Silicon shell tungsten core heater strip and preparation method

A technology of heating wire and tungsten core, applied in the direction of heating element materials, gaseous chemical plating, coating, etc., can solve the problems of affecting service life, interfering with reaction growth conditions, and adverse effects of material preparation, so as to prevent sublimation and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

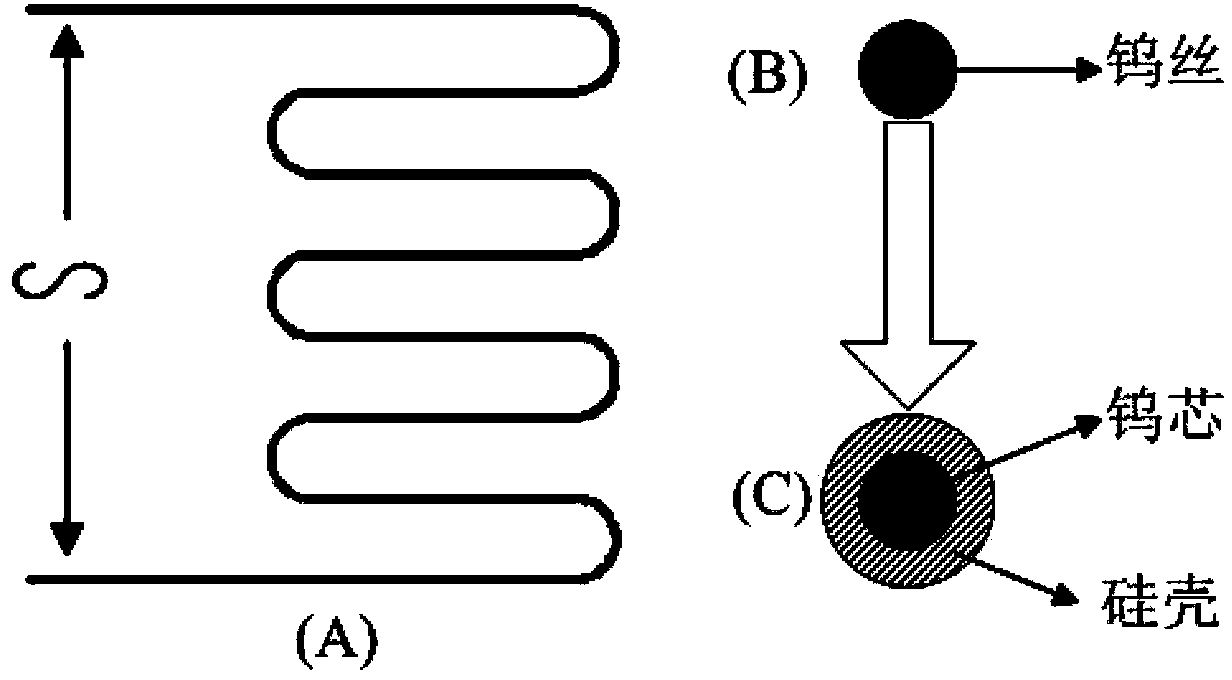

[0020] The silicon shell tungsten core heating wire and the preparation method of the present invention are characterized in that they comprise the following steps:

[0021] Step 1: Wind the tungsten wire (0.7mm in diameter) into the desired shape and put it into the chemical vapor deposition reactor;

[0022] Step 2: Vacuumize the chemical vapor deposition reaction furnace to 3×10 -2 Pa;

[0023] Step 3: Introduce hydrogen into the chemical vapor deposition reaction furnace with a flow rate of 15L min -1 ;

[0024] Step 4: Heat the tungsten wire in the chemical vapor deposition reaction furnace to 1000°C and keep it;

[0025] Step 5: Feed trichlorosilane into the chemical vapor deposition reaction furnace with a flow rate of 30 sccm, trichlorosilane reacts with hydrogen (reaction time 10 minutes), and the reduced silicon is deposited on the surface of the heated tungsten wire to form a shell;

[0026] Step 6: Stop the trichlorosilane injection, slowly lower the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com