Anti-sublimation and water washing-resistant decorative film for textiles and preparation method thereof

A washable, textile technology, applied in the field of polymer decoration, can solve the problems affecting the effect of clothing decorative film, affecting the appearance quality of products, etc., and achieve the effects of preventing sublimation and migration, soft hand feeling, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

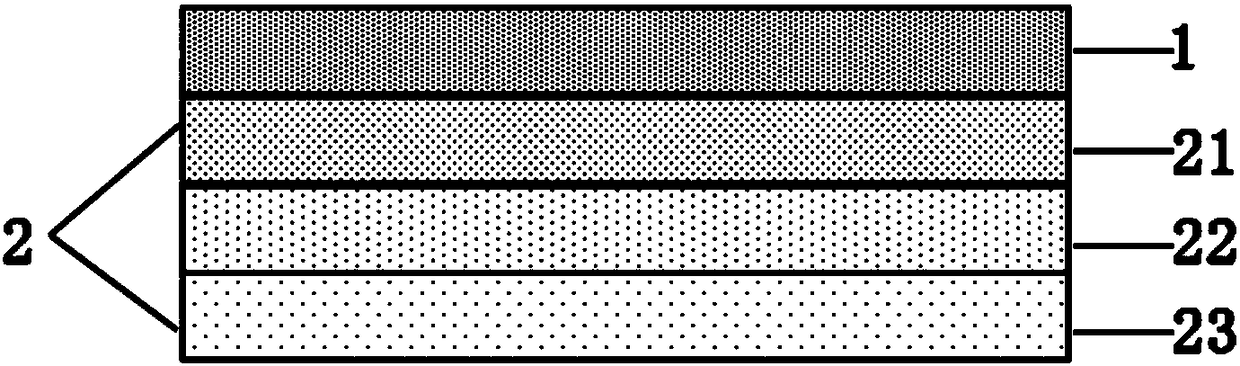

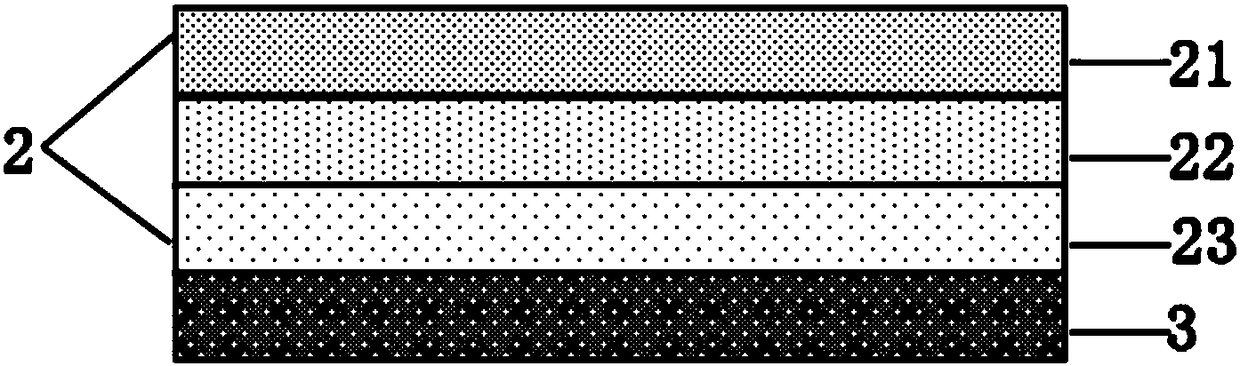

[0042] An anti-sublimation washable decorative film for textiles, consisting of a matte PET release film and an adhesive layer coated on the matte surface of the matte PET release film, the adhesive layer is anti-sublimation from the inside to the outside layer, intermediate treatment layer, glue layer, wherein,

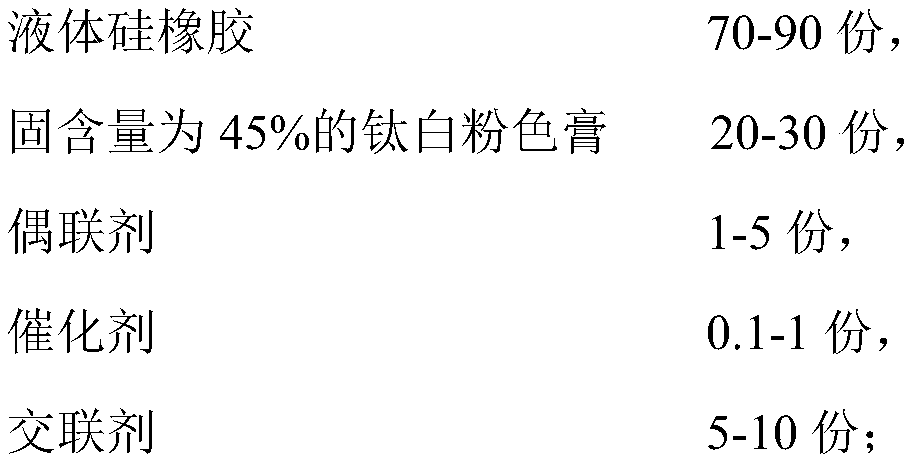

[0043] The anti-sublimation layer comprises the following components by weight:

[0044]

[0045]

[0046] The intermediate treatment layer comprises the following components by weight:

[0047]

[0048] Described glue layer comprises following components by weight:

[0049] 85 parts of polyester polyurethane glue with a solid content of 35%,

[0050] Polycarbodiimide 1 part.

[0051] The preparation method of the anti-sublimation washable decorative film for textiles comprises the following steps:

[0052] (1) Stir the components of the anti-sublimation layer evenly and vacuumize; apply the anti-sublimation layer on the matte surface of the matte PET re...

Embodiment 2

[0056] An anti-sublimation washable decorative film for textiles, consisting of a matte PET release film and an adhesive layer coated on the matte surface of the matte PET release film, the adhesive layer is anti-sublimation from the inside to the outside layer, intermediate treatment layer, glue layer, wherein,

[0057] The anti-sublimation layer comprises the following components by weight:

[0058]

[0059]

[0060] The intermediate treatment layer comprises the following components by weight:

[0061] 90 parts of polyester polyurethane glue with a solid content of 35%,

[0062] 1.5 parts of γ-glycidyl etheroxypropyl trimethoxysilane (KH-560),

[0063] 70 parts of nylon 6 with a solid content of 40%;

[0064] Described glue layer comprises following components by weight:

[0065] 90 parts of polyester polyurethane glue with a solid content of 35%,

[0066] Polycarbodiimide 1.5 parts.

[0067] The preparation method of the anti-sublimation washable decorative film ...

Embodiment 3

[0072] An anti-sublimation washable decorative film for textiles, consisting of a matte PET release film and an adhesive layer coated on the matte surface of the matte PET release film, the adhesive layer is anti-sublimation from the inside to the outside layer, intermediate treatment layer, glue layer, wherein,

[0073] The anti-sublimation layer comprises the following components by weight:

[0074]

[0075] The intermediate treatment layer comprises the following components by weight:

[0076]

[0077] Described glue layer comprises following components by weight:

[0078] 90 parts of polyester polyurethane glue with a solid content of 35%,

[0079] Polycarbodiimide 2 parts.

[0080] The preparation method of the anti-sublimation washable decorative film for textiles comprises the following steps:

[0081] (1) Stir the components of the anti-sublimation layer evenly and vacuumize; apply the anti-sublimation layer on the matte surface of the matte PET release film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com