PLA (polylactic acid) degradable color master batch and preparation method thereof

A color masterbatch and pigment technology, which is applied in the field of plastic coloring, can solve the problems affecting the environmental protection and degradation performance of PLA color masterbatch, and achieve the effects of easy control of processing technology, uniform coloring and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

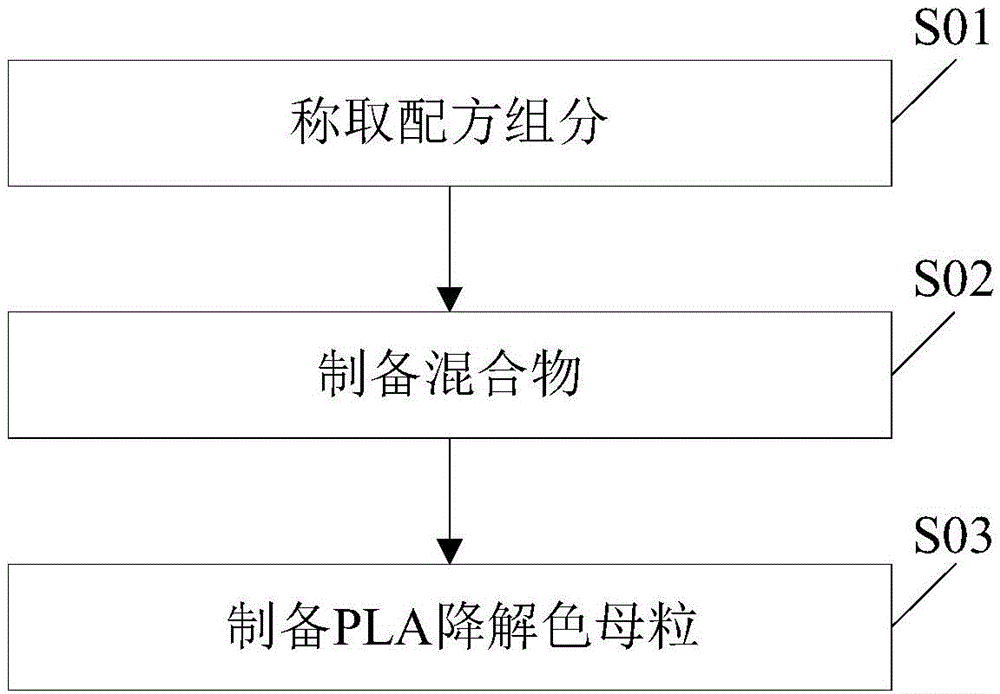

[0036] Correspondingly, the embodiment of the present invention provides a method for preparing PLA degradable color masterbatch, the flow chart of the preparation method is as follows figure 1 Shown, this preparation method comprises the steps:

[0037] S01 Weighing formula components

[0038] Weigh the PLA plastics, refined pigments and auxiliary agents respectively according to the formula of the above-mentioned PLA degraded color masterbatch;

[0039] S02 Prepare the mixture

[0040] Add the PLA plastic, refined pigments and additives weighed in step S01 into a mixer, and mix evenly to obtain a mixture;

[0041] S03 melt extrusion

[0042] Add the mixture obtained in step S02 into a twin-screw extruder, and melt extrude to obtain PLA degraded color masterbatch. The process conditions are: the extrusion temperature is 200-230°C, the long diameter of the twin-screw extruder The ratio is 40:1~52:1, the speed of twin-screw extruder is 300-550rpm, extruded into PLA masterba...

Embodiment 1

[0048] This embodiment PLA degradation color masterbatch, by weight percentage, is made up of following components:

[0049] PLA plastic 70%, refined pigment 22%, additives 8%.

[0050] Its preparation method is as follows:

[0051] (1) take each component by above-mentioned percentage by weight;

[0052](2) Put the PLA plastics, refined pigments and additives weighed in the step (1) into a mixer, and mix evenly to obtain a mixture;

[0053] (3) Add the mixture obtained in step (2) into a twin-screw extruder, and melt and extrude to obtain a PLA degraded masterbatch. The process conditions are: the extrusion temperature is 200-230°C, and the twin-screw extruder The length-to-diameter ratio of the extruder is 40:1~52:1, and the speed of the twin-screw extruder is 300-550rpm.

Embodiment 2

[0055] The PLA degradation color masterbatch of this embodiment, by weight percentage, is made up of following components:

[0056] PLA plastic 66%, refined pigment 25%, additive 9%.

[0057] Its preparation method is as follows:

[0058] (1) take each component by above-mentioned percentage by weight;

[0059] (2) Put the PLA plastics, refined pigments and additives weighed in the step (1) into a mixer, and mix evenly to obtain a mixture;

[0060] (3) Add the mixture obtained in step (2) into a twin-screw extruder, and melt and extrude to obtain a PLA degraded masterbatch. The process conditions are: the extrusion temperature is 200-230°C, and the twin-screw extruder The length-to-diameter ratio of the extruder is 40:1~52:1, and the speed of the twin-screw extruder is 300-550rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com