Method for preparing ether, alkyl diol-bis (p-aminobenzoate)

An aminobenzoate, alkyl diol technology, applied in the field of special chemicals and fine chemicals, to ensure the appearance of color, shorten the time, prevent sublimation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

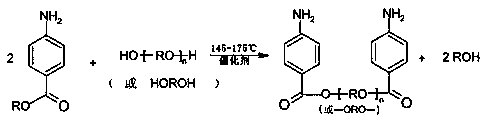

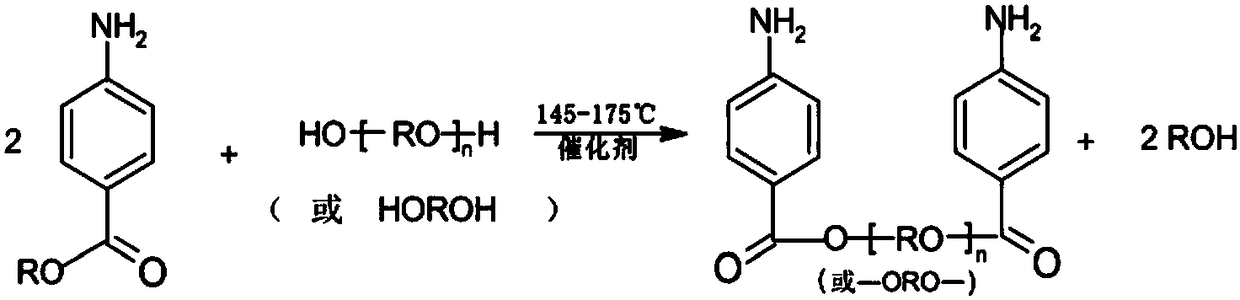

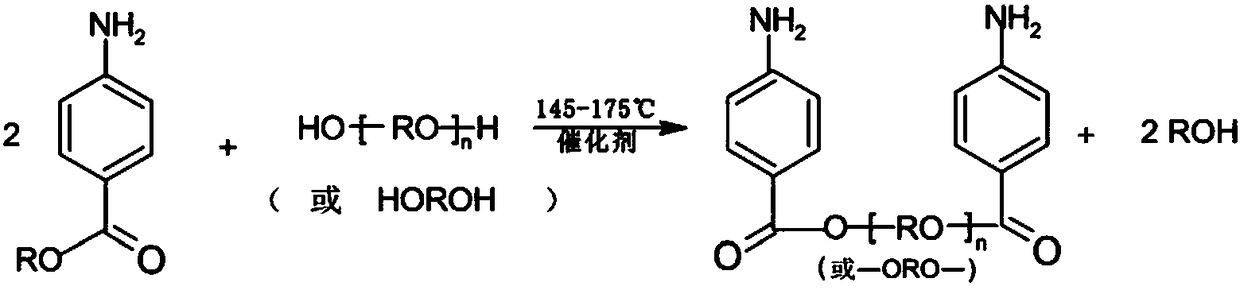

[0027] A method for preparing ether, alkyl glycol-bis-p-aminobenzoate, chemical reaction is carried out as follows:

[0028]

[0029] Wherein, R in -(RO-)n and -ORO- is a linear or branched alkyl group with 2-6 carbon atoms, and n is an integer between 3-30; in the presence of the catalyst Next, using mixed xylene as a solvent, the entire transesterification reaction is completed in two stages, a low temperature stage and a high temperature stage.

[0030] The solvent is mixed xylene, wherein the content of o-xylene is greater than or equal to 10%, and the content of ethylbenzene is less than or equal to 10%. The solvent used is mixed xylene, which has certain requirements on the ratio of each component, mainly to make the boiling point under normal pressure consistent with the controlled reaction temperature.

[0031] The low temperature stage is that the reaction temperature is 140-145°C, the pressure in the reactor is normal pressure, and the reaction time is 2-3 hours; the high ...

Embodiment 1

[0038] Add 500 grams of PTMEG (poly-1,4-butanediol) with a molecular weight of 1000 to a stainless steel reactor with a stirrer, a thermometer, and a distillation column that can withstand a certain pressure, and heat it into a thermal oil jacket heating, and then add 1200 One gram of mixed xylene with a certain proportion is used as a solvent, and finally 167 grams of benzocaine (ethyl p-aminobenzoate) and 3 grams of high-efficiency catalyst (tetraisopropyl titanate) are added. Turn on the stirring and start heating. When the temperature in the kettle reaches 140-145°C, there will be continuous liquid flowing out of the condenser tube connected to the distillation column. Maintain this temperature and use heating to maintain the amount of liquid vaporized. After 2 hours of reaction, Turn off the cork of the condenser and increase the heating power. When the temperature rises to 165-170°C, maintain the temperature and continue the reaction for 1.5 hours. Then fully open the cor...

Embodiment 2

[0040] Add 234 grams of 1,3-propanediol into a stainless steel reactor with a stirrer, a thermometer and a distillation column that can withstand a certain pressure, and heat it into a thermal oil jacket heating, and then add 1800 grams of the above mixed xylene with a certain ratio As a solvent, 1005 grams of benzocaine (ethyl p-aminobenzoate) and 18 grams of catalyst (tetraisopropyl titanate) were added at the end. Turn on the stirring and start heating. When the temperature in the kettle reaches 140-145°C, there will be continuous liquid outflow from the condenser tube connected to the distillation column. Maintain this temperature and use heating to maintain the amount of vaporized liquid. After 3 hours of reaction, Turn off the cork of the condenser and increase the heating power. When the temperature rises to 170-175°C, maintain the temperature and continue the reaction for 2.5 hours. Then fully open the cork of the condenser, continue heating and gradually increase the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com