Spiral single-yarn piezoelectric spray dyeing device

A spiral, piezoelectric technology, applied in the field of yarn dyeing, can solve the problems of air pollution, easy generation of dust, uneven dyeing of yarn, etc., and achieve the effect of high degree of automation, reasonable structure design and high dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention will be described below with reference to the accompanying drawings and specific embodiments. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

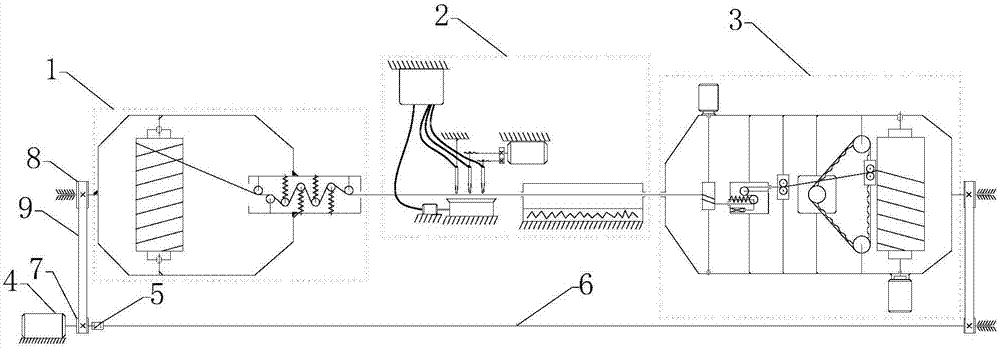

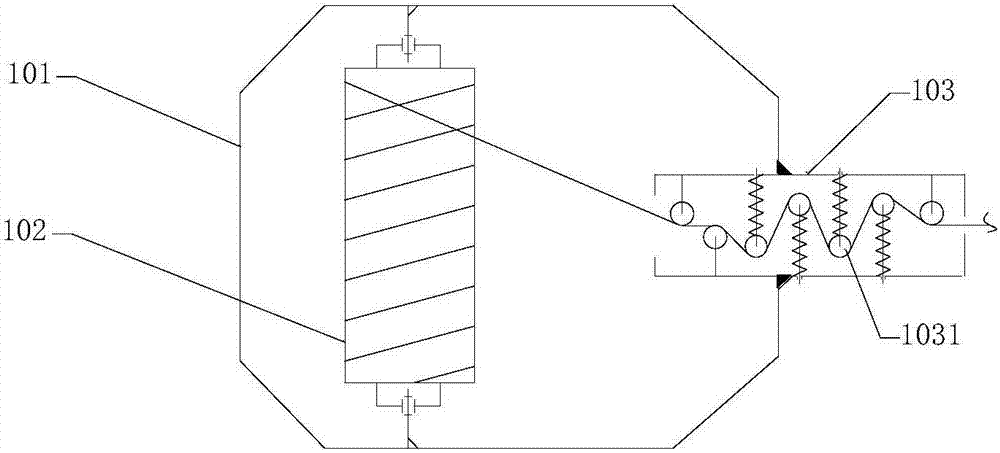

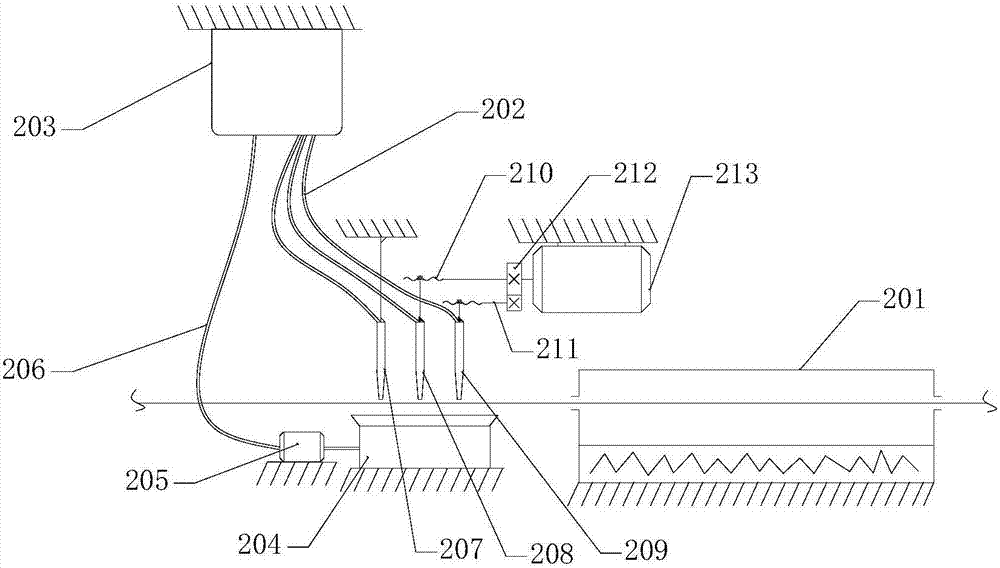

[0028] like Figures 1 to 4 As shown, the present invention provides a helical single-yarn piezoelectric jet dyeing device, which includes a rotary pay-off module 1, a piezoelectric jet-dyeing module 2 and a rotary wire take-up module 3, which are arranged in sequence, and the rotary pay-off module 1 It rotates synchronously in the same direction as the rotary take-up module 3, and the yarn between them rotates around the central axis of the yarn in the piezoelectric jet dyeing module 2, and the rotating yarn is in the piezoelectric jet dyeing module. 2 accepts the jet dyeing of a plurality of piezoelectric nozzles, the rotary pay-off module 1 is used to supply the yarn to be dyed to the piezoelectric jet dye mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com