High-temperature continuous type dyeing machine for woven tapes

A dyeing machine and webbing technology, applied in the field of bleaching and dyeing equipment, can solve the problems of different fabrics and webbing processes and equipment, high production costs, unfavorable environmental protection and energy saving, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below in conjunction with the accompanying drawings.

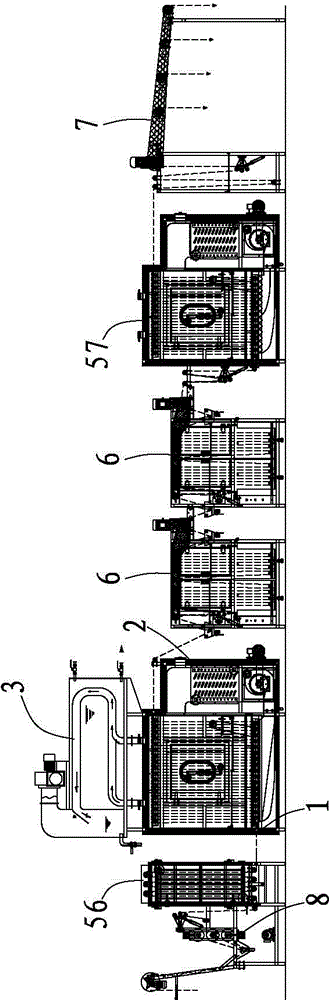

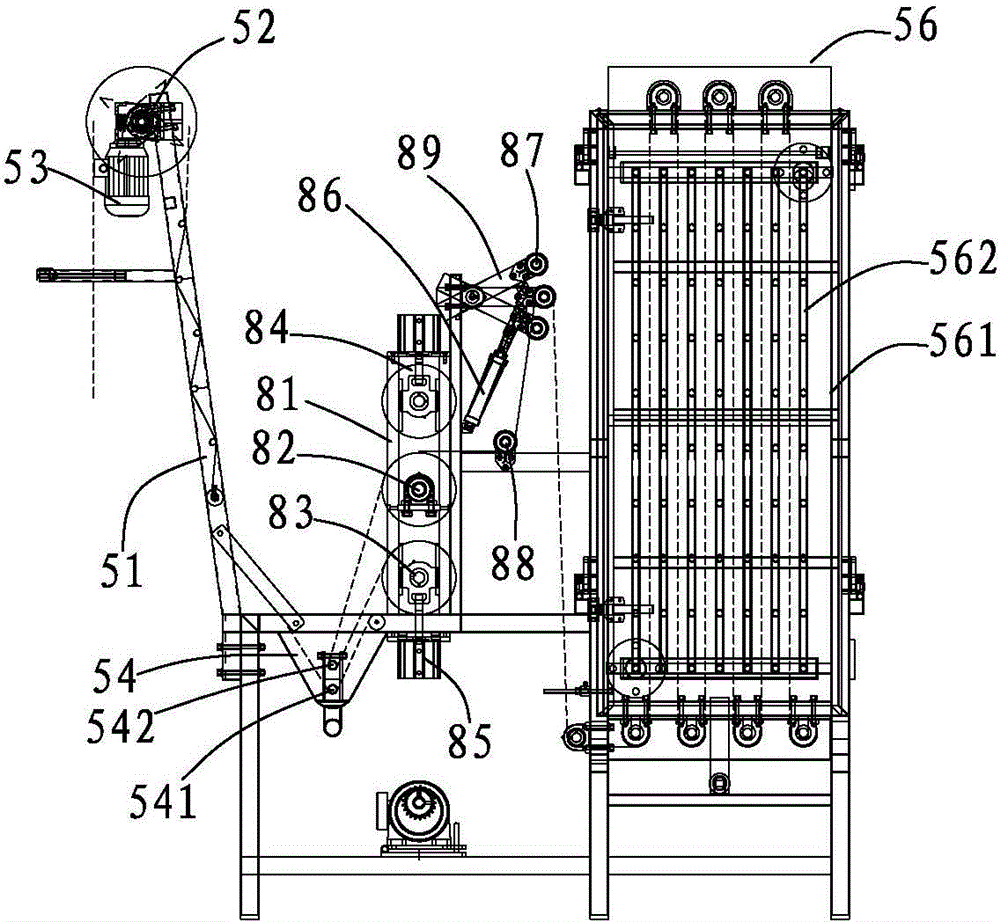

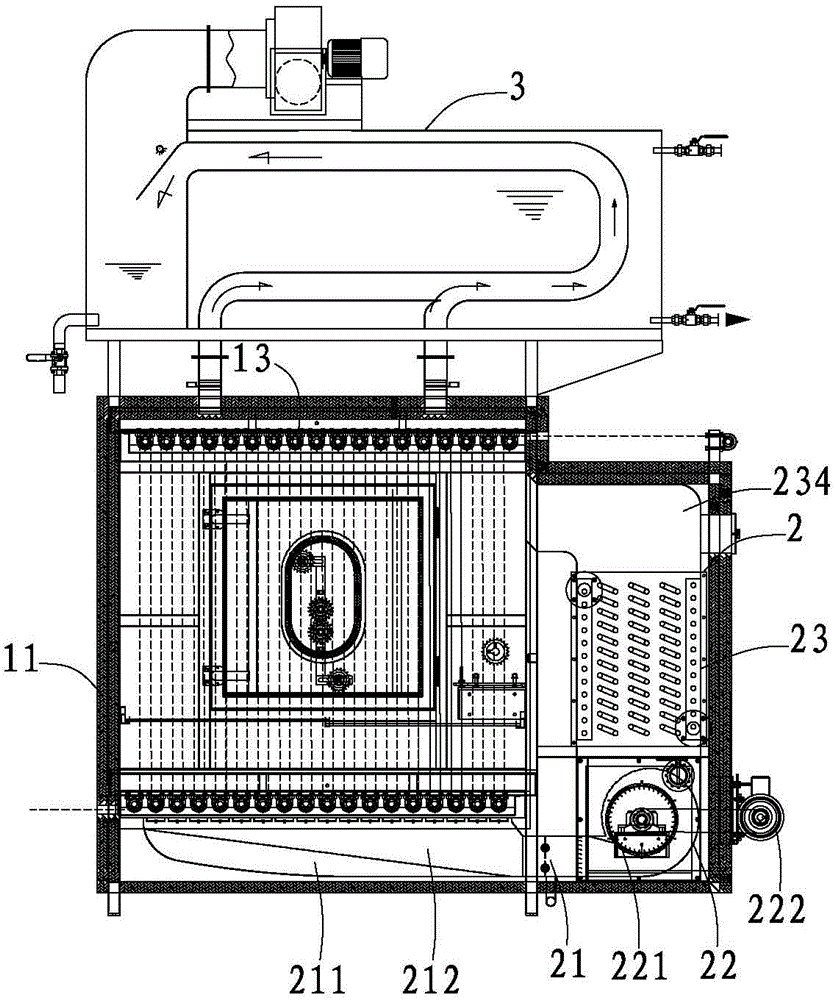

[0066] see Figure 1 to Figure 11 , a high-temperature webbing continuous dyeing machine, comprising a tape release frame 51, the tape release frame 51 is provided with a tape release roller 52 and a tape release motor 53 for driving the tape release roller 52, and the tape release frame 51 The output end of the dyeing tank 54 is provided with a dyeing tank 54, and a dyeing roller for transmitting the ribbon is arranged in the dyeing tank 54. The output end of the dyeing tank 54 is provided with a tension adjustment device 8, and the output end of the tension adjustment device 8 is provided with a fixed Color box 56, the output end of described color fixing box 56 is provided with color fixing box 1, the output end of described color fixing box 1 is provided with washing water tank 6, and the output end of described washing water box 6 is provided with drying box 57,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com