Supercritical fluid material finishing

a technology of fluid material and supercritical fluid, which is applied in the direction of liquid/gas/vapor treatment of definite length materials, textile treatment, textiles and paper, etc. it can solve the problems of unsuitable chemicals entering the wastewater stream, scf dyeing at a large scale, and increase the complexity of the process and componentry of the system, so as to achieve less residual material finish, reduce the effect of residual material finish and efficient material finish transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

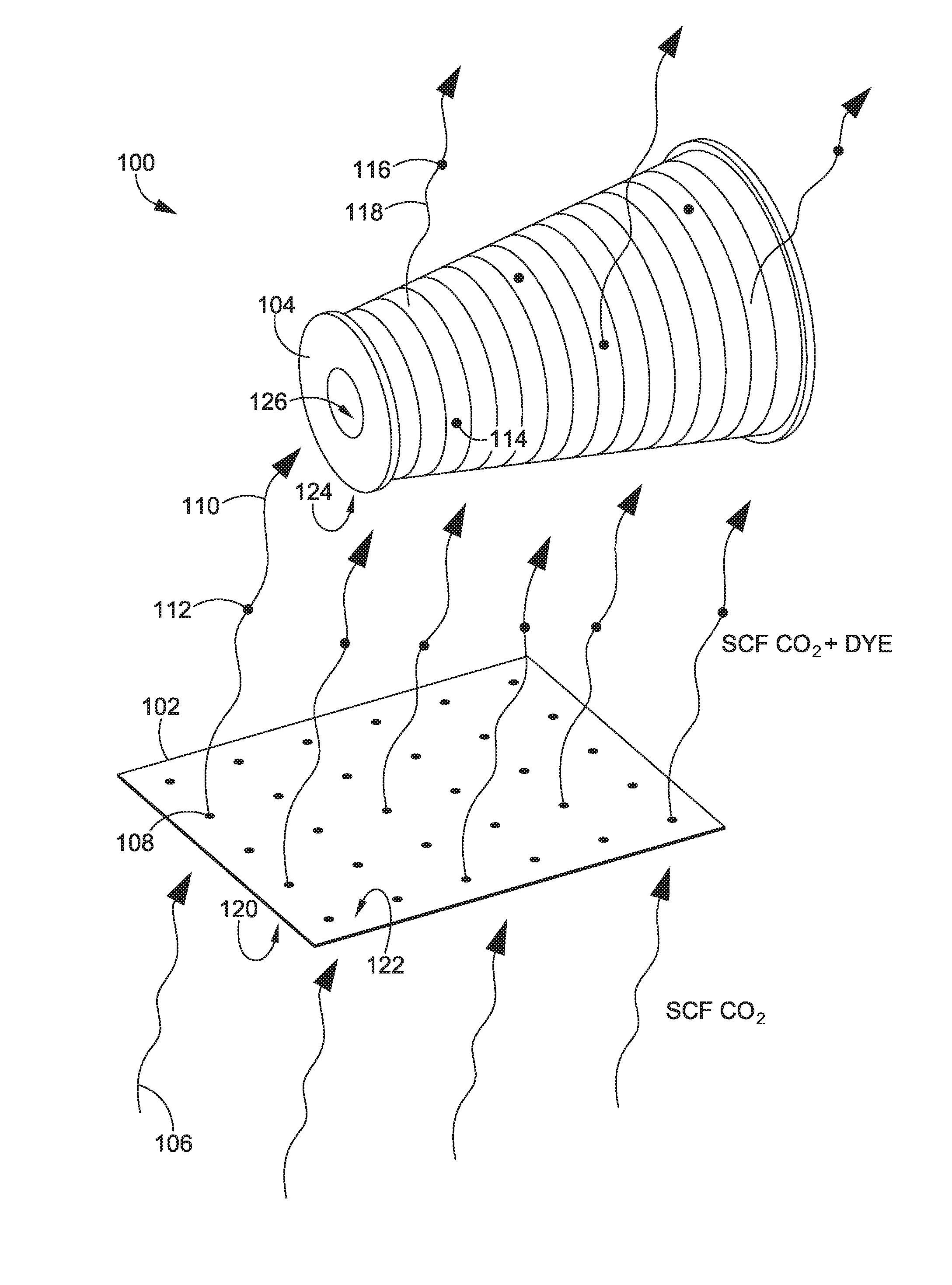

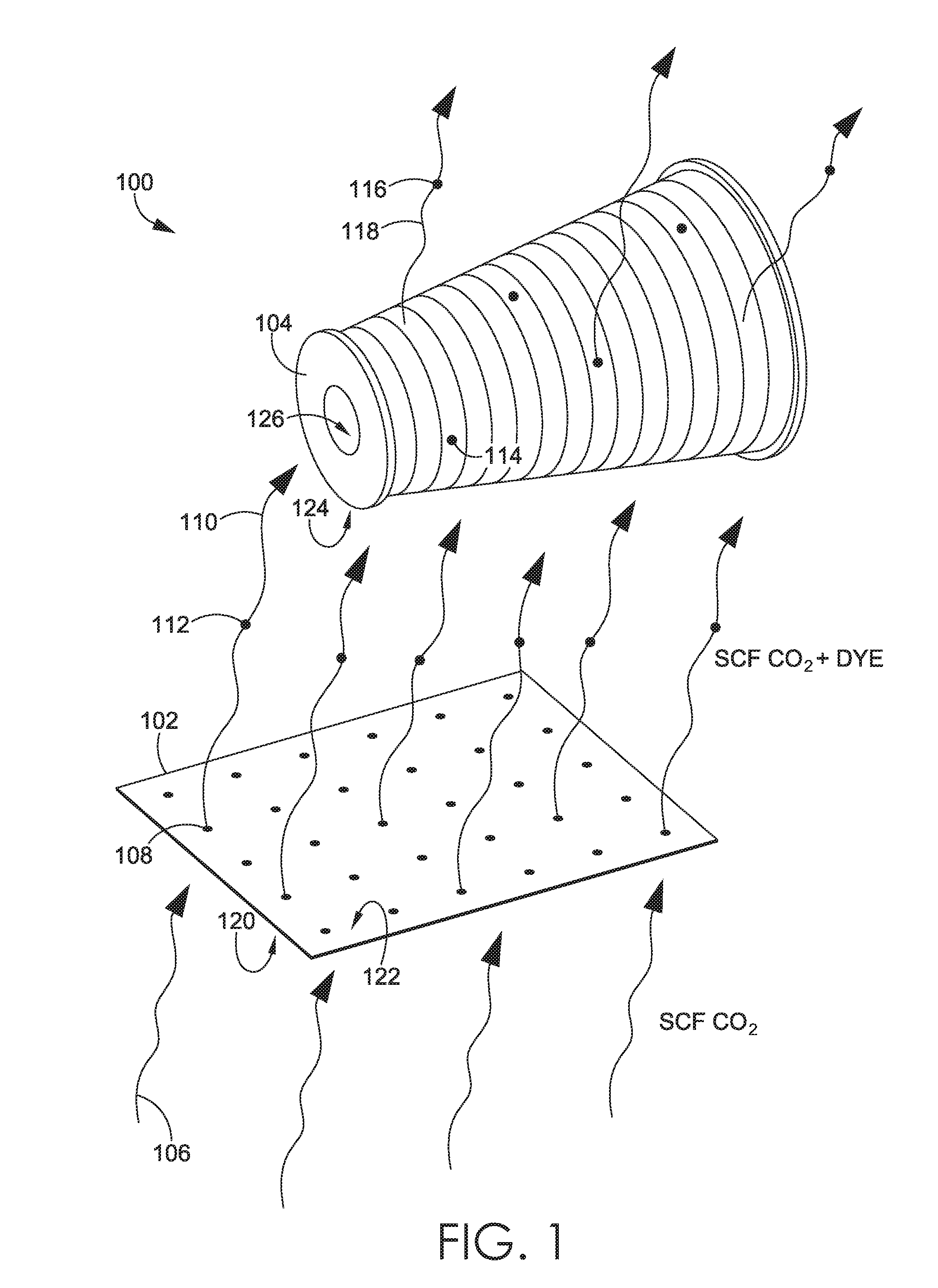

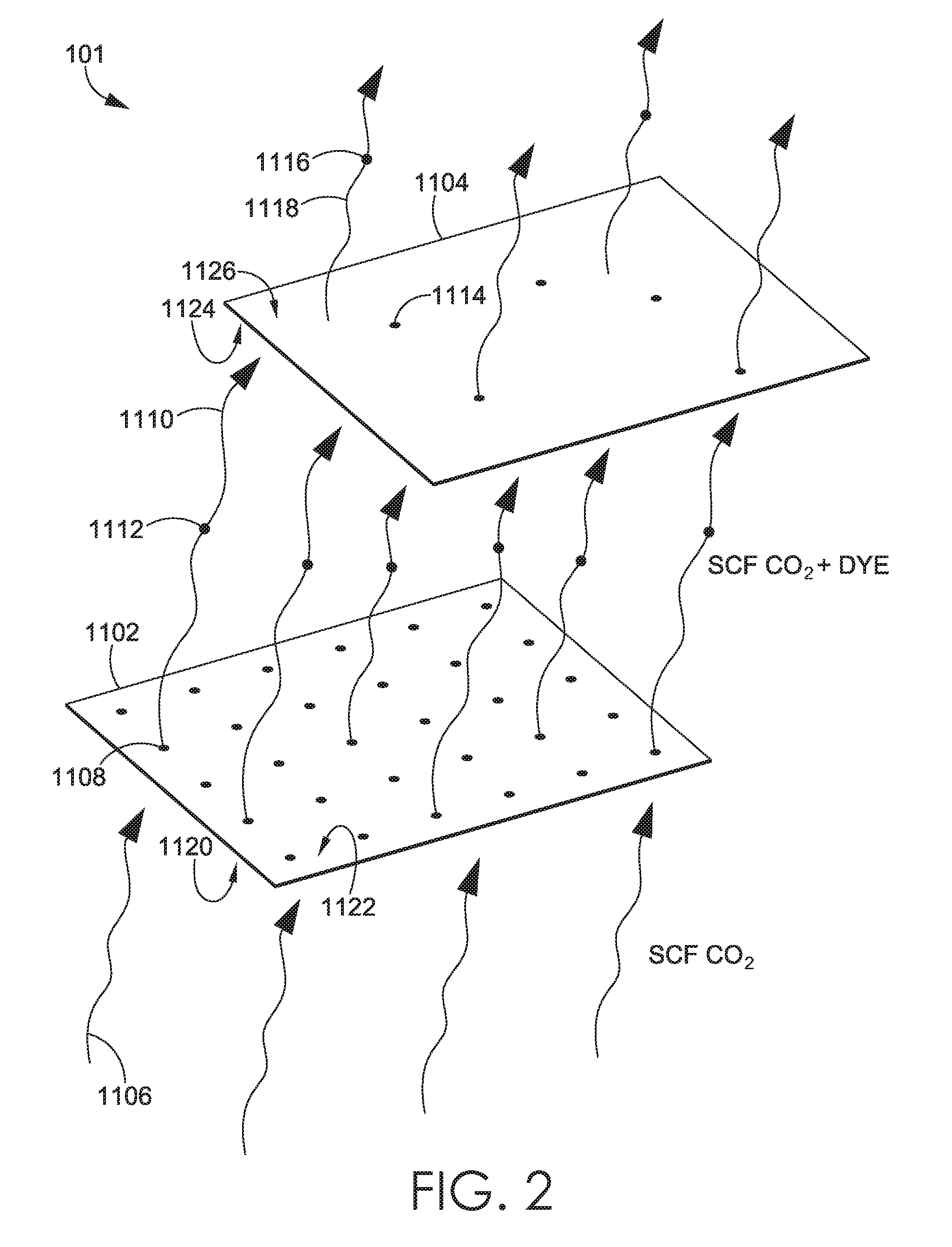

[0026]Methods are directed to finishing a target material with a material finish in a supercritical fluid carbon dioxide environment. Variables of the process are manipulated in different sequences to achieve a more efficient transfer of the material finish to the target material. The variables include, time, pressure, heat, internal flow rate within a pressure vessel, and exchange of the working substance (e.g., CO2). In an aspect, temperature is maintained above threshold values as pressure is decreased from an operating pressure to a transition pressure. For example, the temperature and internal flow rates are maintained above respective threshold values until the density of the CO2 passes a level in which dyestuff comes out of solution with the CO2. The sequencing of variable manipulation allows for a greater uptake of material finish by the target material and less residual material finish deposited on surfaces of the system. As a result, additional aspects contemplate eliminat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com