Supercritical CO2 anhydrous rotating warp beam horizontal type dyeing kettle and dyeing system thereof

A dyeing system and dyeing kettle technology, applied in textiles and papermaking, liquid/gas/steam textile material treatment, liquid/gas/steam treatment of a certain length of textile materials, etc., can solve the problems of uneven dyeing of cloth and achieve reduction The effect of dyeing time, increasing contact time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

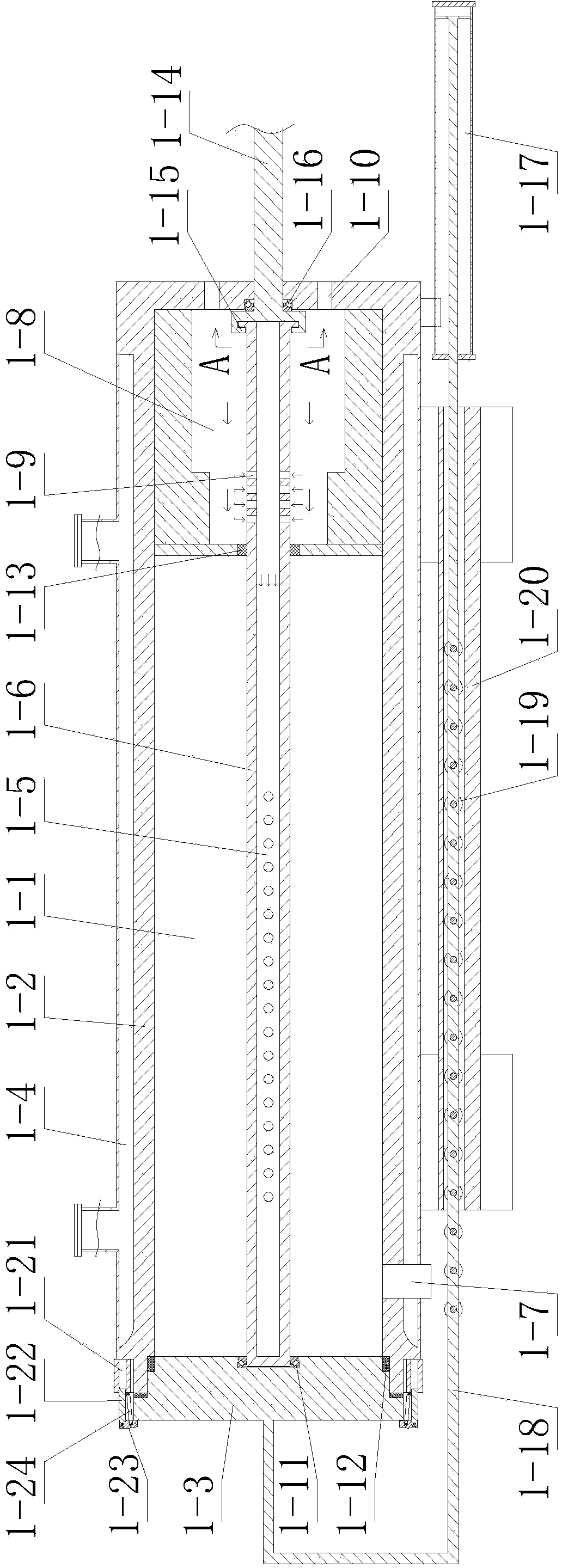

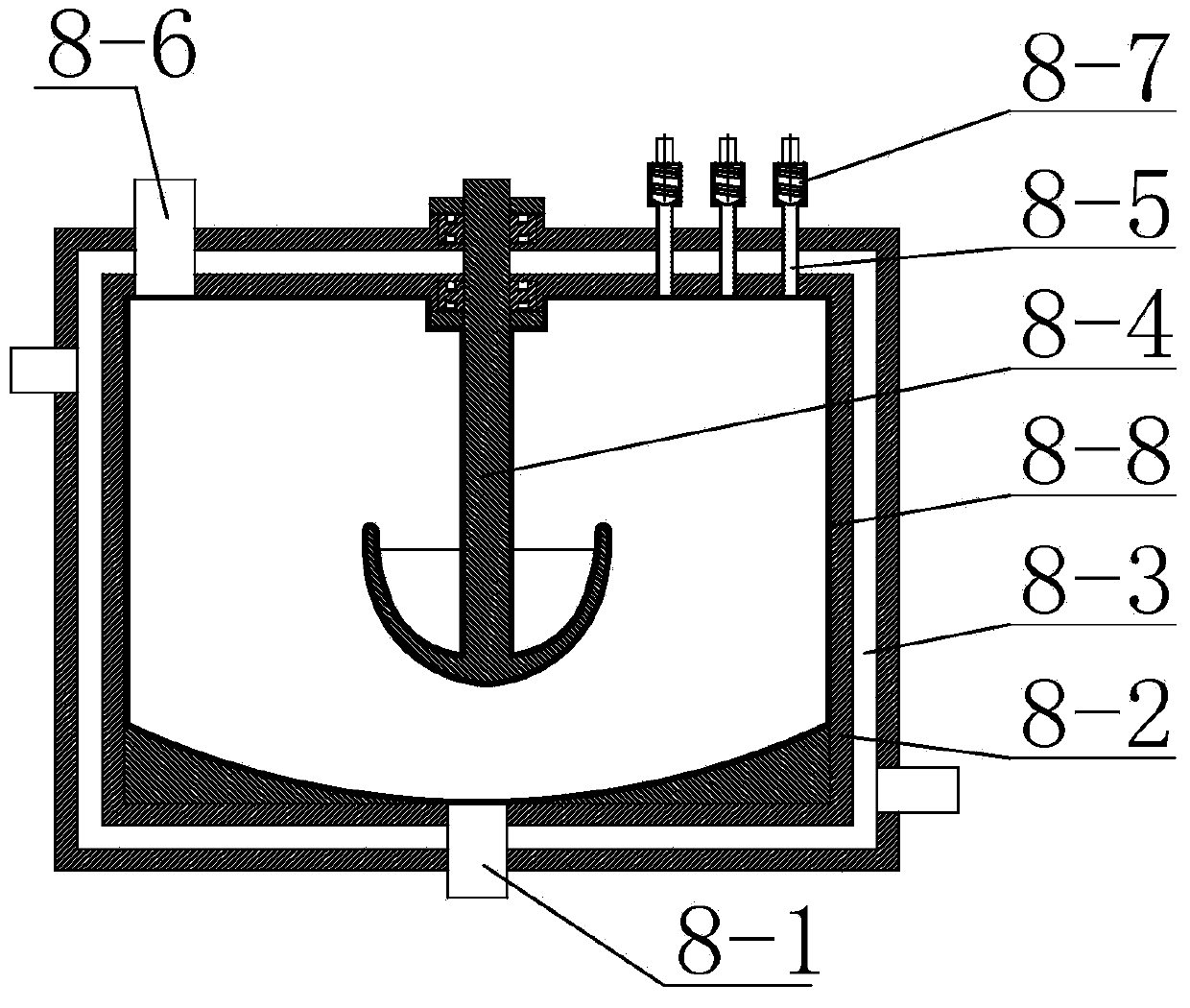

[0038] like figure 2 , Figure 4 , Figure 5 Shown is a kind of supercritical CO provided by embodiment 1 of the present invention 2 An anhydrous rotary warp beam horizontal dyeing kettle, which includes a dyeing kettle body 1-2 with a dyeing chamber 1-1 in the body, and a button placed at one end of the dyeing kettle body 1-2 for opening and closing the opening of the dyeing chamber 1-1 Kettle cover 1-3, a dyeing fabric frame arranged in the dyeing chamber 1-1 and used to set up the fabric to be dyed, and a dyeing kettle heating and cooling device 1-4 for heating the dyeing kettle body 1-2, the dyed fabric The frame includes a hollow dyeing warp shaft 1-6 with a plurality of outlet pores 1-5 arranged on the wall, and the dyeing kettle body 1-2 is provided with a dyeing kettle air outlet 1-1 that connects the dyeing chamber 1-1 to the outside world to vent gas. 7. It is characterized in that: the dyeing kettle body 1-2 is arranged horizontally, and the dyeing warp shaft 1-6...

