Automatic cylinder cover locking device and cheese dyeing machine comprising same

An automatic locking and cylinder head technology, applied in the mechanical field, can solve the problems of unfavorable automatic production, time-consuming and labor-intensive labor, and low labor efficiency, so as to improve the level of mechanization and automation, improve production efficiency, and save labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

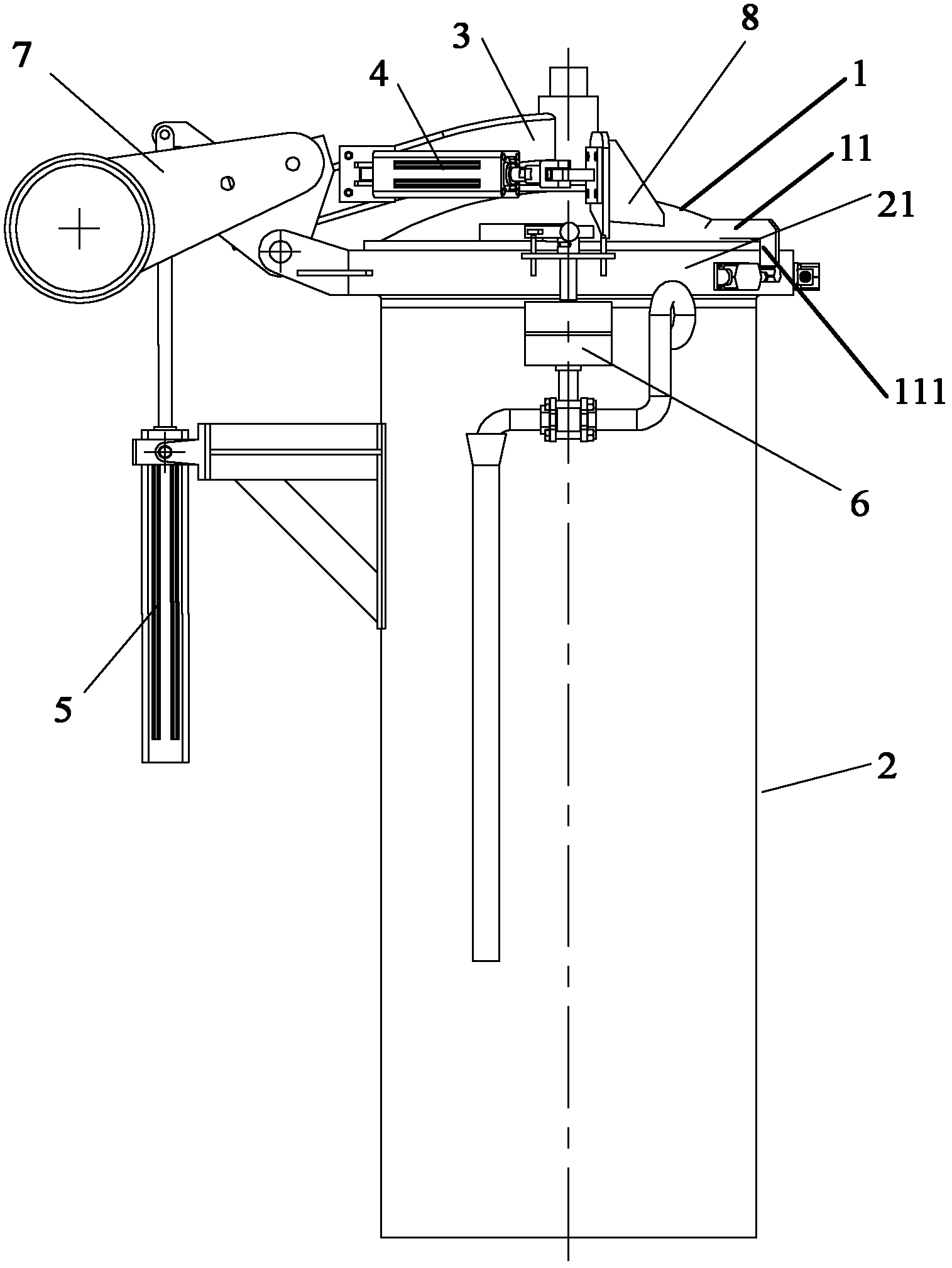

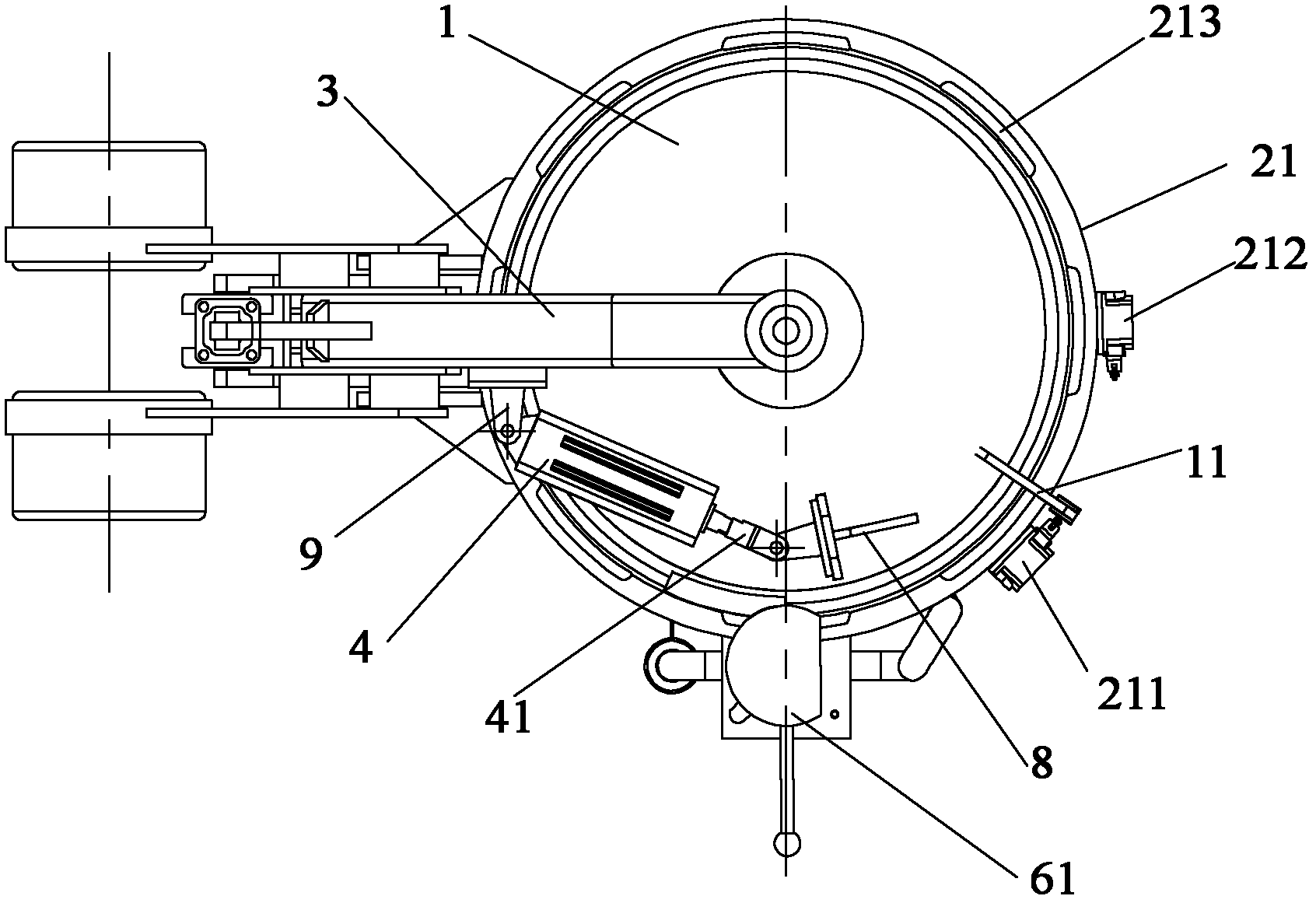

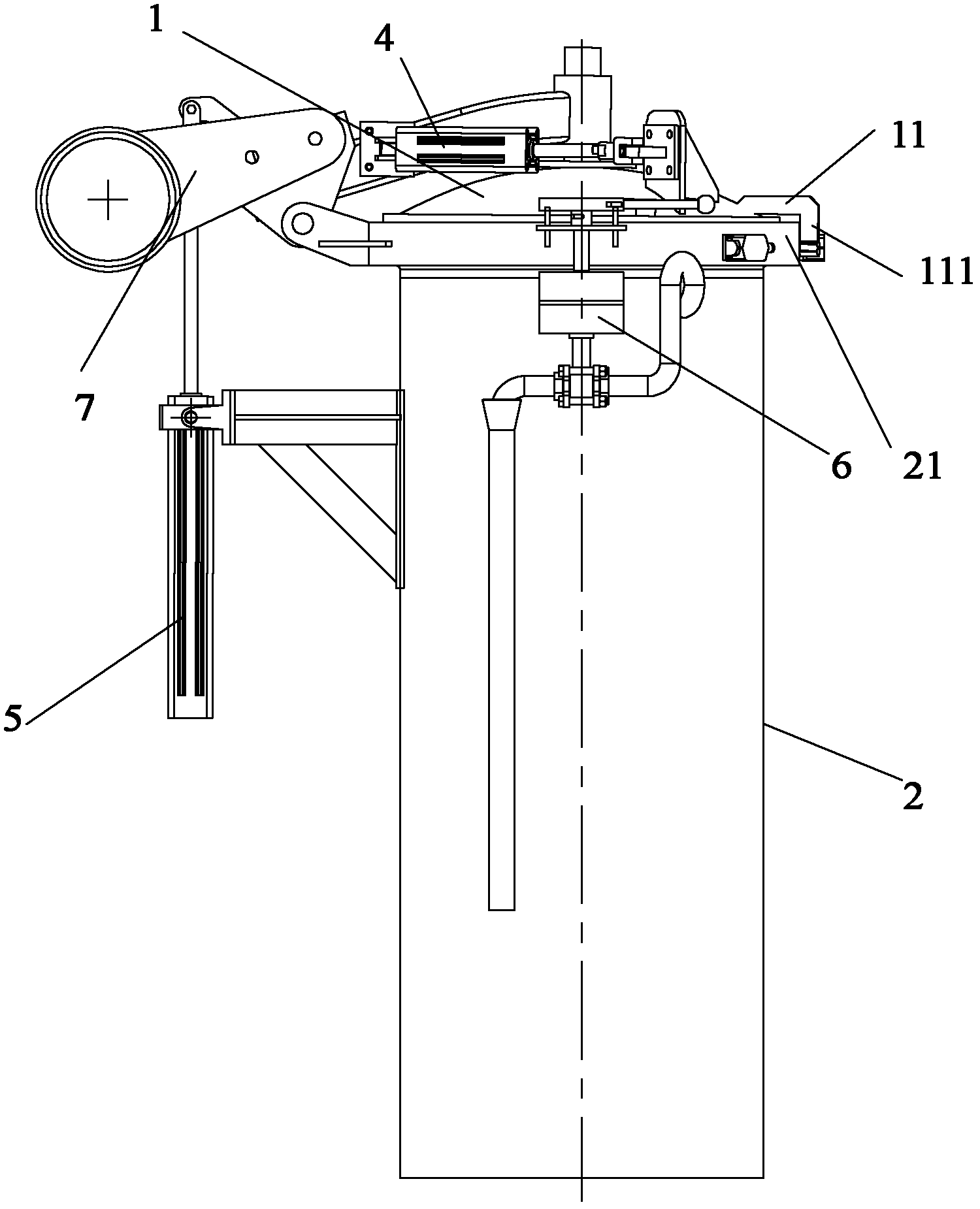

[0029] The cylinder head automatic locking device of the present invention comprises a cylinder head 1 and a cylinder body 2, the cylinder head 1 is provided with teeth 12 uniformly distributed along the circumference, and the upper end circumference of the cylinder body 2 is provided with a hoop supporting the cylinder head 1 21. The clamp 21 has an annular groove for accommodating the tooth 12 and an annular flange above the annular groove. A groove 213 matching the tooth 12 is arranged on the annular flange. A boom 3 is arranged above the cylinder head 1. The boom One end of 3 is pivotally connected to the center of the cylinder