Method for preparing erbium-containing red glass

A glass and red technology, applied in the field of preparation of erbium-containing red glass, achieves the effects of high light transmittance, uniform coloring and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

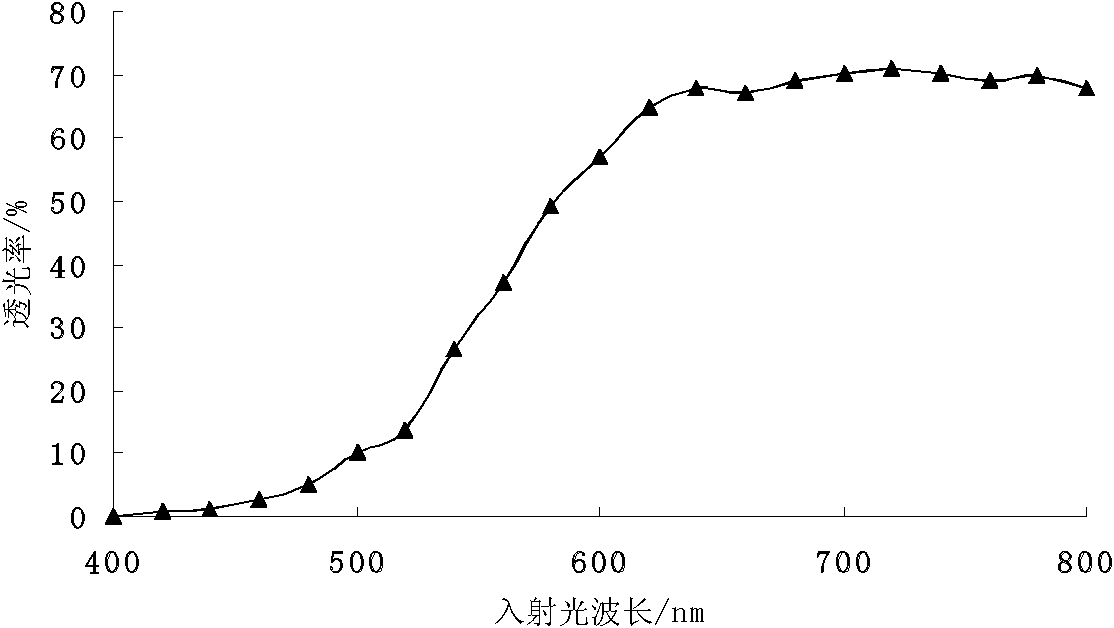

Image

Examples

Embodiment 1

[0009] Embodiment 1: the first step: the preparation of colorant glass 1) at first, by mass percentage, the P of 60% 2 o 5 , 27% BaO, 3.5% Al 2 o 3 , 7% Er 2 o 3 , 2.49% CeO 2 and 0.01% Fe 2 o 3 Mix evenly; 2) Next, add the uniformly mixed raw materials into a corundum crucible or a bisque crucible at 1100°C for melting to obtain molten glass at a melting temperature of 1300°C and keep it warm for 60 minutes at the melting temperature; 3 ) Finally, quench the melted glass in the crucible with water at room temperature, put the crucible back into the furnace, and keep the furnace temperature at 1100°C; take out the water-quenched glass slag, dry and ball-mill it to 50 mesh to obtain the colorant Glass; the second step: the preparation of red glass 1) at first, by mass percentage 61%P 2 o 5 , 30% BaO, 3.99% Al 2 o 3 , 0.01% Fe 2 o 3 , 5% of the above-mentioned colorant glass is mixed uniformly; 2) secondly, the uniformly mixed raw material is added to the above-ment...

