Meta-aromatic polyamide pure-white grey cloth industrialized dyeing method

The technology of grey cloth and original white is applied in the field of dyeing, which can solve the problems of easy wrinkling and uneven dyeing, and achieve the effect of smooth cloth surface, high dyeing fastness and cost saving of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Gray cloth preparation: pure aramid gray cloth weight 220g / m 2 , the dyeing tank is 600 meters, and the cloth weight is 198KG;

[0039] 2) Put the gray cloth above on a stenter drying and setting machine, and perform high-temperature presetting treatment according to the following parameters: setting temperature 220°C, cloth speed 25m / min.

[0040] 3) Put the gray cloth pre-set at high temperature into a high-temperature and high-pressure overflow dyeing machine with a capacity of 400KG, feed in 2600KG of water, heat up to 85°C and wash with hot water for 10 minutes.

[0041] 4) Calculate based on 400kg of dyed aramid gray fabric per cylinder, set the water level according to the bath ratio of 1:13, add 2g / l of water softener and penetrating agent, and run for 10 minutes;

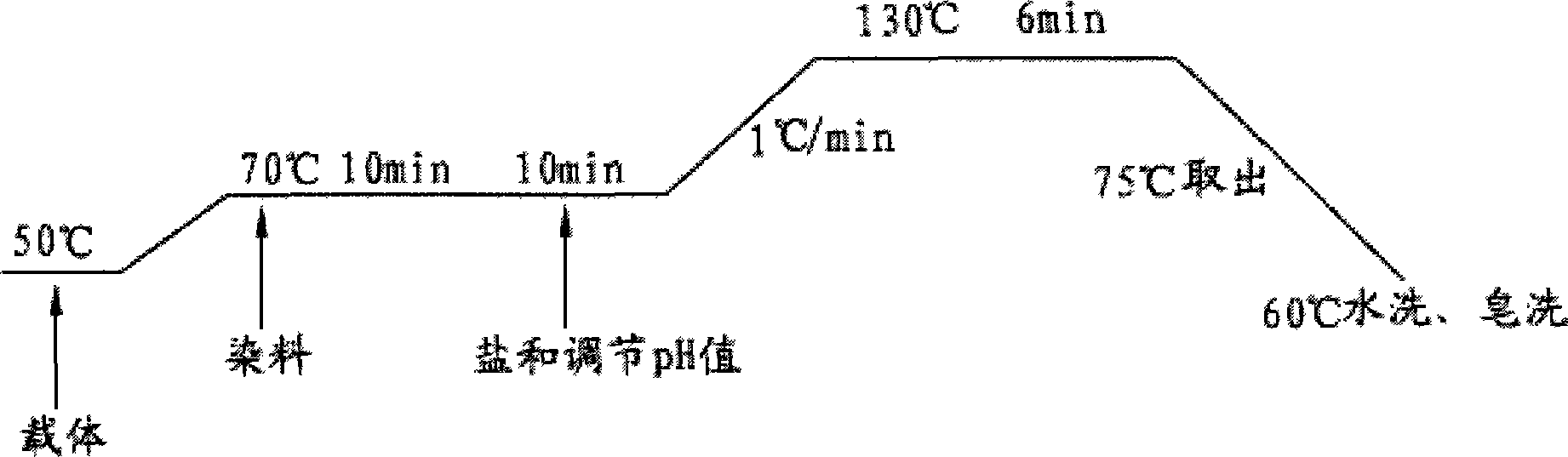

[0042] 5) Raise the temperature to 50°C at a rate of 1.2°C / min, and add 30g / l of dyeing carrier;

[0043] 6) Raise the temperature to 75°C at a rate of 1.2°C / min, add the screened dye, and run f...

Embodiment 2

[0050] 1) Gray cloth preparation: pure aramid gray cloth weight 220g / m 2 , the dyeing tank is 600 meters, and the cloth weight is 198KG;

[0051] 2) Put the gray cloth above on a stenter drying and setting machine, and perform high-temperature pre-setting treatment according to the following parameters: setting temperature 200°C, cloth speed 20m / min.

[0052] 3) Put the gray cloth pre-set at high temperature into a high-temperature and high-pressure overflow dyeing machine with a capacity of 400KG, feed in 2000KG of water, heat up to 80°C and wash with hot water for 15 minutes.

[0053] 4) Calculate based on 400kg of dyed aramid gray fabric per cylinder, set the water level according to the bath ratio of 1:10, add 2g / l of water softener and penetrating agent, and run for 10 minutes;

[0054] 5) Raise the temperature to 50°C at a rate of 1.2°C / min, and add 20g / l of dyeing carrier;

[0055] 6) Raise the temperature to 75°C at a rate of 1.2°C / min, add the screened dye, and run ...

Embodiment 3

[0062] 1) Gray cloth preparation: pure aramid gray cloth weight 220g / m 2 , the dyeing tank is 600 meters, and the cloth weight is 198KG;

[0063] 2) Put the gray cloth above on a stenter drying and setting machine, and perform high-temperature pre-setting treatment according to the following parameters: setting temperature 230°C, cloth speed 30m / min.

[0064] 3) Put the gray cloth pre-set at high temperature into a high-temperature and high-pressure overflow dyeing machine with a capacity of 400KG, feed in 2800KG of water, heat up to 90°C and wash with hot water for 8 minutes.

[0065] 4) Calculate based on 400kg of dyed aramid gray fabric per cylinder, set the water level according to the bath ratio of 1:15, add 2g / l of water softener and penetrating agent, and run for 10 minutes;

[0066] 5) Raise the temperature to 50°C at a rate of 1.2°C / min, and add 20g / l of dyeing carrier;

[0067] 6) Raise the temperature to 75°C at a rate of 1.2°C / min, add the screened dye, and run f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com