Schoenoplectus trigueter (L.) Palla mat dyeing and drying technology

A rush mat and process technology, which is applied to manufacturing tools, wood processing utensils, reed/straw treatment, etc., can solve the problems of high cost and low efficiency, reduce water consumption, improve the hardness of straw mats, and improve the uniformity of color paste. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

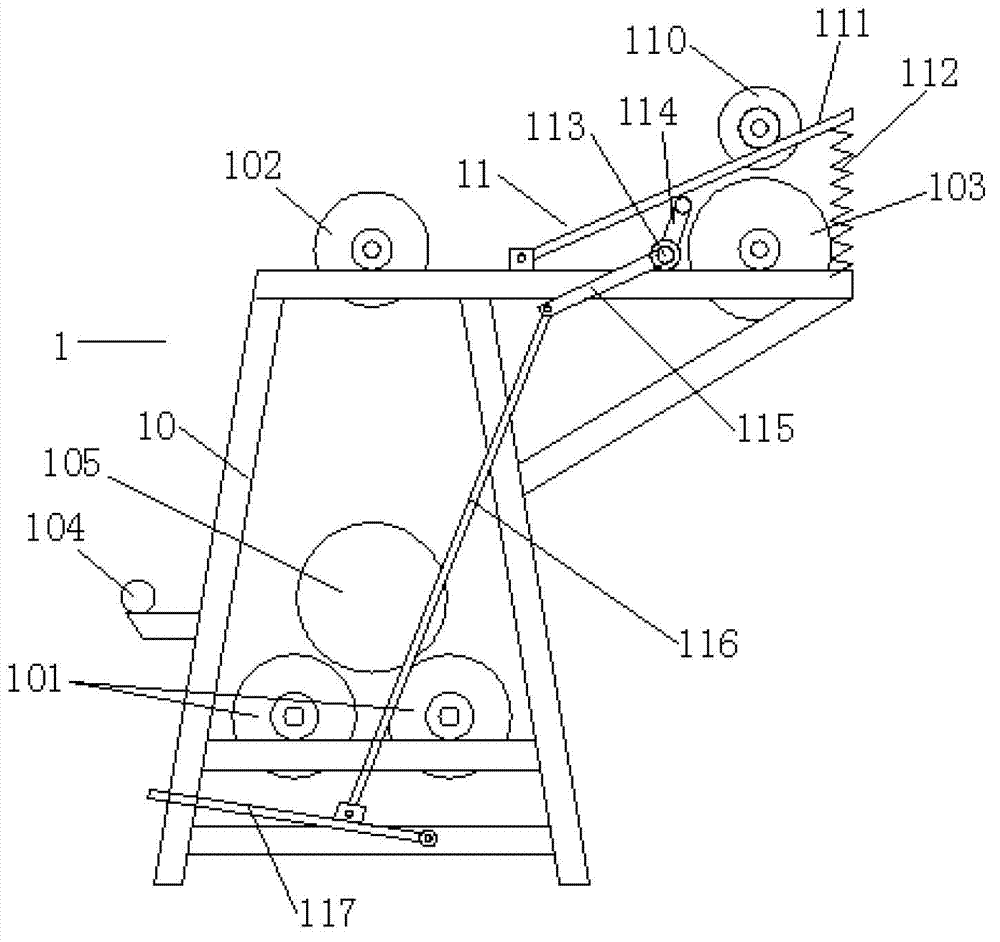

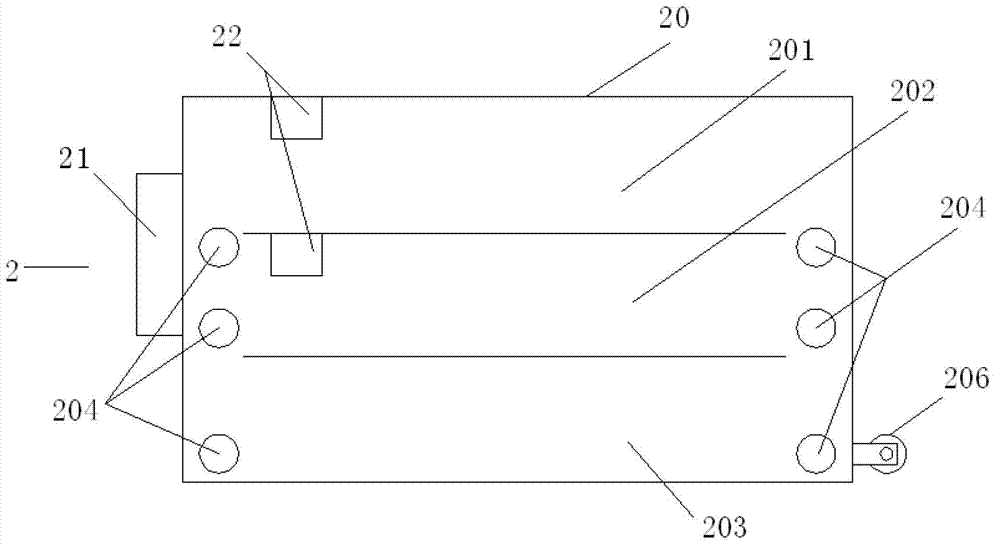

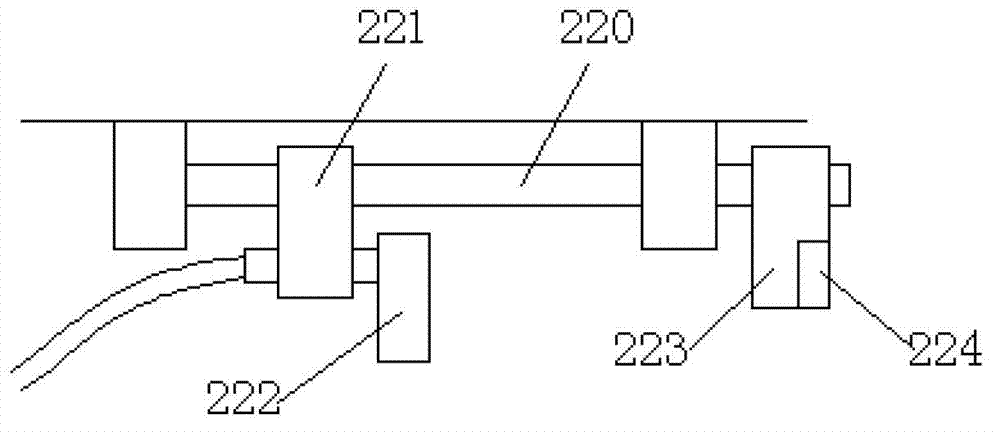

[0031] The rush mat opening, dyeing and drying integrated equipment used in the present invention is composed of a rush mat device 1, a rush mat dyeing device 2 and a rush mat dryer 3 arranged in a row. The bundled and bundled straw mat semi-finished products are first opened by the rush mat device 1, and then dyed by the rush mat dyeing device 2, and the straw mat dyed by the rush mat dyeing device 2 enters the rush mat dryer 3 for further processing. Drying realizes the continuous and automatic operation of rush mat opening, dyeing and drying.

[0032] figure 1 Shown the concrete structure of straw mat device 1, it comprises frame 10, and described frame bottom is provided with a pair of straw mat bundle placement rollers 101 in parallel, and described frame 10 top is provided with a straw mat bundle placement roller 101 tops. Middle transition roller 102, described frame 10 is provided with a straw mat delivery roller 103 in the front of middle transition roller, and descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com