Loose fibre dyeing machine

A dyeing machine and loose fiber technology, which is applied in the field of dyeing machines, can solve the problems of shortening the service life of the motor, prone to failure of the motor, and high maintenance rate, and achieves the effect of eliminating axial movement, not easy to break down, and reducing the maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

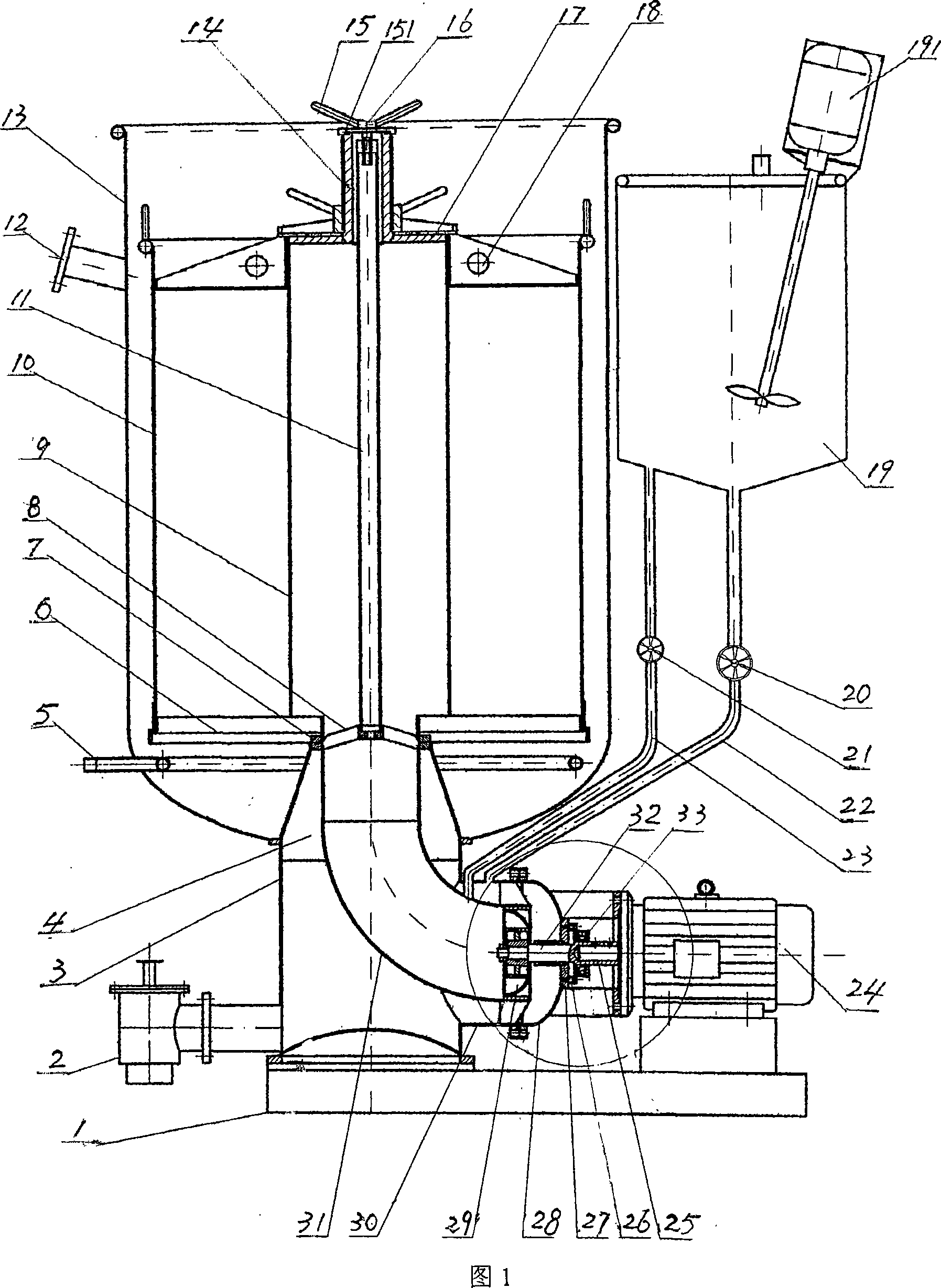

[0011] As shown in Fig. 1 and Fig. 2, the loose fiber dyeing machine of the present invention contains cylinder 13, and this cylinder is cylindrical, and its upper end is open-shaped, and the lower end is connected with arc-shaped cylinder bottom. A water inlet 12 is processed on the top of the cylinder body 13, and a fiber cage 10 is installed in it. Said fiber cage 10 is also a cylinder, and there is a space between the bottom of the cage 6 and the bottom of the cylinder. A heating coil 5 is installed in the space. The steam source and outlet of the same type are connected.

