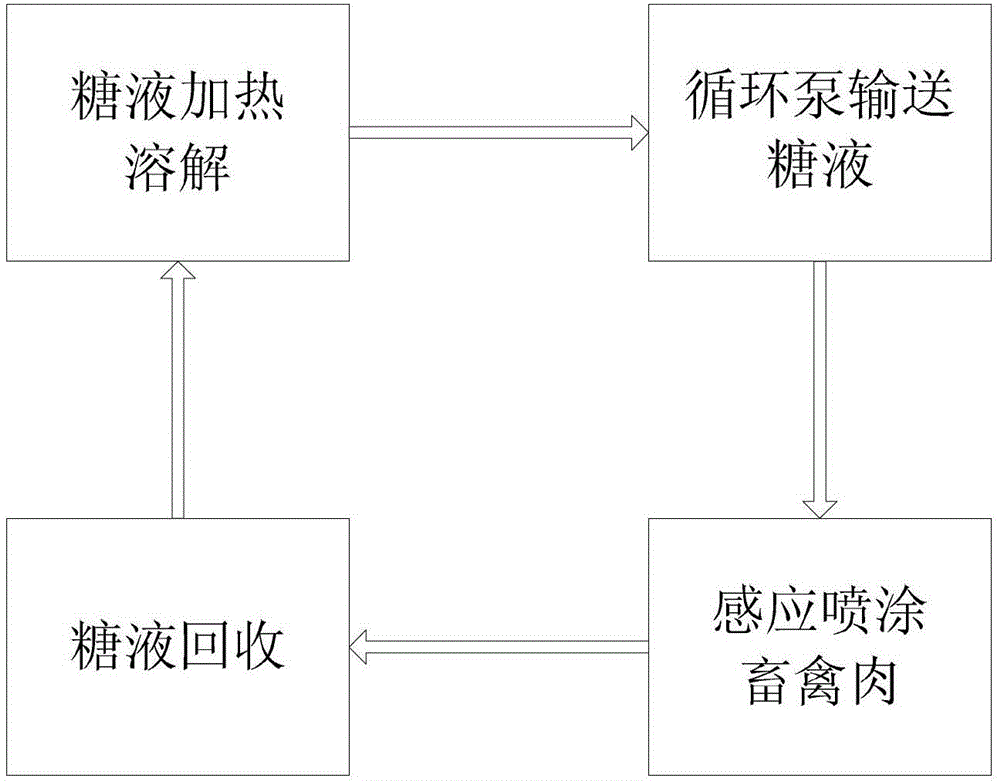

[0026] Such as figure 1 As shown, the present invention includes a baffle plate 1, a nozzle 2, a sugar solution output pipeline 3, a conveying circulation pump 4, a sugar solution pumping pipeline 5, a sugar solution collecting deflector 6, a sugar solution recovery pipeline 7 and a sugar solution storage tank 8.

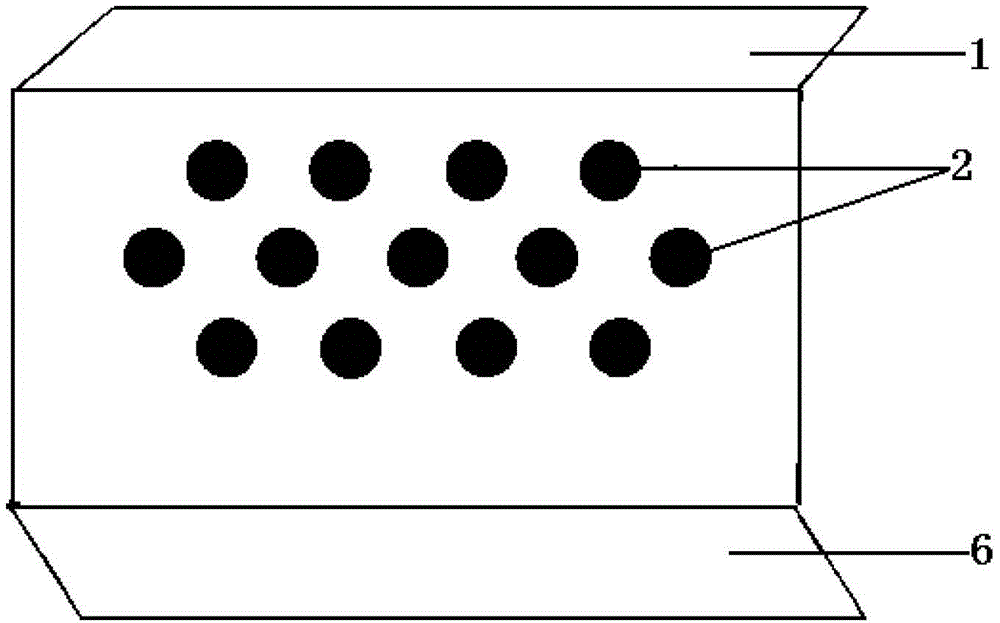

[0027] Spraying equipment (such as figure 2 shown), including two baffles 1 and a plurality of nozzles 2, the two baffles 1 are spaced apart from each other and arranged vertically, and the baffle 1 includes an inwardly inclined part at the upper end and a vertical part at the lower end. The nozzles 2 are evenly distributed on the vertical part of the baffle plate 1, and the plurality of nozzles 2 communicate with the circulating pump 4 through the sugar liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com