Embodiment 2

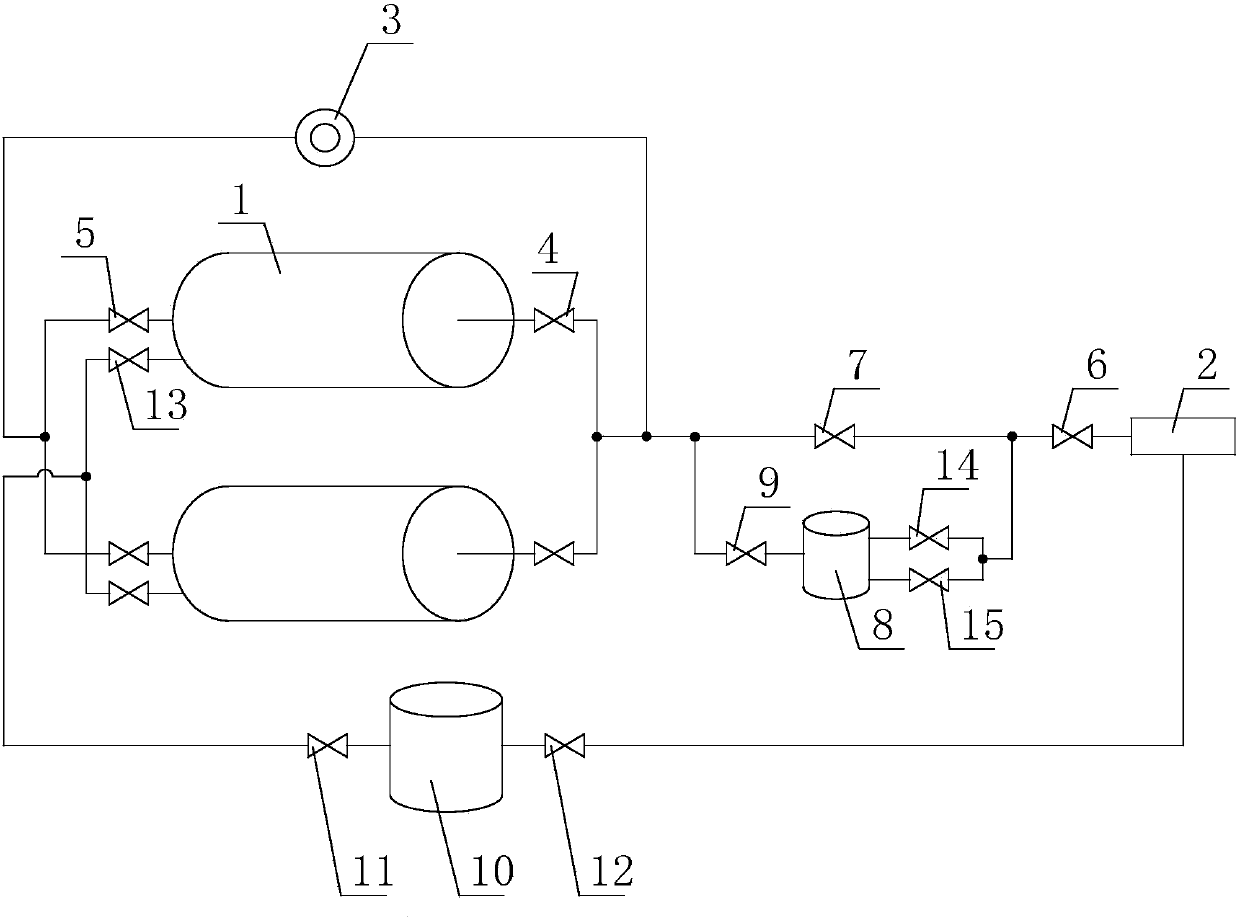

[0047] like Figure 1-Figure 5 Shown is a kind of supercritical CO provided by embodiment 2 of the present invention 2 Anhydrous rotary beam horizontal dyeing system, said dyeing system has two or more supercritical CO described in any one of claims 1-6 2 Anhydrous rotary beam horizontal dyeing kettle 1, the dyeing system also includes CO 2 The pressurized supply device 2 and the circulating air extraction device 3 are characterized in that: the dyeing kettle air inlet 1-10 and the dyeing kettle air outlet 1-7 of each dyeing kettle 1 are connected with the dyeing kettle air intake control valve 4 and the dyeing kettle air outlet respectively. The control valve 5 is connected to form independent dyeing branches, and after each dyeing branch is connected in parallel, the two ends are respectively connected with the two ends of the circulating air pumping device 3 to form a circulating dyeing circuit. 2 The output of pressurized supply device 2 is via CO 2 The output control v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com