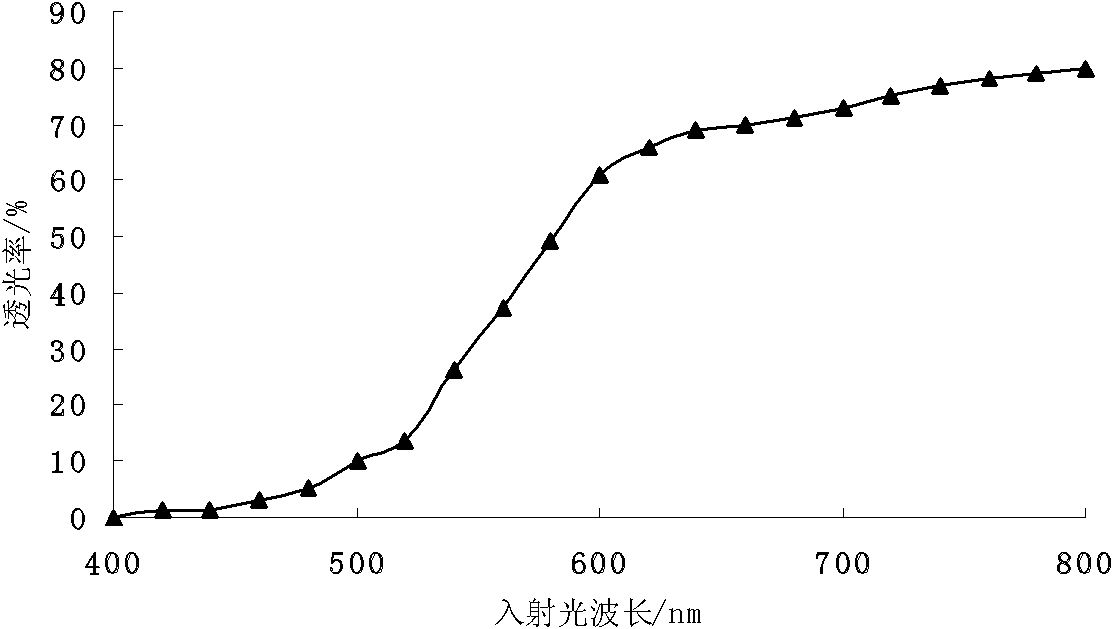

Embodiment 2

[0011] Embodiment 2: the first step: the preparation of colorant glass 1) at first, by mass percentage, the P of 57% 2 o 5 , 30% BaO, 3.5% Al 2 o 3 , 7% Er 2 o 3 , 2.49% CeO 2 and 0.01% Fe 2 o 3 Mix evenly; 2) Next, add the uniformly mixed raw materials into a corundum crucible or a bisque crucible at 1100°C for melting to obtain molten glass at a melting temperature of 1300°C and keep it warm for 60 minutes at the melting temperature; 3 ) Finally, quench the melted glass in the crucible with water at room temperature, put the crucible back into the furnace, and keep the furnace temperature at 1100°C; take out the water-quenched glass slag, dry and ball-mill it to 50 mesh to obtain the colorant Glass; the second step: the preparation of red glass 1) at first, 55% P by mass percentage 2 o 5 , 33% BaO, 3.99% Al 2 o 3 , 0.01% Fe 2 o 3 , 8% of the above-mentioned colorant glass is mixed uniformly; 2) secondly, the uniformly mixed raw material is added to the above-men...

Embodiment 3

[0013] Embodiment 3: the first step: the preparation of coloring agent glass 1) at first, by mass percentage with 40% P 2 o 5 , 25% BaO, 1% Al 2 o 3 , 30% Er 2 o 3 , 3.9999% CeO 2 and 0.0001% Fe 2 o 3 Mix evenly; 2) Next, add the uniformly mixed raw materials into a corundum crucible or a bisque crucible at 1100°C to melt to obtain molten glass, the melting temperature is 1350°C, and keep the temperature for 60 minutes at the melting temperature; 3 ) Finally, quench the melted glass in the crucible with water at room temperature, put the crucible back into the furnace, and keep the furnace temperature at 1100°C; take out the water-quenched glass slag, dry and ball-mill it to 50 mesh to obtain the colorant Glass; the second step: the preparation of red glass 1) at first, 70% P by mass percentage 2 o 5 , 20% BaO, 1% Al 2 o 3 , 0.0001% Fe 2 o 3 , 8.9999% of the above-mentioned colorant glass is mixed uniformly; 2) Secondly, the uniformly mixed raw material is added i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com