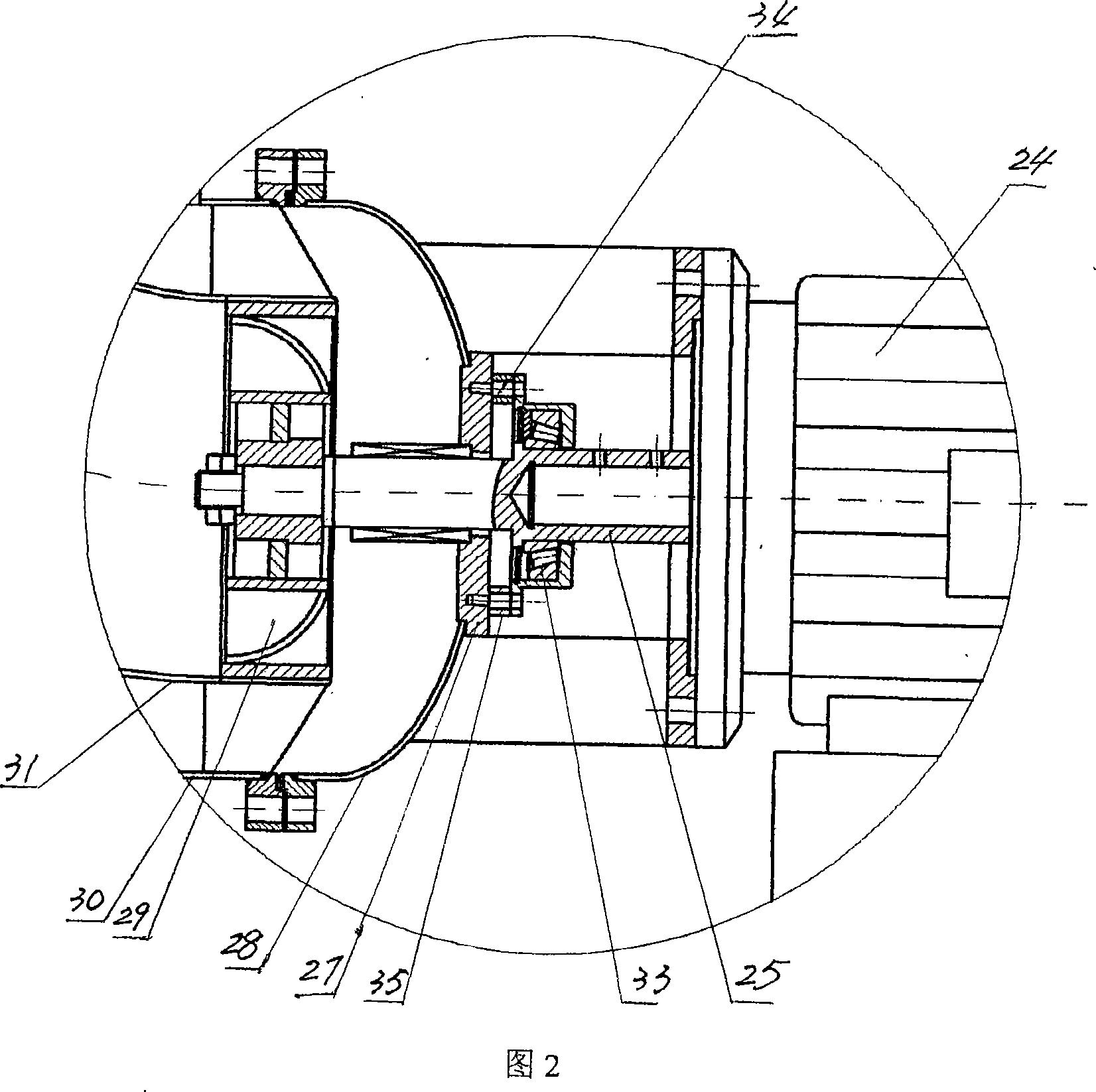

[0012] Both the bottom of the cylinder body 13 and the cage bottom 6 of the fiber cage 10 are processed with a central hole, and a guide cylinder 3 is arranged below the cylinder body 13 . The lower end of the guide cylinder 3 is closed and fixed on the machine base 1, and its upper end is welded circumferentially around the central hole at the bottom of the cylinder body 13. Four connecting ribs 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com