Rib crack or bogging resistant environmentally-friendly photocurable high-filling GLAZE coloring agent

An environmentally friendly, light-curing technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of less improved technology, achieve good fullness, good compatibility and interlayer bonding, good dispersion stability and The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principle of the present invention is to obtain a new type of photocurable glas by selecting suitable photocurable resins and extremely low toxicity and irritating active monomers to solve the above-mentioned shortcomings. The base color can also fill the wood conduit, reduce the coating amount of the primer, no organic solvent volatilizes, and the curing is completed within 5 seconds under the irradiation of ultraviolet light, with high efficiency and suitable for industrial production.

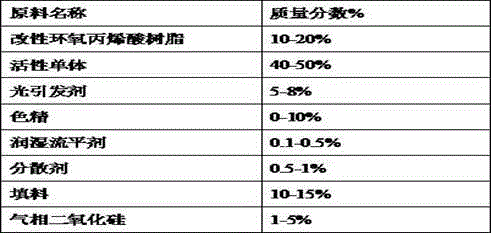

[0015] Production formula of the present invention is:

[0016] raw material name Mass fraction % Modified epoxy acrylic resin 10-20% active monomer 40-50% Photoinitiator 5-8% color essence 0-10% Wetting and leveling agent 0.1-0.5% Dispersant 0.5-1% filler 10-15% fumed silica 1-5%

[0017] Wherein, the modified epoxy acrylic resin is at least one of ETERNAL6202, ETERNAL622-100, CN2101, CN112C60, EB3702, LR8986; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com