head 1 through the central axis, and the other end is pivotally connected to the outer circumference of the clamp 21; the locking cylinder 4 is pivotally connected to the position far from the center of the cylinder head 1 on the boom 3 through the support 9 , the inside of the locking cylinder 4 is provided with a piston rod, one end of the piston r...

Embodiment 2

[0034] The cylinder head automatic locking device of the present invention not only has the structure in Embodiment 1, but also has an unlocked in place travel switch 212 and a locked in place travel switch 211 on the outer edge of the clamp 21, and a bumper on the cylinder head 1. Block 11, one end of the bumper 11 is fixed on the cylinder head 1, and the other end is provided with a bumper 111. When the cylinder head 1 and the cylinder body 2 are closed, the bumper 111 is located between the unlocked limit switch 212 and the locked limit switch. 211, and has the unlocked in place state of touching the unlocked in place travel switch 212 and the locked in place state of touching the locked in place travel switch 211. Unlocked limit switch 212 is electrically connected with the control system. In the unlocked state, the unlocked limit switch 212 sends an unlocked signal to the control system; the locked limit switch 211 is electrically connected with the control system. In the ...

Embodiment 3

[0037] The difference between the cylinder head automatic locking device of the present invention and the second embodiment is that it also includes a pressure relief device, which is electrically connected to the control system to control the maximum pressure value in the cylinder body 2 before the cylinder head 1 is opened. Among them, the pressure relief device preferably includes: a pneumatic ball valve 6 communicated with the inside of the cylinder body 2 and a safety handle 61 arranged on the pneumatic ball valve 6. The safety handle 61 is electrically connected to the control system, and rotates according to the instructions of the control system, so that The pneumatic ball valve 6 communicates with the atmosphere or is isolated from the atmosphere. The safety handle 61 is horizontally arranged on the upper end of the pneumatic ball valve 6. The safety handle 61 has a position above the cylinder head 1; In the tight position, the safety handle 61 is located above the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com