Steel wire adhesive material for tire and preparation method of adhesive material

A technology for bonding glue and steel wire, applied in the direction of adhesive type, natural rubber adhesive, non-polymer adhesive additive, etc., can solve the problem of easy sublimation of resorcinol, reduce the effective effect of resorcinol Smoke and other problems, to reduce environmental pollution and damage to workers' health, improve adhesion, and eliminate smoke effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

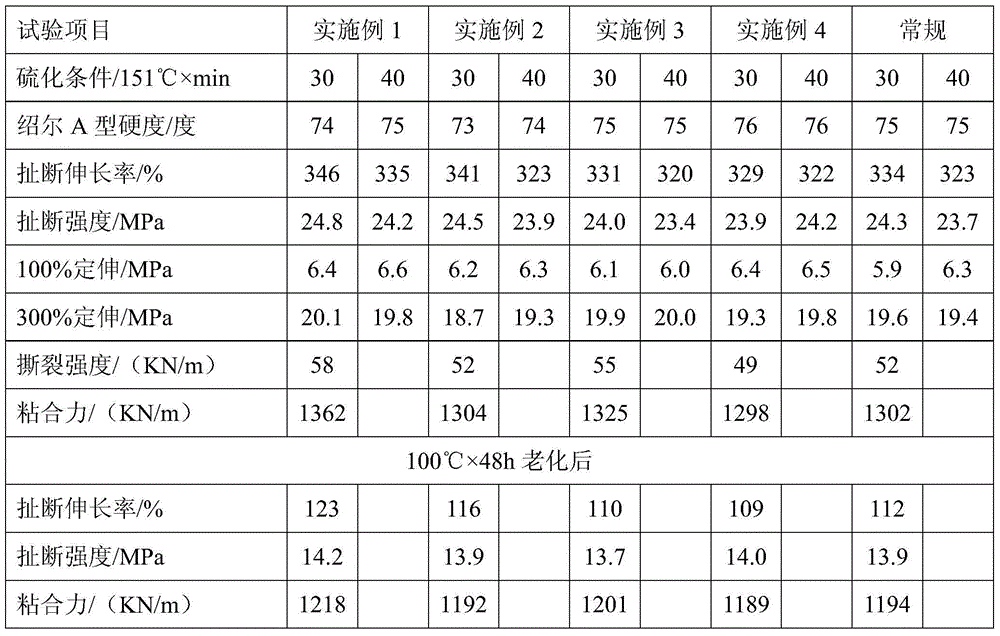

Examples

Embodiment 1

[0028] The mixing method of steel wire bonded rubber compound for tires, the steps are as follows:

[0029] a) One-stage mixing: add natural rubber in the internal mixer, the internal mixer speed is 50 rpm, pressurize 17MPa, and lift the mound for 45s. At this time, the polymer materials of each component have been in a viscous flow state, and then, Put in zinc oxide, anti-aging agent 4020, 60% of the total mass of carbon black, adhesion promoter KOTA, adhesion antioxidant BW-60, white carbon black, pressurize, lift the weight when the temperature reaches 125°C, pressurize 17MPa , When it reaches 155℃, discharge the glue to get a section of mixed rubber.

[0030] b) Two-stage mixing: add one-stage mixing rubber and cobalt decanoate to the internal mixer, press the upper bolt for 35 seconds at the speed of the internal mixer at 40 rpm, lift the mound, add the remaining carbon black, pressurize at 17 MPa, and lift the pressure for 30 seconds. Mound, pressurized at 17MPa, and di...

Embodiment 2

[0033] The mixing method of steel wire bonded rubber compound for tires, the steps are as follows:

[0034] a) One-stage mixing: add natural rubber in the internal mixer, the internal mixer speed is 60 rpm, pressurize 15MPa, and lift the mound for 30s. At this time, the polymer materials of each component have been in a viscous flow state, and then, Put in zinc oxide, anti-aging agent 4020, 65% of the total mass of carbon black, adhesion promoter KOTA, adhesion antioxidant BW-60, white carbon black, pressurize, lift the weight when the temperature reaches 120°C, pressurize 18MPa , When it reaches 170℃, discharge the glue to get a section of mixed rubber.

[0035] b) Two-stage mixing: Add one-stage mixing rubber and cobalt decanoate into the internal mixer, press the upper bolt for 30 seconds at the speed of the internal mixer at 50 rpm, lift the mound, add the remaining carbon black, pressurize at 15 MPa, and lift the pressure for 40 seconds. mound, pressurized at 15MPa, and ...

Embodiment 3

[0038] The mixing method of steel wire bonded rubber compound for tires, the steps are as follows:

[0039] a) One-stage mixing: add natural rubber in the internal mixer, the internal mixer speed is 40 rpm, pressurize 18MPa, and lift the mound for 60s. At this time, the polymer materials of each component have been in a viscous flow state, and then, Put in zinc oxide, anti-aging agent 4020, 70% of the total mass of carbon black, adhesion promoter KOTA, adhesion antioxidant BW-60, white carbon black, pressurize, lift the weight when the temperature reaches 130°C, pressurize 18MPa , When the temperature reaches 160°C, discharge the rubber to obtain a section of mixed rubber.

[0040] b) Two-stage mixing: add one-stage mixing rubber and cobalt decanoate to the internal mixer, press the upper bolt for 50 seconds at the speed of the internal mixer at 50 rpm, lift the mound, add the remaining carbon black, pressurize at 15 MPa, and lift the pressure for 40 seconds. mound, pressuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com