Production device of reclaimed white cotton from coloured cotton fabric an dits technology

A production device and production process technology, which is applied in the field of cotton textile recycling devices, can solve the problems of hidden dangers, damage, and waste of water resources in the regeneration of white cotton from colored cotton spinning waste, and achieve uniform and thorough decolorization, avoid high pollution, and save energy. The effect of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

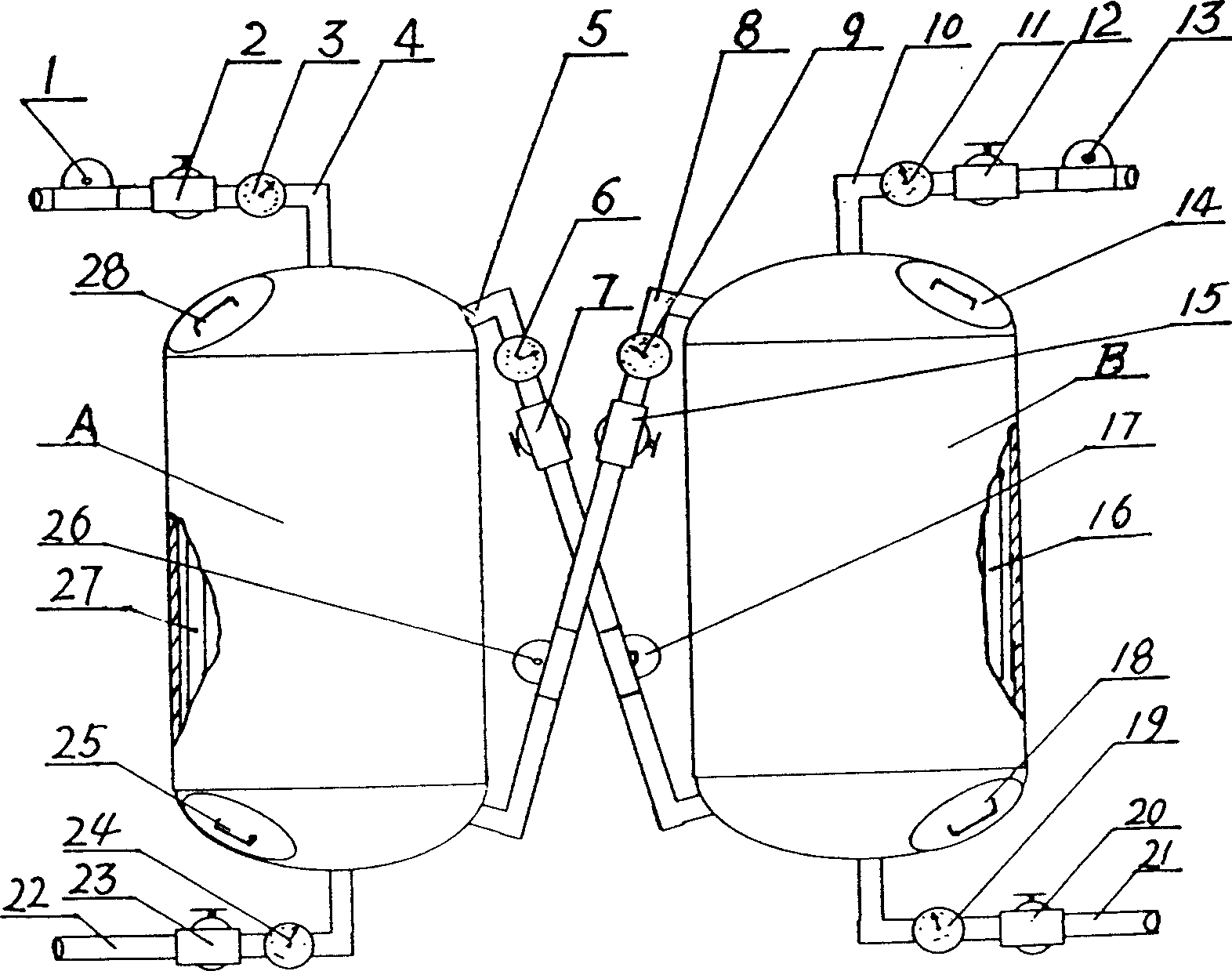

[0013] (1) At first, 250 kg of colored cotton spinning scraps are loaded into tank A through the feed port 28, and the valve 7 on the feed port 28 and the conduit 5 is closed. Under normal pressure, send high-temperature steam to tank A by air inlet pipe 22 for 5 minutes, and control the steam flow through flow meter 24, so that the water content of the colored cotton spinning leftovers in tank A reaches 10%.

[0014] (2) Air is supplied to tank A through the air intake pipe 22, so that the temperature of the cotton fabric in tank A is reduced to 30°C.

[0015] (3) Through the vacuum pump 1 and the air pressure gauge 3, the tank A is evacuated.

[0016] (4) open valve 23 and be 5% ozone to A tank filling concentration by inlet pipe 22, observe flowmeter 24 control flow, make it be full of the A tank of vacuum in 5 minutes. Simultaneously, 250kg of colored cotton spinning scraps are packed into tank B through the feed port 14, and the valve 15 on the feed port 14 and the condu...

