360-degree rotating drum type dyeing machine with low bath ratio

A dyeing machine and drum-type technology, applied in the field of dyeing machines, can solve the problems of low dyeing efficiency, waste of water resources, unfavorable energy saving, emission reduction and environmental protection, etc., and achieve the effect of high dyeing efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

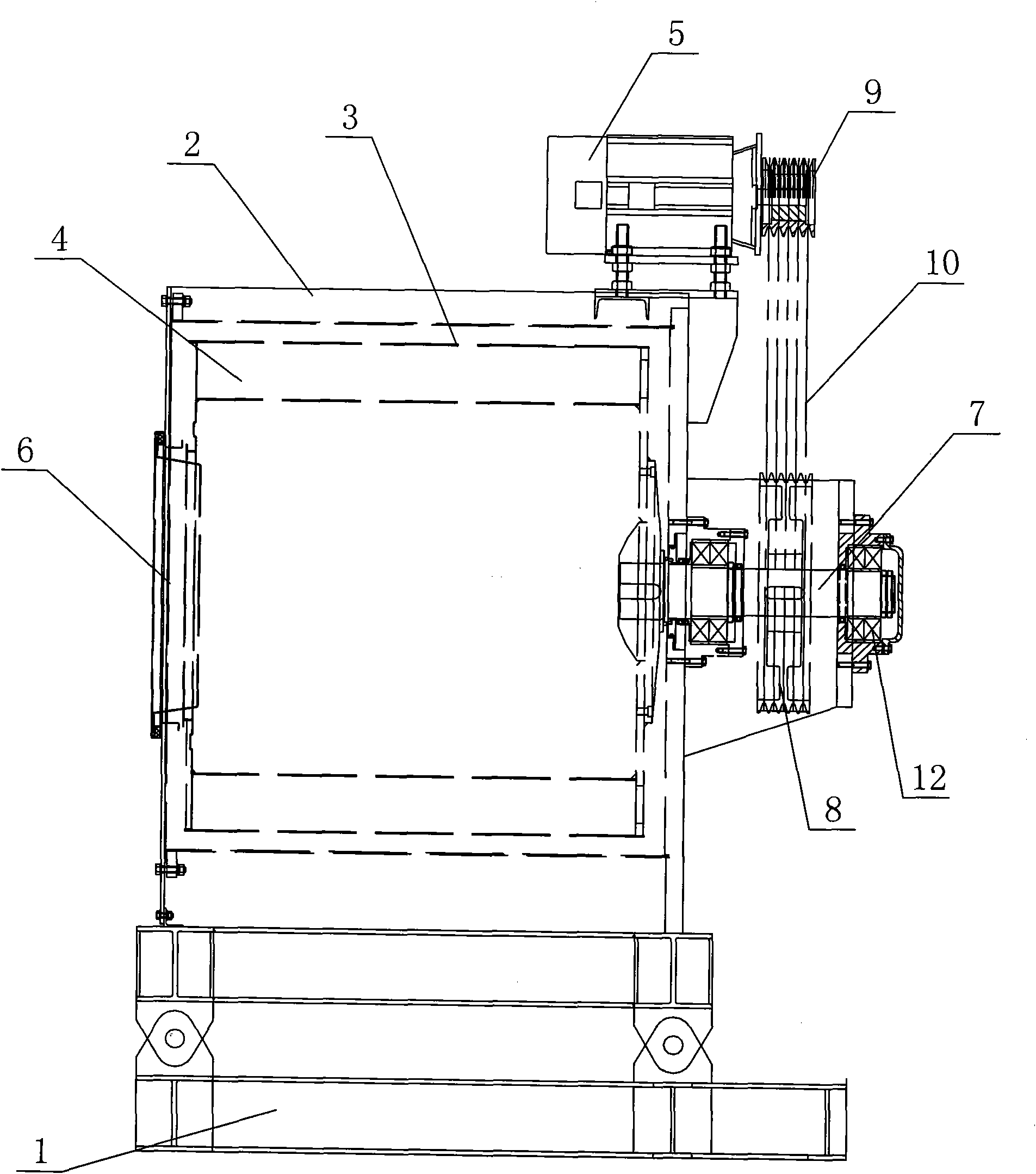

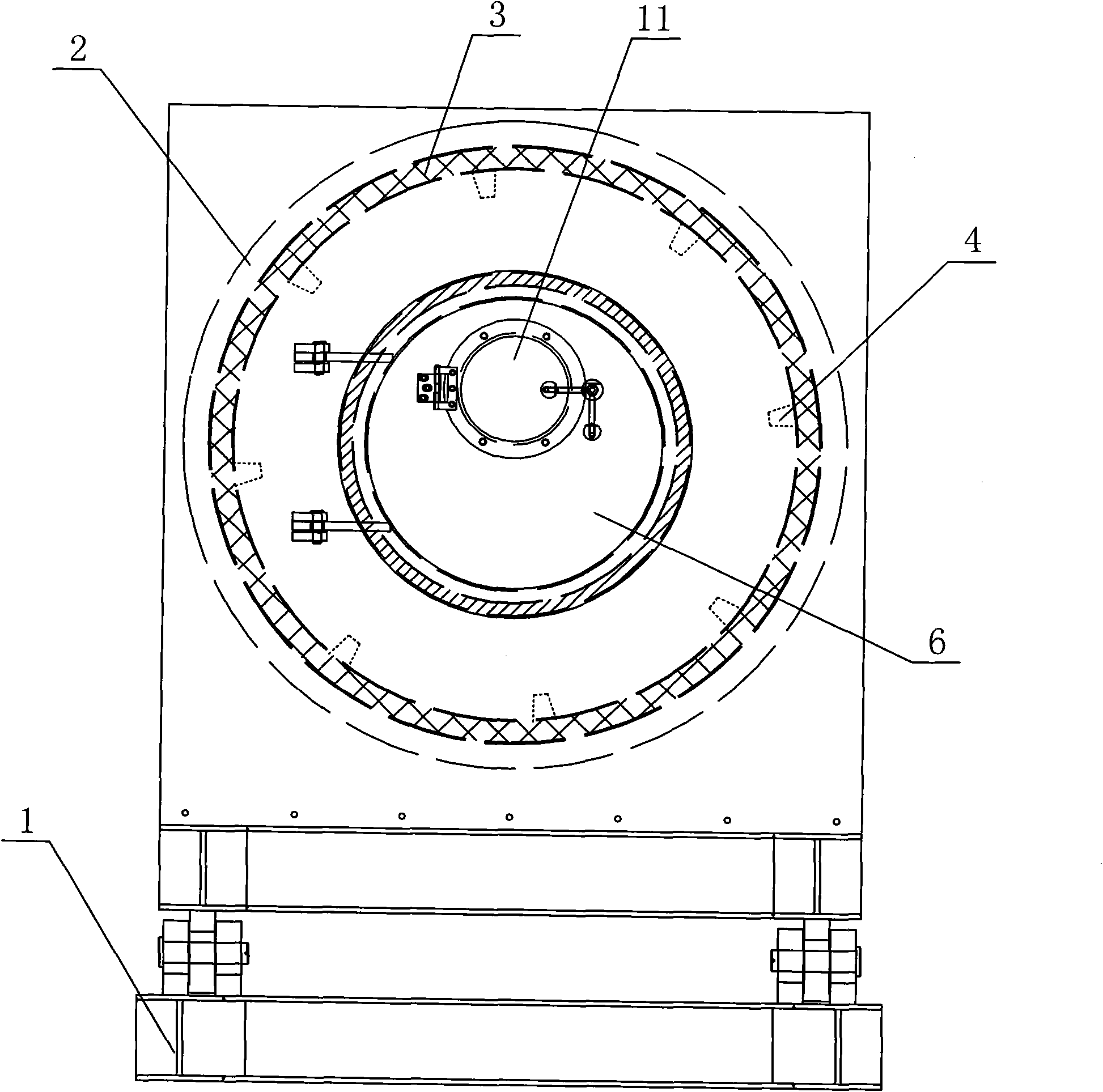

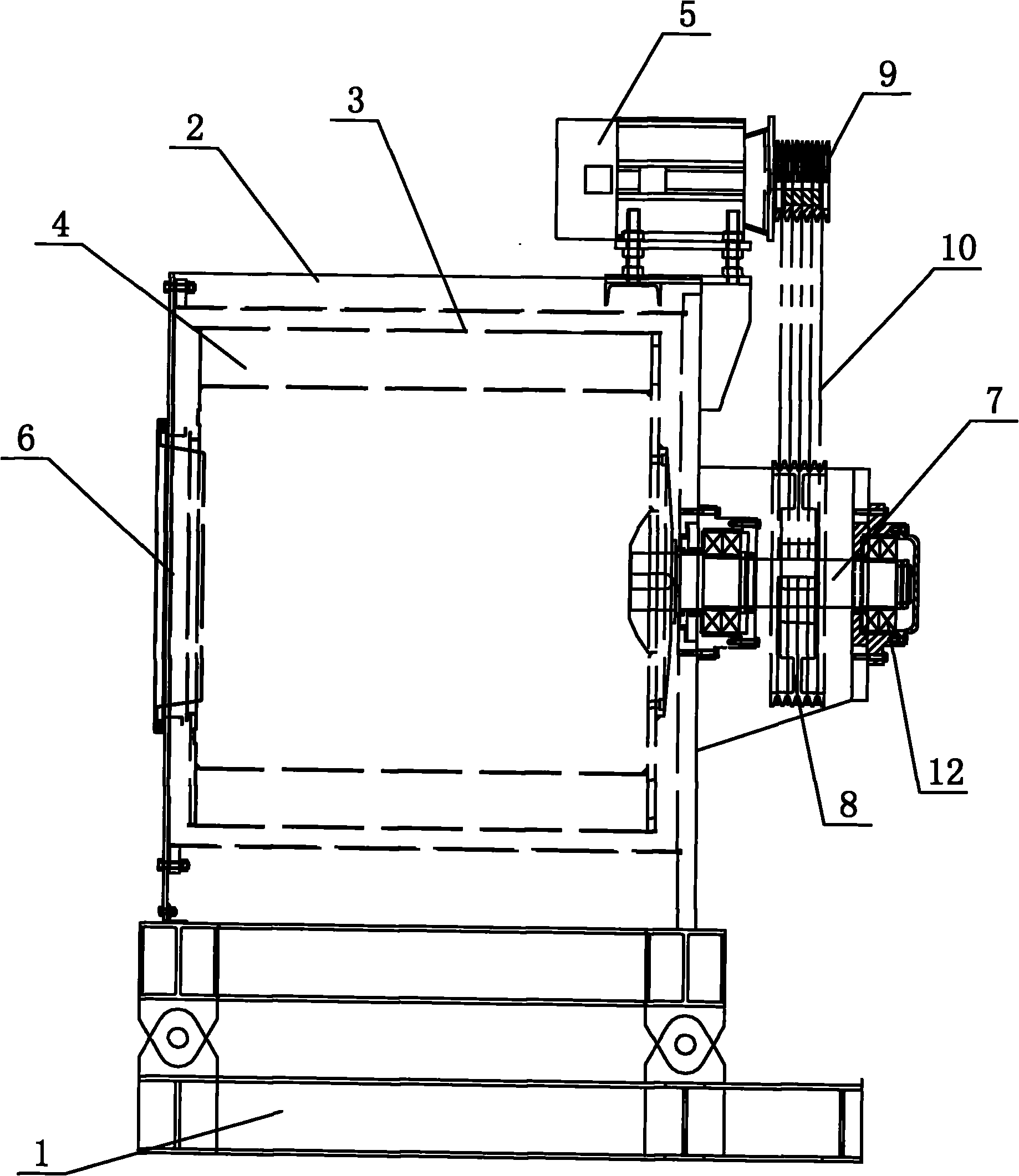

[0016] Please refer to figure 1 and figure 2 as shown, figure 1 It is a sectional view of a 360-degree rotating drum dyeing machine with a low bath ratio of the present invention; figure 2 It is a side view of the low bath ratio 360-degree rotating drum dyeing machine of the present invention.

[0017] In this embodiment, the low liquor ratio 360-degree rotary drum dyeing machine includes a box 2 arranged on the base 1 of the dyeing machine, the box 2 is a cylindrical structure, and the box One end of 2 is provided with door 6, and described door 6 is provided with transparent observation window 11, and described box body 2 is provided with open type drum 3, and described drum 3 cooperates box body 2 to be cylindrical structure, The opening end of the drum 3 is set corresponding to the door 6, and the other end is closed and fixed with a drive shaft 7, and a number of through holes are evenly distributed on the side wall of the drum 3. When dyeing, the dye solution passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com