Embodiment 2

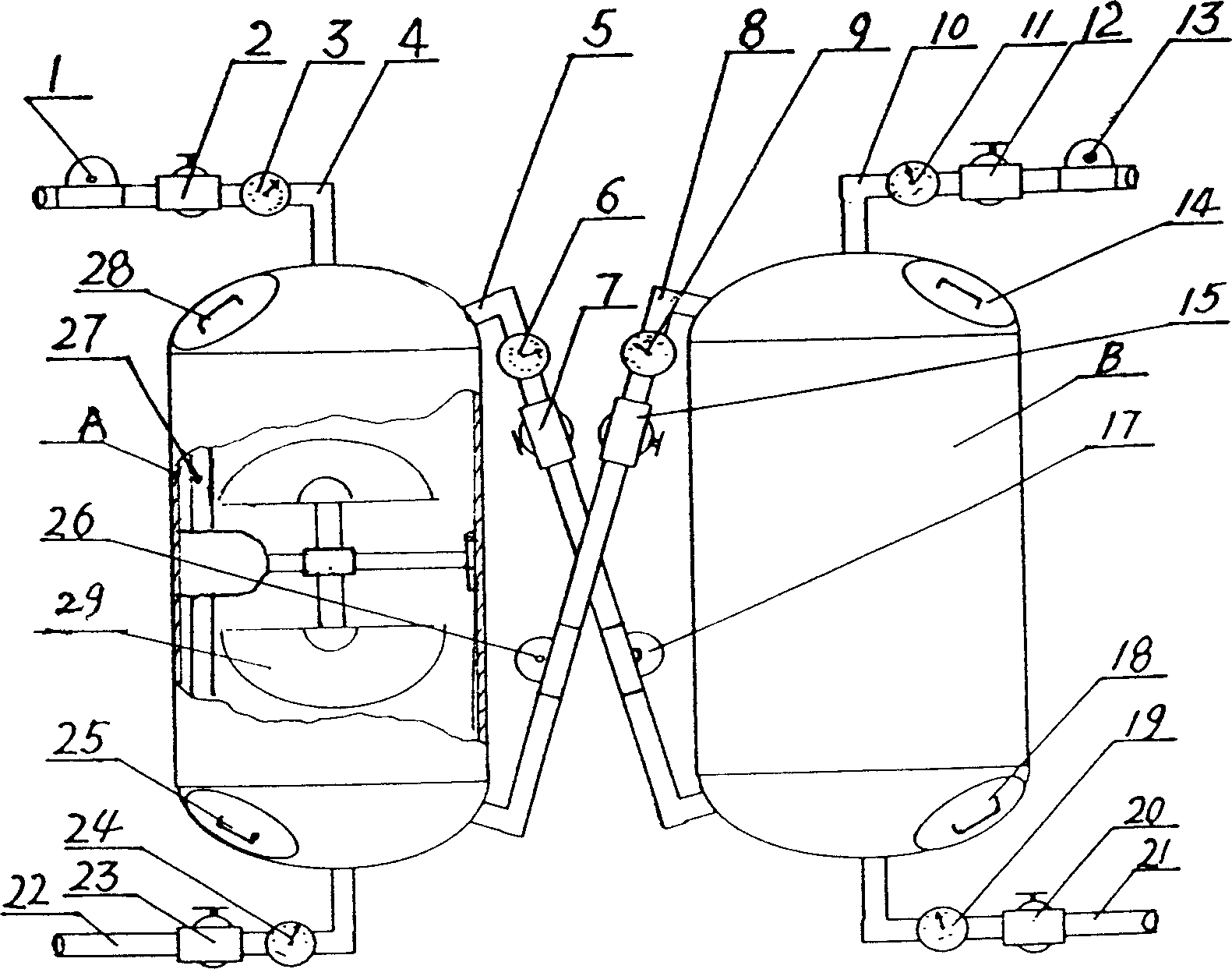

[0030] (1) At first, 250 kg of colored cotton spinning scraps are loaded into tank A through the feed port 28, and the valve 7 on the feed port 28 and the conduit 5 is closed. Start the turning device 29 in the A tank, and the paddles on the turning device make the colored cotton spinning leftovers turn up and down in the tank. Under normal pressure, send high-temperature steam to tank A by air inlet pipe 22 for 5 minutes, and control the steam flow through flow meter 24, so that the water content of the colored cotton spinning leftovers in tank A reaches 10%.

[0031] (2) Air is supplied to tank A through the air intake pipe 22, so that the temperature of the cotton fabric in tank A is reduced to 30°C.

[0032] (3) Through the vacuum pump 1 and the air pressure gauge 3, the tank A is evacuated.

[0033](4) open valve 23 and be 5% ozone to A tank filling concentration by inlet pipe 22, observe flowmeter 24 control flow, make it be full of the A tank of vacuum in 5 minutes. S...

Embodiment 3

[0047] (1) First, put the colored cotton spinning scraps into water to fully soak them, then take them out and load them into a drier to dry them, so that the water content of the colored cotton spinning scraps is 20%, take them out, and obtain the untreated colored cotton spinning scraps.

[0048] (2) At first, 250 kg of colored cotton spinning scraps are loaded into tank A through the feed port 28, and the valve 7 on the feed port 28 and the conduit 5 is closed. Start the turning device 29 in the A tank, and the paddles on the turning device make the colored cotton spinning leftovers turn up and down in the tank.

[0049] (3) Through the vacuum pump 1 and the air pressure gauge 3, the tank A is evacuated.

[0050] (4) open valve 23 and be 5% ozone to A tank filling concentration by inlet pipe 22, observe flowmeter 24 control flow, make it be full of the A tank of vacuum in 5 minutes. Simultaneously, 250kg of colored cotton spinning scraps are packed into tank B through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com